Step-by-step instructions for making a barbecue for a cauldron from car wheels

Almost every person loves meat cooked over a fire or pilaf made in a cauldron. For barbecue and similar dishes you need a grill, which is not cheap. But any man, if desired, can build it himself from car rims and save a decent amount of the family budget. You don’t have to be a jack of all trades; it’s enough to know how to use a welding machine and a grinder. How to make a grill from car rims is described in the article.

Car rims photo

Car owners rarely throw away car rims, so they often lie idle in the garage for years. Even if they were thrown out or taken to a metal collection point, you can buy old wheels for pennies at the nearest service station.

Some craftsmen use metal barrels with ordinary walls, but their thickness does not withstand high temperatures, and holes are burned on the surface. You can also make a stove from steel sheet purchased at a hardware store. Such a grill will be durable, but expensive. Wheels from under a car are the best material for making a stove for a cauldron. They are cheap, durable, and easy to get.

What types of barbecues are there? You can make several types of fireplaces from disks with your own hands:

Advantages and disadvantages

Pros:

Minuses:

- If the barbecue made from wheel rims is made without a stand, then its height may not be enough for full-fledged work. Due to poor draft, the fire goes out.

- Small firebox.

Required materials and tools

There are small criteria for choosing car wheels. The best option for a barbecue is a wheel from under a truck. It is made of thick steel that will last from 20 to 40 years. A fireplace made from a car wheel will not be as reliable.

You will need:

- rim;

- an iron brush to clean the wheel from rust;

- file;

- Bulgarian;

- welding machine;

- drill;

- several bolts;

- a nozzle for cutting metal;

- steel rod or profile tube.

Are you interested in the method of making a barbecue from car rims?

YesNo

Several manufacturing methods step by step

The easiest model to make is a single hearth made from a wheel disk with your own hands. The design is made of one wheel with a stand.

Algorithm of actions:

- Cut out the inner wall, making the wheel resemble a barrel.

- If there are holes in the workpiece, seal them. Take the washers, cover the holes with them and weld them.

- Close the layer, but do not forget to leave holes through which the coals will be blown.

- Weld 4 legs to the bottom of the disk.

- Clean all seams and sand the cuts.

- Cut out a small window so you can watch the fire and clean the firebox.

- Weld the handles so that the grill can be moved from place to place.

DIY wheel rim grill photo

How to make a double grill from stamped disks with your own hands?

- Pick two rims. Choose the size based on the dimensions of the cauldron - 15 or 13.

- Take one disk and mark a line around the circle where you will make the cut. Draw from above the holes.

- Cut out the drawn circle with a welding machine. The cut off part can be used as a lid. It can also act as a stand for a cauldron.

- Prepare your welding machine. Take the second disk and weld a large hole in the center using a previously prepared piece of metal.

- Place one disk on the second and weld them to each other.

- If the seam turns out rough after welding, it can be corrected using a Bulgarian saw. Grind down and cut off any protruding bumps.

- Draw the outlines of the future door that will open the firebox. Cut it along the marked line, leaving a fourth side.

- Doors need a hinge. It can be built with one bolt. Take the bolt, cut off the top and find two nuts that fit.

- Weld the first nut to the door, the second to the grill.

- Screw the bolt into the threads of the first and second nuts. If you wish, you can make several loops.

- Make a handle for the door. Find any nice piece of metal and weld it.

- Also, do not forget to make handles for the entire structure to make it easier to transport and move.

- To ensure that smoke leaves the firebox evenly, make several even holes along the diameter of the structure.

Grill legs

Prepare legs for the structure to make it stable. If you are making a barbecue for a summer house, then simply weld them to the product. But if you need a collapsible mechanism, then the stand can be made removable.

- Prepare several profile sections that will become grooves for the legs (3 or 4). They should be larger in size. Weld them to the main structure at equal distances from each other. The angle of inclination must be the same.

- Cut several equal legs from a metal rectangular profile.

- Check how the pieces are inserted into the grooves. If they are difficult to insert, sharpen the edges with a Bulgarian saw, and then hammer them into the fasteners. The stove for the cauldron is ready with your own hands.

How to weld legs from car rims to a grill

Attention! The best length for legs is 45-50 cm.

Another variation of a homemade stove is smokehouse. To assemble the structure you will need two rims. How to make a stove from rims?

Algorithm of actions:

- Place the two bases next to each other.

- Do not cut the center section out of the top wheel. It will serve as a lid, contain smoke, and become an exhaust system. This is a ready-made stand for a cauldron made from car wheels.

- Cut the base from the bottom disc and weld the two pieces together to make one piece.

- Attach the legs using welding.

- Mark the door in the center of the grill and cut it out. Make a loop according to the method described above.

Decorating the barbecue

To make the product look nice, it needs to be painted. Get rid of old paint by burning the entire structure. Clean off any remaining coating with sandpaper or sandpaper. Next, take heat-resistant paint and paint the grill in any color. Black looks the best.

When doing work, follow safety precautions. Do not neglect protective equipment: goggles, mask, special gloves. When doing work with a Bulgarian saw, guide the blade to form a right angle with the object. If this rule is not followed, then fragments may break off from the disk and injure you.

Photos of finished homemade barbecues:

A design such as a barbecue made from car wheels is an excellent option for reusing waste materials. Such a device is simple to implement, and therefore you can make it yourself. Despite the simplest design, there are enough ways to use the product, it can even replace a complex barbecue model.

Design Features

A self-made grill from a wheel disk has a lot of positive characteristics. This design allows you to acquire a full-fledged grill complex with minimal manufacturing costs. All materials are quite accessible to almost any summer resident. In addition, they guarantee the durability of the product and its strength under any operating conditions. Another plus is the compactness of the grill. It is worth talking about its distinctive features and design options in more detail.

Video: instructions for making a barbecue from rims

Materials used

In order to make a barbecue from disks, you will not need to spend a lot of money, since practically available materials are used for its production. Car wheels that have already used up their useful life are usually thrown away or sold for scrap for pennies. This does not take into account the many ways to use them alternatively, among which making a barbecue is one of the best options.

For a dacha or private home, a barbecue is considered a mandatory attribute. Manufacturing from old disks allows you to save money, since ready-made models are often inferior to this option in terms of their capabilities in relation to the cost.

The onset of the cold season leads to the need for heating or simply creating comfortable microclimate parameters in garages or auxiliary buildings when living outside the city. This problem becomes especially urgent in conditions of impossibility of centralized heating.

Please note: almost every motorist has at least one unnecessary old wheel. Otherwise, you can find suitable material from friends, neighbors in the garage, or buy it for a small amount at a service station or secondhand.

The advantage of using discs to create a grill is the thickness of the metal. Even worn wheels will be suitable for this type of further use. The metal does not fade or deform, and their shape is ideal for creating complex products for cooking on coals.

Principle of operation

The operating principle of a barbecue made from wheel rims is similar to some other homemade models, for example, those made from a barrel or a cylinder. It combines the following features:

- grill - allows you to cook on skewers or a removable grill;

- barbecue - for frying steaks, complemented by a lid that creates the effect of an oven;

- hob - the shape and diameter of the disk allows you to place a cauldron, frying pan or saucepan on the fire;

- smokehouse - some models allow you to hot smoke food.

The principle of operation is extremely simple. Firewood or finished coals are loaded into the lower part. A grate is installed on top or skewers are placed. The dishes can also be placed on the wire rack or directly on the wheel, if their diameter is compatible. The heat from below warms the air and allows you to cook as on a regular grill. To smoke, you need to close the top exit and allow the wood chips to smolder to create smoke.

Each design is thought out individually, tailored to the needs of the owners. However, the main part of the work on manufacturing the product remains common to all models.

Execution options

It is necessary to consider in more detail the possible design options for the product. If you want to make a grill from car rims, you need to pay attention to the following models:

- Simple grill. The wheel is a container for coals on which skewers or a grate are placed (We recommend studying the material on our website).

The simplest option is a grill for skewers

- Double design. 2 wheels are used, thanks to which the grill becomes higher. Due to this, you can put a cauldron on top. Heating from all sides allows you to cook delicious dishes in it, like in the oven or stew them.

- Closed oven. Allows you to smoke food, as the smoke collects inside the chamber and is released in small quantities through special openings.

- Complex models. It combines all 4 functions of the product described earlier. Additionally, other useful elements can be installed, for example, a chimney exhaust.

It is also worth noting that such a grill can be made with or without legs. A stand will be needed for single models, but in double and triple models its function is performed by the lower disk. However, there are restrictions regarding the use of the structure, because wet soil can prevent the formation of heat, and hot metal is not allowed to come into contact with the wooden floor on the terrace.

Making a barbecue from disks yourself

In order to make your own grill from car disks, you need to think in advance about the design of the future product. Decide on the amount of consumables and prepare the tools. To perform high-quality work, you must have the skills to use a grinder for cutting metal, as well as a welding machine.

Preparation of materials and necessary tools

In order to make a barbecue from rims with your own hands, you will need the following materials and tools:

- old car wheels;

- Bulgarian;

- nozzle for cutting metal;

- disc for removing rust in the form of an iron brush;

- file;

- drill;

- hammer;

- bolts;

- profiled pipes or steel rod;

- grill grate.

A grinder and a welding machine are the main tools when working with metal.

All these tools will be needed to process and connect the parts of the grill. It is convenient to make legs from profiled pipes and rods. In total you will need 3-4 of them.

Tip: it is better to make 4 supports for greater stability of the product. The tripod may fall to one side when placed on an uneven surface.

You need to prepare the wheels themselves in advance. If there are traces of rust and paint, clean the surface with a metal brush using a grinder or drill. All excess is cut off.

Simple option

Several options for manufacturing such grill structures should be considered. You need to start with the simplest thing - a single barbecue made from a wheel disk on legs. In order to do it, you will initially need to carry out a number of manipulations with the disk itself:

- On one side, the inner part is cut out - the partition. A container similar to a cauldron is formed.

- If there are too many holes in the bottom or they are large enough for coals to spill through them, you need to weld an additional plate. You should not completely close the gaps, since the coals must be blown out to maintain heat.

- Legs are welded on the sides to the bottom or closer to the top. Usually they are made 40-45 cm in length. This height of the barbecue is optimal, as it ensures the stability of the structure and ease of use.

Next, if necessary, you need to clean the cuts so that there are no sharp edges left. You can additionally install a grille. It is not necessary to weld it; it is more profitable to use removable parts. Also, for the convenience of maintaining heat and cleaning out ashes, you can make a window for firewood on the side of the disk. For transfer, the structure is equipped with handles, welding them symmetrically on the sides of the wheel.

Tip: if you use two or three wheels, you can limit yourself to welding metal bars to the bottom. In some cases, you can do without supports altogether.

Smoking chamber

It is more profitable to make a brazier from car rims that can be used in different directions. For lovers of homemade balyk and sausages, a smokehouse will be an indispensable device. In order to turn old wheels into such a useful thing, you need to use at least two units of material.

The principle of operation is that you need to connect two disks into a solid hollow structure. The top can be adapted for frying kebabs according to the principle of the previous model, but to preserve the smoke you need to take care of the arrangement of the lid and smoke exhaust system. You can leave the partition with holes, which will simplify the task, and use the product as a hob.

Structural and functional features of the grill-steam locomotive, cost of the product, selection of materials for self-production, construction installation technology.

In order to combine two disks, it is necessary to cut off the partitions. Next, the wheels are joined and welded with a continuous seam to each other. The legs are welded to the bottom of the lower element. A door is equipped to provide access inside. To make it, you need to go through the grinder approximately in the middle of the product and cut out a rectangle.

To secure the door, one nut at a time is welded to it, symmetrically with respect to the welding seam. One bolt is also attached to the barbecue by welding so that the door nuts can be put on them.

Tip: to secure the sash without any problems, first screw the bolts into the already welded nuts. Then the door is applied to the opening and fixed on the structure itself.

Such homemade barbecues allow you to create all the conditions for relaxing with barbecue with minimal costs for equipment. In addition, there is no need to apply any extra effort, because all stages of the work are extremely clear and easy to implement.

The thick and durable steel of the disc is suitable for a wide variety of products, but oven models are the best. A stove made from car rims, created with your own hands, is a source of pride for the craftsman. The availability of this high-quality material also plays an important role - a heater or barbecue made from disks will cost very little and will last a long time. All that remains is to turn on your imagination and start interesting and useful work.

Rules for working with disks

The fact that the discs are suitable for ovens can be easily verified by simple experiment.. To do this, you need to heat a piece of one of them, for example, with a blowtorch. Hot metal does not emit any odors and can withstand temperatures up to 900 degrees.

It is important to know! Combustion furnaces can be constructed from automobile wheels to use solid fuel. And no others!

When machine disks are stamped at factories, they do not expect that any additional parts will be welded to them, so when working, you must adhere to certain rules:

- When using welding, make sure the seam is of high quality! There should be no visible defects.

- At one time, you can weld only two parts, and not the entire structure.

- After each stage of welding, the metal must be given time during which the internal stress will subside - 3 minutes for every kilogram of mass of two welded parts. Simply put, you can continue welding if touching the seam does not burn you.

- The finished furnace is kept for a day and then tested at full power for 3 hours.

If during the test run and firing minor defects in the welding seam are discovered, they are eliminated after the furnace has completely cooled, and the run is repeated every other day.

Potbelly stove for a bath

This stove is suitable for use in small spaces, for example, in a bathhouse or garage. To make it, you need wheels from a KrAZ-255B type truck. You can use wheels from UAZ or GAZelle.

A stove made from car disks perfectly performs the function of a sauna stove and will be portable. To make it you will need:

- a metal sheet;

- disks;

- pipes with a diameter from 100 to 150 mm;

- a short pipe with a diameter of 76 mm.

The hardest part is removing the inside. The metal of the disk is quite thick, so it is better to use a gas cutter. You can do this with an angle grinder, but the work will take longer.

The hardest part is removing the inside. The metal of the disk is quite thick, so it is better to use a gas cutter. You can do this with an angle grinder, but the work will take longer.

The discs are hermetically joined and welded together with a strong seam. The rear part of the resulting housing is covered with sheet metal, and the chimney pipe is welded to it. A damper is installed inside the pipe to regulate draft.

If the stove has air supply regulation, then a damper in the chimney is not necessary. Simply insert a pipe with a damper into the door. The damper axis is spring-loaded.

A plate is placed inside the firebox, which will divide the space into two parts. The secondary chamber with a welded chimney pipe will be located on top.

Such a furnace can be of any diameter and length. Orientation in space - vertical or horizontal. The Buleryan design is taken as a basis.

Design for a cauldron

Another product made from car wheels, easy to make. The bottom is made of a metal sheet or a cast iron insert for a conventional stove. If desired, you can weld the legs.

For the design, two disks are used, welded together. The firebox door is cut out of the body. The cauldron is placed on top. No unnecessary details and excellent functionality. Everything ingenious is simple!

The same oven can be used as a grill if a mesh or grate is installed on top.

Barbecue for the dacha

This product deserves special attention. It’s simply impossible to imagine a dacha without a barbecue, and a barbecue made from car wheels is a strong, durable, functional, inexpensive and quite attractive design element.

The advantages of such a barbecue include:

In essence, an auto-disc grill is a universal hearth for cooking. The principle of its operation is very simple: coals or firewood are loaded into the firebox, and food is cooked on top.

Wood chips are used for smoking, and the top exit is closed. Meat and fish are hot smoked.

The design can be individual, but the principles of its manufacture are common to everyone.

Product models

When making barbecues, simple and complex shapes are used. You can make it in the form of such models:

- Simple grill. Coal container - wheel. A fire is lit inside and skewers or a grill are placed on top.

- Double model. Consists of two wheels. Higher than the first option, you can place a cauldron on top.

- Closed oven. It is distinguished by the presence of a door that is tightly closed when smoking products.

- Universal model. Combines all possible functions. Additionally, a chimney can be installed.

The grill can be with or without legs. A simple grill needs a stand, but in double and triple designs, this function is assigned to the lower disk.

The procedure for making a simple grill:

In skillful hands you will get a useful and cute thing. If you have welding skills, you can make any stove model from old, useless disks. As they say, cheap and cheerful.

Self-assembly of a barbecue from car wheel rims is a very cheap way to purchase a useful and functional item needed in the garden. It’s no secret that during the summer season, residents of megacities vacationing outside the city find themselves in an environment devoid of their usual comfort. Instead of convenient stoves and multicookers, you have to adapt to electric stoves with 1-2 burners. In the event of a sudden power outage in a holiday village, a primitive period begins. The problem of the inconvenience of cooking over a fire can be solved with the help of an ingenious device developed by folk craftsmen.

It is very easy for car owners to get 1-2 rims. While these parts don't get replaced as often as tires or tubes, you can still find some barbecue material lying around in your garage. Unnecessary rims are thrown into landfills or handed over to scrap metal collection points. A lightweight structure on a metal site can be purchased for a purely symbolic amount.

In addition to the disks themselves, you will need:

To paint the portable version, you need to choose heat-resistant paint. Painting will give the structure an aesthetic appearance and protect it from exposure to precipitation when stored outdoors.

The easiest way to make a barbecue from rims is to lay the part with the open side up. The standard holes in the cap will serve as a grate for the fuel placed inside. This design can be supplemented with handles and taken with you on picnics: it is lightweight and takes up virtually no space in the trunk, but can reliably prevent forest fires by preventing coals from scattering and limiting the fire to the diameter of the rim. Here is a video instruction on how to quickly do this and what you need to pay attention to when working:

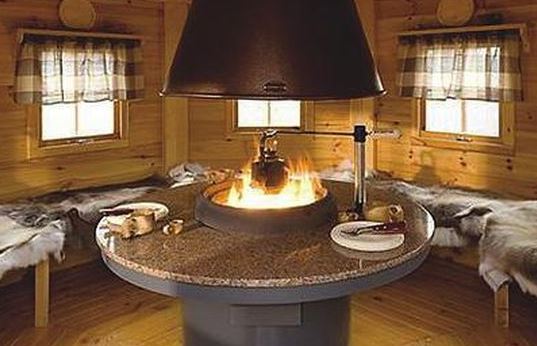

How to make a Finnish hearth from car rims?

A distinctive feature of this type of stove is an open hearth installed in the center of the table. It doesn't take a lot of time or materials to make it. A round metal firebox can be successfully replaced with a wheel rim raised to the desired height. The base for it can be made of stone, cinder block or bricks, not forgetting to leave free space for air flow into the firebox.

Place the disk from the machine on the prepared base and cover it around the circumference with wild stones or bricks, leaving a small hole at the very bottom for ventilation. The height of the masonry should be such as to completely hide the base and the metal hearth. You can improve the design a little by welding a pin with a hook on the side for hanging a kettle or pot.

On the resulting low column with a recess on top, you need to lay a round tabletop. This could be a cut of a large tree, a specially made slab of artificial stone, a sheet of thick metal, or another available item. There should be a hole in the center of the tabletop, the diameter of which corresponds to the size of the wheel rim.

This barbecue made from car wheels is stationary. You can arrange circular seating around it. To protect from rain, it is best to erect a light canopy, and if desired, the master can build a warm gazebo.

Portable barbecue of complex design made from car disks

A metal barbecue made from car wheels, made by a craftsman with imagination, can serve as a source of pride for him. Despite the simplicity of its design, such a stove is a multifunctional device: it is a grill or barbecue, a convenient stand for a cauldron, and a decoration for a relaxation area in the garden. In the photo you can see the design of the miracle stove with forged elements, and the fire-breathing Darth Vader.

Such a fireplace is not very heavy, so it can be installed in any convenient place on the site or taken with you into nature. A special feature of the design is the use of 2 identical disks from the wheels of a passenger car. The material must first be prepared for work: cut out or cut out the middle of one of them so that only the rim remains.

Install the disks from the car in this order:

- place the whole one at the bottom, placing it with the cap down;

- Place the one from which the central part was removed on top.

The upper part of the structure must be positioned so that the rib remaining after removing the hood is located on top, creating a partial overlap of the furnace roof. It is on this that you can lay a grill grate or place a cauldron and a kettle. The sides from the top of the rim will hold the cauldron in the desired position.

Weld the upper and lower parts of the grill along the circumference. So that when using the product you do not have to remove the dishes placed above the fire each time, you need to cut out a door in the side of the oven. Mark and cut out a rectangle of a convenient size so that there is a threshold about 10 cm high above the grate (bottom of the firebox). This will prevent the coals from falling out when the door is opened.  Other hole parameters can be arbitrary. In principle, everything can be seen in the photos provided.

Other hole parameters can be arbitrary. In principle, everything can be seen in the photos provided.

The cut piece must be equipped with loops on one side and a latch on the opposite side. For these purposes, you can use ordinary metal fittings (latches, hooks, door hinges, etc.). Small parts can be attached using a welding machine or bolts and nuts.

The cut piece must be equipped with loops on one side and a latch on the opposite side. For these purposes, you can use ordinary metal fittings (latches, hooks, door hinges, etc.). Small parts can be attached using a welding machine or bolts and nuts.

In order to raise the barbecue to a height convenient for cooking, you need to weld 3-4 legs from the bottom from sections of angle or corrugated pipe. It is most convenient to place these parts inside the rim, the slope of the walls of which will give the structure grace and stability, ensuring the divergence of the lower part of the supports. If desired, the master can solve the problem in another way, by welding a single leg in the center of the structure and complementing it with a wide and heavy base.

Here's another idea on how you can do everything without welding:

After burning off the remaining old paint and applying a heat-resistant coating, the barbecues can be considered ready for use. If desired, you can supplement the design with supports for placing skewers over the neck of the grill, handles for easy carrying and other necessary little things.

Self-made hearths of different types will simplify the process of cooking over an open fire. Each option can become the heart of a friendly company both in nature, in the garden, and in the gazebo. The relatively safe design of portable models requires their installation on non-combustible materials if the floor in the recreation area is wooden. Especially for this purpose, you can lay out the fireplace area with bricks or paving slabs.

For those who are not used to throwing things that have broken down into a landfill, the idea of how to make a barbecue from a wheel rim will be useful. It's quite simple to explain. Firstly, the discs are made of durable and high-quality steel. This ensures a long service life of such a product. Secondly, versatility. By installing the grate, we get a ready-made barbecue or oven that is suitable for cooking in a saucepan or frying pan. Such barbecues can also be used under a cauldron.

Brazier made from wheel rims, pros and cons

When planning to make a barbecue from car rims with your own hands, you should take into account their advantages and disadvantages. Product advantages:

- low cost;

- compactness;

- ease of manufacture;

- easy to clean;

- unlimited possibilities for creativity;

- multifunctionality;

- durability.

- small firebox volume;

- if installed directly on the ground, there will be weak traction, and cooking will be inconvenient due to the low height.

List of required materials and tools

List of required materials and tools

In order to make a barbecue from car rims with your own hands you will need:

- a used or unnecessary wheel from a car, size R16 or 15 can be considered optimal;

- profile pipe 20 X 20 and 25 X 25;

- grille, preferably made of stainless steel;

- wire (6-, 8- or 10 mm);

- dye;

If desired, a barbecue made from car wheels can be decorated with forged elements. From the tool you need to have:

- grinder;

- sandpaper;

- grinding, cutting wheels;

- welding machine;

- drill with a set of metal drills;

- brush or spray gun.

Work order

Work order

When analyzing how to make a barbecue at home from car rims, there are 4 main stages. This means the simplest and most classic model. Although there are a lot of options here.

First stage

The holes in the stamped wheel rim should be welded. This is necessary in order to prevent coals from spilling. Use pieces of 3 or 4 mm sheet metal. Patches are pre-cut from it according to the diameter of the holes.

There is no need to completely weld all the holes. It's better to use wire. This ensures air circulation.

Second phase

Welding legs to a barbecue made from a wheel rim. The standard quantity is 3 pieces. Here it is important to consider how you plan to use the product, whether stationary or portable. In the first case, the legs are welded directly to the disk from the wheel. If you plan to take the barbecue grill with you periodically on trips, and it must fit in the trunk of a car, then it is better to make the legs removable. The simplest option is to weld pieces of pipes, making them into kind of nests for the legs. The latter are then simply inserted into them. For this, pieces of 25 x 25 profile pipes are used, and the legs themselves (removable) are made from 20 x 20 pipes. Bolts, studs, and so on are used as clamps.

If you want the legs not to be pressed too much into the ground, it is recommended to weld nickels to them.

Third stage

Making stands for skewers and handles. To make the product truly versatile, it is enough to also equip it with a stainless steel grill. This way we also get a barbecue.

Craftsmen recommend that when making a barbecue from a car wheel with your own hands, use 10- or 8-mm wire for the handles. It bends easily, so giving the required shape is not difficult. For fastening to the body, use appropriate nuts, which are put on the ends of the wire, then they are welded.

Advice - in order to prevent the handles from heating up while using the barbecue, you must avoid pressing them. To do this, the ends of the wire are bent at right angles. This makes it possible to position the handles so that they rest against the body of the grill.

Fourth stage

All that remains is to give the product a beautiful aesthetic appearance. To do this, using a grinder, the structure is cleaned and painted with heat-resistant paint. The best result can be achieved using a spray gun or special cans of special paint, but you can get by with a regular brush.

Making a barbecue yourself takes literally a few hours and requires a minimum of financial expenses. Especially when there are rims in the garage or at the dacha that are no longer needed, but it’s a shame to throw them away. At the same time, a grill made from disks is truly universal and will allow you to diversify your menu with dishes on an open fire, if you want kebab, please, grilled fish or meat, pilaf, fish soup and much more. All this is available with a homemade design from car rims. Plus a neat appearance, beautiful design and ease of maintenance.