Mini-hydroelectric power station - Leneva's dam-free hydropower unit - with a river flow speed of 1 m/s, a mini-hydroelectric power station installation with dimensions of 1.5 * 0.7 * 0.6 m produces 11 kW.

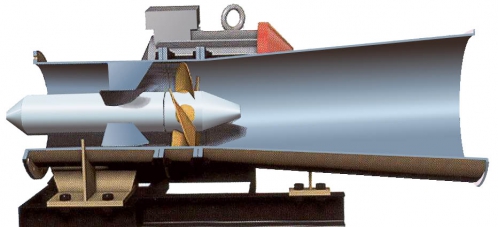

Mini-hydroelectric power station - Leneva hydropower unit:

Mini-hydroelectric power station - hydropower unit Leneva N.I. uses original, not previously used in any of the existing structures, a method of obtaining energy both from water flow of any kind (rivers, streams, tides, sea waves, etc.) and from movement air masses. In this case, the natural flow is used, without preliminary transformation (construction of dams, canals, pressure pipes).

This method of extracting the power of the water flow is the most beneficial from an environmental point of view, since it does not at all disturb the natural bed of the river, occupying from 1% to 10% of the area, thereby not interfering with the free movement of river fauna and flora, unlike existing hydroelectric power stations .

At a river flow speed of 1 m/s hydropower unit Leneva N.I. dimensions 1.5*0.7*0.6 m produces 11 kW.

Design of the Leneva hydropower unit:

Mini-hydroelectric power station - Leneva hydropower unit is a system (two rows) of blades rectangular shape(flat plate) whose axes divide them into two (1/2) unequal parts, the larger of which is always (due to the action of the flow) located behind the axis further down the flow. This ensures minimal rotation around its axis and, consequently, minimal turbulent turbulence.

The axes of the blades, with their upper and lower parts, in turn, are fixed on the upper and lower, closed in rings - PRL chains (or on any other flexible element). The chains transmit force through sprockets (impellers) to two vertical shafts, from which the mechanical energy of the moving medium (water, air, etc., etc.) through a flexible coupling and intermediate shaft is transmitted to the shafts electric generators. The installation shafts through sliding (rolling) bearings are rigidly fixed to the frame of the hydraulic power unit, which has 2/3 closed side walls and a blank bottom wall, which does not prevent the flow of additional water from the surrounding flow through the top and 1/3 of the side walls of the hydraulic power unit.

It is rational to place at least three in one frame block installations of mini-hydroelectric power stations.

The position of the blades in relation to the main flow is regulated by fixed guides for the chain and movable ones for the larger side of the blade, and by changing the distance between the movable guide for the blade and the fixed one for the chain, we set required angle rotation between the blade and the direction of the main flow from 0 0 to 45 0, thereby achieving the optimal operating mode of the hydraulic power unit or stopping it completely. Thus, the flow acts on the blade virtually perpendicularly, at 90 0. One of the shafts of the hydropower unit has stretching device regulating chain tension. The blades must have freedom of rotation on their axes, and the axes must also rotate freely when attached to the chains. Between the blade and the place of attachment to the chain, rollers must be installed on the axles, which will roll along fixed guides, thereby keeping the chain constantly in a perpendicular position relative to the direction of the main flow.

The sizes of mini-hydroelectric power stations are not limited. Determined by the required power and size of the river. As an example, let’s take: width – 1200 mm, depth – 700 mm, length – 1250 mm, i.e. volume – 1 m3. It allows you to place 3 installations with 17 blades in each, which, in turn, have a width of 150 mm and a depth of 500 mm, i.e. each area is 0.075 m2. Since two blades will always be on the turns, then the total working area of one hydropower unit installation is 1.125 m2, the sum of 3 mini-hydroelectric power plant installations in one frame (1 m3 of flow) will be 3.375 m2!!!

The shaft rotation speed is only 30-60 rpm.

It is this design of the hydropower unit that allows for the fullest use of each cubic meter flow of a moving medium, resulting centrifugal and centripetal accelerations, significantly increasing both the speed of the flow and the effect of gravity of the flow of a moving medium, in our case a river, divided into sections.

The material consumption of one kilowatt of mini-hydroelectric power station, depending on the materials used for production, will vary from several hundred grams (plastic, ultra high molecular weight polyethylene) up to 2-3 kg (steel) per 1 kW of installed power.

Description of the operating principle of mini-hydroelectric power stations:

Hydropower unit Leneva N.I. creates in front of it a small backwater of 10 centimeters at a flow speed of 1 m/sec, and behind it - a vacuum, and therefore the water falling from this backlash affects the blade at a different speed than in the surrounding flow. If there is also a vacuum at the outlet of the mini-hydroelectric power plant, the flow increases its speed under the influence of centrifugal force and the gravitational constant! This is not difficult to see in the photographs presented by the outgoing flow and the breakers it creates. The hydraulic power unit works like a pump.

Advantages of the Leneva hydropower unit:

– increased working area of the hydropower unit. In the installation of a mini-hydroelectric power station there is not a single blade that would not work at any given moment or would interfere with the work of the others. The blades are arranged in two rows, each of which is a working one. When turning, the blades also work,

– the form of installation creates a modular design of the hydropower unit, which makes it possible to build larger ones hydroelectric power stations from miniblocks for small, medium and large consumers,

– the working blades of the hydraulic power unit are located in relation to the moving flow under optimal angle at 45 degrees. Thus, the mini-hydroelectric power station not only does not stop the movement of water, taking away all its energy, but also provokes the emergence of additional forces that significantly increase the power of the water flow, and, accordingly, our own

Hydroelectric power plants use the power of water to generate electrical energy. Self-made stations solve the problem of distance from centralized power grids or help save on electricity.

Advantages and disadvantages of hydroelectric power stations

Hydroelectric power plants have the following advantages over other types of alternative energy sources:

- They do not depend on the weather and time of day (unlike). This allows more energy to be produced at a predictable rate.

- The power of the source (river or stream) can be adjusted. To do this, it is enough to narrow the channel with a dam or provide a difference in water heights.

- Hydraulic installations do not make any noise (unlike).

- Many types of low power stations do not require any installation permits.

The disadvantages of homemade hydroelectric power plants include the inability to work in cold weather. In addition, the aquatic environment is aggressive, so the station parts must be waterproof and durable.

When designing mini-hydroelectric power plants for use as an alternative energy source for own home The following factors should be decisive:

- Proximity of the river to the house. Install homemade station It's not worth it far from home. The further away the installation, the lower its efficiency, because some of the energy will be lost during transmission. In addition, it is more difficult to protect your hydroelectric power station from theft or damage.

- Sufficient flow speed or the possibility of increasing it. The power of the station increases by geometric progression with increasing water speed.

It's easy to find out the speed. Throw a piece of foam or a tennis ball into the water and time the time it takes for it to swim a certain distance. Then divide the meters by seconds and you will know the speed. The minimum sufficient water speed for a homemade hydroelectric power station is 1 m/s.

If the flow rate of your river or stream is below this value, then it will be increased by a small dam or narrowing pipe. But these options can cause additional difficulties. The construction of a dam requires permission from the authorities, as well as the consent of neighbors.

Do-it-yourself mini hydroelectric power station

The design of a hydroelectric power station is quite complex, so it will be possible to build only a small station on your own, which will save on electricity or provide energy to a modest household. Below are two examples of the implementation of a homemade hydroelectric power station.

How to make a mini hydroelectric power station from a bicycle

This version of the hydroelectric power station is ideal for cycling trips. It is compact and lightweight, but can provide energy to a small camp set up on the banks of a stream or river. The resulting electricity will be enough for evening lighting and charging mobile devices.

To install the station you will need:

- Front wheel from a bicycle.

- A bicycle generator that is used to power bicycle lights.

- Homemade blades. They are cut out in advance from sheet aluminum. The width of the blades should be from two to four centimeters, and the length should be from the wheel hub to its rim. There can be any number of blades; they need to be placed at the same distance from each other.

To launch such a station, it is enough to immerse the wheel in water. The immersion depth is determined experimentally, approximately from a third to a half of the wheel.

To build a more powerful station for permanent use, more durable materials. Metal and plastic elements, which are easier to protect from exposure, are best suited aquatic environment. But they are also suitable wooden parts, if you soak them in a special solution and paint them with waterproof paint.

The station requires the following elements:

- Steel cable drum (2.2 meters in diameter). The rotor-wheel is made from it. To do this, the drum is cut into pieces and welded again at a distance of 30 centimeters. Blades (18 pieces) are made from the remains of the drum. They are welded to a radius at an angle of 45 degrees. To support the entire structure, a frame is made from angles or pipes. The wheel rotates on bearings.

- Installed on the wheel chain reducer(gear ratio should be four). To make it easier to bring the axes of the drive and generator together, as well as to reduce vibration, rotation is transmitted through the cardan from the old car.

- Suitable for generator asynchronous motor. To it should be added another gear reducer with a coefficient of about 40. Then for three-phase generator with 3000 rpm and a total reduction ratio of 160, the number of revolutions will drop to 20 rpm.

- Place all electrical items in a waterproof container.

Described starting materials easy to find at a landfill or from friends. You can pay specialists for cutting a steel drum with a grinder and for welding (or do everything yourself). As a result, a hydroelectric power station with a capacity of up to 5 kW will cost a small amount.

Generating electricity from water is not that difficult. It's harder to line up autonomous system power supply based on a homemade hydroelectric power station, maintain the station in working order and ensure the safety of people and animals around it.

If there is a river or even a small stream flowing near your home, then with the help of a homemade mini hydroelectric power station you can get free electricity. Perhaps this will not be a very large addition to the budget, but the realization that you have your own electricity costs much more. Well, if, for example, at a dacha, there is no central power supply, then even small amounts of electricity will be simply necessary. And so, to create a homemade hydroelectric power station, at least two conditions are necessary - the availability of a water resource and desire.

If there is a river or even a small stream flowing near your home, then with the help of a homemade mini hydroelectric power station you can get free electricity. Perhaps this will not be a very large addition to the budget, but the realization that you have your own electricity costs much more. Well, if, for example, at a dacha, there is no central power supply, then even small amounts of electricity will be simply necessary. And so, to create a homemade hydroelectric power station, at least two conditions are necessary - the availability of a water resource and desire.

If both are present, then the first thing to do is measure the speed of the river flow. This is very simple to do - throw a twig into the river and measure the time during which it floats 10 meters. Dividing meters by seconds gives you the current speed in m/s. If the speed is less than 1 m/s, then a productive mini hydroelectric power station will not work. In this case, you can try to increase the flow speed by artificially narrowing the channel or making a small dam if you are dealing with a small stream.

As a guide, you can use the relationship between the flow speed in m/s and the power of electricity removed from the propeller shaft in kW (screw diameter 1 meter). The data is experimental; in reality, the resulting power depends on many factors, but it is suitable for evaluation. So:

- 0.5 m/s – 0.03 kW,

- 0.7 m/s – 0.07 kW,

- 1 m/s – 0.14 kW,

- 1.5 m/s – 0.31 kW,

- 2 m/s – 0.55 kW,

- 2.5 m/s – 0.86 kW,

- 3 m/s -1.24 kW,

- 4 m/s – 2.2 kW, etc.

The power of a homemade mini hydroelectric power station is proportional to the cube of the flow velocity. As already indicated, if the flow speed is insufficient, try to artificially increase it, if this is of course possible.

Types of mini-hydroelectric power plants

There are several main options for homemade mini hydroelectric power plants.

This is a wheel with blades mounted perpendicular to the surface of the water. The wheel is less than half immersed in the flow. Water presses on the blades and rotates the wheel. There are also turbine wheels with special blades optimized for liquid flow. But that's enough complex designs more factory than homemade.

It is a vertical axis rotor used to generate electrical energy. A vertical rotor that rotates due to the pressure difference on its blades. The pressure difference is created due to the flow of liquid around complex surfaces. The effect is similar to the lift of a hydrofoil or the lift of an airplane wing. This design was patented by Georges Jean-Marie Darrieux, a French aeronautical engineer in 1931. Also often used in wind turbine designs.

Garland A hydroelectric power station consists of light turbines - hydraulic propellers, strung and rigidly fixed in the form of a garland on a cable thrown across the river. One end of the cable is fixed in the support bearing, the other rotates the generator rotor. The cable in this case plays the role of a kind of shaft, rotational movement which is transmitted to the generator. The flow of water rotates the rotors, the rotors rotate the cable.

Also borrowed from the designs of wind power plants, a kind of “underwater wind turbine” with a vertical rotor. Unlike an air propeller, an underwater propeller has blades of minimal width. For water, a blade width of only 2 cm is sufficient. With such a width, there will be minimal resistance and maximum rotation speed. This width of the blades was chosen for a flow speed of 0.8-2 meters per second. At higher speeds, other sizes may be optimal. The propeller moves not due to water pressure, but due to the generation of lifting force. Just like an airplane wing. The propeller blades move across the flow rather than being dragged in the direction of the flow.

Advantages and disadvantages of various homemade mini hydroelectric power station systems

The disadvantages of a garland hydroelectric power station are obvious: high material consumption, danger to others (long underwater cable, rotors hidden in the water, blocking the river), low efficiency. The Garland hydroelectric power station is a kind of small dam. It is advisable to use in uninhabited, remote areas with appropriate warning signs. Permission from authorities and environmentalists may be required. The second option is a small stream in your garden.

The Daria rotor is difficult to calculate and manufacture. At the beginning of work you need to unwind it. But it is attractive because the rotor axis is located vertically and power can be taken off over water, without additional gears. Such a rotor will rotate with any change in flow direction - this is a plus.

The most widespread designs for the construction of home-made hydroelectric power plants are the propeller and water wheel. Since these options are relatively simple to manufacture, require minimal calculations and are implemented at minimal cost, have high efficiency, and are easy to configure and operate.

An example of a simple mini-hydroelectric power station

The simplest hydroelectric power station can be quickly built from an ordinary bicycle with a dynamic headlight. Several blades (2-3) must be prepared from galvanized iron or thin sheet aluminum. The blades should be the length from the wheel rim to the hub, and 2-4 cm wide. These blades are installed between the spokes using any available method or using pre-prepared fasteners.

If you are using two blades, place them opposite each other. If you want to add more blades, then divide the circumference of the wheel by the number of blades and install them at equal intervals. You can experiment with the depth of immersion of the wheel with blades in the water. It is usually one-third to one-half immersed.

The option of a traveling wind power plant was considered earlier.

Such a micro hydroelectric power station does not take up much space and will serve cyclists perfectly - the main thing is the presence of a stream or rivulet - which is usually the place where the camp is set up. A mini hydroelectric power station from a bicycle can illuminate a tent and charge cell phones or other gadgets.

Hydroelectric power plants use the power of water to generate electrical energy. Self-made stations solve the problem of distance from centralized power grids or help save on electricity.

Advantages and disadvantages of hydroelectric power stations

Hydroelectric power plants have the following advantages over other types of alternative energy sources:

- They do not depend on the weather and time of day (unlike). This allows more energy to be produced at a predictable rate.

- The power of the source (river or stream) can be adjusted. To do this, it is enough to narrow the channel with a dam or provide a difference in water heights.

- Hydraulic installations do not make any noise (unlike).

- Many types of low power stations do not require any installation permits.

The disadvantages of homemade hydroelectric power plants include the inability to work in cold weather. In addition, the aquatic environment is aggressive, so the station parts must be waterproof and durable.

When designing a mini-hydroelectric power station for use as an alternative source of energy for your own home, the following factors should be decisive:

- Proximity of the river to the house. There is no point in installing a homemade station away from home. The further away the installation, the lower its efficiency, because some of the energy will be lost during transmission. In addition, it is more difficult to protect your hydroelectric power station from theft or damage.

- Sufficient flow speed or the possibility of increasing it. The power of the station increases exponentially with increasing water speed.

It's easy to find out the speed. Throw a piece of foam or a tennis ball into the water and time the time it takes for it to swim a certain distance. Then divide the meters by seconds and you will know the speed. The minimum sufficient water speed for a homemade hydroelectric power station is 1 m/s.

If the flow rate of your river or stream is below this value, then it will be increased by a small dam or narrowing pipe. But these options can cause additional difficulties. The construction of a dam requires permission from the authorities, as well as the consent of neighbors.

Do-it-yourself mini hydroelectric power station

The design of a hydroelectric power station is quite complex, so it will be possible to build only a small station on your own, which will save on electricity or provide energy to a modest household. Below are two examples of the implementation of a homemade hydroelectric power station.

How to make a mini hydroelectric power station from a bicycle

This version of the hydroelectric power station is ideal for cycling trips. It is compact and lightweight, but can provide energy to a small camp set up on the banks of a stream or river. The resulting electricity will be enough for evening lighting and charging mobile devices.

To install the station you will need:

- Front wheel from a bicycle.

- A bicycle generator that is used to power bicycle lights.

- Homemade blades. They are cut out in advance from sheet aluminum. The width of the blades should be from two to four centimeters, and the length should be from the wheel hub to its rim. There can be any number of blades; they need to be placed at the same distance from each other.

To launch such a station, it is enough to immerse the wheel in water. The immersion depth is determined experimentally, approximately from a third to a half of the wheel.

To build a more powerful station for permanent use, more durable materials will be needed. Metal and plastic elements, which are easier to protect from exposure to the aquatic environment, are best suited. But wooden parts are also suitable if you soak them in a special solution and paint them with waterproof paint.

The station requires the following elements:

- Steel cable drum (2.2 meters in diameter). The rotor-wheel is made from it. To do this, the drum is cut into pieces and welded again at a distance of 30 centimeters. Blades (18 pieces) are made from the remains of the drum. They are welded to a radius at an angle of 45 degrees. To support the entire structure, a frame is made from angles or pipes. The wheel rotates on bearings.

- A chain gear is installed on the wheel (the gear ratio should be four). To make it easier to bring the axes of the drive and generator together, as well as to reduce vibration, rotation is transmitted through the cardan from the old car.

- An asynchronous motor is suitable for the generator. To it should be added another gear reducer with a coefficient of about 40. Then for a three-phase generator with 3000 revolutions per second with a total reduction coefficient of 160, the number of revolutions will decrease to 20 revolutions per minute.

- Place all electrical items in a waterproof container.

The described starting materials can easily be found in a landfill or from friends. You can pay specialists for cutting a steel drum with a grinder and for welding (or do everything yourself). As a result, a hydroelectric power station with a capacity of up to 5 kW will cost a small amount.

Generating electricity from water is not that difficult. It is more difficult to build an autonomous power supply system based on a homemade hydroelectric power station, maintain the station in working order and ensure the safety of people and animals around it.

Mini hydroelectric power station. Microhydroelectric power plants

Small hydroelectric power station or small hydroelectric power station(SHPP) - a hydroelectric power station that generates a relatively small amount of electricity and consists of hydropower plants with an installed capacity of 1 to 3000 kW.

Micro hydroelectric power station designed to convert the hydraulic energy of a fluid flow into electrical energy for further transmission of the generated electricity to the power system. The term micro means that this hydroelectric power station is installed on small water bodies - small rivers or even streams, technological streams or differences in elevation of water treatment systems, and the power of the hydraulic unit does not exceed 10 kW.

SHPPs are divided into two classes: micro-hydroelectric power plants (up to 200 kW) and mini-hydroelectric power plants (up to 3000 kW). The former are used mainly in households and small enterprises, the latter - in larger facilities. For the owner country house or small business, obviously the former are of more interest.

Based on the principle of operation, micro-hydroelectric power plants are divided into the following types:

Water wheel . This is a wheel with blades, mounted perpendicular to the surface of the water and half immersed in it. During operation, water puts pressure on the blades and causes the wheel to rotate.

From the point of view of ease of manufacture and obtaining maximum efficiency with minimal costs, this design works well. Therefore, it is often used in practice.

Garland mini-hydroelectric power station . It is a cable thrown from one bank of the river to the other with rotors rigidly attached to it. The flow of water rotates the rotors, and from them the rotation is transmitted to a cable, one end of which is connected to the bearing, and the other to the generator shaft.

Disadvantages of a garland hydroelectric power station: high material consumption, danger to others (long underwater cable, rotors hidden in the water, blocking the river), low efficiency.

Rotor Daria . This is a vertical rotor that rotates due to the pressure difference on its blades. The pressure difference is created due to the flow of liquid around complex surfaces. The effect is similar to the lift of a hydrofoil or the lift of an airplane wing. In fact, SHPPs of this design are identical to wind generators of the same name, but are located in a liquid medium.

The Daria rotor is difficult to manufacture; it needs to be untwisted before starting work. But it is attractive because the rotor axis is located vertically and power can be taken off over water, without additional gears. Such a rotor will rotate with any change in flow direction. Like its airborne counterpart, the efficiency of the Darrieus rotor is inferior to that of propeller-type small hydroelectric power plants.

Propeller . This is an underwater “windmill” with a vertical rotor, which, unlike an air one, has blades of a minimum width of only 2 cm. This width provides minimal resistance and maximum rotation speed and was chosen for the most common flow speed - 0.8-2 meters per second.

Propeller SHPPs , as well as wheeled ones, are easy to manufacture and have relatively high efficiency, which is the reason for their frequent use.

Classification of mini hydroelectric power stations

Classification by power output (areas of application) .

The power generated by a micro hydroelectric power station is determined by a combination of two factors, the first is the pressure of water flowing onto the blades of the hydraulic turbine, which drives the generator generating electricity, and the second factor is the flow rate, i.e. the volume of water passing through the turbine in 1 second. Flow is the determining factor when classifying a hydroelectric power station as a specific type.

Based on the generated power, small hydroelectric power stations are divided into:

- Household power up to 15 kW: used to provide electricity to private households and farms.

- Commercial up to 180 kW: supply electricity to small businesses.

- Industrial with a capacity of over 180 kW: they generate electricity for sale, or energy is transferred to production.

Classification by design

Classification by installation location

- High-pressure - more than 60 m;

- Medium pressure - from 25 m;

- Low pressure - from 3 to 25 m.

This classification implies that the power plant operates at different speeds, and a number of measures are taken to stabilize it mechanically, because the flow rate depends on the pressure.

Components of mini hydroelectric power station

The power generating installation of a small hydroelectric power station consists of a turbine, a generator and a system automatic control. Some elements of the system are similar to or. Main elements of the system:

- Hydro turbine with blades, connected by a shaft to the generator

- Generator . Designed to produce alternating current. Attached to the turbine shaft. The parameters of the generated current are relatively unstable, but nothing similar to power surges occurs during wind generation;

- Hydro turbine control unit provides start and stop of the hydraulic unit, automatic synchronization of the generator when connected to the power system, control of operating modes of the hydraulic unit, and emergency stop.

- Ballast load block , designed to dissipate power currently unused by the consumer, avoids failure of the electric generator and monitoring and control system.

- Charge controller/stabilizer : designed to control charge batteries, blade rotation control and voltage conversion.

- Bank AKB : a storage tank, the size of which determines the duration of autonomous operation of the object powered by it.

- Inverter , many hydro-generation systems use inverter systems. If there is a battery bank and a charge controller, hydraulic systems are not much different from other systems using renewable energy sources.

Mini hydroelectric power station for a private house

Rising electricity tariffs and lack of sufficient capacity make topical issues o the use of free energy from renewable sources in households. Compared to other sources of renewable energy sources, mini hydroelectric power stations are of interest, since with equal power with a wind turbine and solar battery they are capable of delivering much more energy in an equal period of time. A natural limitation on their use is the lack of a river

If a small river, stream flows near your house, or there are elevation changes on lake spillways, then you have all the conditions for installing a mini hydroelectric power station. The money spent on its purchase will quickly pay for itself - you will be provided with cheap electricity at any time of the year, regardless of weather conditions and other external factors.

The main indicator that indicates the efficiency of using SHPPs is the flow rate of the reservoir. If the speed is less than 1 m/s, then it is necessary to take additional measures to accelerate it, for example, make a bypass channel of variable cross-section or organize an artificial height difference.

Advantages and disadvantages of microhydropower

The advantages of a mini hydroelectric power station for the home include:

- Environmental safety (with reservations for juvenile fish) of equipment and the absence of the need to flood large areas with colossal material damage;

- Ecological purity of the energy produced. There is no effect on the properties and quality of water. Reservoirs can be used both for fishing activities and as sources of water supply for the population;

- Low cost of generated electricity, which is several times cheaper than that generated at thermal power plants;

- Simplicity and reliability of the equipment used, and the possibility of its operation in autonomous mode (both within and outside the power supply network). Produced by them electricity meets GOST requirements for frequency and voltage;

- The full service life of the station is at least 40 years (at least 5 years before major repairs);

- inexhaustibility of resources used to generate energy.

The main disadvantage of micro-hydroelectric power stations is the relative danger for the inhabitants of aquatic fauna, because Rotating turbine blades, especially in high-speed flows, can pose a threat to fish or fry. The limited application of the technology can also be considered a disadvantage.