Among heating devices, the rocket stove deserves special attention. It has an original structure, which involves the use of available materials and components. Almost anyone can organize one. It is enough to understand how to read drawings, as well as to be able to use basic construction tools and materials.

Option for making a rocket stove with your own hands

Despite the simplicity of the design, the rocket stove involves the use of two operating principles at once:

- free flow of wood gases through channels;

- pyrolysis is the afterburning of gases that are released during combustion.

The simplest rocket stove uses only the first principle of operation, since there are not enough conditions for pyrolysis.

A neat, homemade rocket stove

A neat, homemade rocket stove First, let's look at the options for jet stoves used for cooking. In such a device, a short pipe located horizontally is used as a firebox, and then it is directed upward. This is the simplest design.

Fuel is placed into the rocket stove directly into the pipe, after which it is ignited. As a result, a flow of hot gases is formed, which is oriented to go out, which means it tends to the vertical section.

At the end of the pipe there is a container used for water or food. There is a gap between it and the pipe so that combustion products can escape.

Many people are interested in why such a stove is called a rocket. The design has a nozzle turned upward, from which, when the device is operating, a flame bursts out. Hence the name.

Flames escaping from a rocket stove

Flames escaping from a rocket stove Of course, such a unit will not be able to warm up the room. The rocket furnace must be supplemented with a heat exchanger, as well as channels for removing combustion products. To ensure high temperatures, the vertical part of the pipe is insulated with fire-resistant material.

The nozzle can be covered with a cap. This is necessary for high-quality heat selection. A channel is created at the bottom of the horizontal section of the pipe to supply secondary air.

The modern version involves a slightly different design. Such a reactive furnace involves the afterburning of pyrolysis gases, which is possible due to the supply of secondary air. In addition, combustion products collect under the top of the hood, which increases the pressure to excess. Over time, heat is transferred outward through the walls of the pipe, forcing the gases to cool and flow downward. Hot air awaits them there, so they have to go into the space between the walls of the hood and the pipe, going into the chimney channel.

Application of a rocket stove with a hood on the site

Application of a rocket stove with a hood on the site Due to pyrolysis processes, efficiency increases significantly. And thanks to the flow of gases, a self-regulating system is organized.

Productive heat removal

The gases that are sent to have a high temperature. Therefore, it is clear that you should not get rid of them so easily. Otherwise, the effect of the device will be minimal. Therefore, several solutions have been invented for a do-it-yourself rocket stove:

- a water circuit is installed on the rocket stove;

- gases are passed through channels equipped under the stove bench.

A water-heated rocket stove is made without a hood; the energy of combustion products is used in a metal heat exchanger. You should not use a coil with water, it is better to make a water jacket.

You can also make chimney channels lined with brick. They can be placed on the floor, and a bed can be equipped on top. And in this case, the length of the channels must be accurately calculated, otherwise natural draft will have to be organized.

Design of a brick rocket stove with a stove bench

Design of a brick rocket stove with a stove bench Advantages

Create a rocket stove with your own hands and get the following benefits:

- You can add fuel during the process;

- Efficiency is not a constant value, but with proper selection of thermal energy from gases, it can be very high;

- natural draft of the chimney is not a prerequisite;

- accessibility of installation - to organize a rocket stove with your own hands, a little experience in the stove business is enough, minimum costs for materials.

Using a rocket stove outdoors

Using a rocket stove outdoors Such advantages make the rocket stove a popular device.

Flaws

Note: And although the rocket stove is characterized by simplicity and attractiveness, it also has disadvantages. For example, there are certain requirements for fuel quality. The firewood should not be wet, otherwise the pyrolysis effect will not be achieved. In addition, the structure requires constant supervision.

A do-it-yourself rocket stove is not very suitable for a bathhouse, since it gives off little of the heat needed for a steam room. The small surface area of the stove prevents effective heating of the bath.

Kinds

There are several types of rocket stoves:

- Brick boilers. They differ from stoves - they are equipped with a built-in heat exchanger, from which the coolant is supplied to the heating system: tank, pipes, radiators.

- Heating. They demonstrate the efficiency of heating rooms using the convection principle of operation.

- Designs with a hob, they are called heating and cooking.

- Fireplaces. Most often they are used for heating one room in which they are located.

- For the bath. They have an original design. The main task of the device is to increase the temperature of the stones, thereby heating the air in the steam room. An important indicator of decisions is intensity.

A simple DIY rocket stove design

A simple DIY rocket stove design Of course, these are not all the species that exist.

From a cylinder

This is a fairly popular option, which is successfully implemented by the hands of many craftsmen. Most often, a 50 liter gas cylinder is used for production. It will serve as a cap. To create a loading hopper and firebox, you can use a pipe with a diameter of 15 cm. A pipe with a diameter of 10 cm is used for the chimney, and 7 cm for the internal channel.

Using a rocket stove from a gas cylinder on the site

Using a rocket stove from a gas cylinder on the site It is necessary to cut the products to the required length, and cut off the upper part of the cylinder. Next, using the drawing, you should weld the parts together with your own hands. Fill the 7 and 15 cm gap between the pipes with heat-insulating material. You can use sand, but it is recommended to calcinate it to kill the organic environment. Otherwise, the heating process will be accompanied by an unpleasant odor.

When assembled, a rocket stove made from a gas cylinder weighs little, so it does not require a special base. The legs need to be welded to the device.

Made of brick

You can make a rocket stove out of brick with your own hands. In this case, you will have to work hard to get a high-quality design. The fire channels of the device are made using. You can use a barrel as a cap.

What a rocket oven made of brick might look like

What a rocket oven made of brick might look like To position the structure, it is recommended to dig a small hole, since it should be below floor level. The bottom needs to be compacted, after which a concrete base 10 cm thick is poured. When it hardens, you can begin laying. For this purpose, a solution is used, which includes refractory clay. When the structure is built, the solution has hardened, and the dug hole can be filled in. A barrel is placed on the channel, the bottom of which is cut out with your own hands. The space between the brick and it is filled with insulation.

The end of the device is coated with a solution, a large barrel is placed on top, and a chimney is welded to the bottom.

Let's sum it up

Note: A rocket stove is an original solution that you can build with your own hands. It is enough to choose the appropriate design option, take into account the recommendations and requirements. You must first make a drawing. If you can’t draw a diagram with your own hands, you can use ready-made options presented by experts.

In this matter, the main thing is not to rush, then the result will definitely comply with accepted standards and will become an effective tool for heating.

A detailed description of the manufacture of a rocket furnace from steel elements.

Features of the design and use of a simple rocket stove, which you can take with you on fishing or outdoor recreation.

Branded rocket stove. Description by a specialist.

Today, quite a lot of varieties and models of wood-burning stoves have been developed and implemented. In this series, the do-it-yourself rocket stove, the drawings of which will be presented below, fully meets all expectations. Such a heating structure certainly deserves close attention, as it has some specific advantages that are indispensable in certain conditions.

This version of a wood-burning stove is simple and original in design and does not require a large number of expensive components and materials for production. Probably anyone can install such a stove by making it on their own, even if they do not have experience in constructing such structures, but can read the provided drawings and work with some tools.

It is interesting to note that, if necessary, a rocket stove can be made even in 20–30 minutes, for example, from an iron can. However, if you make every effort, it is possible to get a comfortable stationary structure for your home with a heated couch that can even replace an ordinary sofa. At the same time, a rocket stove will not require complex arrangements, like bell-type or Russian stoves, which are massive structures.

Operating principle of the rocket stove

The rocket stove was originally conceived as one of the functional survival items in difficult conditions. Therefore, its design had to meet certain criteria:

- Efficient room heating.

- Possibility of cooking.

- High efficiency of the device when used for heating of various wood fuels of any quality.

- The ability to add fuel without stopping the combustion process.

- In addition, the stove had to retain heat for at least 6-7 hours to allow the owners to spend the night in comfortable conditions.

- Maximum safety of the design, in terms of eliminating the possibility of carbon monoxide leaking into the room.

- Another condition that had to be met was the simplicity and accessibility of the design for its manufacture by any non-professional.

Therefore, we took as a basis basic principles several types of heating devices using wood solid fuel:

- Free circulation of heated air and gases through all channels. The stove operates without forced air, and the draft is created by a chimney that draws out combustion products. The higher the pipe is raised, the more intense the draft.

- The principle of afterburning gases released during combustion from fuel (pyrolysis), which is used in long-burning devices. This operating principle is extremely important due to the high efficiency of the device, which is achieved by creating special conditions for the afterburning of pyrolysis gases for the most complete use of the energy potential contained in the fuel.

The term “pyrolysis” means the decomposition of solid fuel into volatile substances under the influence of high temperatures and simultaneous “oxygen starvation”. Under certain conditions, they are capable of burning, also releasing a large amount of thermal energy. It is important to know that the pyrolysis of insufficiently dried wood takes quite a long time in the gas phase, that is, the released pyrolysis gas will require a lot of heat to create a mixture (wood gas) that can burn completely. Therefore, it is not recommended to use wet fuel for a rocket stove.

Variety of rocket stoves - from simple to complex

The simplest design of a rocket stove

In a simple design of a rocket stove, heated by bunches of branches or splinters, combustion products are almost immediately sent into the chimney, without having time to form flammable wood gas in the stove body, so it will not be possible to heat the room with it. Such ovens can only be used for cooking. This model is manufactured in stationary and mobile versions; it only operates on the principle of free circulation of heated air, since the required conditions are not created in it for a full-fledged pyrolysis process.

In such furnaces, a small section of pipe is used as a fuel chamber. It can have a horizontal position, as shown in the diagram, or be turned upward. In the latter case, fuel is loaded vertically.

After igniting the fuel placed in the pipe, the heated gases released from it rush up the vertical section of the pipe to the outside.

Containers for cooking or heating water are installed on top of the vertical pipe. To ensure that gases escape freely and the bottom of the container does not completely block the draft in the pipe, a special metal stand is installed on top of the stove. She creates gap of the required size, which Helps maintain cravings.

On top is a very original stand for a container with heated water

By the way, this simplest type of stove device was the first to be invented, and because of the upward opening of the firebox and the flame escaping from it, the stove most likely received the name rocket. In addition, if the combustion mode is incorrect, the structure emits a whistling “rocket” hum, but if the stove is configured correctly, it rustles quietly.

Advanced Rocket Stove

Since it is impossible to heat the room using the simplest rocket stove with a free exit of gases, the design was later supplemented with a heat exchanger and smoke exhaust ducts.

After the improvements, the entire operating principle of the rocket stove has changed somewhat.

- To maintain the high temperature of heated air in a vertical pipe, it was insulated with fire-resistant material, and then covered on top with another metal casing made from a larger diameter pipe or a metal barrel with a closed top.

- A door was installed on the opening of the firebox, and a separate channel for secondary air appeared in the lower part of the furnace. Through it, blowing began to take place (necessary for afterburning pyrolysis gases), which previously occurred through an open firebox.

- In addition, the chimney pipe was moved to the lower part of the body, which forced the heated air to circulate throughout the body, going around all the internal channels, rather than going directly into the atmosphere.

- The combustion products, which have a high temperature, first began to rise to the ceiling of the outer casing, accumulate there and heat it, which made it possible to use the outer horizontal surface as a hob. Then, the flow of gases cools down and goes down, turns into an elbow and only from there goes into the chimney pipe.

- Thanks to the intake of secondary air, gases are burned at the end of the lower horizontal channel, which significantly increases the efficiency of the furnace. The free circulation of gases creates a self-regulating system that limits the flow of air into the combustion chamber, since it is supplied only as the hot gases cool under the “ceiling” of the housing.

A very popular scheme is made from a metal profile and an old gas cylinder

The stove model shown in the figure operates like a “stove stove” and has a chimney leading outside. However, it is unsuitable for use in residential premises, since, due to changes in external pressure, reverse draft may occur, which will contribute to the entry of carbon monoxide into the room. Therefore, such a stove should always be supervised, and it is most often used for heating utility rooms or a garage.

Rocket stove with a warm bed

A rocket stove with a stove bench is also constructed on the principle of afterburning pyrolysis gases, but in this version the heat exchanger is a structure of combined long channels coming from the stove and laid or formed from non-flammable plastic materials under the surface of the stove bench.

It should be noted that such a heating system is by no means new, and, in fact, such a rocket stove has a fairly rich history. It was invented a long time ago, presumably in Manchuria, called “kan”, and is still traditional for peasant houses in China and Korea.

Similar stoves called “kan” have long been used to heat homes in East Asia.

The system is a wide bed made of stone, brick and clay, inside which The air heated in the stove passes through the arranged channels, which are essentially an elongated chimney. Passing through this labyrinth and gradually giving off heat, the gas flow, cooling, exits into a chimney with a height of 3000 ÷ 3500 mm, located on the street, next to the house.

The stove itself is located at one end of the stove bench and, as a rule, is equipped with a hob, which allows it to be used for cooking.

The top of the stone-clay “kan” structure is covered with straw or bamboo mats, or a wooden flooring is placed there. At night, the couches were used as beds, and during the day - in the form of a seat, on which, traditionally for Asian peoples, a special low table 300 mm high was installed - meals were taken behind it.

This heating system is quite economical in terms of fuel consumption, since to heat it it is enough to use a medium-thick branch. This rocket stove can retain heat for a long time, creating comfortable conditions for sleeping throughout the night.

And Korean “ondol” stoves probably became the prototypes of modern “warm floors”

Korean homes use a heating system similar to “kan”, which is called “ondol”. This heating option, unlike the Chinese one, is installed not inside the couch, but under the entire floor of the house. In principle, it can be argued that this method of transferring and distributing heat into living spaces seems to form the basis for the design of the modern “warm floor” system.

Furnace design with connected the pipes to it can be clearly seen in the diagram presented.

Nowadays, with the modern rich variety of materials, the channels in this furnace design can be made of metal pipes laid in the form of a coil and well insulated with non-flammable materials. Therefore, the last section of the chimney system can exit from the structure of the stove next to the stove itself or at the end of the stove, and then go through the wall into a chimney installed on the street.

In the presented diagram you can see the results of the design work, which made it possible to achieve a relative simplicity of the scheme, which has high efficiency, and also meets all the requirements for a speech rocket.

Fuel is loaded vertically into the combustion hole. Then it is set on fire, and, burning out, gradually settles down. The air that supports combustion enters the bottom of the combustion chamber through an opening that acts as a blower. It must provide sufficient air flow for afterburning of the released products of thermal decomposition of wood. But, at the same time, there should not be too much air, since it can cool the initially released gases, and in this case, the process of afterburning the pyrolysis gases will not be able to take place, and the combustion products will settle on the walls of the housing.

In this version, the vertical loading furnace has the chamber has a blind cover, which will eliminate the risk of gases entering the room when creating reverse draft.

In a completely isolated volume of released gas, thermal energy is generated, temperature and pressure rise, and thrust increases. As the fuel burns, the burning gases escape through the channels of the furnace body into the heat exchanger, heating the internal surfaces along the way. Since the channels have a complex configuration, gases are retained inside the furnace for a longer time, giving off heat to the body and surfaces of the channels, which, in turn, they heat the surface of the couch and, accordingly, the room itself.

Over time, any furnace and its ducts require cleaning of soot deposits. In this design, the problem area is the heat exchanger pipes located inside the bench. In order to carry out these preventive measures without problems, a hermetically sealed cleaning door is installed at the level of the heat exchanger turning from the furnace body into the pipes under the stove bench (indicated “Secondary Airtight Ash Pit” in the diagram). It is in this place that all unburnt products of thermal decomposition of wood concentrate and settle. The door is periodically opened and the passages are cleared of soot - this process guarantees long-term operation of the chimney. In order for the door to close tightly, asbestos gaskets must be secured to its inner edges.

How to properly heat a rocket stove?

To get the maximum heating effect, it is recommended to preheat the stove before adding the bulk of the fuel. This process is carried out using paper, dry shavings or sawdust, which are set on fire in the firebox. When the system warms up, it will change the sound it makes - it may fade out or change its tone. The main fuel is placed into the heated unit, which will ignite from the heat already created by heating.

Any firewood and even thin branches are suitable for the rocket stove, but the main thing is that they be dry.

Until the fuel burns well, the combustion chamber or ash door must be kept open . But only when the fire becomes intense and the stove begins to hum, the door is closed. Then, during the combustion process, the access of air from the ashpit is gradually blocked - here you need to focus on the tonality of the sound of the stove. If the air damper accidentally closes and the intensity of the flame decreases, it must be opened slightly again and the stove will flare up with renewed vigor.

Advantages and disadvantages of the rocket stove

Before moving on to a description of the manufacturing process of a rocket stove, it is advisable to summarize information about its advantages and disadvantages.

Rocket stoves are quite popular due to their positive qualities , which include:

- Simplicity of design and small amount of materials.

- Even a novice master can make any of the furnace designs, if desired.

- The construction of a rocket stove does not require the purchase of expensive building materials.

- Undemanding requirement for forced chimney draft, self-regulation of stove operation.

- High efficiency rocket furnace with a pyrolysis gas afterburning system.

- Possibility of adding fuel while firing the stove.

Despite the large number of advantages of this design, its operation also has a number of shortcomings :

- When using the simplest design of a rocket stove, you can use only dry branches and splinters, since excess moisture can cause backdraft. In a more complex device system, the use of damp wood is also not recommended, because it will not provide the required temperature for pyrolysis to occur.

- The rocket stove cannot be left unattended during combustion, as this is very unsafe.

- This type of device is unsuitable for heating a bathhouse, since it does not give off enough heat in the infrared range, which is especially important for a steam room. A rocket stove with a stove bench can only be suitable for the recreation room of a sauna building.

Video: special opinion on rocket stoves

Making a rocket stove with a stove bench

Rocket stoves can have different sizes, and a variety of materials are used for their manufacture - these are metal pipes, barrels and gas cylinders, bricks and clay. A combined option consisting of pipes, stones, clay and sand is also quite acceptable. It is he who deserves special attention.

From a gas cylinder you can make a stove that is simple in design, including using it for a version with a stove bench.

How to make a simple stove itself is more or less clear from the drawings presented above and the description of its operation, so it is worth considering the manufacture of a heating unit, specifically equipped with a stove bench.

Video: homemade rocket stove from a gas cylinder

You might be interested in information on how to make with step by step instructions

To make it completely clear what and where is located in the design of the rocket furnace, this diagram will be used to describe the work.

So, the rocket stove in question consists of the following elements:

- 1a– a blower with an air supply regulator, with the help of which the oven is adjusted to the desired mode;

- 1b– fuel chamber (hopper) with a blind lid;

- 1c– a channel for supplying secondary air, ensuring complete combustion of pyrolysis gases released by wood;

- 1g– flame tube 150÷200 mm long;

- 1d– primary chimney (riser), with a diameter of 70÷100 mm.

The flame tube should not be made too long or short. If this element is too long, then the secondary air in it will quickly cool down and the process of afterburning the pyrolysis gases will not reach completion.

The entire structure of the flame pipe and riser must be thermally insulated as efficiently as possible. The task of this unit is to ensure complete combustion of pyrolysis gases and supply hot masses from the riser to other channels, which will already transfer heat to the room and to the bench.

It should be noted here that in order to obtain optimal efficiency from the furnace, the diameter R The azer should be made with a size of 70 mm, and if the goal is to achieve maximum furnace power, then it should be made with a diameter of 100 mm. In this case, the length of the flame tube should be 150÷200 mm. Further, when describing the installation of the furnace, dimensions will be given for both cases.

It is impossible to immediately pass heated air from the riser into the heat accumulator, since its temperature reaches 900÷1000 degrees. High-quality heat-resistant heat-accumulating materials have a fairly high price, therefore, most often, adobe (clay mixed with chopped straw) is used for these purposes. This material has a high heat capacity potential, but is not heat resistant, so the design of the secondary furnace (cylinder body) begins with an air temperature converter, which must be heated to only 300 degrees. Part of the generated heat is immediately released into the room and replenishes current heat loss.

The described functions are performed by the furnace body, made from a standard 50 liter gas cylinder.

- 2a– furnace body cover. Heated air enters under it from the riser;

- 2b– a cooking surface that is heated from the inside by heated gases escaping from the riser;

- 2v– metal insulation of the riser (shell);

- 2g– heat exchange channels. Heated gas enters them, diverging under the ceiling of the housing;

- 2d– lower metal part of the body;

- 2e– exit from the housing to the cleaning chamber.

The main task when arranging these parts of the furnace is to ensure complete tightness of the smoke exhaust line.

In the housing (drum), at a height of ⅓ from its “ceiling”, the gases cool down and already have a normal temperature for their entry into the storage tank. From approximately this height to the floor of the room, the oven thermally insulated several layers of different compositions - this process is called lining.

- 3a– the second cleaning chamber, through which the heat exchanger (“hog”) located under the stove bench is cleaned of carbon deposits;

- 3b– sealed door of the second cleaning chamber;

- 4 - “hog”, a long horizontal section of the chimney located under the stove bench.

Having passed through the “hog” pipes and almost completely transferred the heat to the adobe bench, the gases escape through the main chimney channel into the atmosphere.

Having understood the structure of the rocket furnace in detail, you can proceed to its construction.

Construction of a rocket stove with a stove bench - step by step

First of all, you need to prepare lining compounds. Their components will cost very little, since they can often be found completely free, literally right under your feet:

- 5a– adobe. As mentioned above, this is clay mixed with chopped straw and mixed with water until the masonry mortar becomes thick. Any clay for making adobe is suitable, since it will not be influenced by external atmospheric influences;

- 5 B– oven clay mixed with crushed stone. This will be the main heat insulator. The mortar should have the consistency of a bricklaying mixture;

- 5v– heat-resistant lining made of oven clay and fireclay sand in proportions 1:1 and having the consistency of plasticine;

- 5g– ordinary sifted sand;

- 5d – medium-fat clay for stove masonry.

Step-by-step work on the design is carried out in the following sequence:

Bed for the couch

Having prepared all the necessary compositions, a bed is made - a durable wooden shield of the required configuration. Its frame is made of timber with a cross-section of 100×100 mm. Frame - with cells measuring 600x900 mm under the stove and 600x1200 mm under the stove bench. If a curvilinear shape of the bed is planned, then it is brought to the desired configuration with the help of boards and scraps of timber.

The bed is a frame base for the further construction of the furnace structure

The frame is sheathed with a tongue and groove board 40 mm thick - it is fixed across the long sides of the frame. Later, after the installation of the stove is completed, the side façade of the bed will be covered with plasterboard. All parts of the wooden bed structure must be impregnated with biocide and then painted twice with a water-based emulsion.

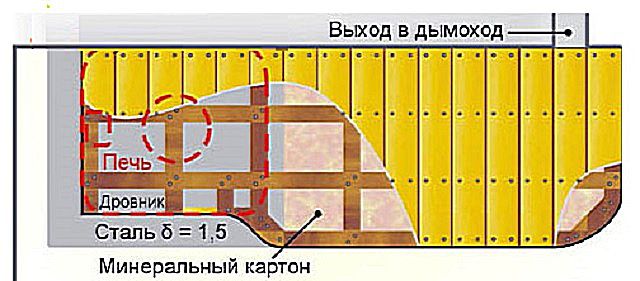

Next, on the floor, in the place of the room where the stove will be installed, mineral cardboard (cardboard made of basalt fibers) 4 mm thick, the size and shape completely corresponding to the parameters of the bed, is laid. Directly under the stove, a sheet of roofing iron is fixed on top of the cardboard, which will extend 200–300 mm from under the stove in front of the firebox.

Then, the bed is transferred and firmly installed on the selected and covered location oven, so that the frame stands stable, without play. At the end of the future bed, at a height of 120–140 mm above the bed level, a hole for the chimney is made in the wall.

Formwork and pouring the first level of adobe mixture

A durable formwork is installed along the entire contour of the bed, having a height (A -40÷50 mm) and a smooth upper edge.

The adobe mixture (5a) is poured into the formwork and its surface is leveled using the rule. The sides of the formwork serve as beacons for leveling.

Manufacturing of the furnace body

- While the adobe filling dries, and this process will take 2-3 weeks, you can start making the stove body from a cylinder. It should be noted that a rocket stove is made from a barrel in exactly the same way.

Cutting a gas cylinder and making a lid with a “skirt”

- The first step is to cut off the top of the empty cylinder to obtain a hole with a diameter of 200÷220 mm. Next, this hole is closed with a pre-prepared steel round timber 4 mm thick - this surface will play the role of a hob. After this, another cut is made 50÷60 mm below the hob to form a lid.

- It is welded along the outer perimeter of the resulting cover, so-called“skirt” made of thin sheet steel. The width of the skirt should be 50÷60 mm, the seam of this strip is welded. If you have no experience in welding, then it is better to entrust this process to a professional.

- After this, along the entire circumference of the skirt, stepping back from the bottom edge of 20÷25 mm, holes are evenly drilled into which the bolts will be screwed.

- Next, the lower empty part of the cylinder is cut off at a height of approximately 70 mm from the bottom. Then, a hole is cut in the bottom of the cylinder to allow the riser to enter the body.

- After this, it is necessary to attach a well-woven asbestos cord to the inner edge of the lid using Moment glue, and then immediately put it on the body of the cylinder and press it on top with a load of 2.5–3 kg. The cord will serve as a sealing gasket. Next, through the holes in the metal “skirt”, through holes are drilled in the cylinder body, in which threads are cut for the bolts.

- After this, you need to measure the depth of the case, since it is necessary to determine the height of the riser.

- Then the cap is removed from the cylinder to protect the gasket from being completely saturated with glue, otherwise the asbestos will lose its elasticity.

Manufacturing of the furnace combustion part

The next step is to make the following elements from a square pipe (or channel) with a cross-section of 150×150 mm: 1a - blower, 1b - combustion chamber; 1g - heat channel.

The riser (1d) is made from a round pipe with a diameter of 70÷100 mm.

The angle of insertion of the combustion chamber (hopper) into the blower and flame pipe can vary within 45÷60 degrees from the horizontal. Its upper edge is placed flush with the blower element protruding forward, as shown in the diagram.

At the bottom of the blower and flame pipes, you need to separate the secondary air channel (1c). It is separated by a metal plate 3÷4 mm thick. Its rear edge should end exactly at the level of the front wall of the riser, and the front edge should extend forward of the blower by 25÷30 mm. The plate is pinched in four places by welding inside the pipe.

Then, at the end of the flame tube, a hole is cut out from above, into which the riser is welded at a right angle, and the end of this channel is closed with a metal square, also secured by welding.

Must be installed on the blower door - latch, which will help regulate the air supply. The combustion chamber lid is made of galvanized metal. The bunker does not require a hermetically sealed closure - the main thing is that the lid fits tightly to the inlet.

After this, the finished structure is coated with a 5B solution. A continuous lining is made only at the bottom, and the sides and top of the blower are left free of lining. To make the coating mixture dry faster, the structure is placed on the pole with a blower chamber. It is necessary to ensure that the mixture does not slide off the surfaces or disgrace, since the lining plays a big role in retaining heat. If this happens, then the coating must be done again, using thicker clay.

Insulation for rocket stove

After the adobe layer has dried, formwork is installed to provide heat-resistant thermal insulation for the furnace. It is done only under the location of the stove. The height of the formwork together with the adobe layer will be 100÷110 mm.

The installed formwork is filled with composition 5b and leveled along the beacons, which will serve as the sides of the formwork. In the main diagram, this layer is designated by the letter B.

Manufacturing of the drum bottom and shell

The shell is made of a round pipe with a diameter of 150÷200 mm or it is rolled up from a steel sheet.

The bottom round timber, which will be placed inside the drum, is cut from sheet metal 1.5÷2 mm thick, and a round hole is cut in the middle of it. The diameter of the circle of this element should be 4 mm less than the internal size of the cylinder, and the diameter of the middle cutout for the shell should be 3 mm larger than its outer diameter.

Installation of the combustion structure

After the thermal insulation layer has dried in the formwork, the combustion structure is mounted on it. It is installed by controlling the level vertically and horizontally, and then fixed to the heat-insulating layer using pegs. Then, formwork with a height of 350÷370 mm from the floor is installed around the furnace. Here you need to take into account that the cleaning chamber (3a) and its door (3b) must be installed next to the frozen mixture (5b) with which the formwork will be filled. The connection (2e) of the cleaning chamber with the heat exchange channel (2d) will pass over the lining composition poured into the formwork. The mixture is also leveled to perfection, level with formwork, using rules.

Cleaning chamber

While the mixture dries in the formwork, you can start making a cleaning chamber with a door and a transition to the heat exchanger. It is made of galvanized steel, 1.5÷2 mm thick, and its front part is made of metal 4÷6 mm thick. A hole with a diameter of 150÷180 mm is cut in the side of the cleaning chamber to install the end of the chimney pipe, which will pass under the bed.

The cleaning chamber door is made with dimensions of 160×160 mm, also from steel 4÷6 mm. Before installing it, a sealing gasket made of mineral cardboard is installed around the perimeter of the inner surface. The door itself is screwed to the camera box with fastening bolts, for which threads are cut in the drilled holes.

This diagram shows the dimensions of all elements and the location of installation and connection of the chamber with the drum (cylinder). Next, after trying on the elements, a window 70 mm in size is cut out in the lower part of the furnace drum, into which the connecting channel (2e) will be mounted by welding.

The corrugated pipes under the bed can be located arbitrarily, depending on the configuration of the bed; it is only important to adhere to the dimensions indicated on the drawing for the manufacture of the cleaning chamber, indicated under the letters A, B and C. How to correctly attach the “hog” pipe will be discussed below.

Drum installation

When the solution in the formwork dries, it is removed. A combustion system drum made from a gas cylinder is placed on the riser, on top of the hardened thermal insulation. The drum is currently installed without a cover - its installation is shown in the diagram presented.

Solution 5b is laid out on the bottom of the installed drum, and with the help of a spatula, an inclined surface of 6-8 degrees is formed from it, towards the outlet window of the cleaning chamber. Then, a round piece of metal sheet is put on the riser and lowered to the bottom of the drum and pressed against the laid mortar. The solution is removed from the middle hole around the riser, otherwise it will be impossible to install the shell pipe. After this, the pipe itself is put on the riser into the freed space and lightly screwed into the solution. All gaps formed along the external and internal contours are coated with clay (5d).

Lining the fuel structure from the inside

After installing the shell and hearth, there is no need to wait for the thermal insulation solution to dry; you can immediately proceed to lining the riser. The composition (5 g) is poured into the shell, around the riser, in 6–7 layers. Each layer must be compacted as much as possible, while wetting the dry mixture with water from a spray bottle. From above, this space filled with sand is covered with a clay layer (cork) 50÷60 mm thick, using a 5d solution.

Installation of the cleaning chamber

After installing the drum, you need to install a cleaning chamber. Installing the box is not difficult - to do this, a layer of 5d solution, which has a thickness of 3÷4 mm, is applied to the transition channel and the hole in the drum, as well as to the side and bottom of the box. The box is installed in place, and the window of the transition channel (2e) is inserted into the prepared hole of the drum and pressed well and pressed down. The solution that appears on the sides is immediately smeared. The entrance of the cleaning chamber to the drum must be well sealed, therefore, if there are gaps left, they must be sealed well.

Laying the thermal insulation layer

Formwork for level D

Next, formwork is installed along the outer contour of the bed, just as in the manufacture of level A. The height of this level D must be determined, focusing on the hole for connecting the “hog”. Above the upper edge of the hole, the level should be raised by approximately 80÷100 mm.

Filling the formwork

The next step is to fill the formwork with adobe solution (5a) to the lower edge of the hole prepared for installing a “hog” in the cleaning chamber On the one side, and at the end of the bench - to the lower edge of the outlet for the chimney.

The mixture is laid out and leveled manually, while ensuring that the mixture adheres as closely as possible to the previous layer. Thus, from the cleaning chamber to the chimney outlet a rise is formed for “hog” pipes, the height difference of which should be 15÷30 mm. This design is necessary to ensure that the bed warms up evenly.

You might be interested in information on how to choose

Corrugated pipe installation

The next step is to stretch the corrugated pipe over the entire length of the bed. One end of it is connected to the cleaning chamber, inserted into the hole to a depth of 20÷25 mm and flaring inside the chamber with a flathead screwdriver through the cleaning door. Then the entrance of the pipe to the ash pan is coated with 5d solution, and the beginning of the pipe 150÷200 mm is coated with adobe. This will secure the pipe well in the desired position and prevent it from slipping out of the hole during further work.

After this, the pipe in the formwork is laid in the form of a coil, but it should always be at a distance of about 100 mm from the edges of the formwork and the wall. During the installation process, the pipe is pressed into the adobe layer laid underneath. Having laid the pipe along its entire length, its second end is fixed with clay mortar into the chimney outlet.

After this, the entire “hog” is covered with adobe mortar, which must be compacted well, especially between the bends of the pipe, so that no voids form in it. After the space is filled with adobe mass flush with the top of the corrugated pipe, a more liquid adobe solution is poured into the formwork, and at the end the surface is smoothed using a rule that is carried out along the walls of the formwork, which act as beacons.

You might be interested in information about what wood burning is like

Installing covers

After this, the covers of the cleaning chamber and drum are secured with bolts. They need to be tightened tightly so that they press the gaskets installed inside.

Furnace drum coating

Next, the furnace drum is coated with adobe ⅔, from the bottom of the body. The upper part of the drum is left free from the adobe layer. Thermal insulation is applied with a thickness of at least 100÷120 mm, and the coating configuration is chosen by the master himself.

Furnace finishing

After two or two and a half weeks, the adobe layer should dry out and the installed formwork can be removed. Then, if necessary, the right corners of the structure are rounded. In addition, the drum is covered with heat-resistant enamel that can withstand temperatures up to 450÷750 degrees. The adobe surface of the couch is coated with acrylic varnish in two layers, each of which must dry well. The varnish will hold the surface material together, preventing it from collecting dust, protect the adobe from moisture and give the aesthetics of glazed clay.

If desired, a wooden flooring made of thin boards can be laid on the surface of the bed - it is often made removable. The side parts of the bed are sometimes finished with plasterboard or covered with stone. Decorative finishing is carried out to the taste of the home owner.

You may be interested in information about how to build

Carrying out a furnace test

A dry oven must be tested. To do this, you should warm up the structure by placing light fuel in the form of paper in the ash pan and replenishing it during the combustion process. When you feel warmth on the surface of the stove, you can add the main fuel to the combustion chamber. When the stove begins to hum, the vent closes until the sound changes to a “whisper.”

In conclusion, it must be said that the rocket stove can also be made of brick or stone - it all depends on the financial capabilities and creative abilities of the master. The main thing that can attract you in this design is the opportunity to improvise and create, using different materials for construction and decoration. Therefore, those who dream of installing a stove with a heated bench in their home should take a closer look at this option.

Prices for ready-made rocket stoves

oven rocket

Video: example of building a rocket stove with a warm bed

Evgeniy AfanasyevChief Editor

Author of the publication 18.01.2016

Some sources claim that the rocket stove got its name due to the special sound it makes during use. Let's make a reservation right away - a strong hum is heard only during kindling, and then, a properly built stove should not hum. The sound that you can hear from a well-built structure will be more reminiscent of a rustle, a whisper, but nothing like the sound of a rocket taking off.

The efficiency of the furnace is increased due to the design features, which allow the use of not only the thermal energy obtained as a result of fuel combustion, but also the additional part of the heat generated during the afterburning of pyrolysis gas.

Attention! This gas is formed during the combustion of wood. Its ignition is possible only at a sufficient temperature level. With a large supply of oxygen or in an unheated furnace, such gases cool, do not ignite and evaporate freely.

Of course, the rocket stove is easy to manufacture, easy to use, practical, and not demanding on the quality of wood fuel. However, its operation depends on the correctness of the calculations and the accuracy of the manufacturing of the entire structure.

The general diagram of the furnace structure is as follows:

- Despite the simplicity of the design, an ultra-efficient long-burning rocket stove requires precise adherence to the proportions of its parts:

- The diameter of the chimney is not less than the diameter of the fuel bunker;

- The length of the horizontal compartment of the combustion zone is no more than half of the vertical expanding section;

- The height of the fuel bunker is equal to the length of the horizontal section;

- The length of the chimney is 6-10 times greater than the height of the vertical secondary combustion chamber.

- Thermal insulating adobe coating of the stove bench is at least 2/3 of the height, at least 15 cm above the chimney pipe.

Principle of operation

Fuel is loaded into a vertical bunker. With the correct design of the rocket furnace, the fuel burns only in the lower part, gradually settling under its own weight. Combustion in the primary combustion chamber is supported by suitable oxygen penetrating with the air flow through the ash pan. Then the fuel gases move freely into the afterburning zone, ignite as a result of the pyrolysis reaction, and heat the secondary combustion chamber and the hood. Due to the temperature difference in the primary combustion chambers and the vertical hood, draft is created, and hot air passes into the chimney channel. The exhaust system for combustion products consists of an internal part (heating the home) and an external part (removing smoke and gas from the room to the outside).

During operation, the fuel burns almost 100%, leaving only water and carbon dioxide at the exit. The long chimney provides almost complete cooling, so water can flow from the pipe. And as a result, a high pipe is not required; most often it is removed simply by continuing the horizontal section through the wall.

A rocket stove can be used simultaneously as a means of cooking and heating a small room. Design features allow the surface of the hood to be heated up to 400°C; this section of the stove is used as a cooking surface, and the long chimney most often turns into a lounger that can give off heat for up to 12 hours after heating. The effect of a heat accumulator increases with properly lining (coating) of the chimney body.

This is interesting! The principle of a jet stove without a heat-storing casing is used in small, portable camping structures. This type of stove uses only the energy generated by direct combustion. In this case, the amount of fuel burned increases, and the efficiency of the stove decreases significantly, but it is quite enough for cooking and heating the tent.

DIY rocket stove

When making a rocket stove with your own hands, you will need the following materials:

- For a large-volume furnace - barrels of fuels and lubricants with a volume of 200 liters and a diameter of 600 mm. For the outer body of a medium-sized oven, gas cylinders with a diameter of 300 mm are used (it is also possible to use tin buckets, 400-450 mm);

- For the fire duct of a furnace based on a barrel of fuel and lubricants, a 135 mm steel round or profile pipe (120x120 mm) is prepared. For a furnace with an outer casing made of a gas cylinder, round pipes of 70 mm or profile pipes of 70 and 150 mm are used;

- The entire structure is made of tin or thin sheet steel 2-3 mm thick. (Thinner sheet metal can only be used for chimney installations).

- Thermal insulating gaskets made of mineral cardboard;

- For the chimney - corrugated pipe. The diameter of the pipe should be one and a half times the diameter of the fire pipeline;

- Fireproof brick, fireclay scrap, clay, sand. Straw (for adobe);

- Fittings for the stove (doors of the firebox and ash pan). A mandatory requirement is integrity and tightness, which is ensured by gaskets made of mineral cardboard.

Advantages and disadvantages

The main advantage - ease of installation - has already been mentioned by us, however, this type of stove has gained popularity due to an additional number of features.

- Firewood and wood of any quality and condition can be used as fuel. Of course, the combustion reaction of the pyrolysis gases of raw wood will require a high temperature, but even in this case, as a result of the primary combustion of fuel, thermal energy will be released, which is sufficient for boiling water and cooking;

- Despite the simplicity of the design, the thermal output of which a rocket oven made from a barrel of fuel and lubricants is capable can reach 18 kW. These parameters are enough to heat a room up to 20 m². A small stove (based on a gas cylinder), subject to all installation and installation rules, can have a power of up to 10 kW.

- A well-heated jet stove can retain heat for a long time, for half a day (up to 12 hours) without requiring additional flooding.

However, some disadvantages of structures of this type cannot be mentioned:

- Some types of rocket stoves cannot be used to heat water and then feed it into radiators or into the hot water supply system, because. in principle, the connection of additional heat exchangers (coils) breaks the tightness of the internal bunker, or reduces its thermal insulation characteristics, which makes it impossible to use the technology of afterburning pyrolysis gases;

- General adjustment of the stove operation is possible only by reducing or increasing the amount of firewood. The blower, which regulates the air flow, is used only for primary ignition.

- The rocket stove is not a fast-acting design. (On the contrary, it requires quite a long preparatory time for kindling and heating its own body and takes just as long to cool down). Therefore, such a design cannot be used in garages and bathhouses.

Video

Imagine the situation: to heat a room at home or cook food, you need to quickly build a simple wood-burning stove. Fuel quality and consumption are secondary. A suitable option is a homemade rocket stove made from scrap materials. We invite you to familiarize yourself with the design of the heater and the assembly process at home.

Design and principle of operation

The rocket stove shown in the diagram consists of the following main elements:

- a bunker for storing firewood of a vertical or inclined design;

- horizontal combustion chamber;

- pipe with lining - afterburner (the second common name is riser);

- a metal cap that plays the role of an air heat exchanger;

- blower;

- chimney channel.

In operation, the stove uses 2 principles: the occurrence of natural draft inside the vertical section and the combustion of wood (pyrolysis) gases. The first is realized due to the heating of the firebox and waste combustion products tending to rise through the afterburner channel. The released pyrolysis gases burn out in it.

Reference. The name rocket or jet stove is associated precisely with the principle of operation - a powerful natural draft arises in the vertical channel, causing intense combustion in the firebox and the release of heat.

The stove operation algorithm is as follows:

- Firewood loaded into the bunker is ignited from below. The air supply is provided through the blower hatch.

- During the combustion process, flue gases heat the insulated walls of the afterburner and rush under a thin metal hood, where they give off most of the heat to the room air.

- With a sufficient amount of secondary air, pyrolysis gases have time to burn inside the riser, releasing additional heat.

- Combustion products are discharged directly into the chimney or first sent into the smoke circulation of the stove bench.

Options for portable stoves "Robinson"

In a simplified camping version, the stove is made without a hood and insulation. Accordingly, secondary gases do not burn completely, since they have time to fly out into the chimney. A small-sized portable heater, called “Robinson”, is designed for quick cooking using fuel of any quality and degree of humidity.

Requirements for element sizes

The main heat exchange element of the rocket stove is a metal cap; the intensity of heating a room in the house depends on its size. In stationary structures made of brick, a 200-liter barrel with a diameter of 60 cm is usually used. Portable versions are made from standard gas cylinders Ø300 mm.

Diagram of a rocket heater with a stove bench

Accordingly, the remaining dimensions depend on the dimensions of the barrel - diameter and cross-sectional area:

- the height of the cap is provided to be 1.5-2 times the diameter;

- the cross-sectional area of the afterburner is 5-6.5% of the diameter of the barrel;

- the length of the riser is made such that there is a minimum gap of 7 cm between the upper cut of the pipe and the cover;

- the internal size of the firebox is equal to the cross-section of the afterburner, the ash duct is half as large;

- chimney diameter is 1.5-2 times larger than the afterburner cross-section, height is at least 4 m.

To make it easier for you to calculate the diameters of pipes and linings, we present a drawing for various versions of rocket furnaces - from a cylinder, a barrel and old buckets (the riser is made of a round or profile pipe).

We make a stove - a rocket

The easiest way to make a light camp stove, shown in the drawing, is to find the following materials in the household:

- round steel pipe with a diameter of 133-150 mm and a length of 0.5 m;

- profile pipe 14 x 20 cm, length 0.4 m;

- sheet of metal 2-3 mm thick for grates;

- rod Ø8-10 mm for legs;

- scraps of iron for the stand.

A vertical round pipe is welded to the profile at an angle of 45°, then eyes for the legs are attached to the body (they should be easily removed). A grate is placed inside the inclined firebox, and a lid is attached to the outside. To make it easier to clean the ash below, it is advisable to install a second door.

Advice. Be sure to weld a stand to the upper edge of the fire channel - gases must penetrate between the bottom of the dish and the body, otherwise “rocket” thrust will not occur.

Drawing of an improved version of the portable stove

The design of the furnace can be improved by organizing the supply of secondary air inside the flame tube. Modernization will increase the efficiency and duration of firewood burning. Drill holes on both sides on both sides, covering them with rocket “nozzles” according to the presented drawing. How this stove functions is demonstrated in the video:

From a gas cylinder

The following materials will be used to make a do-it-yourself rocket stove:

- round pipes with transverse dimensions of 70 and 150 mm; with a wall thickness of 4 mm;

- square corrugated pipe 150-200 mm in diameter;

- chimney pipe Ø10-15 cm;

- low-carbon steel (grade St20) sheet;

- dense basalt wool (80-120 kg/m3) or bulk fire-resistant materials, for example, vermiculite or perlite gravel.

To begin, cut the rolled metal into blanks in accordance with the drawing. Then you need to saw off the lid of the propane tank, after unscrewing the valve and filling the tank to the top with water. The tool is an ordinary grinder with a metal circle.

Further assembly technology is as follows:

The master will tell you in detail about the manufacture of a rocket stove from a cylinder in the video:

Made of brick

The simplest rocket stove for cooking can be built from bricks without using mortar, as shown in the diagram with the order. Such a structure can be easily disassembled and moved if necessary.

The rocket stove with a stove bench must be placed on a foundation made of concrete or rubble stone. Material – ceramic or refractory brick, sand-clay or fireclay mortar, respectively. The finished base is covered with roofing felt for the purpose of waterproofing, then a continuous first row of bricks is laid. The further work order looks like this:

Important. The construction is carried out in compliance with the rules of stove masonry, described.

The length of the smoke channels inside the stove is limited by the draft in the rocket stove and the external chimney. It is better to keep the total length of the flue pipes within 4 m. To prevent the heater from smoking back into the room, raise the top of the chimney to a height of 5 m, counting from the grate. How to build a brick stove - a rocket without a barrel, watch the video:

In conclusion - the pros and cons of the stove

Such structures are indeed made quickly, and the contractor does not necessarily have to be highly qualified. The first and main advantage of rocket-type furnaces is their simplicity and undemanding use of materials. In addition, they accept a variety of fuels well - raw firewood, branches, brushwood, and so on.

Now about the negative points:

For the above reasons, a rocket heater is extremely inconvenient for a garage, where it is necessary to heat the room quite quickly. But the hiking option is indispensable in nature at any time of the year.

Design engineer with more than 8 years of experience in construction.

Graduated from the East Ukrainian National University. Vladimir Dal with a degree in Electronics Industry Equipment in 2011.

Related posts:

Dear visitors to the “” site, today we will look at detailed instructions for independently assembling a camping rocket stove with your own hands without the use of welding. The jet stove appeared relatively recently and was invented abroad, but in a short period of time it gained people’s love and respect in our Country, especially among tourists, fishermen and hunters, and of course, this stove is distinguished by its efficiency in the consumption of firewood and the output of the maximum amount of heat due to the jet thrust created by the design of the furnace itself. With its help, you can quickly cook food or boil a kettle, which is very important during a hike.

The design of a jet stove is very simple - it is a vertically located pipe (also known as a body and a chimney) and a firebox adjacent at an angle, divided inside by a plate into two parts (top for loading firewood, bottom for air access to the combustion center), thus creating jet draft, from here and a great name « «.

The presented stove is made with compactness in mind, since every gram of cargo and space in a backpack is very important on a hike. To make it, a used helium cylinder was taken (you can use a fire extinguisher), its upper part was sawed off, and a technological hole was sawn on the side for installing the firebox, the design is completely dismountable and all the parts are located inside the body in the stowed position. We remind you that during its manufacture a welding machine is not needed, which simplifies the creation process to the maximum.

Let's look at all the stages of assembling a jet stove.

Materials

- helium cylinder or used fire extinguisher

- square pipe

- metal perforated plate

- bolts and nuts

- metal sheet 1-2 mm

Tools

- grinder (angle grinder)

- drill

- pliers

- can of heat-resistant paint

Step-by-step instructions for creating a traveling rocket stove.

First, let's look at the drawing of the domestic Robinson stove. It is also an excellent design, but welded, and the one presented below is much universal and is rightfully considered a camp stove.

The first thing you need to do is find a used helium cylinder or an old fire extinguisher, bleed out the remaining contents, unscrew the valve and rinse with water, then cut off the upper part, and also make a technological hole in the lower part for installing a firebox from a square pipe.

The first thing you need to do is find a used helium cylinder or an old fire extinguisher, bleed out the remaining contents, unscrew the valve and rinse with water, then cut off the upper part, and also make a technological hole in the lower part for installing a firebox from a square pipe.

We make a grate from a perforated plate.

We make a grate from a perforated plate.  Support legs for the firebox.

Support legs for the firebox.  We collect all the details into a single whole.

We collect all the details into a single whole.

A pointed metal pin is screwed into the lower part; it is necessary so that when installing the stove in the working position, it stands firmly on the ground, and this stake is buried in the ground. In the stowed position it unscrews.

A pointed metal pin is screwed into the lower part; it is necessary so that when installing the stove in the working position, it stands firmly on the ground, and this stake is buried in the ground. In the stowed position it unscrews.  We cut out a burner from 1-2 mm sheet metal.

We cut out a burner from 1-2 mm sheet metal.

By the way, here is the pin in the stowed position.

By the way, here is the pin in the stowed position.  Also, in addition to the components from the stove, you can put a small supply of dry firewood in the cylinder, which can be very helpful in damp and rainy weather. Just imagine.. you went on a hike and you were caught in heavy rain, everything around you was wet, damp and disgusting, and you calmly take out your camping rocket stove and light a fire, cook food, boil the kettle and everything is fine with you 😉

Also, in addition to the components from the stove, you can put a small supply of dry firewood in the cylinder, which can be very helpful in damp and rainy weather. Just imagine.. you went on a hike and you were caught in heavy rain, everything around you was wet, damp and disgusting, and you calmly take out your camping rocket stove and light a fire, cook food, boil the kettle and everything is fine with you 😉  Additionally, a cable was pulled to secure the firebox.

Additionally, a cable was pulled to secure the firebox.  This is such a wonderful stove, its advantage is that it is economical, compact, and collapsible.

This is such a wonderful stove, its advantage is that it is economical, compact, and collapsible.

This design is made without the use of welding, which simplifies the assembly process as much as possible for those people who do not have a welding machine or do not know how to use welding. We hope our material was useful to you. You can also watch a video of the oven in action. Enjoy watching!

This design is made without the use of welding, which simplifies the assembly process as much as possible for those people who do not have a welding machine or do not know how to use welding. We hope our material was useful to you. You can also watch a video of the oven in action. Enjoy watching!