A table with your own hands can easily be made even by a home craftsman who does not have any accumulated experience in carpentry. Of course, this will become possible if the design of the table is quite simple and understandable.

For example, it is not always possible to find a suitable ready-made table model for a kitchen that is extremely small in size. Purchasing custom-made solid wood furniture is quite expensive. Therefore, sometimes you have to take up the tools and construct your own “work” yourself, starting from the specific dimensions of the place where you plan to install the table.

In addition, there is often a desire to show one’s creative abilities in a summer cottage, especially since there is always a desire to beautifully arrange a veranda or gazebo in a suburban area. If you have suitable materials and tools at hand, then you can either sit down to draw up a drawing of the future table, or use a ready-made project, and then get to work.

To figure out which type of table you can build with your own hands, it is advisable to consider several options for this piece of furniture.

Tools for work

Before starting work, you need to prepare the appropriate tools that will be required to make any wooden table. The amount of material for each model will be different.

You can use regular, traditional hand tools that carpenters have always used. This list usually includes:

- A plane used to level wood and cut parts to the required size.

- Chisels for selecting various holes and grooves, removing small protrusions.

- Saws of various sizes and modifications, which are used to cut thick boards or make small cuts.

- Pencil, tape measure, corner and ruler.

- Screwdriver Set.

- Clamps for temporary fixation of glued parts.

- Sandpaper for sanding.

Many of the tools can be replaced with more modern and convenient devices:

- An electric jigsaw will do all the work that the various saws mentioned above were previously used for.

Rating of jigsaws

Rating of jigsaws - A sanding machine will help make surfaces smooth and polish them to a shine, eliminating the very tedious procedure of manual sandpaper.

- Milling machine with a set of cutters. This device will help round sharp corners, drill shaped grooves for furniture hinges, and if you need it and have some experience, you can use it to decorate a table with a relief pattern.

- will significantly speed up the work, since you won’t have to spend several minutes tightening each screw. In addition, during certain operations it is possible to install one of the milling cutters or ordinary drills into it, for example, in order to process an edge or make a perfectly even large or small hole (groove).

- The construction level will help make the product even and neat, as it will show all possible irregularities and distortions.

To prevent the finished furniture from being “crooked”, the assembly is controlled by level

To prevent the finished furniture from being “crooked”, the assembly is controlled by level An easy-to-make table for a summer cottage

Anyone can make a table like this

Anyone can make a table like this Necessary materials

For such a country house, which has a tabletop size of 1680×850 mm, you will not need too many wooden blanks. You need to prepare the following:

- Beam, cross-section - 750×100×50 mm - 4 pcs. (table legs).

- Self-tapping screws, bolts and possibly metal corners.

- Wood glue.

- Board size:

- 1680×100×25 mm – 4 pcs. (longitudinal frame elements);

- 850×100×25 mm – 2 pcs. (transverse frame parts);

- 1580×100×25 mm – 2 pcs. (cladding boards for the side elements of the frame);

- 950×100×25 mm – 17 pcs. (boards for tabletops).

All wooden elements must be treated with compounds and have a prepared smooth surface. If you plan to “darken” the wood, then it is covered with stain, and to reveal the textured pattern, the top is carefully sanded with a sanding machine. Fine-grit sandpaper will remove the stained, raised parts of the wood grain, making them lighter than the depressions.

Installation of a garden table

When all the parts for the frame are prepared, you can proceed to assembly.

Frame or “box” of the table

Frame or “box” of the table - The first step is the details of the tabletop frame - four longitudinal boards measuring 1680x100x25 mm and two end boards 850x100x25 mm, laid out on a large table or on the floor. The location of the internal and external boards is marked on the end boards. Using a ruler, based on the drawing, the required distances are measured and marked with a pencil. It is imperative to accurately mark the width of the longitudinal board at the junction with the end board, especially if the connection will be made using the tie-in method.

The elements can be connected in different ways:

Connection with a choice of “quarters” and using metal corners

Connection with a choice of “quarters” and using metal corners - using a steel angle - this is the simplest and most reliable way;

- the insertion method is a more complex method, since it requires precise dimensions not only in the width and length of the connecting elements, but also in the depth of the board;

Several types of joints based on the tongue-and-groove principle

Several types of joints based on the tongue-and-groove principle - “groove-tenon”, shown in the second figure a), b), c), d) and e) such a connection is also quite difficult for novice craftsmen with no experience;

- connection with dowels is shown in fragment e) - this method also requires perfect accuracy when marking and drilling holes in the parts to be connected.

- All connections are usually made using glue. The only exception is the fastening of parts end-to-end with a metal corner.

- The frame must have perfectly aligned right angles, so after connecting all the elements, you need to carry out control using a construction angle and measuring and comparing the lengths of the diagonals.

- If parts are secured with glue, they must be fixed in clamps and left until it dries completely, otherwise they will not be connected securely.

- When the glue dries and the frame acquires a certain rigidity, facing boards measuring 1580 × 100 × 25 mm are attached to the outer longitudinal sides. The place of their attachment also needs to be marked, since there should be a distance along their edges for mounting the legs. The facing boards are also installed with glue and fixed with self-tapping screws, the heads of which should be recessed into the wood by 1.5 ÷ 2.0 mm.

- The next stage is the transverse cladding of the tabletop with boards 950×100×25 mm. The place where they are attached must also first be marked, starting from the middle of the frame, since they must be installed at a distance of 5 mm from each other. The protrusion of the tabletop above the frame should be 25 mm on all four sides.

- Next, each of the boards is fixed in four places to the longitudinal elements of the table “box,” and the outer boards are also attached to the end sides. In order for the heads of the self-tapping screws to be recessed, recesses with a diameter of 8 mm are drilled into the boards to a depth of 2–3 mm, then, in the center of these recesses, through holes are drilled with a drill of a smaller diameter (usually 3 mm), into which the self-tapping screws will be screwed. To avoid cracking of the boards during installation work, through holes must be drilled.

- After this, legs made of timber with a cross-section of 750×100×50 mm are attached to the edges of the longitudinal boards; they must exactly match the width of the tabletop.

The next step is installing the legs

The next step is installing the legs - The legs can be secured to the frame with self-tapping screws, but it is better to fix each of them with two bolts, placing them diagonally at the connection point. Through holes are drilled for the bolts, and the nuts are tightened on them from inside the frame using a wrench.

- The final stage of manufacturing is sealing the heads of the screws with a mixture made from carpentry or epoxy glue and sawdust. Use this homemade putty to fill the recesses above the caps and level them well. After the glue has dried, the entire tabletop, and especially the areas covered with “plugs” of glue, must be sanded well.

- After this, the table can be covered with varnish or water-based paint. After waiting for the decorative or protective layer to dry, the product can be installed in a country gazebo, on a veranda or terrace in a recreation area.

If desired, it would be easy to make a bench to go along with the table.

Small folding table for the kitchen

This small folding table is perfect for a small kitchen or a very small room.

- Its design is designed in such a way that the tabletop cannot fold on its own if the table leg is accidentally touched, so the table is quite safe for installation in a children's room.

- The presence of a spacious double-sided bedside table will allow you to store various small items and small toys in it.

- The table is equipped with a tabletop of sufficient size so that the child can do homework while sitting at it.

- In addition, there is room on the tabletop for a laptop or books necessary for study.

- If necessary, this small table can easily replace an ironing board if you lay a soft cloth on its surface.

Considering all of the above, the table can be called multifunctional, despite its very compact size.

Find out how, and also check out several models with detailed instructions in a special article on our portal.

Necessary materials and parts for a folding table

To assemble such a convenient piece of furniture, you need to prepare all the parts that make it up. The list of necessary blanks is given in the table below, and how to make them will be described and shown below:

Diagram of the table with the numbers of assembly parts marked (the illustration is clickable - click to enlarge)

Diagram of the table with the numbers of assembly parts marked (the illustration is clickable - click to enlarge) | Part number on the drawing | the name of detail | Quantity, pcs. | Part size, mm | Material of manufacture, thickness, mm |

|---|---|---|---|---|

| 1 | Folding part of the table top. | 1 | 600×600 | |

| 2 | Fixed table top of the cabinet. | 1 | 600×475 | Multilayer plywood 25 mm thick |

| 3 | 2 | 530×30 | ||

| 4 | 2 | 120×30 | Multilayer plywood 18 mm thick | |

| 5 | The upper end part of the groove that limits the movement of the leg. | 1 | 122×30 | Multilayer plywood 18 mm thick |

| 6 | Groove element for leg movement on a folding tabletop. | 2 | 530×20 | Multilayer plywood 18 mm thick |

| 7 | A groove element for the movement of the leg on the tabletop of the cabinet. | 2 | 120×20 | Multilayer plywood 18 mm thick |

| 8 | The lower end part of the groove that limits the movement of the leg. | 1 | 122×20 | Multilayer plywood 18 mm thick |

| 9 | Side walls of the table cabinet. | 2 | 720×520 | MDF 19 mm |

| 10 | Horizontal parts of the cabinet forming shelves. | 3 | 520×312 | MDF 19 mm |

| 11 | The lower vertical part of the internal partition of the cabinet. | 1 | 418×312 | MDF 19 mm |

| 12 | The upper vertical part of the inner partition of the cabinet. | 1 | 312×184 | MDF 19 mm |

| 13 | The middle horizontal part of the cabinet. | 1 | 310×250 | MDF 19 mm |

| 14 | Cabinet door. | 1 | 477×346 | MDF 19 mm |

| 15 | Cabinet shelf. | 1 | 310×250 | MDF 19 mm |

| 16 | Cabinet drawer front panel. | 1 | 346×209 | MDF 19 mm |

| 17 | The front panel of the drawer (located behind the front panel). | 1 | 418×312 | MDF 19 mm |

| 18 | Drawer side panels. | 2 | 341×250 | MDF 19 mm |

| 19 | Back panel of the drawer. | 1 | 272×120 | MDF 19 mm |

| 20 | Drawer bottom panel. | 1 | 341×272 | MDF 19 mm |

| Handles for drawers and cabinet doors. | 2 | Ø 30 mm | Wood | |

| Upper leg element. | 1 | 80×80×18 | Multilayer plywood 18 mm thick | |

| Mobile table leg. | 1 | Ø top 55, bottom 30, height 702 | Wood | |

| Furniture hinges for connecting two parts of the tabletop. | 2 | Ø 50 mm | Metal | |

| Furniture door hinges. | 2 | The size depends on the shape. | Metal | |

| Bottom end panels covering the gap under the cabinet. | 2 | 20×300×5 | Plywood 5 mm |

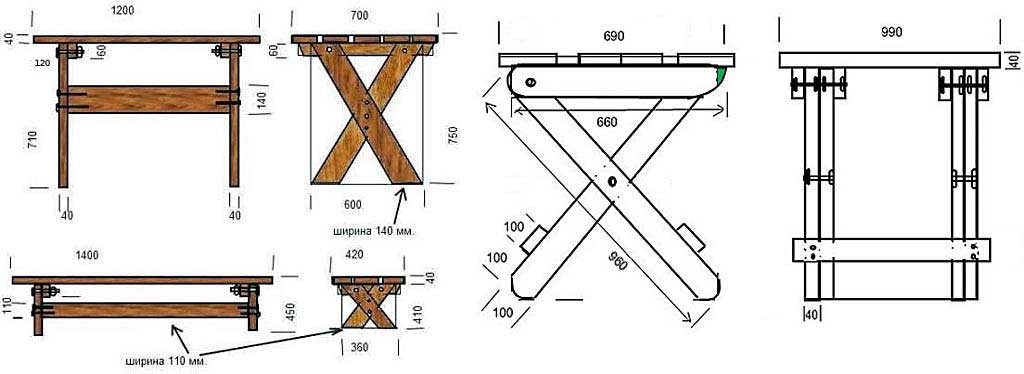

The drawings show a drawing of a table that can be relied upon in the process of manufacturing and assembling elements into a single structure.

Main dimensions of the table (illustration is clickable - click to enlarge)

Main dimensions of the table (illustration is clickable - click to enlarge)  Separate components of the table - a drawer and a guide channel for moving the legs (the illustration is clickable - click to enlarge)

Separate components of the table - a drawer and a guide channel for moving the legs (the illustration is clickable - click to enlarge) To manufacture all the parts listed in the table, you will need modern electric tools that can bring the workpiece to professional perfection.

Find out how to do it with a photo and description in a special article on our portal.

Installation of a folding table-cabinet

You should start making a table with its most important and largest part - the tabletop. Since the table is folding, this element will consist of two parts - stationary and “mobile”, that is, one that can be folded down if necessary. When folded, this table can easily serve as a regular compact cabinet.

| Illustration | Brief description of the operation performed |

|---|---|

| The first step is to cut out blanks for the tabletop, measuring 600×600 and 600×475 mm, from plywood 25 mm thick, using a jigsaw or circular saw. |

| Next, markings are made on the larger panel - a semicircle is drawn, since the front of the table should be rounded. In order to achieve the correct shape of a semicircle, you can use a large construction compass, or make one yourself - from a nail, pencil and rope. |

| Then, along the marked line, the tabletop is rounded. This can be done using a jigsaw or circular saw, installing the appropriate compass attachment on it. |

| Next, a cutter of the desired configuration is installed on the milling machine, which will make the edges of the tabletop smooth, or, if desired, even or rounded. |

| The semicircular part of the panel is processed with a milling cutter, leaving the side that will join the second part of the tabletop flat. Then its edges are processed in the same way. |

| The next step is to place the two processed parts of the tabletop on a flat table at a distance of 5 mm from each other. Markings are made for installing furniture hinges. They must be placed at a distance of 100-120 mm from the edge of the tabletop. Furniture hinges can have different shapes, so they should be laid in the marked place and outlined with a simple pencil. Then, using a router, special shaped grooves are made in the plywood, the depth of which should be equal to the thickness of the furniture hinges. The hinges are fixed into the finished holes using self-tapping screws. |

| After connecting the two parts of the tabletop with hinges, in the middle of the panels, markings are made on their lower side to secure the parts that will form a closed channel for the movement of the moving table leg. The guides should be fixed at a distance of 30 mm from the junction of the two parts of the tabletop. For the manufacture of parts, plywood with a thickness of 18 mm is taken. Then, 10 elements are cut out of it and processed with a milling cutter: 530×30 mm in size - 2 pieces, 530×20 mm - 2 pieces, 120×30 mm - 2 pieces, 122×30 mm - 1 piece, 120× 20 mm - 2 pcs., 122×20 mm - 1 pc. It is important to remember here that long slats should have 45˚ cuts on one edge, and short elements on both sides, so that when joined, they form a right angle. In addition, the upper long and short parts, fixed on top of the lower rails of the guides, are cut off from the ends, also at an angle of 45˚. These cuts are necessary so that their angles do not interfere with the movement of the leg along the formed channel. Then, the parts are glued with wood glue to the marked area of the rounded, and then to the rectangular part of the tabletop. First, the longest slats measuring 530×20 mm are fixed with glue and then screwed with self-tapping screws; then a piece of 122×20 mm covers the channel. On top of the long and short fixed slats, second ones are glued, having the same length, but greater width; they are also additionally screwed with self-tapping screws. Thus, an even channel is formed between the table top and the top rail, along which the leg will move. It is very important to calculate the location of the places where the screws are screwed in so that the top ones do not collide with those that secure the bottom slats. Four parts are fastened to the rectangular part of the tabletop in the same way. All elements must be processed until smooth and perfectly evenly fastened to each other, otherwise the leg will bump into obstacles and jam when moving. |

| The leg is usually made on a lathe. If it is not there, then you can order it from a master or purchase it ready-made. As a last resort, you can make it square by processing the timber of the required height until smooth. Then, using a dowel and glue, a square plywood guide plate measuring 80x80x18 mm is attached to the upper end of the leg using a dowel and glue. |

| Next, after the glue has dried, the leg can be installed in the channel intended for it and tested for its free movement, without jamming. If necessary, minor adjustments and modifications can be made. |

| The finished tabletop is painted or coated with water-based varnish - if the goal is to preserve the textured pattern of the plywood. After this, the finished tabletop is put aside and proceed to the manufacture of the cabinet. |

| The elements of the cabinet do not have complex configurations, therefore, to make them, it is enough to accurately transfer the dimensions of the parts indicated in the table on an MDF panel or thick plywood and carefully cut them out using a jigsaw or saw. After the parts are made, their end parts must be processed smoothly with a milling cutter, otherwise they will look sloppy. |

| If you plan to cover the visible end parts of the cabinet parts with a special laminated edge tape, then this process is carried out using a regular iron. The tape on its inner side has a layer of glue, which heats up under the influence of heat and ensures reliable fixation of the edge on the surface of the end parts of the MDF panels. |

| The next step in the cabinet door panel is to make shaped grooves into which furniture hinges will be installed and secured. The holes are made in the same way as in the countertop using a router, but in this case the cutter can also be installed in a screwdriver, since MDF has a lower density than plywood and is easier to process without chipping the material. The hinges should be placed at a distance of 100 mm from the edges of the door - before starting drilling, it is necessary to carry out careful markings. A similar procedure is carried out with the wall of the cabinet on which the door will be attached. Then the walls and doors are joined together to check the correct installation and to mark holes for the screws. |

| In addition to the hinges, you can immediately screw the prepared handle to the door. To do this, step back 50 mm from the edge of the panel and find a convenient height position, mark a point through which a through hole is drilled to secure the handle. |

| All manufactured parts of the cabinet are painted with paint of the selected color using a roller and brush. Paint will not only make the product aesthetically attractive, but will also protect the material from the negative influence of a specific kitchen humid environment. |

| Next, you can proceed to assembling the bedside table. Professionals carry out this process using special tools, but they can be easily replaced with improvised devices. For example, you can carry out the assembly on a flat table, and for ease of installation of the cabinet, it is additionally installed on flat bars. Mutual fastening of parts can be done using wooden dowels, metal furniture corners or self-tapping screws - the latter option is the simplest, but also the most unreliable. In addition, the screw heads will have to be masked with various compounds after assembly. The assembly process proceeds as follows: - The bottom panel is placed on the stands. - One of the side panels is leveled on it and using a construction corner, and its location is marked with a pencil. -The location of the fastening parts is immediately marked on the horizontal and vertical panels. - Exactly the same procedure is carried out with the second side and dividing middle wall. - Then holes are drilled at the marked points on the bottom and the end sides of the side panels for installing dowels. - After this, before gluing the parts together, locations for installing shelves are determined on the side walls. Then, shelf support brackets are mounted in the marked places, for which holes are also drilled. - Next, dowels coated with glue are installed in the holes drilled in the bottom, and the side walls are put on their upper, protruding part. - Fixed shelves-lintels are mounted in the same way, simultaneously with the side walls. |

| Before continuing work, you need to make sure that the glue in the assembled structure has dried well. To make the cabinet stand more rigidly, it is laid on its side and pressed with clamps while it dries. |

| While the glue dries, you can start assembling the drawer. Since it will be completely assembled from MDF, the installation of the box can also be carried out using dowels. The sides are attached to the bottom of the box, and a line is drawn along them with a pencil, and then marks are made of the places where the dowels will be installed. Then, the sidewalls are removed, and at the marked places, holes are drilled in their end for installing fasteners. The same is done on the bottom panel. Next, the dowels are coated with glue and carefully inserted into the holes, connecting the sides to the bottom. |

| The sidewalls are screwed together using self-tapping screws, the heads of which are recommended to be recessed into the wood, and the holes to be sealed with a mixture of epoxy glue and sawdust. Another fastening option can be furniture corners, which are screwed from the inside to the sides with self-tapping screws. Each side will require two corners. |

| When assembling the box, it is necessary to control the evenness of its corners using a construction angle and changing the diagonals, otherwise a skew may occur. |

| If you plan to install metal roller guides for easy movement of the drawer, then first, the location of their attachment is determined on the sides of the drawers and on the inner walls of the cabinet. To do this, using a pencil and a ruler, draw a line along which the guides will be fixed. |

| Next, a front panel is installed to the front of the drawer. It is screwed from the inside of the box, through pre-marked and drilled holes. In addition to self-tapping screws, it is recommended to use glue to fasten the panel: it is applied to the front panel, and then the front panel is pressed against it, and they are tightened with four or five self-tapping screws. After the glue dries, a hole is drilled in the center of the facade panel, through which the handle is screwed. |

| Finally, the long-awaited moment comes - connecting the cabinet and the countertop. It is recommended to first glue the stationary part of the tabletop to the surface of the cabinet, and then secure it with screws that are screwed in from the inside of the lower cabinets. But first, the tabletop needs to be positioned correctly. Part of the channel located on the permanently installed tabletop panel should rest against the side of the cabinet - it will serve as a stopper for the movement of the leg towards the table. The tabletop should extend beyond the edges of the cabinet on the drawer side by 50 mm, open shelves by 30 mm, and on the leg side by 120 mm. |

| Having secured the tabletop, they proceed to the final installation and screwing the bedside table door onto the screws. Then the drawer is inserted, and the shelves are installed on the shelf supports. |

| When closed, the table is compact, so it does not take up much space and looks quite aesthetically pleasing. If desired, you can choose other colors to decorate it, which will better harmonize with the interior of a particular room. |

| When open, the table also does not take up much space and fits perfectly into one of the corners of the room. Thanks to its “light” design, it does not weigh down the interior, and the shape of the tabletop makes it safe for children. Therefore, this table option can be considered ideal for small apartments with small kitchens and rooms. |

If there is a need to save money, or you simply have a great desire to express yourself in carpentry, then you should not put off making your own. Moreover, the assembly will become not only an interesting and useful activity, but also very enjoyable, especially at the moment when the work is successfully completed.

For those who are confident in their abilities, we offer another interesting option for a round table, which can easily serve both at home and on the site.

Video: example of assembling a round table

And one more idea for a kitchen table, which, if not true, would also be within the power of a skilled owner to implement:

Video: lightweight kitchen table with collapsible design

This piece of furniture is one of the most versatile in use. The table can be a dining room, a utility table, or installed in a living room, on a veranda, on a property, in a workshop, and so on. In a word, it is impossible to do without it. But many people are not satisfied with purchased products due to a number of parameters - size, design features, shape, or for other reasons.

Considering that wood is relatively easy to cut and sand, making a table from it according to your own drawing, with your own hands, is not a problem for a good owner. And it will come out much cheaper. Plus - satisfaction from such work.

Room

Ideally, this is an extension, a barn, an empty garage, although a small area under a canopy will do. Working with wood on the site, in the open air, means being completely dependent on the vagaries of the weather. If there are “square meters” suitable for making furniture, then you should worry about quality ventilation in advance. Natural is sometimes not enough (besides, it depends on changes in wind direction and pressure), and a hood is installed.

Arguments that if you use protective equipment, you can work in a closed space do not stand up to criticism. Wood dust will immediately settle on everything, including the sample with which some action is being performed. Neither an accurate cut along the line nor high-quality surface treatment of the wood (not to mention the impregnation and finishing coating with paint and varnish) will be possible.

One cannot ignore the fact that many preparations used for wood processing contain toxic components. For example, varnishes, paints, impregnations: if they are not natural, then harmful fumes are guaranteed.

Tools

Their set depends on the extent to which it is planned to “ennoble” a simple wood structure, what shape it will be given, and a number of other nuances. If the master does not lay claim to the elegance of a wooden table and does not aim to achieve its originality, then an ordinary carpenter’s set will be enough.

For more “delicate” work in the process of making a table of unusual shapes and external design, special devices will be needed.

El/jig saw. It will not be possible to make an inclined vertical cut with a regular saw, maintaining the angle exactly. The canvas will begin to “play”, and therefore the quality of work will be extremely low. An electric jigsaw is universal in use and also provides high precision cutting of wood or cuts in it.

Many of the listed devices can be rented if making furniture is not a hobby, but a necessity.

Impregnating and other compositions

Rot protection:

- Recycling machine oil is an effective, and also free, remedy. But not for dining tables.

- Flaxseed oil. A natural and effective product that penetrates deeply into the wood structure and protects it from mold and mildew. The downside is the high cost. But if the table is intended for eating, this is a great option. The drug has no color, therefore, after processing lumber, it does not leave any traces in the form of darkening, stains, or streaks, unlike processing.

- Water-polymer emulsion. It is characterized by long-lasting action and safety for health.

- Acrylic varnishes. They have practically supplanted their predecessors in the “NC” category, since they are harmless and in many respects better than compounds that are diluted with solvents.

- PVA, bone glue and a number of others. More detailed information about joinery compositions -.

To decorate a tree:

- Clear varnishes are used not only to protect the material from moisture. With their help, you can preserve the texture of the wood and shade it.

- Stains.

- Varnishes with a coloring effect (tinting).

- Paints (but only for wood!).

- Putties.

Using colorless varnish and pigments, you can make a coloring composition of any shade. It is enough just to correctly determine the proportion of components. This is easy to do by experimenting with mixing and applying a sample to a discarded board. This will allow you to choose an acceptable tone. It is more than advisable, since it is not always possible to purchase exactly what you need on the market.

Fasteners

It is better to ignore all advice on assembling a wooden table using nails (the reasoning is simple, quick and cheap). The reasons are as follows:

- The nail easily pricks dry wood (and this is exactly what is used; more on that below).

- It is quite difficult to direct its leg correctly (strictly vertically). In some cases, it is even more difficult to redo your mistake.

- A tree, even the most protected from rot, succumbs to it over time. The maintainability of a table knocked down with nails is extremely low. Practice shows that it is rarely possible to remove such fasteners without damaging adjacent structural parts. As a result, instead of the planned replacement of one element, 2–3 will have to be changed.

- When assembling a wooden table, if glue alone is not enough, you should use only self-tapping screws.

- Sometimes its individual parts (at joints) require reinforcement. Strengthening the strength with hardware with a thicker and longer leg is impractical. The reason is the same - the likelihood of the tree splitting. For these purposes, metal strips, brackets, and corners are used.

Features of choosing wood

Some people focus on the cost of lumber, others care about the wood’s resistance to rot, and for others, its texture. What can you recommend to a novice furniture maker? Do not use the same type of wood for a table unless it is intended to be installed somewhere in a utility room or garage. This is exactly what many novice “craftsmen” do, selecting the same type of boards and bars from what is left from construction or renovation and gathering dust in the barn.

When making a wooden table for a living space, veranda, etc., you need to take into account the properties of individual species. Naturally, if you do not have sufficient experience in assembling furniture, you should pay attention to cheaper wood. The first table (chair, stool) in your life is just a kind of training in making and gaining experience.

Tabletop. Here, strength and minimal moisture absorption come first. It is on this part of the table that something constantly spills. The optimal choice is pine, larch, oak (although the latter is more expensive). Thickness – at least 3 cm.If the size of the countertop is small, then you can use wood-based slab products (OSV, OSV and the like). But only with lamination to prevent the material from swelling when liquid gets on the table surface. For example, chipboard.

Low-grade lumber is not used in the furniture industry. This is not economically feasible, since pre-treatment of wood increases the production cycle time. But when making something, wood of lower grades, substandard wood is just right. The same pallets left over after using stacks of foam blocks or bricks.

And not just because it is free or relatively cheap. Many of the disadvantages of such wood can be turned into advantages with the right approach. For example, after coating with colorless varnish, the tabletop acquires a unique, original look.

The main thing is that the boards do not have obvious defects in the form of rot, cracks, falling knots and wormholes.

If pine is chosen for the tabletop (this also applies to many other conifers), then you need to pay attention to the location of the annual rings. These arches are called humps. The cuts of the boards show how they are oriented, and this is taken into account when laying them in a row. Samples obtained by tangential cutting are arranged alternatingly (one top down, the next one up); radial cutting - the same (with arcs in the same direction). The nuance is insignificant, but compliance with this recommendation eliminates the risk of warping and splitting of the boards.

For furniture, if you think about its durability, you should take only dry lumber. As wood shrinks, it will become deformed; This is a natural process, and its consequences in the form of twisting, warping, and bending are inevitable. Such a table will quickly become warped, and you will have to repair it. And here you need to decide whether to purchase highly dry wood or rid it of moisture yourself. The first option is simpler, but such a tree is more expensive. The second one will cost less, but there are a number of purely technical difficulties.

- Firstly, it is necessary to ensure a stable temperature regime in the place where the workpieces are stored. Changes in its value will lead to uneven evaporation of moisture, which will negatively affect the strength of the tree.

- Secondly, good ventilation must be organized.

- Thirdly, and perhaps this is the most unpleasant moment - you will have to wait up to about six months, depending on the initial moisture content of the tree. But this is not a guarantee that the result will be as expected; Even this requires practice.

This once again confirms the idea that when starting to make furniture from wood for the first time, you should focus on the simplest table for household needs made of cheap lumber, without pretensions to its sophistication and originality of design. For example, for a barn, garage and the like.

Options and patterns of wooden tables

It should immediately be noted that any work related to design and self-assembly is a creative process. There are no stereotypes in this matter, so you can only take the model you like as a basis, and everything else - linear parameters, shape, manufacturing specifics - depends on the purpose of the product and your own imagination. Here are just a few examples of what wooden tables can be like. For example, for summer cottages and small utility rooms, it is worth choosing structures whose geometry can be easily changed - folding, camping, hanging, garden, level, and so on.

Tables that are intended to be used for eating, playing, or as coffee tables for installation in living rooms for their intended purpose are made stationary, that is, of unchangeable dimensions. These assemblies are more “solid”, since all articulated parts are rigidly fixed; no hinge joints.

Features of assembling wooden tables

If a person undertakes to make something, it means that he knows how to use tools, read blueprints and work with lumber. Such a home craftsman does not need to be taught the basics of carpentry. But it would be worth noting a number of nuances when making a wooden table. These notes will only help in the process.

Let's start with the types of connections. There are quite a few of them, but for a table that you assemble with your own hands, the ones listed below are quite enough.

On the dowels

In this case, the parts are fastened by placing them on an adhesive composition (Fig. 1 – 3).

The nuance is that to make the “cylinders” that are inserted into pre-drilled “channels”, a tree of a denser structure than the table elements is taken. This is what ensures the strength of the connections. Before installing them, chamfers are removed from the edges of the dowels and holes.

These round sticks are available for sale in any furniture showroom in several sizes. Turning them, even if you have a carpentry machine, is a waste of time. It is not recommended to purchase plastic dowels for the table; they are used for detachable connections. For example, frame furniture (walls, multi-level shelving, etc.).

You should not use nails to fix table elements (Fig. 4). Metal and wood differ in the degree of thermal expansion. Such a connection will not last long - it will begin to “shatter”, especially if the table is intended to be installed on the territory or in an unheated room.

On the kings

It is advisable to make such connections if the table either has to be disassembled periodically, or without this it is impossible to move it through the doorway. Although not all drawers require dismantling the structure. The most commonly used options are shown in the figures.

Bolted

Such connections are used mainly for garden furniture or those installed in extensions; for utility tables. An example is shown in the figure.

The nuance of working with fasteners

In order for the self-tapping screw to be easily screwed in and “go” in the desired direction, a hole is first made at the point of its installation using a drill with a diameter slightly smaller than the fastener leg. The main thing is to maintain the coincidence of the axial lines, that is, to prevent skew. In this case, to “plant” the screw, you can do without a screwdriver.

Features of wood processing

Everyone knows that a plane is used first, an abrasive with a large grain, and then a fine one. But sometimes it turns out that the last stage, polishing, has to be done many times. Much depends on the type of wood and the degree of drying. After applying the first layer of varnish, the fibers may “stand up”. Nothing wrong with that. You should wait for the workpiece to dry and repeat its processing with abrasive. The work is painstaking and takes time. But it is precisely this method that can bring “problem” wood to ideal “smoothness.”

To eliminate the risk of injury to a person, all edges and corners of the table should be slightly rounded.

Features of external decoration

- Minor defects in the form of cracks and chips are eliminated with putty.

- Once sanding is complete, all wood dust must be removed. In this case, a regular household vacuum cleaner with an appropriate attachment will help out. It is recommended that after such cleaning, wipe the entire table with a slightly damp cloth, let it dry and repeat removing any remaining dust. After this, you can safely start applying stain or varnish - there will be no “pellets” on the wood.

- You can add originality to the table not only with the help of curly cutouts, an unusual shape of the tabletop or legs, a combination of textures of different species, and so on. One of the good options is artistic painting.

And finally. The work of independently making something out of wood (for example, a table) is just the initial stage of mastering the skill of a “designer-assembler”. Having developed technologies and techniques on wood and acquired the necessary skills, it is enough to simply switch to other materials - metal, plastic, glass. So the benefits of a wooden table made even according to the simplest drawing (besides the pleasure of work and money saved) are obvious - time not wasted.

A table is the second item after a stool that every beginning amateur furniture maker should be able to do. The table can be created from different materials and have unique characteristics. An excellent intention for you would be the desire to make your own product from wood.

A table made of wood is quite easy to create with your own hands; having minimal skills in working with carpentry tools is enough. And the cost of the material will be significantly less than for a table using metal, glass or plastic.

A piece of furniture made with your own hands will most accurately correspond to the wishes of the happy owner, and will be incomparably more pleasing to the eye than what was purchased. And most importantly, when creating a table with your own hands, you acquire important skills in working with the material, which will make the restoration of operational defects much easier.

What can you make a good table from?

A particularly beautiful tabletop can be made from cheap, non-grade pine boards, knotty and twisted (without falling knots, rot, fungus, wormholes), which, when well processed, give a wonderful pattern, to achieve which when working with expensive wood, much more expense and effort is required .

When choosing a material, it is important to take care of the strength of the future product. To do this, you should pay attention to the density of the wood.

Soft wood (spruce, pine, chestnut, dogwood) is easily damaged during use, which negatively affects the durability of the table. But scratches and dents can be hidden, although the restoration process will be quite frequent.

Hardwoods (beech, ash, maple, oak, walnut, fruit trees, elm) are quite difficult to process on your own. And you may have to look for experts to work with them. But you will ensure the durability of the product.

External characteristics

It is very important to determine in advance the appearance of your future product. The basic rule of a good table is if the structure fits well into the space allocated for it and leaves a lot of free space for those sitting.

It is also important to consider that a table with a rectangular tabletop will accommodate fewer people than a table with a round or oval shape with the same area. And it would be more expedient to make a table for guests in a folding version, which is folded out for big holidays, but in everyday life is folded. Also, such a folding table will be convenient in the utility room.

Most often you need to choose a kitchen table. It should be roomy and pleasing to the eye to facilitate the process of working with it. But it should not interfere with movement in the room and in no way interfere with the process of culinary creativity.

Based on this, it is absolutely clear that the size of the table is selected depending on the area of the room. Also, soft wood cannot be used for a kitchen table due to its use in “extreme” conditions.

Choosing the external characteristics of a product is a responsible process, therefore, before starting to personally create a table for a summer house, it is extremely necessary to thoughtfully assess the needs for which this table is being made.

Transferring an idea to paper

When creating a design that is the fruit of your imagination, you will have to develop the diagram and drawings of your table yourself. Why are there so many electronic programs?

After a thorough development process, it is extremely important to transfer the resulting result to paper. For fast and high-quality work, it is very important to use this manual constantly.

Creative process

Preparation of drawings is the last preparatory stage. Next, you can begin the most important part of the work - manufacturing the parts. Do-it-yourself wooden tables are much easier to create if the drawings and diagrams are as informative as possible. This reduces the likelihood of errors to a minimum.

You can personally make a desk, a coffee table or a children’s table. With some skill, it is possible to create a computer desk. As well as a dining or country model. Each of the options is quite easy to implement.

The canvas for the tabletop and the boards with beams from which the remaining parts will be formed are processed with the available tool or, at worst, with coarse sandpaper to remove any defects present in the form of unevenness and protruding knots.

The boards are sanded on all sides, including the side edges and corners. If you are creating a canvas from wood cuts, you need to make sure that they are sufficiently dry, and also repair small cracks discovered after a visual inspection. And it’s better to tongue and groove them. To get more reliable adhesion of the canvas and save time on assembling elements.

Transfer the diagram to the finished canvas. The main elements are cut out with a jigsaw and, if necessary, the sections are polished. Protruding support elements are cut off by approximately 3 centimeters. Horizontal cuts are made on both sides of the supports (legs).

The blanks are coated with a preparation that prevents the entry of moisture and pests, and only after final drying is it possible to resume the process of creating a table with your own hands.

Putting the details together

After making all the necessary parts, you can begin the sacred ceremony. Namely, to put together the desired masterpiece. And this can be either a round table or some other selected product.

First, you need to assemble the supporting structure using screws and glue (first, thin channels are drilled with a drill to the length of the screw, otherwise there is a possibility of the part splitting). Galvanized screws can be used for connections, as they do not rust, and this is very important for wood products. Or wood glue.

According to the basic rules, the length and width of the frame should be 30-25 cm less than the tabletop.

Additional boards need to be attached to the sides to add rigidity and to hide the place where the legs are attached. Cut chamfers where the legs are installed.

Then the table leg is secured in place with clamps, and holes for the bolts are drilled in the frame. Place the supporting elements in place and secure them with stoppers. Reinforce the structure with wood glue. Then install the tabletop in place for which furniture corners are used. At the very end, all visible screws are hidden with plugs matching the color of the wood.

The final stage. Finishing

A photo of the completed table can be seen below. Achieving this result is surprisingly easy. If desired, you can round either only the corners or the entire end, depending on the type of table. It will be nice to make chamfers on the edges of the tabletop.

Irregularities in the entire structure are sanded down, and mistakes made are hidden using putty. To extend the service life of a hand-assembled table, it is necessary to cover it with several layers of varnish or stain.

Thus, making a beautiful wooden table with your own hands is a fairly simple leisure activity. And easy to do. The guarantee of obtaining a high-quality, ideal in dimensions and aesthetic result according to your drawings is: strict adherence to the instructions, error-free execution and carefully selected material. And the resulting table will harmoniously fit into the exterior.

Photos of tables with your own hands

It is no secret that the dacha uses furniture that has served its time in the apartment. The table is no exception. However, in dacha conditions, the furniture that served well at home cannot always fulfill its purpose. We are talking about modern tables made mainly from laminated chipboard. Such tables are not suitable for a gazebo, veranda, garden, and in a house with high humidity in the off-season, their service life is limited. In such conditions, a wooden table is needed, but a wooden table is not a cheap pleasure. The solution to the problem is to make a table with your own hands. This is quite easy to do. In addition, this will allow you to save significantly, including on delivery.

The simplest table design

The simplest table design is shown in the photo below. At the same time, this design is the least expensive both in terms of materials and manufacturing effort.

Fig.1.

Optimal overall dimensions of the table

One of the advantages of making a garden table with your own hands is that the table can be made of any size. Thus, the table can be easily adjusted to the dimensions of the gazebo, veranda or kitchen.

To make it easier to navigate the sizes, I will give a size chart, which is most often used in the production of tables. The size chart is based on the size of the countertop.

- 60x90 cm. A table with this size is optimal for 3 people. At such a table it is convenient to have lunch, drink tea, etc. Thanks to its size, it will fit well into any small space.

- 80x120 cm. 4 - 6 people can comfortably sit at this table. Typically, a table of this size is appropriate to place in a large kitchen or on the veranda.

- More than 120 cm. Tables with these sizes are good for feasts. In the conditions of a dacha and limited space in a country house, such a table is usually installed in a gazebo or under a canopy in the open air.

Naturally, when making a table with your own hands, you can make the size arbitrary, however, in order to be comfortable at the table, you should adhere to the recommendations given above.

Manufacturing procedure and table drawing

The table drawing is shown in the figure below.

Fig.2.

The legs for the table are made of a wooden block with a cross-section of 40x40 mm and a length of 70 cm. If you want to decorate the table, you can use balusters as legs. They are carved and will make the table design more interesting.

The support for the tabletop can be made from a board with a cross-section of 25x150 mm, sawing it lengthwise into two halves. For support you need 2 boards 650 mm long and 2 boards 1050 mm long.

With the countertop everything is much more interesting. The tabletop can be made in various ways. The easiest option is to purchase a furniture panel of the required size. It can be purchased at online building materials hypermarkets.

Fig.3.

If you take this path, you should remember that furniture board is made by gluing small sections of boards, and if it is constantly exposed to precipitation, it will quickly become unusable. Therefore, a table with a tabletop made of furniture board must be varnished or painted to protect it from moisture.

Another option is a plank countertop. Boards can be used in any size. For example, with a section of 25x100 mm. This is a simple and cheap countertop option. This option does not have the disadvantages that are inherent in furniture panels.

Fig.4.

However, without special equipment it is unlikely that it will be possible to fit the boards tightly. Therefore, the tabletop will have gaps between the boards. This looks good for a garden table. But not very practical.

You can get rid of the gap mentioned above by using an unusual, tongue-and-groove board. It will cost a little more, but you will get a smooth, even tabletop.

Fig.5.

Euro floor boards can be used as tongue and groove boards. They are easier to find in the store. It’s just important not to forget to stitch them from the wrong side.

Table assembly

Once all the elements of the table are ready, you can begin assembling the table. The table is assembled in a certain order.

First, assemble the support for the tabletop and attach the legs to it. This is the most difficult moment in assembling the table. As described earlier, the tabletop support consists of 4 boards. They need to be connected to each other. There are several ways to do this.

The photo below shows how to assemble a tabletop support and secure the leg to it using a special tie.

Fig.6.

This method is an ideal solution, except for this fact. It may not be easy to purchase a special screed.

Another way is to tighten the entire structure using a wooden block.

Fig.7.

When using this method, you need to pay attention to the fact that the block must be sawed off at an angle of strictly 45 degrees. Otherwise, the table will not be rectangular.

In my opinion, the simplest and most affordable option for assembling the legs and supports for the tabletop is to use a metal general construction corner measuring 50x50 mm. You can buy it in any store, and it has the correct geometric shape.

The last step in assembling the table is installing the tabletop. Depending on the type of tabletop, it can be secured in various ways. The furniture panel can be attached with corners or with glue. Separate boards using screws and glue.

Fig.8.

As you can already understand, making a table for a summer house or at home with your own hands is quite simple. It is important to approach the issue creatively. This table can be decorated with any paint and varnish coatings. A wooden table made by yourself will delight you every day and will last for many years.

Wooden tables and design ideas

Fig.9.

Fig. 10.

Fig. 11.

Fig. 12.

Let's look at practical tips that make it easier to assemble a table with your own hands and help you achieve the best results. The construction of a country house is divided into several stages. A serious step is the arrangement of the dacha. Furniture plays an important role in the comfort zone. A wooden table complements the overall interior and improves the functionality of the room. But buying one may not always be successful, so we suggest considering a homemade option. It can be placed outdoors or in the house. Such furniture plays an important role in the arrangement.

We use either pallets or wooden boards as building materials. An unforgettable requirement for the material is the absence of moisture. With sufficient funds and desire, new boards will be very effective in construction. The quality and long service life of any furniture depends on the quality of the purchased materials for its assembly; how well they are treated before use. After successfully purchasing the necessary materials, and in this case these are wooden boards, stack them in rows and leave them to ventilate. The longer this type of material sits and ventilates, the better it will serve in the future.

Any furniture is primarily made only from dry wood.

As mentioned above, tables are suitable for a variety of places and serve as a complementary element of furniture literally anywhere. Individual manufacturing methods are selected for each table. For example, you set out to decorate a gazebo with a wooden table. And this is quite convenient and correct, since spending time in a gazebo without a table in the summer is somehow uncomfortable. Just homemade furniture won’t hurt. It is not necessary to glue the boards together during the work. It is enough to secure it using special fasteners. This approach greatly simplifies the manufacture of outdoor countertops. Or you can purchase them on the website https://stone-fortress.ru/. Firstly, you don't spend a lot of time assembling. Secondly, it is quite possible to replace glue with other effective means, which means financial costs will be reduced.

Pallets, like wooden parts, are very distinguishable by color. Accordingly, you visually decorate the table the way you want. Pallets have side parts. They are used as a frame. However, before this, the material needs to be sanded properly. It is worth considering that all the material will not be used up. The remaining planks can serve as fastening elements of the countertop. The fastening point is in the area of the board joints. To join the board you only need two self-tapping screws. For the last solid one - one.

The sides and two boards will be used to build the frame. We secure the frame parts to the end using self-tapping screws. The frame does not need to be attached with self-tapping screws, just gluing it on is enough. Since the screws are long, we drill separate holes.

Our table will soon be released. All that remains is to turn it over and start sanding. Use coarse-grit sandpaper at first, and fine-grit sandpaper later. The next step is to install the legs. To do this, you will need four boards with exactly the same size. If necessary, of course, you will have to adjust the wooden boards in order to achieve an overall positive result. In this case, grinding is also an integral part of the work. Then each leg needs to be screwed on. To do this, you will need two self-tapping screws, which are important to be positioned diagonally from each other. Installing a jumper will help ensure maximum stability. The distance between the floor and the jumpers should be at least 10 cm. When everything is fixed, we begin to drill holes for the screws. This way we will secure the material so that it does not crack.

Now you have a complete design. Naturally, it doesn’t hurt to decorate it somehow. For example, start with painting. Of course, the first time a hard pile will appear. There is no need to be afraid, it is in the order of things. We take up the sandpaper again and begin to sand the surface until it becomes smooth. This amount of work will definitely create dust. Accordingly, you will have to get rid of it. Then we take up the varnish again and cover the surface with it. You may need to sand a third time, since the varnish will not lie flat the first time. In general, it all depends on the type of wood. So it’s better not to neglect unnecessary sanding, but to ensure that your wooden product looks beautiful. Having completed all the necessary procedures listed above, we get a beautiful wooden table made by ourselves.

We will accept the option of making it from a newer material if you do not want visible traces of nails to remain or the boards will be frightening due to their heterogeneity. The tabletop is made in a variety of shapes: rectangular, square and round. The result depends on your personal preferences.

Table made from leftover materials

Sometimes it happens that at the time of construction or the next renovation of a dacha, extra boards of various types remain. Instead of throwing them away, it is better to use this remaining material for more significant tasks. Make the same table. To do this, we select pine boards that will go on the frame (thickness 25 mm, width 50 mm). For the legs, we will leave planks 15 mm thick and 50 mm wide. As for the size of the frame, everything is purely at your personal discretion. This table is well suited for the veranda. And since this room is not large, it is advised to make it narrow (60 cm width, 140 cm length, height 80 cm). Of course, if family members are not tall, it is quite acceptable to play with the size of the tabletop.

Next you need to assemble the frame and secure the boards that act as legs. It is necessary to cut two boards 140 cm long. The width parameters are 60 cm. You need to subtract twice the thickness of the used board - 5 cm. That is, the used bars should be 55 cm. Now fold the frame by twisting the screws. How the bars were folded, everything needs to be double-checked. The diagonal arrangement of the bars is worthy of attention. If something doesn’t add up, you should definitely pass it on, since the design of the tabletop itself will suffer in the future.

Cut four boards and secure them inside the frame (80 cm long). Use four screws for each board. The bottom shelf can become a complementary element to the tabletop. To equip it, attach a crossbar in the middle of the two legs. It will serve as a frame for the future shelf. The work is done in a similar way with other pairs of legs. In addition to the fact that the shelf will provide more convenience, two jumpers significantly increase the level of rigidity of the structure as a whole. The fastening of the jumpers should be done strictly at a right angle (check with a special square).

Now the frame is ready, all that remains is to check it. If the structure is made correctly, the frame does not wobble. All that remains is to polish it. Next comes the assembly work. You may have boards of different colors left. Why not put them to good use. For example, arrange the boards on the surface in such a way that they alternate in color.

The last stage of making the tabletop involves fastening the boards with nails. We secure the shelf from below with nails or self-tapping screws. Again, you need to polish the assembled product. And finally all that remains is to paint. But it happens that you made a mistake with the choice of varnish or paint. So what should we do then? If you want to change the appearance, you will have to re-sand the surface. Next you need to start painting again with a new color.

Table with glued surface

The difference between the previous options is that the legs of this design go in the letter “L”. They are assembled from boards of the same width and thickness (20 mm thickness). Since the volume of the legs here is larger than the previous ones, more screws will be required (5 pieces). You need to drill holes with a diameter of 1-2 mm in advance (the hole should be smaller than the diameter of the screw itself). The second time you need to drill a hole with a larger diameter. It is intended for the screw head, which is then covered with a furniture plug. In other cases, it is preferable to choose a furniture-colored rod.

Another great idea is furniture putty. Add wood dust to the mixture you will use to putty (take the leftover sanding). When the putty dries, traces of holes will be difficult to find.

Working on the legs

When assembling the legs, you need to carefully ensure that the angle is 90 degrees. If there is no pattern, use a regular beam. To join two boards, coat one and the other with wood glue. Install the screws in the required places. When the glue dries, coat each leg with varnish. But before that, don’t forget to sand it.

Assembling the tabletop

As the legs are done, the turn goes to the top of the table. The tabletop is made of boards of equal thickness. Choose the sizes you want. Boards can be of different widths. It is important to maintain an organic appearance. It is important that the side parts of the boards align smoothly with each other without gaps. We also lubricate the side of the boards with glue. Next, lay them flat on the surface.

To avoid possible gaps, tighten the boards with clamps. Leave the table surface overnight. After a day has passed, remove the clamps - the tabletop is already ready. As before, sand the surface and smooth out the edges. Using a jigsaw or saw, start trimming. Sometimes a grinder is also used, but in this way it is difficult to ensure an even line. And now the sanding stages are over, and you get a completely flat tabletop with a diligent appearance.

Glued board tabletop

Using the above method, make a round, oval or any other shaped tabletop. Of course, you can achieve evenness of the cut tabletop if you draw in advance the lines along which its shape is cut out. Frames can give an attractive look, but it’s better to make them with your own hands. Take a thin strip and sand it. Fasten according to the perimeter of the tabletop. Finishing nails and glue are suitable for fastening (first of all, you need to treat the planks with glue). The glue will dry, and the plank will need to be sanded at the joints.

There is no table without legs

The tabletop is ready, which means it remains to put the table on its feet. To attach the legs to the main part of the table, you will need a frame made of boards. It is attached to the back with glue. But this is not enough, because you need to secure it from above using confirmations. First, you need to drill holes on the tabletop with a diameter for the hat. And then mask them off like you did the previous holes. Now the table frame is firmly secured, begin attaching the legs. The connection point must be inside the frame. For fastening we use ordinary self-tapping screws. The table is ready!

Table and benches in the garden

When making tables and benches, boards of different sizes can be used. To connect the benches to the table, 16 cm studs are used (in addition to them, washers and nuts). Other connecting fasteners - no longer than 80 mm. So, each part of the garden table is installed in its right place. Then through holes are drilled with a drill. And then, as you yourself already understood, it’s time for the washers and nuts.

When tightening nuts and washers, it is better to use a wrench. Thanks to this approach, in winter you can easily unwind the structure and take it to a warehouse, garage, shed or any other place for storing similar things.

Each board should be carefully sanded and trimmed. To fasten the three boards that are intended for seats, you need to cut short bars. We cut each of them at 45 degrees. The first step is to start assembling exactly that part of the structure that is located below. We take one large board (160 cm in size) and attach small bars to it. At the moment of joining, they should be fastened in the middle of one large one. Now we add legs to this structure (fasten with nails). Add short boards again. All these elements need to be tightened with studs, bolts and nuts. This creates a support unit that secures the seat from below.

All that remains is to attach the boards for the seats. By the way, if this design is intended for the street, it is not at all necessary to create a narrow gap between the boards. At least 5 mm is sufficient. The planks are attached to sawn supports. We have formed two shops. It wouldn’t hurt to secure them with four 160 cm long boards. To secure all four legs, use 2 pins for each leg. Install them either at the same level or diagonally.

Table for kindergarten

The principle of assembling the table is completely different from previous options. The tabletop is supported on boards that are cut at 52 degrees on the sides. The sawn supports must be positioned in such a way that the legs for the table can fit between them. Secure them with finishing nails. If you do not want to allow the caps to be clearly visible, drive them deeper. Simply coat the surface with a special lubricant as a mask.

The table legs here are not standard, but look like crosspieces. To assemble them, take two boards and cross them in such a way that at the bottom the gap between the objects is 65 cm. In the middle of the boards, leave a mark for crossing the boards. The mark is drawn in the shape of a square and half the thickness of the board itself. The same thing needs to be done on the other board. We get two materials of the same plane. The joining process takes place using four nails. The second pair of legs is made by analogy.

Now we have to assemble the table as a whole. First of all, the most important thing is to secure two pairs of legs into the main structure on which the benches are placed. We place the legs parallel to each other in the middle. Naturally, they need to be secured with pins so that they do not fly off in the future. The tabletop is attached using a similar method. Once the studs are screwed in, start sanding and painting. Paint the structure in any color that suits you. In addition to this design, those options that involve a separate table from the benches are also acceptable. The structure is assembled in a similar way. Of course, except for the seats.

Making a wooden table with your own hands, as it turned out, is not so difficult. There are moments that require utmost attention to some things during manufacture. If you follow the above recommendations, your table will turn out perfect. The choice of good materials and proper execution of the work will ensure the product has a long service life. The design will impress with its functionality and decent appearance.

Video: DIY wooden table

Photo gallery: DIY table