To protect your home from leaks and collapses, you need to properly install the roofing. In addition, this will ensure comfortable living in the cottage.

Almost all experts recommend using roofing material made from corrugated sheets. This is an environmentally friendly product that is also very durable. If you are in doubt, we advise you to look at photo and video materials on the topic of do-it-yourself corrugated roofing. We're confident that once you learn more about this process, you'll get started right away.

So, you have decided to install the metal profile yourself. The first step is to carefully take the necessary measurements of the roof.

Tip: When taking measurements of the roof, remember that the edge of the profiled sheet must protrude beyond the edge of the eaves by 50 millimeters.

When planning with your own hands, keep in mind that there are a lot of options. All of them are presented in various catalogs. Therefore, you can choose any material to your taste.

Tip: Give preference to those sheets of corrugated sheets that are long enough to cover the entire roof from the ridge to the eaves. In addition, it will be important to add another 50 millimeters of material. This is necessary to connect the roofing sheets to each other.

If the roof requires large sheets of corrugated sheets, then divide them into several parts. After this, it will be easier for you to transport the material and lift it onto the roof.

We cover the roof with corrugated sheets with our own hands: technology

Tip: when purchasing material, ask the seller for instructions. Remember that it is very important for product manufacturers that their products are popular. Therefore, if a product is certified, it must have installation instructions. In addition, a high-quality product has greater reliability and warranty.

Installation of corrugated sheets and its diagram

At the level of the sheathing, place a wooden deck on both sides of the gutter at a distance of 60 centimeters. The overlap for the bottom valley boards should be at least 200 millimeters. Attach the bottom strip to the edges using several nails. Then all you have to do is secure it together with the entire roof.

Tip: For a flat roof slope, use sealing mastic.

When installing the bottom (bottom) valley strip, bend its upper ridge over the roof or make a flange.

Attention: the bar must fit under the ridge at least 250 millimeters. It is recommended to install an additional universal seal between the profile and the bottom valley strip.

The end top board should be installed higher than the sheathing. Next, the end strip is attached to the board. As a result of all the above actions, you will get a windy corner.

We install the end overhang assembly on the roof

Important: The location of the eaves strip must be below the waterproofing carpet. This is necessary so that condensation can roll down the waterproofing, fall on the eaves strip and flow to the ground.

A do-it-yourself metal profile roof must have a cornice strip under the corrugated sheeting. It is important to provide ventilation. This is necessary to eliminate water vapor. Be sure to install a seal that should not let air through.

Option for installing a cornice overhang

Cover the drainage channel on the corrugated sheet with the subsequent sheet. There is no difference in the installation: from left to right or from right to left - as is convenient for you. The only thing that needs to be noted is the overlay of the sheet under the previous one. But you can also slip one profile under another.

The design of a roof made of corrugated sheets involves the process of laying sheets from a profile. If you are working with a gable roof, then start installation from the end of the roof. When installing a roof with a hip, laying the corrugated sheeting begins from the center of the hip.

Important: To align the sheets, it is best to use a cord that must be pulled along the cornice. Alignment should not be carried out at the end of the slope.

Considering the thickness of the corrugated board, secure the middle part in a checkerboard pattern. In other words, you need to tighten 5 screws per square meter.

Multi-row laying of corrugated sheets and its methods:

- Vertical installation. The first sheet is laid on the bottom row and temporarily secured. The first sheet in the second row is laid in the same way. Next, the second sheet is laid on the first row and the second sheet on the second row. Thus, a whole block is obtained. After this, you need to create and attach a subsequent block. This method is ideal for roofs with gutters.

- The second option is that the block includes 3 sheets. Place two sheets on the first row and secure them together. Then attach one sheet from the second row to them. The final fixing of the block will occur after alignment with the cornice. Next, a similar block of 3 sheets is attached. This method is suitable for sheets without a gutter.

Never forget that profile sheets are very light. They should not be subjected to high loads or walked on during installation work.

Installation of end and ridge strips

The length of the end strip should be about 2 meters. When building up 50–100 millimeters, overlap the planks on each other. According to experts, it is best to lay the end strips from the side of the roof overhang, gradually directing them towards the ridge.

Mounting the ridge assembly

The overlap when laying ridge strips should be more than 100 millimeters. Use self-tapping screws for fastening. In this case, the step length should reach up to 300 millimeters.

Which corrugated sheeting is better for the roof?

The roof is an important element of the building; the safety and durability of the entire structure depends on proper installation and high-quality coating. The building materials market offers a huge selection of products for roofing work, among which corrugated sheeting occupies a leading position. The article will tell you how to properly cover a roof with corrugated sheeting with your own hands. It is worth saying that the technology itself is simple if you know the features of this material and follow some installation rules.

Characteristics of corrugated sheets

During production, the metal sheet passes through special rolling equipment, which creates a profile of varying heights from 8 mm to 75 mm. Due to the wavy, rectangular and trapezoidal profiles, additional rigidity is achieved. Thanks to this, the corrugated sheet easily withstands mechanical damage and high loads.

- The galvanized coating makes this material reliable and durable. It is not afraid of chemically aggressive substances, corrosion, precipitation (weather conditions).

- Corrugated sheeting is one of the few materials that is easy to install and convenient to transport.

- Roofing work using profiled sheets is completed faster than with other materials. This significantly saves not only time, but also money.

- During the production process, the corrugated sheet is coated with a colored polymer; this coating serves as an additional protective layer and gives an attractive appearance. This allows you to choose this roofing material of any color in accordance with the general appearance of the structure.

Roof angle

The laying of corrugated sheets depends on the slope of the roof; the minimum slope is at least 12°. Upon completion of work, the working seams should be sealed using mastic or sealing tape.

- tilt up to 15° - adjacent sheets are mounted with an overlap of 200 mm;

- tilt up to 30° - the overlap in this case is 150-200 mm;

- tilt more than 30° - permissible overlap is 100-150 mm.

Calculation of roofing material

Before calculating the amount of material required, you should measure the roof. Because, during the stages of project implementation, roof slopes may undergo changes.

- To do this, you need to measure the slopes diagonally and compare these values, the discrepancy should not exceed 20 mm. It is also necessary to check the plane of the slopes; this measurement is performed with a level with a cord, where a deviation of no more than 5 mm is allowed for every 5 m. Otherwise, the sheets will not fit together.

- The ideal option is if the length of the sheet corresponds to the length of the slope; to this parameter you need to add about 40 mm more for the overhang of the cornice. Next, the amount of corrugated sheeting is calculated, where the length of the cornice is measured and divided by the installation (taking into account the overlap) width of the sheet.

- You can also calculate the number of sheets in another way: divide the length of the cornice by the useful (overlap) width of the sheet, and round the resulting value up.

- If the roof has a complex configuration, then it should be visually divided into geometric shapes. Each form is calculated and the final results are summed up. When calculating the material, it is important to take into account such additional elements as: windows, pipes, ends, ridges.

Roof structure made of corrugated sheets

The roof structure, in addition to the covering itself, consists of a whole complex of structural elements such as: heat, hydro, vapor barrier and ventilation. Each of them performs its role, ensuring the proper operation of the entire roof. In order for the roof to last a long time and fulfill its direct function, it is necessary to ensure the correct arrangement of all layers of the pie.

Vapor barrier. Its task is to prevent moisture from penetrating into the insulation. Here special films are used, which are laid from the inside of the roof using a construction stapler along a horizontal line. Seams formed during installation are sealed with tape or butyl tape.

Insulation . The next layer consists of insulation, which serves as a compensator for air temperature differences, thus preventing the accumulation of moisture and condensation under the roof during operation of the building. Its thickness is selected depending on the region of residence; it is recommended to use insulation with a thickness of at least 200 mm. Tile or roll material is laid in the space between the rafters.

Waterproofing . The final stage is the installation of a waterproofing membrane (wind protection). It acts as additional insulation and, thanks to its waterproof surface, protects the entire structure from condensation, thereby extending the service life of the roof.

The membrane is rolled out horizontally from the eaves to the ridge (from bottom to top). Positioning it in such a way that the joints of the rolls are on the rafters, it must be secured with an overlap of 150 mm.

The material for hydro- and thermal insulation is calculated in the same way as the number of profiled sheets.

- sheets are lifted onto the roof using logs made of one or two boards of the required length;

- It is not recommended to carry out work in windy weather, as there is a possibility of missing the sheet and damaging it;

- during work, you should walk on the profiled sheets in soft shoes, stepping only into the deflections between the waves in the areas of the sheathing;

- You can avoid the formation of corrosion on the material if you treat all cuts or other damage to the sheet with repair enamel;

- when working with corrugated sheets, it is necessary to use thick protective gloves, since the edges of the sheets are quite sharp;

- debris generated during installation should be swept away with a brush or washed with soapy water;

- the protective film of the material must be removed immediately after installation;

- It is prohibited to use a grinder (grinder) to avoid the development of a corrosion process.

Required Tools

- lever shears or electric shears for cutting sheets;

- a screwdriver for fastening the material or a hammer if fastening will be done using nails;

- construction stapler for fastening films and insulation;

- drill and drill No. 5, if the corrugated sheet will be attached to a metal structure with a thickness of over 2.5 mm;

- and such auxiliary tools as: marker, knife, level, tape measure, sealant gun.

Material and additional elements for corrugated roofing

Profiled sheeting. To cover a light roof with a slight slope, you can use profiled sheets C35 or C44 of a sinusoidal or trapezoidal shape.

Their length ranges from 2 to 6 m, but some manufacturers offer the production of sheets in individual sizes from 0.5 to 12 m and more.

It is recommended to install a pitched roof using CH35 grade corrugated sheeting; this model is better suited for these purposes. Profiled sheets of grade N are used for equipping load-bearing structures. The height of its profile can range from 57 to 114 mm.

Self-tapping screws. This polymer-coated fastener is matched to the color of the sheet. Thus, it is as invisible as possible in the architectural ensemble. They are chosen depending on the material: wood and metal. Its drill tip allows for fastening to a metal structure whose thickness does not exceed 2 mm. When purchasing self-tapping screws, you need to check the presence of a sealing washer (neoprene rubber).

Seal. You can seal gaps, for example, between the ridge and the roofing, using a special sealant. It prevents debris and moisture from entering the under-roof space, thanks to the repetition of all bends of the profiled sheet.

The ridge is semicircular or rectangular. Performs both a functional (protects the joints between profiled sheets) and a decorative role. The ends of the semicircular ridge are covered with special plugs.

Wind bar. It prevents rain from falling on the walls of the building and gives the roof a finished look.

Depending on the complexity of the roof structure itself, the following additional elements will be needed:

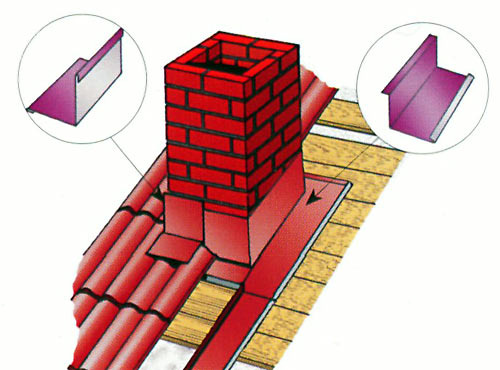

- Upper and lower valley strips. The bottom strip prevents rainwater from entering the roof space. The upper valley serves as the final detail, giving the roof a finished look.

- External and internal corner. With their help, sheets are connected at external and internal corners.

How to cover a roof with corrugated sheeting

- The lathing for laying corrugated sheets can be continuous or stepwise. The lower the roof slope, the smaller the pitch of the sheathing, for example, if the slope is less than 15°, then wooden or metal planks are mounted at a distance of 300-400 mm; if the roof slope is over 15°, the pitch can be 500-600 mm or more.

- Installation of profile sheets always begins from the bottom up, and moisture (rain or formed from melting snow) will not get into the space between the sheets. Such wavy material is laid against the prevailing wind direction in the area. If the wind blows more often from the right side, then the installation of the corrugated sheet should be laid from left to right, and vice versa. The correct sequence to cover the roof with corrugated sheeting is shown in the photo.

- If the length of the slope allows the use of a single sheet, then installation begins from the end of the roof. It must be aligned along the cornice, not forgetting the additional 40 mm (overhang of the cornice); alignment of the corrugated sheet along the edge of the end is not allowed.

- The first roofing sheet is installed in place and secured with one self-tapping screw approximately in the center. The second one is laid with an overlap on the previous sheet and fastened in the same way. Having secured the required number of sheets along the entire length of the roof, they are aligned along the horizontal line of the eaves. Next, you need to connect the corrugated sheets together at the ridge at every second deflection of the wave.

Then the final fastening is performed:

- Self-tapping screws are screwed in along a vertical line through the pitch of the sheathing;

- horizontally - in every second deflection of the profile sheet;

- It is advisable to strengthen the sheet at the end of the roof according to the pitch of the sheathing;

- the upper edge of the sheet (at the ridge) and the lower edge (on the eaves) - in each deflection of the wave;

- It is recommended to strengthen the joint between the sheets with hardware, both on the wave and on the deflection of the sheet.

- Excess material is cut off using electric scissors or an electric saw. Similar manipulations are performed from the ends of the building and on the other side of the slope, if we are talking about a gable roof.

- At the next stage, the end strip is installed and secured to the wave crest using the same screws. Its installation begins from below towards the ridge of the roof. When increasing the length of the planks, the overlap should be no less than 50 mm, the fastening step should be up to 1 m.

- Finally, the ridge is fastened. It is recommended to lay a self-adhesive seal between it and the profiled sheet. The ridge strips are built up with an overlap of 100 mm, the fastening pitch is at least 300 mm.

Installation of complex roof structures

Complex structures often have internal corners (valleys), ventilation or stove pipes, parapets, and so on are located on the roofs. The resulting joints must be carefully sealed, since through such places moisture can enter the under-roof space.

Endy. At these points, continuous sheathing is required on both sides of the valley. The lower (bottom) strip is attached at the edges with self-tapping screws or nails; when lengthening it, an overlap of 200 mm is required. A bend (flanging) is made from the upper end of the plank at the roof ridge.

The top strip is installed on top of the corrugated sheet, serving rather a decorative role, covering the joint between the edges. It is also advisable to install it using sealing materials that protect the installation joints from possible leaks.

Pipe. The sheathing around the pipe must be continuous, where the abutment strip (apron) is attached to the chimney using dowels (200 mm pitch), and to the sheathing with self-tapping screws.

Installation of the lower apron can be done by first cutting a groove on the brick pipe, with the obligatory sealing of this joint. A roofing covering with a sealant is mounted on top of it. The top strip is installed without grooves, after the installation of the coating around the pipe is completed. Installation of both longitudinal and transverse junctions of pitched surfaces to the wall is carried out in the same way.

Many manufacturers are ready to produce additional elements of non-standard shapes, so difficulties associated with the installation of roofing materials on complex roofs will not arise.

More clearly how to cover a roof with corrugated sheeting is demonstrated in the video presented.

Cover the roof with corrugated sheeting, cost of work

- installation of corrugated sheeting will cost approximately 200 rubles per m²;

- performing step lathing - 120 rubles per m²;

- installation of the ridge, wind and cornice strips, abutment strips - 100 rubles per linear meter;

- bypassing the pipe costs 2,000 rubles per element.

The roof made of profiled sheets fits harmoniously into modern architecture. Affordable cost and easy installation make this material popular among consumers. Roofing made from corrugated sheets has high strength and has aesthetic qualities.

A do-it-yourself corrugated roof is one of the simplest and most affordable ways to arrange a roof in private construction. Profiled metal sheets can be used as roofing on houses with pitched roofs, outbuildings, terraces, and gazebos.

Popularity of the material

Sheet roofing material made of durable steel by cold profiling is distinguished by sufficiently high strength due to its configuration - stiffeners ensure the resistance of the corrugated sheet to external loads.

Affordable cost, a wide selection of colors and ease of installation make the material popular in private and industrial construction. with your own hands, corrugated sheeting will be done with high quality if you install the coating in accordance with the instructions and technological map.

The durability and reliability of the finishing coating is determined not only by compliance with the installation technology, but also by the correct execution of the entire roofing pie.

Corrugated roofing structure

When designing a roof truss system covered with corrugated sheets, the light weight of the roofing material should be taken into account - there is no need to use powerful, reinforced structures. The angle of inclination of the slopes is selected, first of all, based on aesthetic preferences and the appearance of the building under construction. Corrugated sheeting is successfully used on pitched roofs with an inclination angle of 12 degrees. It is also possible to install the coating on roofs with a lower slope, but in this case it is necessary to treat vertical and horizontal overlaps with sealant, and the vertical overlap must be carried out in two waves, regardless of the brand of corrugated sheeting.

To make a roof from corrugated sheets, you should use load-bearing or wall sheet material. For arranging roofs with a sufficiently large slope angle, corrugated sheeting of the NS-35, NS-20, S-44 brands is popular. Installation of roofs with a small slope angle (5-8 degrees) requires the use of a self-supporting profile N-60 or N-75.

If the rafters are installed with a pitch of less than 1 meter, then boards with a minimum cross-section of 30×100 mm are used for the sheathing; if the rafter pitch exceeds 1 meter, then the cross-section of the material for the sheathing should be increased. For profiled sheet metal, the lathing can be padded in increments of up to 30 cm. It is permissible to use an unedged board as the material. In places where the valley is attached, continuous sheathing is performed.

To ensure optimal humidity conditions for the roofing pie, you need to take care of high-quality ventilation. Before installing the corrugated sheeting, waterproofing material is laid on the rafters and a counter-lattice is attached, thereby ensuring the necessary air gap between the waterproofing layer and the finishing coating made of.

Before covering the roof with corrugated sheets with your own hands, all roof elements made of wood must be pre-treated with fire-retardant and bioprotective agents.

Tools for installing corrugated sheets

Installing corrugated sheeting on the roof does not require the use of complex equipment. The list of required tools may include:

- roulette;

- level;

- rope;

- marker or pencil;

- metal scissors (electric and perforated);

- screwdriver;

- drill;

- hammer;

- construction stapler;

- construction gun with sealant.

It should be noted that the profiled sheet with a polymer coating is not resistant to high temperatures, so cutting and installation are carried out in a “cold” way, without the use of welding, etc. To cut sheets, in addition to metal scissors, you can use a jigsaw or a hacksaw with fine teeth.

When cutting profiled sheets and other metal roofing elements, it is recommended to treat the sections with an anti-corrosion primer to extend the service life of the coating.

Seals and screws

To lay corrugated sheets on the roof as a reliable covering, profiled roofing sheets are attached to the sheathing with self-tapping screws. Fastening elements for mounting corrugated sheets are made of hardened, galvanized steel. Each self-tapping screw is equipped with a special elastomer gasket (neoprene rubber), which ensures the tightness of the fastening point - access of moisture to the wooden elements of the sheathing should be avoided in order to prevent their rotting, as well as contact of moisture with the edges of the fastening hole of the corrugated sheet - metal with a damaged protective layer is susceptible to corrosion .

Technical parameters of self-tapping screws:

- size 4.8×35, 4.8×60, 4.8×80 mm;

- type of surface treatment – electrolytic galvanizing with a thickness of 12 microns;

- features of the manufacturing material - the presence in the composition of stabilizers that prevent aging of the material under the negative influence of ultraviolet radiation;

- protective and decorative coating of the cap – powder paint with a layer thickness of 50 microns;

- protective gasket - made of elastomer (for installation of the coating), made of aluminum sheet (for installation of valleys).

When installing a roof made of profiled sheets with a colored polymer decorative protective coating, it is recommended to use fasteners painted in the same color.

Laying corrugated sheets on the roof can be done using special seals. These are elements made of polyurethane foam or polyethylene foam. The seal is located between the sheathing and the roofing. The universal seal is a rectangular strip. It is more effective to use a sealing material that is cut in accordance with the profile of the corrugated sheet.

The seal allows you to reduce the noise of a metal roof, increase the thermal insulation parameters of the roofing pie, and extend the service life of the coating. For ease of installation, the seal strips are coated with an adhesive on one or both sides. To install a roof made of corrugated sheets, it is recommended to use a seal with special perforations for ventilation of the under-roof space.

Installation of the seal makes it possible to eliminate large gaps that are formed when the profiled sheet adheres to the plane of the roofing structure. Birds, insects, cold and humid air can penetrate into the gaps, which negatively affects the condition of the roofing pie. The material from which the seal is made is moisture- and bio-resistant, durable - its service life is more than 20 years.

Fastening corrugated sheets on the roof

The corrugated sheet is fastened with self-tapping screws, which are screwed into the lower wave adjacent to the sheathing using a screwdriver. Each sheet requires 7-8 fasteners. The installation scheme for a roof made of corrugated sheets involves laying the material with an overlap vertically and horizontally. The amount of overlap between adjacent sheets should be at least one wave. The overlap parameters of the top row of corrugated sheets on the bottom are determined by the angle of the roof slope and can range from 100 to 300 mm - the greater the angle of inclination of the roof, the less the overlap.

Where should you start laying corrugated sheeting on the roof? If the slope has a rectangular shape, fastening the sheets can begin from any end along the eaves line, left or right. If the slope has the shape of a trapezoid or a triangle, you should first consider the layout diagram, but in general it is recommended to first lay the sheet in the center of the eaves line, and then mount the sheets symmetrically in both directions.

Along the eaves line, corrugated sheeting is laid with an overhang of 60 mm, if installation of a drainage system is provided. If it is absent, it is recommended to increase the overhang of the cornice, taking into account the grade of material:

- for NS-20 – up to 100 mm;

- for S-44 and NS-35 – up to 200-300 mm.

The first sheet of material is aligned along the end of the roof and the eaves, then secured with a self-tapping screw in the upper part. Subsequent sheets are pre-fastened along the longitudinal side, aligned along the cornice, and then attached to the sheathing. Next, laying the corrugated sheets on the roof follows the same technology, installing row by row.

The corrugated sheeting should be laid on the roof in such a way as to provide a front overhang up to 70 mm wide. The corrugated sheet at the eaves should be fastened at a distance of 30 - 40 cm, and the subsequent rows of screws are arranged in a checkerboard pattern, with the fastening step being about 1 meter. At the gable, the screws are screwed in at intervals of 50-60 cm. Fastening elements on the longitudinal overlap should be placed along the top of the profile at a distance of 30 to 50 cm.

To screw in the fasteners, you can use a screwdriver or a drill that has a reverse stroke and is equipped with a smooth speed control.

Installation of cornice and ridge

If you make a roof made of corrugated sheets yourself with an organized drainage system, then the necessary elements are mounted on the eaves before laying the roofing. First of all, the cornice is hemmed, the gutter and cornice strip are installed. Roof ventilation is ensured by installing perforated soffit.

At the point where the roof ridge is attached, it is necessary to provide additional sheathing boards on both sides of the slope. The ridge must have two gaps for ventilation. Waterproofing is laid on the slopes, not reaching the ridge by 10 cm. The corrugated sheeting should not reach the ridge by 5 cm - this will facilitate normal ventilation of the under-roof space.

The ridge element is attached with 4.8×80 self-tapping screws to the structure through a wave along the top of the profile in increments of 30-40 cm. The ridge is closed at the end with plugs. The overlap along the length of the ridge element should be 15 cm.

At the final stage, the end of the roof should be covered with a wind strip, which is fastened with 4.8×35 self-tapping screws in increments of 50 cm along the upper wave of the profile. The overlap of the planks is 5-10 cm.

To care for the finished roof, you should use tools made from materials that do not damage the protective coating of the corrugated sheeting. Accidental scratches should be painted over immediately to prevent corrosion.

In order to properly cover the roof with corrugated sheets with your own hands, it is recommended that you familiarize yourself with the video with all the intricacies of the installation of the material.

Features of laying corrugated board on the sheathing

Each roofing process has its own characteristics. The roof that needs to be covered can have a different number of slopes and be of any slope. First you need to make a roof sheathing; it can be constructed from either boards or steel. When designing, it is necessary to take into account the presence of additional elements, such as gutters, snow catchers.

For error-free roof installation with corrugated sheeting, you need to take into account some principles, including:

- Having a roof slope angle of no more than 12 degrees, the projection of profiled plates should be about 20 centimeters. In this case, the use of sealants is recommended.

- Having a roof slope of no more than 15 degrees, the optimal spread of sheets is about 20 centimeters.

- Having a roof slope of 15–20 degrees, an overlap of sheets of 15 to 20 centimeters is recommended.

- Having a roof inclination angle of more than 30 degrees, the approximate overlap of the corrugated sheet is about 15 centimeters.

The smaller the slope angle, the greater the load from precipitation, which subsequently leads to roof leakage. In this case, it is more advisable to increase the overlap.

Installation stages

One of the many advantages of using corrugated sheeting in the roof is the ability to choose the material by type and size, as well as color and wave level based on your own preferences. Once the choice has been made, you can begin a number of stages in the process of laying corrugated sheets.

Preparatory work

In order not to make a mistake with the dimensions and the required number of profiled plates, before purchasing you need to calculate the required quantity by dividing the total width of the slope by the width of one sheet.

Before starting the main work, you will need to carefully consider the transportation of the purchased plates, as well as their subsequent lifting to the roof. To ensure complete safety of the surface of the profiled sheet, carefully consider methods of safe movement.

To lift the corrugated sheeting onto the roof, it is advisable to involve several working hands. You need to lift the sheets one at a time.

Hydro- and vapor barriers

Any residential building must be provided with reliable hydro- and vapor barriers; they provide reliable protection against moisture getting into the insulation, which is also provided in the roof structure.

Insulation layers are made from a variety of materials that are freely sold in hardware stores. The main thing is to make the right choice and not get confused in the assortment.

First of all, such a layer serves not only as an obstacle to liquid, it is also capable of evaporating it. Moreover, waterproofing performs its function from the outside of the roof structure, and vapor barrier is reliable from the inside.

The roof needs high-quality insulation; this is achieved with the help of matte insulation, which is laid after using a vapor barrier film. The final stage will be the laying of a waterproofing film, which is a membrane that is resistant to ultraviolet rays and temperature changes.

Required tools and materials

Laying the roof with corrugated sheets by hand, the process is quite complicated. First of all, it requires basic knowledge in this area, as well as the presence of mandatory materials and fixtures, on which, in essence, the quality of the original roof will depend.

- Scissors for cutting metal (special hand scissors, electric scissors).

- Bend pliers.

- Gun for removing sealant from the bolt.

- Strip bender.

- Stapler.

- Screwdriver.

- Roulette.

- Construction knife.

- Level.

- Drill.

- Hammer.

- Self-tapping screws made of galvanized steel with a neoprene rubber gasket.

If corrugated sheets are treated with a colored polymer coating, it is recommended to select fasteners in accordance with the color.

DIY installation

The corrugated sheeting is laid on the sheathing, which serves as a reinforcing structure, to eliminate possible bending of the roof under the weight of precipitation and strong winds.

Installation diagram

You need to start by attaching the end strip, which is fixed at the height point of the roof profile, above the frame. At the level of the frame, under the strip of the gutter with the funnel, a flooring is made of planks. It should be on both sides with an indentation size of sixty centimeters.

The option when the groove is made of galvanized alloy provides for an overlap of 20 centimeters. The bottom strip is attached using self-tapping screws to the edges. Its main and reinforced attachment is carried out during the process of laying and fixing the corrugated sheet. It is advisable to equip the joints with a sealant, especially if the roof is flat.

For any roof structure, the stage of installing the eaves strip is suitable. A universal seal is placed between it and the corrugated sheet plate, and ventilation is also thought out. The curved edge of the profiled plate, which provides for water drainage, should be located at the bottom during installation.

Having familiarized yourself with the details of the installation diagram, you can proceed to the specifics of laying corrugated sheets.

Step-by-step instruction

- The installation of any roof should begin from the right end.

- When covering a hip roof, laying the profiled plates begins on both sides, starting from the highest point of the slope.

- Using self-tapping screws, install and secure the eaves strip, leaving an overhang indentation of 4 cm. Place the sealant in the gap between the profiled sheet and the strip.

- It is necessary to pay attention to the slope; if it is less than 14–12 degrees, then a sealant will be required on the longitudinal seams, and the overlap of the sheets should be 2 waves.

- First of all, secure the first sheet with one self-tapping screw (this is necessary so that it can be rotated), then it is aligned along the edges in accordance with the cornice.

- Subsequent sheets are laid overlapping and secured at the corners with self-tapping screws.

- The first four laid sheets must be aligned with a cord and then secured.

- Starting the second level of corrugated sheeting, you should attach the first sheet of the second row to the first sheet of the first row.

- When choosing the order of laying corrugated sheets, you will need to take into account the factors of temperature differences, as well as the possibility of strong winds and snow.

Laying methods

There are two ways to lay corrugated sheeting on the roof.

1 way. This method is called vertical laying. Lower the first sheet down from the overhang by 4 cm and attach it using a self-tapping screw. Next, take the second profiled plate and align it with the sides of the first plate and secure it. Using this method, assemble the four sheets together, and then fasten them at the top of the waves using self-tapping screws. New blocks are added to the resulting section.

Method 2. With this method, a section is made that includes three profiled plates. Two plates are laid in the first row and aligned along the edge, followed by fastening. The whole point of this method is that the third plate from the second row should be docked last. All subsequent sections are assembled using the same method.

If all instructions are followed and fastened well, the corrugated roofing will be reliable and of high quality.

Ridge and end strips: how to install

The standard length of the end strip is 2 meters; to increase it, you can overlap the planks. When installing them, choose the direction towards the ridge starting from the roof overhang. The end strip must necessarily overlap at least one wave crest. In increments of about a meter, this bar is secured using self-tapping screws.

The next mandatory stage in roof construction will be attaching the ridge.

The skates are installed using an overlap of 20 centimeters and secured using self-tapping screws to the profiled plate. The distance between the fasteners should not be less than 25 centimeters. All ridge elements must have a smooth surface.

Junction strips

Just like the end strip, the abutment strip has a factory length of 2 meters. At the junction of the plank with the corrugated sheets, it is fastened in increments of 40 centimeters with self-tapping screws.

Having familiarized yourself with all the secrets and features of installing a roof with corrugated sheets, you can draw a clear conclusion that anyone can do it with their own hands!

Do-it-yourself corrugated roofing: video installation instructions

Features of laying corrugated board on the sheathing. DIY installation: instructions. Ridge and end strips: how to install.

The procedure for laying corrugated sheeting on the roof

The undeniable advantage of profiled sheets is the low weight of such roofing material and ease of installation. The positive properties of profiled sheets do not require developers to have special skills and abilities. In addition, all installation work takes place quickly and with minimal effort and money. The technology for installing profiled sheets on the roof is quite simple, but must comply with basic standards and requirements.

Work technology

Roofing using profiled sheets is quite easy to install yourself. This type of work must be carried out in accordance with the technological requirements for the installation of profiled sheets. The main stages of work on installing the roof covering are as follows:

- fastening of profile sheets to the sheathing frame is carried out using white metal screws equipped with a special drill;

- the standard dimensions of the hardware used are 4.8x20 millimeters;

- It is most convenient to use self-tapping screws with hexagonal heads and a neoprene gasket;

- in the process of attaching the material to the frame, it is necessary to control the tightening force of the fasteners;

- pitched ends are used in the fastening process, so the dimensions of the side overlap should be half the profile wave;

- slopes that are flatter require overlaps of one and a half profile waves;

- regardless of the pitch, fastening is always carried out in the lower wave segment using special self-tapping screws;

- for additional sealing of longitudinal and transverse joints, it is necessary to use bitumen mastic or self-adhesive insulation tape;

- the gable parts of the roofing are mounted using wind linings, which can protect the profiled sheets from gusts of wind and destruction;

- to fix the wind pads, use self-tapping screws in increments of twenty centimeters;

- At the final stage of installation, it is necessary to cover the valleys, ribs and assemblies of roof abutments to vertical surfaces using a metal profile, and also carry out insulation with bitumen mastic.

Instructions for laying corrugated sheets with your own hands

When choosing a method for installing corrugated sheets, special attention should be paid to the type and height of the corrugation, as well as the thickness of the material (more on how to choose the best corrugated sheeting for the roof). It is these indicators that influence the method of fastening roofing sheets.

Rules for fastening sheets

Laying roofing material on the roof surface begins from the lower end corner. If it is necessary to mount several rows of profiled sheets, when laying the bottom row, it is necessary to leave an indentation that will serve as an overhang from the eaves strip. The standard dimensions of such an overhang should be 3.5-4 centimeters.

When attaching the last strip to the roofing edge, use the bottom of every second wave of roofing material.

The end boards located on the sides of the building are covered with a wind angle. Installation of wind strips is carried out after the final fastening of the end row or the last roofing sheet.

Cutting corrugated sheets

Profiled sheets are fairly thin products that are very easily deformed during the cutting process. Coating with a galvanized or polymer layer causes additional inconvenience. It is not possible to use conventional cutting methods for tin sheet material.

It is allowed to use special discs equipped with carbide teeth for cutting. The most economical and convenient way to cut corrugated sheets is to use a hacksaw. In addition, it is allowed to cut profiled sheets using an electric or manual jigsaw, which can perform not only straight, but also curved cuts of the material.

Installation procedure

The main points that must be observed during the installation of corrugated sheets are as follows:

- vertical overlap of sheet material is performed by overlapping the top sheet with the bottom sheet by 20 centimeters;

- for horizontal overlap, the top sheet overlaps the bottom sheet - one wave when using sealing gaskets, and two waves when there is no gasket;

- fastening of the sheet material begins from the roofing edge from the edge center using one self-tapping screw, and further laying of the roofing sheets is carried out in accordance with the first;

- the final fastening of all laid sheets is carried out after careful leveling of the roofing material;

- for longitudinal fastening, a wave crest is used in increments of 50 cm, and vertical joints are secured with hardware along the bottom of each wave;

- for high-quality fastening of profiled sheets, it is necessary to use 4-5 self-tapping screws for each square meter of roofing;

- After fixing the main roofing sheet, the ridge and end strips are installed. When installing ridge strips, no seal is used, but the profile relief must have slots that will ensure high-quality ventilation of the under-roof space;

- The final stage of installation consists of arranging connections between the roof and vertical surfaces and the outlets of chimney or ventilation pipes.

Basic installation mistakes

Any deviations from the technology when installing a roof made of corrugated sheets can provoke a violation of the performance characteristics of the roofing. The most common errors include:

- violation of the place of fastening of profiled sheets;

- incorrect distance between adjacent screws, which at the level of longitudinal joints should be no more than 50 centimeters;

- no displacement of fastening elements in joined waves;

- violation of roof tightness at the joints of roofing sheets.

Cost of work

Accessories for roofing made from profiled sheets are represented by ridges, caps, strips, cornices, snow retainers, gutters, purlins, valleys and other additional elements. Depending on the type of sheets and type of coating, the price of profiled sheets starts from 219 rubles.

A set of professional roofing works for the installation of roofing from profiled sheets, including the installation of all the above components, costs more than 380 rubles. per sq. meter.

Sheet roofing iron, equipped with a polymer coating, is one of the most popular building materials for pitched roofs. Profiled sheets have long been an ideal covering for private homes and industrial premises.

Low price combined with high quality characteristics can satisfy the needs of even the most demanding consumers. The budget is due to the low cost of raw materials and economical technology for the production of roofing sheets.

Proper execution of installation work, taking into account the technology and specifics of the material, allows us to obtain a roof made of profiled sheets with unique properties. This coating is durable and reliable, and in terms of technical characteristics and parameters is on par with modern metal tile roofing.

Instructions and technology for laying corrugated sheets on the roof with your own hands

Laying profiled sheets on the roof is the best option for installing reliable roofing coverings not only for country houses and simple

Do-it-yourself corrugated roof: how to lay it correctly

A do-it-yourself corrugated roof is one of the simplest and most affordable ways to arrange a roof in private construction. Profiled metal sheets can be used as roofing on houses with pitched roofs, outbuildings, terraces, and gazebos.

Popularity of the material

Sheet roofing material made of durable steel by cold profiling is distinguished by sufficiently high strength due to its configuration - stiffeners ensure the resistance of the corrugated sheet to external loads.

Affordable cost, a wide selection of colors and ease of installation make the material popular in private and industrial construction. Do-it-yourself roofing with corrugated sheets will be done with high quality if you install the covering in accordance with the instructions and technological map.

The durability and reliability of the finishing coating is determined not only by compliance with the installation technology, but also by the correct execution of the entire roofing pie.

The durability and reliability of the finishing coating is determined not only by compliance with the installation technology, but also by the correct execution of the entire roofing pie.

Corrugated roofing structure

When designing a roof truss system covered with corrugated sheets, the light weight of the roofing material should be taken into account - there is no need to use powerful, reinforced structures. The angle of inclination of the slopes is selected, first of all, based on aesthetic preferences and the appearance of the building under construction. Corrugated sheeting is successfully used on pitched roofs with an inclination angle of 12 degrees. It is also possible to install the coating on roofs with a lower slope, but in this case it is necessary to treat vertical and horizontal overlaps with sealant, and the vertical overlap must be carried out in two waves, regardless of the brand of corrugated sheeting.

To make a roof from corrugated sheets, you should use load-bearing or wall sheet material. For arranging roofs with a sufficiently large slope angle, corrugated sheeting of the NS-35, NS-20, S-44 brands is popular. Installation of roofs with a small slope angle (5-8 degrees) requires the use of a self-supporting profile N-60 or N-75.

If the rafters are installed with a pitch of less than 1 meter, then boards with a minimum cross-section of 30×100 mm are used for the sheathing; if the rafter pitch exceeds 1 meter, then the cross-section of the material for the sheathing should be increased. To install a roof made of corrugated sheets, the sheathing can be packed in increments of up to 30 cm. It is permissible to use unedged boards as the material. In places where the valley is attached, continuous sheathing is performed.

To ensure optimal humidity conditions for the roofing pie, you need to take care of high-quality ventilation. Before installing the corrugated sheeting, waterproofing material is laid on the rafters and a counter-lattice is attached, thereby ensuring the necessary air gap between the waterproofing layer and the finishing coating of the metal profile.

Before covering the roof with corrugated sheets with your own hands, all roof elements made of wood must be pre-treated with fire-retardant and bioprotective agents.

Before covering the roof with corrugated sheets with your own hands, all roof elements made of wood must be pre-treated with fire-retardant and bioprotective agents.

Tools for installing corrugated sheets

Installing corrugated sheeting on the roof does not require the use of complex equipment. The list of required tools may include:

- roulette;

- level;

- rope;

- marker or pencil;

- metal scissors (electric and perforated);

- screwdriver;

- drill;

- hammer;

- construction stapler;

- construction gun with sealant.

It should be noted that the profiled sheet with a polymer coating is not resistant to high temperatures, so cutting and installation are carried out in a “cold” way, without the use of welding, etc. To cut sheets, in addition to metal scissors, you can use a jigsaw or a hacksaw with fine teeth.

When cutting profiled sheets and other metal roofing elements, it is recommended to treat the sections with an anti-corrosion primer to extend the service life of the coating.

Seals and screws

To lay corrugated sheets on the roof as a reliable covering, profiled roofing sheets are attached to the sheathing with self-tapping screws. Fastening elements for mounting corrugated sheets are made of hardened, galvanized steel. Each self-tapping screw is equipped with a special elastomer gasket (neoprene rubber), which ensures the tightness of the fastening point - access of moisture to the wooden elements of the sheathing should be avoided in order to prevent their rotting, as well as contact of moisture with the edges of the fastening hole of the corrugated sheet - metal with a damaged protective layer is susceptible to corrosion .

Technical parameters of self-tapping screws:

- size 4.8×35, 4.8×60, 4.8×80 mm;

- type of surface treatment – electrolytic galvanizing with a thickness of 12 microns;

- features of the manufacturing material - the presence in the composition of stabilizers that prevent aging of the material under the negative influence of ultraviolet radiation;

- protective and decorative coating of the cap – powder paint with a layer thickness of 50 microns;

- protective gasket - made of elastomer (for installation of the coating), made of aluminum sheet (for installation of valleys).

When installing a roof made of profiled sheets with a colored polymer decorative protective coating, it is recommended to use fasteners painted in the same color.

Laying corrugated sheets on the roof can be done using special seals. These are elements made of polyurethane foam or polyethylene foam. The seal is located between the sheathing and the roofing. The universal seal is a rectangular strip. It is more effective to use a sealing material that is cut in accordance with the profile of the corrugated sheet.

The seal allows you to reduce the noise of a metal roof, increase the thermal insulation parameters of the roofing pie, and extend the service life of the coating. For ease of installation, the seal strips are coated with an adhesive on one or both sides. To install a roof made of corrugated sheets, it is recommended to use a seal with special perforations for ventilation of the under-roof space.

Installation of the seal makes it possible to eliminate large gaps that are formed when the profiled sheet adheres to the plane of the roofing structure. Birds, insects, cold and humid air can penetrate into the gaps, which negatively affects the condition of the roofing pie. The material from which the seal is made is moisture- and bio-resistant, durable - its service life is more than 20 years.

Fastening corrugated sheets on the roof

The corrugated sheet is fastened with self-tapping screws, which are screwed into the lower wave adjacent to the sheathing using a screwdriver. Each sheet requires 7-8 fasteners. The installation scheme for a roof made of corrugated sheets involves laying the material with an overlap vertically and horizontally. The amount of overlap between adjacent sheets should be at least one wave. The overlap parameters of the top row of corrugated sheets on the bottom are determined by the angle of the roof slope and can range from 100 to 300 mm - the greater the angle of inclination of the roof, the less the overlap.

Where should you start laying corrugated sheeting on the roof? If the slope has a rectangular shape, fastening the sheets can begin from any end along the eaves line, left or right. If the slope has the shape of a trapezoid or a triangle, you should first consider the layout diagram, but in general it is recommended to first lay the sheet in the center of the eaves line, and then mount the sheets symmetrically in both directions.

Along the eaves line, corrugated sheeting is laid with an overhang of 60 mm, if installation of a drainage system is provided. If it is absent, it is recommended to increase the overhang of the cornice, taking into account the grade of material:

The first sheet of material is aligned along the end of the roof and the eaves, then secured with a self-tapping screw in the upper part. Subsequent sheets are pre-fastened along the longitudinal side, aligned along the cornice, and then attached to the sheathing. Next, laying the corrugated sheets on the roof follows the same technology, installing row by row.

The corrugated sheeting should be laid on the roof in such a way as to provide a front overhang up to 70 mm wide. The corrugated sheet at the eaves should be fastened at a distance of 30 - 40 cm, and the subsequent rows of screws are arranged in a checkerboard pattern, with the fastening step being about 1 meter. At the gable, the screws are screwed in at intervals of 50-60 cm. Fastening elements on the longitudinal overlap should be placed along the top of the profile at a distance of 30 to 50 cm.

To screw in the fasteners, you can use a screwdriver or a drill that has a reverse stroke and is equipped with a smooth speed control.

To screw in the fasteners, you can use a screwdriver or a drill that has a reverse stroke and is equipped with a smooth speed control.

Installation of cornice and ridge

If you make a roof made of corrugated sheets yourself with an organized drainage system, then the necessary elements are mounted on the eaves before laying the roofing. First of all, the cornice is hemmed, the gutter and cornice strip are installed. Roof ventilation is ensured by installing perforated soffit.

At the point where the roof ridge is attached, it is necessary to provide additional sheathing boards on both sides of the slope. The ridge must have two gaps for ventilation. Waterproofing is laid on the slopes, not reaching the ridge by 10 cm. The corrugated sheeting should not reach the ridge by 5 cm - this will facilitate normal ventilation of the under-roof space.

The ridge element is attached with 4.8×80 self-tapping screws to the structure through a wave along the top of the profile in increments of 30-40 cm. The ridge is closed at the end with plugs. The overlap along the length of the ridge element should be 15 cm.

At the final stage, the end of the roof should be covered with a wind strip, which is fastened with 4.8×35 self-tapping screws in increments of 50 cm along the upper wave of the profile. The overlap of the planks is 5-10 cm.

To care for the finished roof, you should use tools made from materials that do not damage the protective coating of the corrugated sheeting. Accidental scratches should be painted over immediately to prevent corrosion.

Do-it-yourself corrugated roof: how to cover it correctly, video

Learn how to make a roof from corrugated sheets with your own hands. How to lay and fasten corrugated sheets on various types of roofs. The procedure for installing corrugated sheets.

“How to properly cover a roof with corrugated sheeting and is it possible to do it yourself?” – these are the questions asked by every homeowner who has decided to use corrugated sheeting as a covering for the roof of their home or outbuildings. Corrugated sheet metal as a roofing material is a leader not only in terms of price-quality ratio, but also in ease of installation. If you act step by step and strictly follow the simple technology, then covering the roof with corrugated sheeting will not cause any particular difficulties.

For the roof, choose metal profiles of grade H57 or NS35. H57 corrugated sheeting with an additional stiffening rib, the so-called load-bearing one, is ideal as a roofing material, but a bit expensive. Usually they use the universal NS35, it is suitable in quality and more affordable in cost. You can choose a regular galvanized sheet, or one with a polymer coating, it all depends on your wishes and wallet. Before covering the roof with corrugated sheeting, you need to decide on the number of sheets of material and additional elements. If the roof is simple enough, then you can do the calculation yourself. Roof slopes are rectangles, isosceles trapezoids or triangles, that is, the length of the slope is the measurement from the ridge to the base, add 5 cm and get the length of the metal profile sheet.  When roofing with corrugated sheeting, it is desirable that the slope be covered in length with one sheet, since the fewer overlaps, the more reliable the roof, but if you still have to cover it in several rows, then you need to add another 20 cm for each overlap. Hence:

When roofing with corrugated sheeting, it is desirable that the slope be covered in length with one sheet, since the fewer overlaps, the more reliable the roof, but if you still have to cover it in several rows, then you need to add another 20 cm for each overlap. Hence:

- LENGTH OF SHEET OF PROFILE SHEETS = LENGTH of slope + 5 cm, if the roof will be covered in one sheet.

- LENGTH OF SHEET OF PROFILE SHEETS = LENGTH of slope + 5 cm + 20 cm (for each row with overlap), if the roof will be covered in several horizontal rows.

The roof can be covered in 2 rows of 4.3 m each - 20 cm will be left for the overlap, 5 cm for the overhang, and the result is a working LENGTH of the sheet = 4.3 m-0.2 m-0.05 m = 4.05 m. For Each type of metal profile has its own working width, but in this example we consider the most common corrugated sheeting for roofing, NS35. The useful width of the NS35 metal profile sheet is 1 m, so the working area of the sheet for such a slope is 4.05 × 1 = 4.05 m2. We count the number of sheets: 128:4.05=31.6, that is, you will need 32 sheets of metal profiles of 4.3 m each. You can take and cover the roof with one sheet 8.15 m long, you will need 128:8.15=15 such sheets, 7, that is 16 sheets. But will it be convenient to work with such a length yourself... If the roof is “broken”, with many bends, you need to unroll all the slopes and count the number of sheets for each slope and fold them. You can also contact specialists; they have special programs that will make calculations and even a diagram of the best installation. There are also online calculators for calculating the amount of corrugated sheeting, but before entering the data into the program, check the correctness of their calculation using a simple example, at least the one given above. Depending on the type of roof, additional elements are also purchased, such as ridges, end, eaves and butt strips, and screws for fastening them. Self-tapping screws are purchased at the rate of 11 pieces per 1 m2. Thus, before covering the roof with corrugated sheeting, you need to carry out painstaking work on measuring and counting all the materials that will be used in the work. You should work through this stage very carefully so as not to interrupt work in the future due to a lack of some parts.

The roof can be covered in 2 rows of 4.3 m each - 20 cm will be left for the overlap, 5 cm for the overhang, and the result is a working LENGTH of the sheet = 4.3 m-0.2 m-0.05 m = 4.05 m. For Each type of metal profile has its own working width, but in this example we consider the most common corrugated sheeting for roofing, NS35. The useful width of the NS35 metal profile sheet is 1 m, so the working area of the sheet for such a slope is 4.05 × 1 = 4.05 m2. We count the number of sheets: 128:4.05=31.6, that is, you will need 32 sheets of metal profiles of 4.3 m each. You can take and cover the roof with one sheet 8.15 m long, you will need 128:8.15=15 such sheets, 7, that is 16 sheets. But will it be convenient to work with such a length yourself... If the roof is “broken”, with many bends, you need to unroll all the slopes and count the number of sheets for each slope and fold them. You can also contact specialists; they have special programs that will make calculations and even a diagram of the best installation. There are also online calculators for calculating the amount of corrugated sheeting, but before entering the data into the program, check the correctness of their calculation using a simple example, at least the one given above. Depending on the type of roof, additional elements are also purchased, such as ridges, end, eaves and butt strips, and screws for fastening them. Self-tapping screws are purchased at the rate of 11 pieces per 1 m2. Thus, before covering the roof with corrugated sheeting, you need to carry out painstaking work on measuring and counting all the materials that will be used in the work. You should work through this stage very carefully so as not to interrupt work in the future due to a lack of some parts. Standard stage. Insulation and vapor barrier

For our climatic conditions, a corrugated roof necessarily requires insulation. The insulation technology is the same as for all other types of covering: mineral wool between the rafters and a vapor barrier layer, the insulation layer must be at least 15 cm.Hydrobarrier

In order to protect the heat-insulating layer from moisture and prevent roof leaks, a waterproofing layer is laid. This is a mandatory stage and cannot be neglected. Let's look at how to properly waterproof a roof. It is better to choose modern waterproofing materials for corrugated roofing. Both membrane and polypropylene films are widely used. The technology for laying them is very simple. If the roof is new, being built from scratch, then, of course, it is better to use a membrane. The waterproofing layer is unrolled over the main rafters in horizontal rows. The overlap of the top row on the bottom should be 15 cm, the film should sag slightly, sag by 2 centimeters (but there should remain a distance between the insulation layer and the waterproofing of about 3 cm) and is stapled to the rafters, the overlaps should be taped with adhesive tape. If you plan to simply cover a roof with corrugated sheeting that was previously covered with another material, then there is no point in using a membrane. A dense, thick polyethylene film is laid on top of an old insulating layer, for example, roofing felt. In any case, the waterproofing is fastened using a stapler, and the joints are glued with construction tape.

If you plan to simply cover a roof with corrugated sheeting that was previously covered with another material, then there is no point in using a membrane. A dense, thick polyethylene film is laid on top of an old insulating layer, for example, roofing felt. In any case, the waterproofing is fastened using a stapler, and the joints are glued with construction tape. Counter-lattice and sheathing

After the waterproofing layer has been laid, the counter-lattice is installed. Along the main rafters, on top of the hydraulic barrier, bars are placed with gaps of 20 mm. For counter-lattice, 25×40 mm bars are usually used. Lathing is placed on the counter-lattice. For different types of corrugated sheeting, different types of sheathing pitch, the thinner the corrugated sheeting and the smaller the roof slope angle, the smaller the sheathing pitch. This article discusses how to properly cover a roof with corrugated sheeting, and therefore considers the recommended correct option for the roof - NS35 metal profile. However, in the table below we indicate the recommended step for different types of corrugated sheets.| Type of corrugated sheet | Roof slope | Corrugated sheet thickness | Lathing step |

|---|---|---|---|

| S-8 | more than 15 degrees | 0.55 mm | solid |

| P-18; MP-20; P-20; S-20 | up to 15 degrees | 0.7; 0.55 mm | solid |

| more than 15 degrees | 0.7; 0.55 mm | no more than 500 mm | |

| NS-35 | up to 15 degrees | 0.7; 0.55 mm | no more than 500 mm |

| more than 15 degrees | 0.7; 0.55 mm | no more than 1000 mm | |

| S-44 | up to 15 degrees | 0.7; 0.55 mm | no more than 500 mm |

| more than 15 degrees | 0.7; 0.55 mm | no more than 1000 mm | |

| N-60 | 0.7; 0.8; 0.9 mm | no more than 3000 mm | |

| N-75 | less than 8 degrees is not allowed | 0.7; 0.8; 0.9 mm | no more than 4000 mm |

Laying profiled sheets

The time has come to directly attach the corrugated sheeting to the roof. The sheets are fastened only with special roofing screws with a rubber lining near the cap and a drill at the end, matching the color of the corrugated sheets. For fastening, use a regular screwdriver. First, the cornice strip is attached. The sheets are lifted onto the roof along inclined boards so as not to deform them. The first sheet begins to be laid from the lower corner of the roof, the sheets are carefully aligned with the eaves. The corrugated sheeting is fastened to the sheathing using self-tapping screws measuring 4.8×35 mm in the bottom wave..

The sheets are lifted onto the roof along inclined boards so as not to deform them. The first sheet begins to be laid from the lower corner of the roof, the sheets are carefully aligned with the eaves. The corrugated sheeting is fastened to the sheathing using self-tapping screws measuring 4.8×35 mm in the bottom wave..

There are several schemes for laying corrugated sheets, but the rules for working with corrugated sheets are always the same:

There are several schemes for laying corrugated sheets, but the rules for working with corrugated sheets are always the same: - The lowest row (along the cornice) and the highest row (along the ridge) are attached with self-tapping screws to each deflection of the wave.

- The middle of the slope is secured through the wave in a checkerboard pattern.

- The screws are screwed in clearly perpendicular to the plane of the sheet; distortions are unacceptable.

- The longitudinal step for fastening the sheet is 1 m.

- Vertical overlaps between adjacent sheets are 1 wave (for a flat roof 2 waves).

- The top row lies on the bottom row with an overlap of 20 cm.

- The horizontal overlap line is attached with self-tapping screws to each lower wave.

- The corrugated sheets along the edges of the roof are attached to each sheathing strip.

- Cutting of profiled sheets is done either with a jigsaw or electric scissors (not a grinder!).

- You should move along the roof along the lower wave in soft shoes.

Since covering the roof correctly with corrugated sheeting is not so difficult, attaching the sheets should not take much time. After all the metal profile sheets have been secured, we begin to attach additional elements: ridges, end (wind) strips, snow guards. The ridge is attached with self-tapping screws into every second upper wave, with an overlap on the sides of 150-200 mm.

Since covering the roof correctly with corrugated sheeting is not so difficult, attaching the sheets should not take much time. After all the metal profile sheets have been secured, we begin to attach additional elements: ridges, end (wind) strips, snow guards. The ridge is attached with self-tapping screws into every second upper wave, with an overlap on the sides of 150-200 mm.  The end (wind) strips are installed with an overlap of at least 50 mm.

The end (wind) strips are installed with an overlap of at least 50 mm.  All additional elements are fastened with special long screws for metal profiles - 4.8 × 50 (60) mm.

All additional elements are fastened with special long screws for metal profiles - 4.8 × 50 (60) mm.