Let’s agree right away: in this article we will only talk about autonomous heaters, that is, those that can operate when the car’s engine is turned off. Let us recall that standard heaters, as a rule, receive heat from the liquid circulating in the engine cooling system and, therefore, cannot heat the air in the cabin if the engine is not running and the liquid in the cooling system is not warmed up.

Those who know how important a auxiliary heater is prepare their truck or road construction equipment for winter long before the cold weather sets in. Summer is the most favorable time both for installing a heater (new or replacing an old one), and for its prevention or repair, because during this period the choice of heaters and spare parts for them is maximum, and there are no queues. But with the onset of cold weather (and this always happens unexpectedly), everything changes exactly the opposite: the queues grow, the assortment in stores is reduced. Nevertheless, now is not too late to talk about autonomous heaters.

All autonomous heaters intended for commercial vehicles and special equipment can be divided into two main groups: liquid and air. Their difference is that an air heater (the so-called “dry hair dryer”) heats only the air in the cabin, while a liquid heater heats the liquid in the engine cooling system, and only after the temperature in the cooling system reaches +40 ° C does it sends a command to the standard heater fan, which begins to pump warm air into the cabin. That is, the liquid heater needs to preheat the engine to heat the cabin.

The advantages and disadvantages of each of these two types of heaters are obvious: liquid, which is also a pre-start heater, allows you to warm up both the engine, which makes starting easier in any frost, and the cabin. However, this type of heater consumes more fuel and electricity. To heat the cabin of a regular long-haul truck, an air heater needs 2 kW of energy, and a liquid heater needs 7...10 kW.

The world leaders in the production of autonomous heaters are Webasto and Eberspächer. These German companies are the undisputed leaders in the market, which means that any European-made truck is equipped with a heater from one of these manufacturers, without any exceptions. Accordingly, any European manufacturer of heavy equipment has two suppliers of heaters - Webasto and Eberspächer. Typically, these units are installed in a 50 to 50 ratio on all trucks, which means that it is basically impossible to say what kind of heater will be on a new truck or excavator of any make and model. Every dealer will say that a 2 kW heater is installed on the truck without specifying its manufacturer, because the products of both of these manufacturers are absolutely equivalent. And although each of them has its own characteristics, it is impossible to say that one of these two brands is better.

If we talk about air heaters, then Eberspächer has a slightly more successful design of the fuel atomization unit - there is a simple mesh there, which is an evaporator. At Webasto, the evaporator is a rather complex unit, the repair of which is more expensive. In general, they are approximately the same in terms of reliability.

In addition, the world market also includes Czech air heaters Ateso, Russian dry heaters Planar, liquid heaters Teplostar from Advers, as well as Japanese Mikuni. Ateso heaters are used mainly in the secondary market of European countries and CIS countries, Russian heaters are used only in the post-Soviet space, and Mikuni heaters are used mainly in Japan.

In general, in the world, including in the USA, Webasto and Eberspächer are the most common. In our market, the Webasto brand is more popular, and many ordinary people even call any autonomous heater, be it on a truck or a car, by the name “Webasto,” just as the word “copier” has become a common noun. However, Webasto is a more well-known brand not only here, but also in Europe and throughout the world, although Eberspächer is no less serious and no less strong company, and both manufacturers are on the same level both in terms of sales volumes and the price of heaters, their reliability and level of fuel consumption.

An air heater (“dry hair dryer”) functions in the same way as a regular hair dryer, only the heater in it is not electric, but a torch, powered by diesel fuel from the main or additional fuel tank. Diesel fuel burns inside a special closed chamber, blown from the outside by a fan that supplies heated air into the cabin. Eberspächer models of this type are called Airtronic D2 and D4 and have a heating power of 2 or 4 kW, respectively. Webasto has similar models with a thermal power of 2; 3.5 and 5 kW are called Airtop 2000, Airtop 3500 and Airtop 5000.

The fuel consumption of a 2-kilowatt heater in maximum power mode is 0.25 l/h. In maximum power mode, these heaters operate only when they are turned on to quickly warm up the cabin, and then the heater automatically switches to reduced power, consuming correspondingly less fuel. Therefore, as practice shows, the average fuel consumption of such heaters does not exceed 0.15 l/h. Liquid heaters have significantly higher fuel consumption. So, for a 4-kilowatt unit in maximum power mode it is 0.6 l/h.

European manufacturers provide a two-year warranty on their heaters, but diesel fuel in Europe is of much better quality than ours. And cleanliness in the cabin has a significant effect on the performance of the heater, because during operation it, like a vacuum cleaner, draws in air, and with it dust and dirt. And when the blower fan jams, the heater instantly fails, since if its combustion chamber is deprived of airflow, it instantly overheats and is deformed as a result.

The heater kit does not include a fuel tank, since the manufacturer provides for its connection to the main fuel tank. In Russian conditions, it is more correct to use an autonomous tank; it is usually installed on the rear wall of the tractor or on the front wall of the van. The fact is that none of the imported heaters “like” our winter diesel fuel. It differs from the European one mainly in the presence of additives, which are used to turn summer diesel fuel into winter fuel.

Diesel engines equally successfully “eat” both European and Russian diesel fuel, since combustion there occurs at high temperatures and pressure, while in heaters “our” additives do not burn completely and accumulate in the combustion chamber in the form of a liquid mass resembling tar, due to which the unit fails. Moreover, this applies equally to both dry and liquid heaters.

That is why it is recommended to install a separate 10-liter tank on the truck and fill it with “summer” diesel fuel, and to prevent it from freezing, add kerosene to it. In principle, gasoline can also be added instead of kerosene, but only A-76, since all other brands of gasoline also contain additives that do not completely burn in the heater.

If you use normal diesel fuel, there will be no problems with heaters. Those who installed a separate tank and fill it with “summer” diesel fuel with kerosene may not appear at the service for years. But if you fill the autonomous tank with diesel fuel from the same gun as the main tank, the bad diesel fuel quickly does its job - it happens that a week after installing the heater, the car arrives with a complaint about its failure. After disassembly, half a liter of an incomprehensible “tar-like” liquid leaks out of the heater, and in this case it is necessary to change at least the mesh, but often the glow plug, which ignites the fuel in the combustion chamber, fails.

The resource of a modern heater is quite large. For example, for his compressor it is 5000 hours. Complaints that combustion chambers in “dry hair dryers” burn out can only apply to Eberspächer heaters of the very first models - D1L and D3L, the “youngest” of which is now more than 20 years old. This is purely due to age and is the result of normal wear and tear.

If the heater is handled correctly, filled with the recommended fuel and the cabin is kept clean, it will only require preventive cleaning, which is best done annually, or once every two years if good diesel fuel is used. In this case, the heater is dismantled, disassembled, the combustion chamber is cleaned and the evaporator mesh is replaced. Such work costs about 110...150 dollars.

Preventative cleaning is required for the simple reason that carbon deposits are deposited on the walls of the combustion chamber, which reduces the size of the combustion chamber, impairs thermal conductivity and heat transfer, and this reduces the efficiency of the heater, its service life and increases fuel consumption.

The optimal time for preventative cleaning is the beginning of August, since with the onset of frost, when most drivers and car owners think about heaters, queues invariably form at the service.

It should be emphasized that it is advisable to start autonomous heaters for preventive maintenance during the warm season, at least once every two weeks for 15…20 minutes. No equipment likes long periods of downtime, and the heater must work to warm up and disperse the lubricant through the bearings: then it will last longer.

Modern autonomous heating equipment is quite reliable and does not accidentally fail. All of them are equipped with a control unit that monitors operation and has many degrees of protection, which is primarily explained by the use of an open flame in the combustion chamber on the car. If any malfunctions occur, the control unit generates an error code, by which you can easily determine what needs to be replaced: a compressor, a spark plug, a flame sensor, an overheating sensor, or something else. All of the above applies equally to both air and liquid heaters.

It would seem that all cars are now equipped with autonomous heaters, however, the demand for the installation of these devices is now quite high. First of all, this applies to old trucks whose heaters have expired (the same D1L and D3L) and the cost of repairing them will be close to installing a new heater. Cars made for warm regions also need a heater. The same applies to cars produced in the CIS countries, where until recently additional heaters were considered a luxury element.

Over the past few years, any European-made truck equipped with a sleeper must be equipped with an autonomous heater. Previously, there was no such strict requirement, and any buyer could refuse an autonomous heater, thereby reducing the cost of the car. Now such cars are also “consumers” of new heaters. It happens that the car is not equipped with a sleeping place, but is often in standby mode for loading and unloading, and then in order to warm the cabin, you have to start the engine. To avoid excessive fuel consumption in such cases, it is also advisable to equip the truck with an autonomous heater.

It is difficult to say unequivocally which heater is better - air or liquid. In Russian conditions, it is still preferable for a truck and special vehicle to install a “dry hair dryer”, which is currently equipped at the plant with most of the equipment.

Currently, many owners of cars and construction vehicles equipped with liquid heaters at the factory are asking for additional installation of air heaters, because a liquid unit consumes not only more fuel, but also more electricity. If the batteries are weak and the frost is severe, such a heater, after working all night, will use up almost the entire charge of the battery; it will not be enough to start even a warm engine. Among other things, repairing liquid heaters is more expensive than air heaters.

The ideal option is if the truck has both liquid and air heaters, but this will also be expensive. And yet, cars operating in Russia and making flights to Scandinavian countries cannot do without this, because there are often frosts below minus 40, when it is problematic not only to start an unheated diesel engine, but also to warm it up to operating temperature while driving.

When operating a truck or, for example, a bulldozer mainly in central Russia, you can, of course, get by with an air heater, although it is clear that for pre-heating the engine there is nothing better than a liquid heater.

As for the cost of air heaters, a 2-kilowatt Eberspächer Airtronic D2 with an autonomous tank will cost 1,180 euros, including installation costs. Installation of a similar Webasto Airtop 2000 heater will cost 970 euros, a 1.9-kilowatt Ateso Breeze will cost 875...920 euros, a 3.8-kilowatt Ateso Wind 4W will cost 1,035...1,075 euros and 1,150...1,200 euros for an 8.2-kilowatt Ateso X7. And for 26 thousand rubles. you can install a 4-kilowatt “Planar” 4D.

The price of a liquid heater can vary greatly depending on the presence of certain control elements (mini-timer, modular timer, radio control, etc.) and is approximately 2000 euros for 10-kilowatt Webasto and Eberspächer models, while a 10-kilowatt Russian "Teplostar" 14TS-10 can be installed for 26...27 thousand rubles. It should be noted here that Russian heaters are perfectly adapted to domestic diesel fuel and are very unpretentious, but they consume more fuel than their modern European counterparts. Nevertheless, the same “Teplostar” can be used as a pre-heater.

Hannover's new Webasto products

At the Hannover International Commercial Vehicles Exhibition IAA 2008, Webasto presented new, improved models of autonomous air heaters of the Air Top Evo series mod. 3900 and 5500. Thanks to the improved combustion process, the fuel consumption of both models is very low. In maximum power Plus mode, the unit produces 3.9 kW of thermal energy while consuming only 0.49 l/h of fuel. Maud. 5500 consumes fuel from 0.19 to 0.63 l/h. In Plus mode, the unit consumes 0.69 l/h, developing a thermal power of 5.5 kW.

The heater can be equipped with the Thermo Coll function - turning on the heater via a cell phone. It is also possible to equip the unit with remote control devices.

The company also demonstrated improved models of compact autonomous liquid heaters of the Thermo Pro series mod. 50 and 90, which now have a longer service life of about 5000 hours and are capable of running on biodiesel fuel.

The heaters can be used both as pre-heaters and as additional heaters while the machine is operating. At the same time, they are characterized by high fuel efficiency.

Maud. 50 develops a thermal power of up to 4.5 kW, and a thermal power of mod. 90 is infinitely adjustable from 1.8 to 9.1 kW. The heater is capable of long-term and stable operation even in maximum power mode, for example, on snow removal machines.

The control systems of both models are CAN bus compatible, allowing them to be integrated into the overall electronic control system of modern trucks.

It has long been known that a comfortable temperature for a driver is the range from +21...23 degrees Celsius. Low temperatures negatively affect concentration and alertness while driving, causing irritability. And safety is affected by driving with limited visibility due to icy windows.

If you have at least once had to get to your car in a parking lot in severe frosts or simply get into an icy car interior after leaving a warm home, then you know firsthand that this feeling is not a pleasant one. And how I would like to warm up at this moment. You can, of course, run around the car or leave the snow while the interior warms up, but there are also less radical methods. As always, there is a way out and it has long been known among motorists - an autonomous one, which will gladly give you comfort.

Do-it-yourself autonomous interior heater (12 volts)

The market offers a wide range of different autonomous stoves of different types and layouts. They all have their pros and cons. But if you live by Ferdinand Porsche’s principle: “If you want something done well, do it yourself,” then the information in this article will be very useful for you. So, let's get straight to the point.

In order to assemble an autonomous interior heater, you do not need to reinvent the wheel. It is enough to familiarize yourself with the methods of air heating that have long been known to us and adapt them to the necessary requirements. Let's start with what we need:

- Power supply;

- A heating element that will convert absorbed energy into heat;

- to create a flow of warm air;

- Heater control mechanism;

- Fuse.

As a power source for a 12 V heater, we will take a rechargeable battery and a car generator. We advise you to get a battery charge indicator, since an autonomous stove will be a good consumer of energy.

The choice of heater is as obvious as in any heating element - a nichrome spiral. Due to its properties, nichrome (an alloy of nickel and chromium) has a high resistance, but is still a conductor, so it gets very hot when an electric current is applied.

To create air flow, we will use a regular cooler, for example, from a computer power supply. The power supply housing itself can be used as a . And the button placed on it is like a heater control mechanism (for proper and safe operation it must be connected via a relay).

The connection diagram of the autonomous heater must be interrupted by a fuse of the required rating. The closer it is located to the battery, the less likely it is to damage the vehicle's electrical wiring in an emergency.

We figured out the general design. But this, as practice shows, is not enough. It is also important to select the resistance of the heating elements and their connection diagram in order to prevent overloading the on-board electrical network. Which, as a result, will lead to battery discharge. We will try to select the optimal current consumption. For example, for a Daewoo Lanos car with a Bosh or Hella generator with a charging current of 85 A. For such a power source, a consuming current of 10–15 A will be almost unnoticeable.

Let's start with the assembly itself. We install the entire autonomous heater into the computer power supply housing. We attach nichrome spiral threads to ceramic tiles using bolts and nuts. When installing tiles into the housing, the main thing is to ensure that the air flow passes through the heating element, taking away its heat.

It is important to select the cross-section of wires for connection, taking into account the calculated current strength. For example, for a 10 A copper wire you need 1 sq. mm section. The fuse is also selected according to the calculated current strength.

A twelve-volt autonomous interior heater will bring twice as much pleasure to the owner, since he not only made his car more comfortable, but also saved the budget. Now you are not afraid of any frost and the fear that the standard heater will fail at the most inopportune moment. If the rear window heating fails, it can be heated with a similar heater. Still, don’t forget to insulate your car. To do this, you need to replace the old door seals, and also treat the car with thermal insulation so that it does not release precious heat into the atmosphere.

Remember how the great Mendeleev was indignant: “Oil is not fuel, you can heat it with banknotes!” But then the scale of extraction and combustion of this valuable chemical raw material could not be compared with today. And even today, when almost all transport is powered by petroleum products, heating boilers with fuel oil is considered a luxury due to poverty and despair - in developed countries they use much cheaper and renewable energy sources. But all these macroeconomic truths are negated by a simple everyday situation: night, frost, a KAMAZ with a truck on the side of the highway... And the driver is faced with a dilemma: whether to use engine cylinders as heating boilers, directing the instantaneous fuel consumption parameter to infinity, or, tightening the of that steppe and the deaf coachman froze...", repeat the fate of the hero of the folk song?

Money down the drain

At idle, a Kamaz engine consumes about 8 liters of fuel per hour, and the engines of most foreign-made tractors, threshing in place, are not particularly economical. Simple calculations show that even in the temperate climate of central Russia, at least 60,000 rubles are wasted every season on heating the cabin during overnight stops! From every car. And this does not take into account the costs of premature overhaul of the engine, hundreds of hours of idle rubbing of the cylinder pistons. What can we say about our northern regions, where in the days of state diesel fuel there was a “good” tradition of starting the engine at the end of October in order to turn it off at the beginning of April... Pre-start heaters helped to avoid such barbarity, and “autonomous cars” were produced for army-spec trucks "with the supply of combustion products to the engine sump, which, in the absence of current oils, ensured the melting of the gel-like M8G2 and subsequent start-up even in bitter cold. However, the pre-starter does not solve the problem of heating the cabin - driving heated antifreeze through the cooling system, it dissipates most of the power - at least 14 kW out of 15 developed - in the engine compartment, that is, it mainly heats the environment. In addition, the pre-starter will heat the standard KAMAZ “stove” simultaneously with the heavy engine, that is, for a very long time and a maximum of 60 degrees. Which is clearly not enough in severe frost - even sitting behind the wheel will be cold, not to mention sleeping. And the roar of a 15-kilowatt burner is not very conducive to sound and healthy sleep. Autonomous liquid heaters also have an objective technical drawback - high (90–130 W) electricity consumption by the water pump - there are often cases when an old battery is completely “dead” in the morning, and instead of going to the line in a warm cabin, the driver is faced with fiddling around in the cold with wires and Katyusha. It is no coincidence that when pre-starters are optionally installed at the factory, for example, on German cars, an additional battery is usually included with the heater. Another thing is the air “autonomous” vehicle, which works on the principle of a hair dryer, as, by the way, it is called in driver’s slang. Cooling of the heat exchanger by the flow of air taken from the cabin and, naturally, leaving back into the cabin, is not as intense as with liquid, therefore, with equal power, the “hair dryer” turns out to be larger than the pre-starter. But he doesn’t need the power of the latter, because almost all the energy from the burned fuel (with the exception of 3–5%, which is carried away by exhaust gases heated to 300–400°C) is released in the form of heat in the car cabin, then dissipated into the environment by its walls and glasses. Two kilowatts for the “air blower” is enough to give the driver of a long-haul truck or the driver of a truck crane, excavator, etc. a real “Tashkent”. With a power of 4 kW, there is more than enough heat even for a winter overnight stay in Yakutia, but 8-9 kW units heat the interiors of large buses. The much smaller volume of the flame ensures quiet operation - there is no trace of the roar of a “blowtorch”, like with a liquid heater. Only low-power consumers consume energy from the battery - even in the 4-kilowatt maximum output mode, the current from a 24-volt battery does not exceed 2 A, and with a power of 1.5 kW - only 0.5 A. That is, during a long winter night the battery does not will spend even a twentieth of its capacity. Fuel consumption in such a moderate mode will be about 0.2 liters per hour, that is, 40 (!) times less than that of a KAMAZ engine at idle. But not only savings play in favor of an autonomous heater - the growing intolerance of society towards air pollution is also important. European culture is gradually penetrating among our truck drivers - many of them, having traveled around the world and installed all sorts of “airtronics” in their cabs, have already begun to forget how they once coughed at night, inhaling the blue smoke from their own and their neighbors’ diesel engines. Today, if you don’t turn off your engine in a shared parking lot, you run the risk of hearing a baseball bat knock on the door within five minutes. And when you settle down with your rattling car for the night in the city, an empty bottle will be thrown from the balcony immediately “to defeat” - into the roof of the cabin. Without a warning throw onto the asphalt... And don’t be surprised that it was the Germans, with their warm winters, about zero degrees, who became adept at producing autonomous heaters. Yes, in Europe, truckers - all of them - sleep in comfortable three-star motels, but they also have to stand for an hour or two in a warehouse or customs office under the chilly Baltic wind. What else can you do to warm yourself up, if not a hairdryer, when the law prohibits threshing at idle? In Russia, the path of distribution of air heaters is painful, long and thorny - among the people, this type of “stove” is firmly associated with the word “Zaporozhets” and is subjectively perceived as a thing of poor quality in its essence. Experienced drivers still have fresh in their memories the pictures of “humpbacked” and “big-eared” cars suddenly smoking right on the move, and some have forever imprinted the sight of a burning gasoline track running after a car with an unsuspecting driver... The extreme capriciousness of autonomous heaters (them for Melitopol minicars were produced by the Shadrinsk Automotive Unit Plant) forced the owners to look for any alternative, such as winding thick copper wire on the exhaust pipes to directly transfer heat to the cabin - just to get rid of the hated, annoying smell of gasoline and burning unit. But years passed, a wave of “used” foreign cars, including minibuses, rolled in, and Russia finally learned what an autonomous heater “made by hand” is. With skillful hands...

Everything ingenious is simple

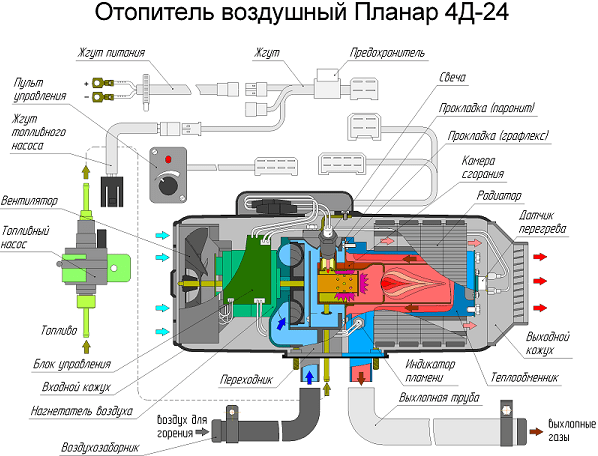

So, let’s take a closer look at the “air vent” device. The principle of operation of products from different manufacturers is the same - fuel supplied by an external electromagnetic pump embedded in the line closer to the tank (pumping is always easier than sucking in), dosed, under electronic control, enters the combustion chamber, or rather, the evaporator. The latter is a heat-resistant body with a fairly large surface area - usually a package of wire mesh made of refractory “stainless steel”. An electric glow plug with a ceramic rod is installed in front of the evaporator (open coils are a thing of the past). Air is supplied to the combustion chamber by a supercharger driven by the electric motor shaft; there, at the cold input end of the heater, there is an electronic control unit - its microcircuits are not in danger of overheating. The fins on the outer surface of the heat exchanger, where hot gases from the combustion chamber enter, are blown with air from the cabin - it is driven by a fan mounted on the electric motor shaft behind the supercharger impeller. A wiring harness is laid from the unit to the control panel installed on the instrument panel, and since the communication channel on modern units is usually digital, only three wires are enough: “plus”, “minus” and signal. Using the rotary control or buttons on the remote control, you can set several heater operating modes - depending on the selected one, the processor will set the required fan rotation speed and fuel supply volume. Sensors monitor the maintenance of temperature: one can be built into the control panel or at the entrance of the air flow to the heater, the other can be remote, and it is placed, for example, near the bed, with a separate bundle of wires stretched there. The heat exchanger overheat sensor (thermal switch) is a safety element; it sends a signal to the control unit, demanding that the fuel supply be stopped.

When the heater is turned on, the processor diagnoses all systems and launches the program. The voltage at the glow plug gradually increases, then fuel and air are supplied to the combustion chamber, and the combustion process begins, controlled by the control unit based on signals from the flame sensor built into the heat exchanger. When combustion stabilizes, the candle is turned off, and the flame is subsequently maintained by a continuous supply of fuel. If for some reason ignition does not occur - for example, due to thickening of summer diesel fuel in cold weather, the entire cycle is automatically repeated. After two unsuccessful attempts, the heater automatically turns off, the indicator on the control panel lights up, and at the command of the processor, the supercharger purges the combustion chamber for several minutes. After which you can try to ignite again. However, if the fuel corresponds to the season, then such emergency situations on a modern heater that undergoes regular cleaning of carbon deposits are extremely rare, and after ignition, the control unit maintains combustion at maximum mode, comparing the temperature value set by the driver on the control panel with the air temperature in the cabin. If the latter is lower than the set value, the heater continues to operate at full throttle, and when it reaches the desired value, the fuel supply is reduced. It happens that the cabin becomes even hotter than required - then the processor gives the fuel pump a break, and orders the supercharger to purge the combustion chamber with fresh air. When the temperature drops, for example, 2 degrees below that set by the regulator, a digital command is received: “Mahmoud! Light it up!”, and the procedure for heating the spark plug with subsequent fuel supply is initiated according to the above-described scenario. As you can see, the claimed autonomy of air heaters from all companies, without exception, is very conditional, since any such unit is rigidly tied to the car battery, and the death of the battery far from populated areas is fraught with the death of the driver. However, designers are in no hurry to create completely independent “hair dryers”, although, at first glance, there are no technical obstacles to this. Really, what are some 40 watts consumed from the battery if an excess of 2 kilowatts are released during fuel combustion? Why can’t the shaft be rotated by a flow of flammable gases? Why does a “hair dryer” even need an electric motor? And the thermocouple will fully support both the fuel pump and the electronics. Ignition - with a squib. And no battery is needed. Alas, not everything is so simple. The vague resemblance of the “air vent” to a gas turbine engine means nothing, and by forcing the flame not only to heat, but also to rotate, we will create an almost unsolvable noise problem. That is, you will have to sleep under the howl of jets. Not to mention the inevitable difficulties with extracting heat from exhaust gases, because no one needs a “stove” that eats fuel like an airplane. And in terms of technology, a turbine and a hair dryer, to put it mildly, differ - a cabin heater for about twenty thousand (euro) is unlikely to find demand. So, in the foreseeable future, we can’t expect fully autonomous “aircraft”.

Air heater: choose me

And now about the features of heaters of specific brands. The German "autonomous cars" Webasto and Eberspaeher are considered reference - many of the technical solutions implemented by the engineers of these companies regularly appear on competitors' products - with or without licenses. The main feature of the thoroughbred Germans is a solid-cast aluminum heat exchanger; this design provides the best efficiency of the unit, but requires a fairly high production standard. The prices of heaters from both companies are approximately the same - about 29,000 rubles for a 2-kilowatt “air vent” and about 37,000 rubles for a 3.5-4-kilowatt one. One of the unprincipled differences between different design schools is in the shape of the evaporator: Webasto places it around the perimeter of the combustion chamber, and Eberspeher - at the end. Webasto has a brushless electric motor, a low-noise fan and a combustion chamber with a heat-resistant cermet gasket. A wide range of permissible positions allows the heater to be installed at an angle of up to 90 degrees from the horizontal. Webasto's strong point is convenient diagnostics: using switch or timer signals, exhaust gas analysis or using a computer. The self-diagnosis system displays malfunctions by issuing one of 15 codes. The temperature regulator is also a heating switch. A remote temperature sensor on a cable up to 5 m long is an option. The Comfort kit includes a timer that turns on the heater at the set time. Air Top - this is what Webasto designates for most models in its line of “air vents”. Modern models of Eberspaecher air heaters are called Airtronic - four are enough to cover the power range from 2 to 8 kW. Among the advantages are high efficiency and a silent fan with stepless rotation speed control. The option list includes a radio remote control system with a range of up to 1000 m.

The Czech company Brano is represented by two models: the 2-kilowatt Breeze III and the twice as powerful Wind III. The design of the heat exchanger is like the Germans, that is, aluminum casting, and the prices are more attractive. The temperature adjustment is smooth - from 15 to 30 ° C, among the options there is a timer.

“Air vents” from Mikuni, the same company that is famous for its carburetors, are exotic in our market. The design is of good quality, since it is based on a license from Eberspaecher, but the lack of a network of service centers as wide as the Germans have is still holding back the spread of heaters famous for their Japanese quality.

The oldest domestic manufacturer of autonomous heaters is SHAAZ. Ancient and very low-tech, as befits the defense industry, the design of Shadrin heat exchangers (they are welded by hand from stainless steel) has one significant advantage over German casting - production flexibility. It would be as easy as shelling pears for a plant to master a heater for special purposes and a special configuration - if only there was a customer with money. The buyer of a large-scale heater can only rely on the qualifications of the welders - if the heat exchanger is made conscientiously, there will be no fistulas or other holes fraught with the penetration of carbon monoxide into the cabin. 5 models of “air ventilators” of traditional design remain in the SHAAZ production line - with a power from 2 to 11 kW, and, in addition, two new units with electronic control have gone into production: 2 and 8 kW. But they are much more expensive, for example, 02 costs 16,000 rubles versus 10,000 rubles for the equal-power O15.

At the Rzhev Eltra-Thermo plant, on the contrary, they used the most advanced solution, making the heat exchanger one-piece, like the Germans. Moreover, the aluminum fins in it are hollow, that is, the surface heated from the inside by flammable gases is much larger than that of heat exchangers of foreign analogues, which gives good prospects for increasing efficiency. So far, the Rzhevites have only one “air” model - “Pramotronik-4D-24”. The kit for 13,000 rubles includes a 12-liter tank for autonomous power supply of the “stove”, diesel fuel diluted with gasoline - in severe frost.

The Samara plant "Advers", which supplies its "Planar" heaters for the assembly of KAMAZ vehicles, truck cranes and other special equipment, offers "air vents" not only in 24-volt, but also in 12-volt versions, because, for example, American trucks have "passenger" » on-board voltage.

The design feature is an aluminum heat exchanger assembled from two halves. The price of a set with a 7.5-liter tank is 12,500 rubles. Gas fuel heaters stand apart on the market - they are made by the German company Truma. The demand for these is very limited, but for an old gasoline tractor converted to propane-butane, you can’t think of anything better than the 2.4-kilowatt Trumatic E 2400 unit.

Waiting for many hours in a car in a traffic jam or, worse, spending the night in an open field in the cold inevitably leads to the idea that an autonomous interior heater is by no means a whim of a hunter-fisherman or an attribute of a professional driver’s motor home.

In cold or slight frost, every hour we warm up the engine to a more or less comfortable temperature of 60-70 degrees. At -20 o C you have to warm it up every 35-40 minutes at medium speed so that the battery does not die. If an additional electric pump was installed on the stove, we use the heated motor as an autonomous heat source. Depending on the level of insulation of the cabin and the air temperature, the engine cools down in 2-3 hours, the car interior cools down twice as fast.

After 6 hours of waiting, there is a risk of being left with an empty tank and a dead battery. In search of protection from the approaching cold, the driver is ready to buy or make an autonomous interior heater with his own hands. The situation encourages us to think about the benefits of an additional autonomous heater for the car interior better than any advertisement.

It is worth admitting that the standard configuration and equipment of the car are not suitable for long-term parking in the cold. When buying a car, few people want to spend money on additional equipment for the car with a potentially unnecessary unit. But reality makes its own adjustments. The standard version of interior heating is only good when driving. The operation of a car engine as a cabin heater is ineffective; 95% of the heat flies out into the chimney.

Modern designs of an additional interior heater for heating use the following options:

- the heat of air flows flowing around a hot heat exchanger, heated by the flame of an internal burner device; this option is called an autonomous air heater for the car interior;

- the classic option is heating the air by the surface of a heat exchanger, through which an additional amount of coolant heated to a relatively low temperature is pumped through a pump;

- heating using an electric coil made of a metal alloy, a ceramic element or a special metallized carbon fiber fabric.

Car interior air heater

Is a leader in choosing professional drivers. The cost of purchasing and installing an autonomous air heater is approximately half the cost of fuel used to warm up the interior during a year of operation of the tractor.

The structure and design of the air-powered autonomous interior heater is, in general terms, similar to a primitive starting heater. Unlike the latter, an autonomous heater uses air for heating and is installed directly in the cabin or interior of the car.

The heat generated by the combustion of a small amount of fuel in the combustion chamber is transferred through an aluminum heat exchanger to the air flow forced by a low-noise fan into the cabin. Combustion products are discharged through a metal heat-resistant hose outside the cabin. The fuel is stored in a tank, usually located on the rear wall of the tractor cab. A control panel and an air intake regulator are installed in the cabin. On average, an autonomous device consumes 200 ml of fuel per hour with a battery load of 40-50 W. Thermal power ranges from 2 to 7 kW/h.

Modern long-haul trucks and heavy construction equipment are equipped with a 24-volt diesel autonomous interior heater, which is due to the characteristics of the fuel used and the voltage of the on-board network. American tractors use the power supply voltage of passenger vehicles, so an autonomous 12-volt diesel interior heater is installed.

The most respected and respected diesel car interior heaters are Airtronic (Eberspacher) and Air Top ST (Webasto). German quality, trouble-free operation and convenient operation correspond to high product prices. Among the advantages of branded autonomous heaters:

Among the Russian models, it is worth mentioning the own development of the Samara company Teplostar - the autonomous cabin heater Planar. At a low cost, it is unpretentious and reliable. It uses diesel fuel and is controlled manually from a remote control inside the car. The Planar-4D heater model, consuming 0.12-0.4 liters of diesel per hour, is capable of heating the interior of a bus with 30 seats.

Gas interior heater

It should be noted that diesel and gasoline autonomous interior heaters have a serious competitor - a gas car interior heater that uses natural gas or propane-butane as fuel. It is worth noting the autonomous interior heating devices of the German developer - the Trumatic company, whose products are distinguished by:

- the quietest, almost silent operating mode,

- high efficiency - 97%;

- complete absence of the smell of combustion products characteristic of diesel fuel.

For your information! According to operating conditions, an autonomous gas-powered heater is allowed for use even in residential or temporarily inhabited premises.

Gasoline autonomous heaters are used mainly for use in conditions of low temperatures and severe frosts in the northern climate zone.

Is it that simple?

Given the apparent simplicity of the heating principle, an air-powered auxiliary heater can hardly be considered as an additional interior heater that can be manufactured with your own hands. In conditions of home-made production, it is practically very difficult to fulfill the requirements:

- to the quality of welding of elements, taking into account the specifics of the thermal load and deformation of the mating elements;

- to the reliability of control systems necessary for the operation of an autonomous heater;

- to prevent deviations from the specified combustion mode, the formation of a large amount of carbon monoxide, burning of the chamber walls and, as a consequence, mixing of combustion products and heated air;

- to ensure control of the launch procedure without the risk of fire.

For your information! In some hunting lodges on wheels, there are designs that use converted gasoline or gas blowtorches and kerosene stoves as an autonomous heater. But this is rather an exception to the rule. This method does not require automation or special control, but can hardly be used in passenger cars and trucks.

Another heating option

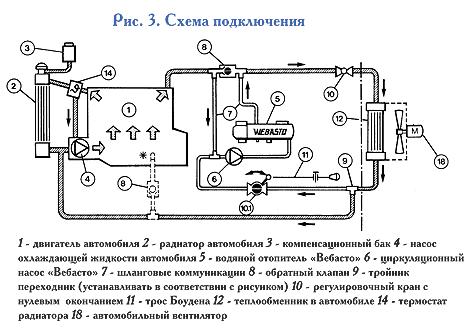

The classic version of an autonomous heater is a scheme where two circuits are simultaneously assembled in the heating device - an engine antifreeze heating circuit and a heat exchanger for the coolant sent to the cabin heating system.

There are options for an autonomous heating system with minor modifications that have a connected thermally insulated container or hot water tank in the interior heating system. Such a boiler plays the role of both a heat accumulator and a source of hot water. An additional pump pumps and heats the container operating in boiler mode. This type of autonomous heater is most often used for mobile living quarters - mobile homes.

Third option

An electric auxiliary heater, colloquially referred to as a “hairdryer,” serves to quickly warm up the interior at low air temperatures. If your car has a battery with a capacity of at least 75 Ah, use an electric car interior heater, which is structurally a 12-volt analogue of a hair dryer, with the difference that instead of a 220 V home power supply, the voltage of the 12 V battery and generator is used car. You shouldn’t expect African heat in the cabin, but while the car’s heater is warming up to the desired 70-80 o C, such a car interior heater, powered by a cigarette lighter, is indispensable if you urgently need to warm up a lock or remove frost from frozen glass.

Disadvantages of the hair dryer:

- low thermal power and heating speed;

- the need to have a “healthy” and fully charged battery and a working generator.

- the heating element of the “hair dryer” heats up to a high temperature and partially burns the oxygen in the air in the cabin.

- Handling the heater requires care to prevent possible contact of flammable substances with the heating element.

The easiest way to make an autonomous electric car interior heater is to make it yourself using an electric fan powered by a cigarette lighter.

The most common and affordable heater design is a circuit consisting of a 12-volt fan-cooler, used in power supplies and computer cooling systems and a heating panel. The latter is made in the form of a frame or tube made of non-flammable and dielectric material. Elements of covers and housings of powerful electric starters made of textolite or fiberglass are suitable.

As an option, a nichrome spiral stretched on special ceramic mounting chips can be used as a heating element for an autonomous heater. In this case, the panel can be made from any heat-resistant material.

Advice! If the electric fan is supplemented with a low-resistance variable resistance, we obtain an autonomous electric interior heater with controlled air flow speed and temperature.

Our additional interior heater operates from a cigarette lighter and a voltage of 12 V, so we use low-resistance nichrome wire in the design:

- Using a tester, measure the resistance of 1 m of wire;

- to obtain a maximum current of 5 A, cut a length of nichrome with a resistance of 2 Ohms and make a spiral by winding the wire around a rod or pencil;

- slightly stretch the resulting spiral so that the distance between the turns of the spiral is at least 2-3 times the thickness of the wire;

- Based on the obtained length of the spiral, we will select the dimensions of the heating panel such that there are at least 4-5 rows of the heating element in the cross-section of the frame.

- Let's fix the spiral on the mounting frame, install the fan and connect a two-core cord with a wire cross-section of at least 1.5 mm 2 to the output contacts.

After assembling the design of the autonomous electric heater, we test it by connecting it to the battery terminals for a short time. If the installation is performed correctly, the heater spiral should not heat up to a “red” state; the direction of movement of the air supplied by the fan must correspond to the calculated one. Otherwise, it is necessary to change the connection polarity and take it into account when connecting the power plug to the cigarette lighter.

Important! Take care of the quality of the wiring contacts, since cooling fans from computer equipment easily fail when the contacts spark or short-term voltage surges.

Video on how to make a cabin heater yourself: