The very first boats on earth were dugouts: in some countries such boats are successfully used to this day. Then other, more advanced models began to appear: longships, gondolas, sampans. They painted in bright colors, acquired painted faces or carved figures on the bow or stern, some even with a motor. IN summer season when the boat turns into the most nice view transport, we reviewed photographs of traditional boats of all varieties and selected the most interesting of them.

(Total 34 photos)

1. Venice, Italy. In the 18th century, several thousand gondolas floated along the city’s canals. At the same time, the shape and size of boats were legislated. They haven't changed since then.

2. Hong Kong. Every summer, Hong Kong holds a traditional dragon boat festival.

3. Essaouira, Morocco. The only people working in the town are the fishermen, who on their bright blue boats (there are hundreds of them at the pier!) go to sea as early as five in the morning.

4. Lake Titicaca, Bolivia. The reed boats on which the aborigines sailed on the lake became the prototype for Thor Heyerdahl's famous reed raft.

5. Thailand. Thai longtail boats are very maneuverable.

6. Crete, Greece.

7. Myanmar. Villagers near Inle Lake operate the oar with their feet rather than their hands.

8. Jakarta, Indonesia. Local fishermen sell all their catch to the Sunda Kelapa market, located in the oldest port of the capital of the same name.

9. State of Goa, India. Traditional Indian boat on the Goa beach.

11. State of Goa, India. For stability, narrow boats are equipped with a “float”.

12. Mexico City, Mexico. Pleasure boats, which today take tourists along ancient canals dug by the Aztecs.

13. Japan. Nagatoro are small river boats designed to transport goods and people.

14. Maldives. Dhoni boats are used for short trips. The locals have long since improved them by putting diesel engine.

15. Ecuador. These dugout boats are made from solid wood. The work takes approximately 3-4 weeks.

16. Bali, Indonesia.

17. Bali, Indonesia. Traditional narrow Balinese boats are equipped with hollow bamboo trunks on the sides for stability.

18. Porto, Portugal. These boats are used to transport new wine down the Doro River to Porto and the Villa Nova de Gaia area.

19. Camiguin Island, Philippines. The boat used in the islands is called "dhoni".

20. China. The Chinese boat sampan is a flat-bottomed boat whose name means “three planks.”

21. Malta. In any harbor on the island you can see boats painted in a certain way.

22. Malta. Eyes are always painted on the bow of boats, which are designed to protect fishermen from various dangers. These are believed to be the eyes of Osiris.

23. Malta.

24. Varanasi, India. Many boats are painted blue and Blue colour. In Hinduism they are considered divine.

25. Hong Kong. Aqua Luna is a vintage pirate boat with hand-woven sails.

» from the presented material you will learn how you can make yourself a “Dolblenka” boat with your own hands. What is it used for? natural material, namely a soft tree, for example willow or aspen. The tree is selected in advance, straight and without branches, and the thickness of the trunk will be responsible for the displacement of the future vessel.

This technology for creating boats is very ancient and was passed down from generation to generation, from Father to Son, today it is almost forgotten, but there are still “Craftsmen - well done” on the Russian Land!

Let's look at what exactly the author will need to build a boat? We’ll also look at all the stages and watch the movie (Cut down your nerd).

Materials

1. softwood (willow, aspen)

Tools

1. chainsaw

2. hacksaw

3. ax

4. adze

5. jointer

6. source of fire (blowtorch)

Master class from Ivan Petrovich Ovchinnikov on building a boat "Dolblenki" with your own hands

And so, the author adopted this technology from his Father, and he, in turn, from his parent). In ancient times in Rus', the main building material, as you know, was wood, and furniture, dishes, peasant implements, carts, etc. were also made.

Boats and longships, respectively, were also built from wood; entire artels and brigades were created for this purpose. It may seem strange... but boats began to be made in the winter, when the tree is still asleep. The most selected in the forest suitable tree(aspen), it was cut down and shaped into a boat, after which the workpiece was covered with snow and remained in this position until early spring. During this time, the tree absorbed moisture properly. Why leave the boat in the forest, and even in the snow??? The fact is that for the further process of forming the boat, it is necessary to dry it over an open fire, place spacers, thereby giving it its final shape (everything is described in detail in the film)

But D. Vanya took a slightly different, easier path, chose a large and thick one (willow) in advance, cut it down to the very root, removed the bark and began to form the boat.

As you can see in the photo, the author first makes a cut, and then cuts it with a hatchet, he does everything professionally with minimum cost labor) The log is turned over by D. Vanya alone, because he is a Russian hero and eats porridge in the morning, and the master also knows the laws of physics and uses a lever (crowbar) and easily twists the workpiece as he wants) Using an ax, he sets the shape.

Then Ivan Petrovich moves on to making the inside of the boat, also using an ax and an adze.

Two partitions were left inside; they will serve as stiffening ribs for the structure of the boat.

This is what actually happens, the botnik is almost ready.

The master skillfully works with an adze, because he adopted this art from his Father.

After the boat has been made. it was processed using blowtorch so that later the wood is not afraid of moisture and serves the owner for a long time.

Our author got such a wonderful boat; now he can sail along the Don and fish. As you can see, it was quite easy for the craftsman to cut down the boat, and the most important thing is that the material is free and given by nature itself.

You can also view very good film, about the production of "Dugout" boats using ancient technology.

We are building a plywood boat from seven parts.

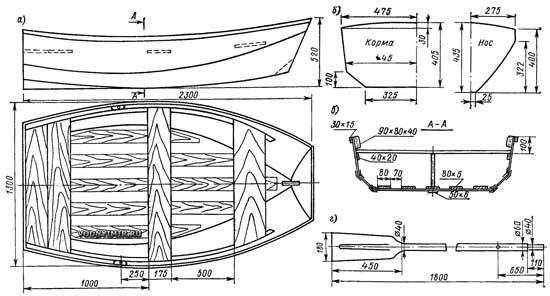

A small article about the Jack Sprat, (), attracted the attention of our team of yachtsmen. I really liked the boat for its compactness (2.3x1.3 m), fairly large capacity - in the photograph there were four adults and two children in it, and simplicity of manufacturing technology.

We took as a basis those given in the article dimensions tuzik and within a week they made a similar one plywood boat.

Sheets of ordinary paper were used to build the boat. construction plywood 4 mm thick, glued (a miter joint is used) up to a length of 2400 mm. From these, in accordance with the sketches provided, sheathing blanks were cut out.

General view of the boat (a), cutting of the transoms (b), section along the midship frame (c) and sketch of the oar (d)

Cut out the outer sheathing sheets.

enlarge, 1303x993, 120 KB

The body assembly looked like this. Having laid the bottom blank on the floor and the corresponding edges to it - the blanks of the zygomatic girdles, we connected them together. First, the blanks are connected approximately in the middle of the length of the boat using paper clips copper wire with a diameter of 1.5 mm. Then, gradually bringing the edges together, the same clips are sequentially placed in the bow and stern along the entire length of the cheekbone. At the extremities, the shape of the hull is determined by the bow and stern transoms.

Holes with a diameter of 2 mm for paper clips must be drilled in advance in increments of 100-120 mm along a line knocked out at a distance of 8-10 mm from the processed one. net size workpiece edges. It is better to twist the ends of the wire with outside housing as shown in the sketch.

The sequence of making connections along the grooves of the casing:

a - placing wire clips and crimping them; b - the groove is ready for laying internal fiberglass tapes; c - diagram of the arrangement of tapes in the connection

In the same way, the side blanks were attached to the zygomatic belts of the skin. Staples were also used to connect the skin to the transoms.

Then all connections were glued from the inside in two or three layers with fiberglass tapes. After the epoxy resin had cured and the ends of the staples had been removed, the same strips of fiberglass were applied to the grooves on the outside of the housing. When the transverse cans and bow book (120X120) were inserted, and the fenders were glued along the upper edges of the sides, the hull acquired the necessary rigidity. The bottom was reinforced with thin pine strips glued to the plywood from the inside.

As it turned out, for ease of assembly of the case similar method It is best to use plywood of the same thickness everywhere, as prescribed by Jack Holt, the author of the tuzik. To increase the moisture resistance and durability of the plywood body, we pasted it on the outside with two layers of thin fiberglass on epoxy resin. A “false keel” with a section of 50x6 was glued to the bottom. A small fin was installed in the stern to increase stability on course. Styrofoam blocks were secured under the cans. The total weight of the boat turned out to be 35 kg.

Four years of operation of the boat as an onboard tug on the yacht “Vityaz” confirmed its high performance. It was also used quite successfully under the Salyut engine.

We think that by slightly reducing the side height, and, consequently, reducing the weight (this will be especially noticeable if waterproof plywood is used), a boat of this type can also be recommended to motorists for transportation on the top trunk of a minicar.

A.K. Kartsev, “Boats and yachts”, 1979, No. 01(077).

======================================================================

Sail on the Chizhik.

A mast with a sail installed on a regular rowing boat does not yet turn it into a real sailboat. In addition to the sail and spar with rigging, allowing you to set the sail and control it, you need a rudder with an increased area of the feather and, necessarily, a centerboard or centerboards that keep the boat from excessive lateral drift (drift) during lateral and, especially, courses steep to the wind - at an angle of up to 40-50° towards the wind.

The placement of the crew, and therefore the arrangement of the cans, on a sailing boat is always different from that on a rowing or motor boat: the crew must tilt the boat, counteracting the heeling pressure of the wind, and for this people need to be placed along the side. In addition, the dimensions and shape of the boat's hull must correspond to sailing conditions, i.e., be designed for movement at a relatively low speed.

“Chizhik” (see “KYa” No. 24) was designed as a rowing boat with the possibility of using a low-power outboard motor: naturally, the design of the boat was designed specifically for these use cases. So, on the “Chizhik” a longitudinal middle bank for the rower was arranged; thanks to this, it is possible to give the boat an optimal trim depending on the number of passengers, there is free space for passage along the boat, on the sides of this can you can sleep on the fir trees. However, this same can is not at all needed on the “Chizhik” - a dinghy.

Basic data of the Chizhik boat

Maximum length 3.47m

Maximum width 1.47m

Side height 0.5m

Load capacity 300kg

Power up to 5 PM, l. With.

To transform the “Chizhik” into a sailing boat, corresponding changes in the design of its hull are necessary, so readers of the collection interested in this issue are offered two options:

Option 1 - most fully takes into account the sailing requirements - rowing boat, but provides for significant changes to the original project. This option is best implemented by those who are just planning to build “Chizhik”;

Option 2 is compromise solution, providing for a minimum of changes to a finished boat, built according to the original drawings.

In option 1, equipment is required for a centerboard well, a transverse and two side cans in the cockpit, and fastening of removable parts - the mast and rudder. The hull of the boat is built according to the original design, but the side stringer is brought to shp. 1. Instead of a longitudinal can, a centerboard well is installed, which is a narrow box, open only at the bottom, secured with screws and glue above the slot for the centerboard in the keel. The well is secured by a transverse can, resting on the side stringer.

The walls of the well and the flooring of the can are cut from waterproof plywood 6 mm thick. Final assembly the well is made after fastening from the inside vertical racks on sp. 2. On the Chizhik, it is the well that is closed at the top that is convenient - through the open well (involuntarily it would have to be made low), with any significant waves, water would begin to splash into the boat.

Alyosha" is the first dinghy based on the Chizhik, built in Gus-Khrustalny by V. Zhirnov.

The hull is manufactured exactly according to the drawings given in No. 24 “KYA”. A rigid canister is placed across the hull, securing the centerboard well. The stern fin is made higher, up to 120 mm, on the transom. The dinghy is armed with a sloop with a sail area of about 6 m2. Full Height mast, fastened with a forestay (st. rope diameter 3) and shrouds with screw turnbuckles, - about 8 m from the steps. The mast and boom (2.0 m) are glued together from pine slats and have a sealed groove. The boom-sheet cable strap is hung on the transom. A block with a diameter of 25 mm slides along the shoulder strap; the sheet is passed through a block approximately in the middle of the boom and a foot block attached to the bottom.

Due to the tourist purpose of the boat, it is necessary to use a centerboard; simpler fixed - “sticking” centerboards cause hard impacts when colliding with underwater obstacles and are inconvenient, and sometimes even dangerous, when sailing in an unfamiliar area.

The centerboard rotates on an axis, the cheeks of which are attached with screws to the outside of the keel to avoid drilling holes in the lower part of the centerboard well. The centerboard is rotated using a rod made of a metal rod or a thick-walled tube with a diameter of 20 mm, riveted to its rear edge (do not forget to put a plug in the tube!). The rod must be very carefully bent around a circle with a radius of 250 mm (along the axis). At its exit from the centerboard well, a seal made of microporous rubber about 10 mm thick is installed, pressed with a metal pad. The hole in the rubber should be smaller in diameter than the rod. The centerboard is raised and lowered by a pusher made of a 4X30 metal strip, hinged to the rod with an M8 screw. At the stern end of the pusher, it is advisable to install a handle in the form of a wooden ball (the idea of this design was borrowed from an old dinghy).

The leading and trailing edges of the centerboard should be sharpened, and it is advisable to fasten a protective brass strip 1 mm thick along the leading edge. The easiest to use are removable side cans, supported by a side stringer, a thrust block on the bulkhead of the aft locker, and a strip of plywood under the transverse can. They are held in place by rotary fasteners, the same as the floor fasteners. Under the longitudinal banks, foam buoyancy blocks must be securely attached to the boat hull.

The steering wheel consists of a steering block and a lifting feather. The block is assembled using glue and bolts with a diameter of 5-6 mm from three layers of bakelized plywood. The middle part, 12 mm thick, has a sector cutout for the rudder blade. The side cheeks are 8 mm thick. The tiller is attached to the block using a metal clip bent from a sheet. The steering loops are cut out of a square with a wall thickness of at least 4 mm or bent from a strip and attached to the block with screws with a diameter of 6 mm. The pins (from M8 bolts with cut heads) are screwed into the threads of the hinge holes and riveted. The lower pin must be about 20 mm longer than the upper one, otherwise the steering wheel will be difficult to install in place. The parts of the steering loops attached to the transom are also cut out from a square and installed on through MB bolts.

The rudder blade is cut from 12 mm thick bakelized plywood and, just like the daggerboard, is sharpened along the edges and protected by a rudder. The axis of the feather is an M8 bolt, the tightening of which is adjusted so that the raised feather is held by friction against the cheeks of the block. The upper part of the steering wheel blade should be sanded so that it fits freely into the slot of the block. The pen is lowered into the water directly by hand; For this purpose, a lever with a handle is provided on its rear edge. To protect against jumping out of the hinges, the steering wheel is fixed with a flat spring attached above the lower steering loop.

On the transom of the boat on the starboard side, at a distance of 400 mm from the DP, a second pair of steering loops is installed, onto which the rudder is hung when rowing. This is very convenient for the helmsman, since the tiller moves freely under right hand, and does not rest against the back; rudder displacement has virtually no effect on the boat's handling.

Equipment of "Chizhik" with centerboard and steering gear

1 - frame made from 1X30 strip; 2-rudder feather, buckplywood 6 = 12; 3 - handle for lifting the pen; 4- steering block; 5 - tiller, 40X40; 6 - mainsheet; 7 - boom holder, 6 = 2 mm; 8- weft for halyard; 9- clip made of 3X40 strip, fasten to the beam with M 6 through bolts; 10- step pad, 6 = 2 mm with rectangular hole for mast spur; 11- seal of hole for rod 12; 12 - rod from a tube 0 20 mm; 13 - centerboard axis - pin 0 12 mm; 14 - centerboard, buckplywood 6 = 12; 15-cheeks of the centerboard axis, 6 = 2.5 mm; 16- well wall; plywood 6=6; 17 - stand (key) of the well 25X60; 18 - gunwale-plug well 25X30; 19- tiller clip, 6 = 2; 20 - side cheeks of the block, back plywood 6=8; 21 - steering loop; 22- plywood gasket 6 = 6; 23 - centerboard thrust; 24 side bench seats; 25 - rudder position when rowing.

The mast blank is glued out of three or four pine bars of the required length. The section of the mast above the cockpit coaming and up to about half the height is a circle with a diameter of 70 /l/l. Above this level, the front and side edges are smoothly planed to a section at the top of 40X50, below - to a section at the spur of 30 X 50 (the larger size in both cases is along the DP).

Option with swivels

1 - forging 20X2; 2 - keel 25X80; 3 - base of the well 20 X 60; 4 - cutout for the centerboard pusher; 5 - well stand 20X60; 6 - well gunwale 25X30; 7 - from the well, 6 = 6; 8 - stiffening rib of the transverse can 20X30; 9 - can flooring, 6=6; 10 - coaming, plywood 4X50; 11 - carleygs, 20X 25; 12 - fender beam, 18X30; 13 - can support block, 18X30; 14 - toptimbers 6 = 20; 15 - zygomatic stringer, 18X30; 16 - sheathing, 6=4; 17- flortimbers 6 = 20; 18-bottom runner 20X30.

The simplest boom swivel.

1 - boom; 2- M5 screw, 2 pcs; 3 - strip b=6 to embed into the boom; 4.6 - M8 bolts; 5 - washer 8; 7 – bracket, fasten to the mast with two 5X32 screws; 8 – clip b=2.

Option for a boat with fenders.

1-shvertsa forging, X40, brass; 2-shverts, back plywood 6=15/16; 3-weed; 4-bearing; 5-holder made of steel, diameter 3; 6-support bar; 7-longitudinal seat; 8 - transverse bank 6=6; 9-pine lining; 10-check; 11 - bent axle; 12-circlip.

A pulley for the halyard is cut into the top of the mast; The boom swivel and halyard cleat are attached below. Along the trailing edge of the mast, a rail for the mainsail sliders is fastened with screws through a 5X10 rail - a carefully aligned 2X20 metal strip.

The mast spur fits into a step socket 25 mm deep, cut out in the rear part of the stem, and reinforced with a 2 mm thick metal bracket placed on top with a rectangular hole cut into it for the spur to pass through. The finished mast, like all parts of the spar, is coated with colorless varnish (oil or pentaphthalic). There is no standing rigging - shrouds and stays are not needed; The mast, along with the boom and sail, can be easily removed from the boat. If necessary, the mast can be made collapsible. In this case, the upper and lower parts of the mast are connected by a coupling made of metal pipe with a wall thickness of about 2 mm. A 400mm long coupling is attached with screws or through bolts to the top of the mast; to fix correct position connecting parts of the mast, a screw with a diameter of MB is screwed into the lower part, and a slot approximately 20 mm deep is made in the coupling. In the area of the coupling, the rail for the mainsail sliders is fastened with short M4 screws screwed into threaded holes.

It is better to glue a boom with a cross-section of 30 X 60 from two pine bars according to the thickness. Towards the ends, the boom is planed along the lower edge to a height of 40 mm.

When equipped according to the second option, the boat is no longer equipped with a centerboard, but with hinged centerboards. On both sides in the shp area. 2 s inside of the casing, a support block is installed for the transverse can (cut on the frame), and on the outside there is a block to support the hinges. The transverse can is attached to these support bars at the side and to the longitudinal can. Below deck on both sides of the beam shp. 2, cushions for the bearings of the hinges are installed.

The doors are cut from bakelized plywood 15-16 mm thick, their vertical edges are sharpened, and protective shanks are placed on them. The upper part of the screw is placed on an axis made of a steel rod with a diameter of 16 mm, bent at a right angle. In the axle cage, the axle is fixed with a stopper in the form of an MB screw without a head, screwed into the axle and running into the slots of the cage. The axis of the screw is inserted into the deck bearing and secured in it with a rotary pin. The transverse movements of the axle in the bearing are limited by a piece of tube riveted to it, from which the cage bushing was made. The shverts are raised by weeds, which are laid on the ducks inside the boat.

The design of the mast, boom and rudder is the same as in option 1, but it is recommended to reduce the sail area by 1 m2, taking into account the fact that the centerboard area is smaller than the centerboard, and the possibilities for heeling the boat due to the different arrangement of the cans are somewhat worse.

Making sailing rigs is a rather complex and time-consuming task, but the pleasure of sailing will, without a doubt, more than pay for this work. However, it must be noted that management sailboat, even as small as the Chizhik, requires special training for the helmsman. The best way to learn sailing is at a yacht club.

When learning the art of sailing on your own, you should strictly follow the basic safety rules:

Don't overload the boat; do not take on board people who cannot swim and small children;

When sailing, the crew must always wear life jackets;

Monitor the weather carefully; if there is a danger of a squall, immediately remove the sail and sit down at the oars;

You cannot sail when the wind is stronger than 4 points, and in the beginning, with insufficient experience, no more than 3 points;

Never lay the sheets on the cleat; always keep the halyard bay clean - ready for lowering the sail;

When going out sailing, check if you have forgotten to take the oars;

Until you have gained confidence in your abilities, do not leave the area where you may receive assistance.

immediate assistance in case of capsize.

I have long wanted to create a record marking the main points in the manufacture of a boat, but it never worked out! Dad is getting older every year, but there are still no cheat sheets, although he and I have put together more than one pair of boats... And this year there was a need to expand our fleet, because the children are growing up and boats are required that are more stable and load-bearing, for reliability movement. I myself used to swim to the surface, but with my sons I have to be careful about this! The time has come to take out the previously stored boards, edge them, plan them, prepare nails, and one weekend we get down to business! (It’s better to use spruce boards, without knots, but you don’t always have what you need)

First of all, Dad sketched out a small drawing with dimensions, based on the requirements and previous construction projects

Then they laid out the boards for the bottom, drew a contour on them according to the dimensions, cut out the main parts with a jigsaw, leaving only the edges, this can be seen in the photographs.

When adjusting the boards to one another, we leave gaps in the stern and in the bow, but in the middle we fit them more or less tightly

When all the parts are prepared, we begin assembling the bottom, first tightly assembling the boards, sewing them with nails in the middle with a cross member, then using a rope and two crowbars we pull together the stern, sew them together with nails, and do the same with the bow

Due to the fact that the crossbars are rounded, and gaps were left between the boards in the bow and stern, when screeding and assembling, the bottom turns out to be a bit of a sphere both across and along its length. In the future, this gives the boat stability on the water. It is not necessary to adjust and tighten the bottom boards to microns, small cracks are quite acceptable, this will make it easier to caulk the bottom.

When the bottom is assembled, we line out the edges according to the planned dimensions and markings so that the edges are smooth, otherwise it will not be possible to bend the side boards clearly

The most interesting thing is ahead, you need to bend the sides at the same time on both sides, if bending one by one can warp and the boat will turn out to be skewed. We apply the side board to the bow on one side and sew it on, then do the same on the other side, then one presses it, bending the boards, the second pierces it with nails towards the stern.

The boards were tied together in the same way as the bottom - with a rope. As a result, some kind of shape was drawn, then it’s easier. We bend the second row of side boards in the same way. We don’t hit a lot of nails when stitching because we still have to caulk! Next, we saw off the excess ends of the boards, both the side boards and the bow and stern. Then you adjust the front bow board.

After completing the assembly, you work with a plane, rounding where necessary, leveling it, going through the entire longboat, cutting out the frames beautifully. After making it beautiful, we caulk it, add nails in places, screw the rowlocks, resin the bottom, nail the strips to the bottom, resin them, then paint. We also make seats and paint them as you like. Our oars are transferable, we change boats, but the oars are the same. The oarlocks on all our boats are the same, so there are no problems.

In principle, I tried to take into account all the stages and subtleties in the photograph, so that it was clear. Two boats have now been put together, one for the opening, the second just recently. The boats were made identically, one was tested, the second was at the stage of completion of work.

If anyone has any questions, please ask, I’ll be sure to clarify! Truth questions usually arise when self-production, suddenly someone will take it and make a piece of wood. For those who live near the lake, a piece of wood is irreplaceable!

Thank you for your attention!

Drawings and photos

Why is the boat “black”?

Somehow I became acquainted with Meshchera fishing dugout boats, which are popularly called “black”. However, this name has already come into use even among scientists. And on the map of the cultural and natural heritage of the Shatura district of the Moscow region, certain symbol shows the distribution areas of such dugout boats on the rivers and lakes of the region today.

It is difficult to imagine a fisherman who has not rowed along a river or lake at least once in his life. I'm not even talking about those avid fishermen for whom a boat has become an urgent transportation necessity, and oars and sails have become unique tools of labor. In general, since ancient times, a fisherman on the water was just as inventive and savvy as in the field, forest, or yard. In accordance with the situation and often acting strictly according to his needs, he spent economically construction material, knew how to quickly find among the coastal vegetation the element needed for the gear and design of the boat. Often, while traveling in remote lake regions, along the banks of small rivers, I met fishermen sitting in roughly built punts. She could have almost square shape and look like a trough or even a box. One talkative fisherman explained it this way: “I live here on the shore. What do I need? He went down, got some change for his money, and that’s all for you. And no one will attach legs to such a vessel.” In Polesie I met the owner of a boat made of tin, which had willow branches instead of frames. By the way, this is how frames used to be made - “springs”. In the reeds of the Dnieper-Bug estuary I somehow came across a long boat with holes cut out on its sides. As the local talkative Berezhanian explained, a curved rod is inserted into these holes, at the ends of which bicycle wheels with blades are attached. “Spin them to your full health and full speed ahead,” he grinned.

Perhaps the most ancient method of overcoming a water barrier was a raft, the logs of which were connected by a bast or a “tack” - steamed in hot water young tree trunks. By the way, you can find fishermen everywhere who prefer to sit comfortably with all their fishing gear not on shaky shuttles, but on wide rafts. The first ship Eastern Slavs was considered a “korab” - a canoe woven from wicker and lined with bark and skins (“korob” - a basket made of bast or wicker). Some researchers even believe that the word “ship” became known to the world from the Byzantines, who adopted it from the Slavs, changing it to “carabos”.

A more advanced floating device was the “dolbanka” - a single-tree boat, which was hollowed out from the trunk of an aspen, willow (“rebovka”), linden (“lipka”), oak (“oak”). Europeans learned about Slavic dugout boats and single-tree boats from the Greeks. “The Slavs cut down monoxyls everywhere in the winter, and in the spring they lower them into the water...” wrote the Byzantine Emperor Constantine Porphyrogenitus, who traveled along the Dnieper in the 10th century. IN different regions the construction of dugout boats had its own peculiarities. In remote Belarusian villages you can still find dugout canoes - “kamyags”. As a rule, they have a trough-shaped shape. Boards (wings, “floats”) are nailed to the sides at the level of the water surface for stability afloat. Fishermen all over the Dnieper told me about dugout canoes, and I had a chance to see them on the outskirts of Kyiv in the village of Korchevat. A local schoolboy, an avid fisherman and lover of water travel, bought a “dug” in a village near the Desna region. She still serves him well. The boy took me through the yards of local residents. In one garden we found three old “dugs” with rotten sides. There was also an old man who explained the technology for making dugout canoes: “The wood for the dugout canoes was cut down in winter or in early spring. The trunk was cut lengthwise into two boats. The stern was located where the trunk was wider. First, an ax and a plane were used to make the “top” - the part that reaches the water. Then they hollowed out the middle with an adze, leaving a “sill” in the stern. To ensure that the thickness of the dovbank along the sides was the same everywhere, pegs were driven into the sides - “beacons” of the same length made of a darker type of wood. As soon as you reach the “beacon”, stop cutting in this place. Then they poured water into the boat and threw hot stones there to “break” the sides. “Strokes”, oars in our opinion, were made of ash, this type absorbs water the least ... "

I did not at all expect to see dolbanki in a “live” form in the Shatura region, which is part of the famous Meshchera. I even managed to photograph several of these boats in the south of the area, near the bridge over the Yalma River. Here in the lake-swamp region, without a boat is like without hands. The muddy peat banks of local reservoirs do not allow fishermen to get close to the water even in high waders. You cannot catch a fish from a peat pond without labor, which is aimed primarily at taking care of the construction and equipment of the swimming device. The idea of a dugout boat was suggested to the ancient Meshcheryaks (one of the versions of the translation of this word is “people of water”) by the hollow - “side” in the tree trunk where bees settled. Burning out a hollow with fire, expanding it with a stone ax and a bone chisel - this is the technological chain for constructing Meshchera dugouts. The boatmen mainly used poplar, linden and aspen, which, as soft woods, could be worked with a Neolithic stone axe. When bronze and iron appeared, pine was used. The patriot and Meshchera expert K.G. Paustovsky mentioned the local boats - “monoxyl” (i.e., made from solid wood): “They look like Polynesian pies. They are hollowed out from one piece of wood. Only on the bow and stern they are riveted with forged nails with large heads...”

With the help of bronze tools it was already possible to split wood along the fibers and create a boat more complex design. It was still a dugout, but already a boat-plane. The most simple design such a boat consists of five parts: an almost flat bottom, two side boards, hollowed along the entire length in the form of a gutter, and two ends. There is no bow and stern, and the ends are either two boards nailed at an angle, or more complex ones - pointed “cocors”. Straight slotted side boards are resistant to bending and allow you to do without additional fastenings. Today they are nailed together with iron nails and staples, but in the old days they were “stitched” together with a flexible juniper root - vitsa.

There is no need to turn such a boat around in narrow erik channels - it moves back and forth well. She has a very low landing - she is not afraid of shallows and snags on the river bottom, which are found in abundance on local lakes and rivers. And carpentry work was carried out using an adze axe, which has been preserved in many villages to this day. The tool is still used by carpenters, sometimes even used as a hoe when cultivating the soil. And finally: why is the boat “black”? There is nothing sinister in the name. Well, firstly, after burning out the core it became black, and the faces of the boatmen became dark from soot and soot. Secondly, before launching boats, they were often covered with resin to hide grooves, joints, and cracks. You can't imagine a more menial job. Well, the color of the water in the peat lake. Complete blackness. By the way, it was there that the dead Meshcheryaks were often sent. Especially those who spent their entire lives on the water. The deceased was placed in a boat, rolled into the river and set on fire. The flaming ark floated through the dark waters until the bottom burned out and the body plunged into the darkness of the kingdom of eternity...