To answer the question how to make a raft from logs you will need to prepare dry pine or spruce wood. If you knock on it with an axe, a ringing sound will come from it. Dry elements with old wood are completely unsuitable for this task. So the tree will quickly become damp, and the raft itself will sink. To calculate the specific gravity, you need to remove a small piece - about 10 cm - from the end of the tree with a saw. Then place it flat in water. If this piece goes deeper by 5-6 cm, then this wood is optimal for constructing a raft.

In order to find out how to make a raft We use logs whose maximum diameter is 25-30 cm, and the smallest diameter is 10 cm.

To ensure that the future log raft has excellent durability, thin timbers are concentrated in the middle zone, and thick ones on the sides. If the logs for the raft are crooked, then they are placed with the crooked places down.

Allowable voids between logs are 2-4 centimeters. Otherwise, the craft will turn out to be weakly stable and inert to floating and make a raft correctly will not work.

The logs are laid on a slipway, then they are rolled out to the sides and their tops are marked.

At a minimum distance of 80 centimeters from the end, grooves are created on the central log (sawed and cut out). The mandatory position of the lower grooves is to be at the same level. Their depth should reach the middle of the log - the most important criterion. Otherwise, when driving a wedge, you risk chipping the sawn wood. A special end is used for the sample. It is hewn from damp birch. With its middle section it lies in an already designated log.

It is easily inserted into the groove on it from above. So make a raft with your own hands it will be much easier. Its lower wide section fills the top of the groove. A wedge is driven between its inclined side and the groove wall. Wedge criteria: wooden and dry. Ronjins must fit in one plane. In order to clearly understand how to make a raft you can see video below:

Using the samples, you can make similar grooves on the remaining logs. They are attached in turn with wedges to the central log. Before laying the outer logs, slightly different grooves are created in them, intended for the logs. Three special stands are also cut out with greatest thickness 10-12 cm, height – 60-70 cm.

The main rope is then pulled over them. Instead of rope, you can rely on the option of twisted wire or rope ties. Make a raft much easier this way.

On calm rivers it is better to use a “P” design of a similar type. First, two posts are cut vertically into the working logs. Then a pillow is put on them. It needs to be wedged out and a rowing area cut out in it. To prevent chipping of these racks, it is better to focus them 50 cm from the stern and bow.

On wild and difficult rivers, it is recommended to use options that have metal frames. Modules and couplings are used to create them. The length of the modules is allowed to vary. Type of couplings – shaped. In order to make a raft it will take a lot of effort. You'll have to do a lot of drilling. There is a need for lathe and welding skills.

But make a raft from logs will be easy to assemble and disassemble. To pack its frame you need a couple of kayak covers. You will need a separate container to pack the oars.

Interestingly, such a frame can be converted into two small rafts, even a catamaran. You can attach car cameras and work areas to it. The latter are placed 30 cm below the frame. This lowers the center of gravity.

An interesting option is if make a raft, on the structure of which floats are arranged transversely. Creating it is quite simple. It has excellent stability. All kinds of flooring and mesh can be used on it. You can also attach some inflatable components to it. This type of raft is used for navigation on various rivers.

Its frame is created using a cable with a parameter of 6 mm and modules with a length of 200 cm. The connecting elements of these modules are hinges. Here we get a deflection of 20 degrees. The weight of the frame reaches 80 kg. On large shafts, cable breaks are likely.

When you are planning a summer vacation on a lake or river, or planning leisure time on the local shore or modest boat trips, you can build a shallow-draft raft for 5-6 people. Their backpacks are also taken into account. Such a raft made of logs will also have excellent stability on steep waves.

The main components for making a raft with floats:

Rubber tires (or barrels). Number: 6-10, diameter – 100-150 cm;

elements of aluminum parts and tubes;

wood, number - 7 pieces, length 3 - 500 cm, 4 - 170 cm, diameter of all - at least 6 cm;

steel sheets 1 cm wide.

So, how to make a raft this design? Place the designated poles of shorter length (170 cm, 4 pieces) parallel to each other. The distance between the first and second, third and fourth poles is 150 cm, between the second and third - 200 cm.

Three longer poles (500 cm) are placed perpendicularly on them. The distance between them is 50-60 cm. These poles are attached to other poles with nails.

Next, you should create the main deck with bridges. Here such bridges are three shields made of tree trunks arranged in a selection.

The deck is based on two 170 cm poles, on which the cuttings of the boards are placed. Their thickness is 2 cm. They are also connected to the poles with nails. “Captain’s” bridges are made using the same principle.

The supporting elements for the awning here are willow twigs. And the raft itself is assembled from logs only after these elements are installed. Make a raft this way it's not that difficult.

The inner tubes used must be inflated. They are tied to the base with ropes. Next comes the installation of the main deck. The sides are made from hewn poles (4 pieces). The awning is made of polyethylene.

The supporting parts of the steering oars are concentrated diagonally on the bridges. Here the process moves according to the following scheme: a support is placed on the left side of the bridge at the back, and a support is placed on the right side of the bridge in front.

After which the three indicated pipes (duralumin) come into play. The supports are bent from them. Steel strips are needed for fastening.

The combs are made from other poles, whose length is 250 cm. The blades are made from plywood or aluminum sheets. You need to decide on their parameters yourself.

The raft is the most simple form water transport, and it is much easier to build than a canoe or boat. There are many ways to build a raft. You can build a traditional raft entirely from logs. You can build a wooden raft that uses barrels or PVC pipes to keep it afloat. You could even build a raft entirely out of soft drinks - it's true! This has already been done. Wide electrical tape is used to glue all the bottles together. But here you will find instructions on how to build a raft... with foam inserts for buoyancy.

What do we need to build a raft?

- Two logs 7-8 cm thick and 1.5 m long

- Eleven wooden planks about 2.5 cm thick, 13 cm wide and 91 cm long

- Five thin planks 5 mm thick, 13 cm wide and 91 cm long

How will we build the raft?

- Place two logs parallel to each other at a distance of 85 cm.

- Place eleven planks across the logs to create a deck. They should protrude a few centimeters beyond the logs. The ends of the logs should protrude slightly from below the deck on each side. Nail the boards into place.

- Turn the raft upside down. Insert foam into the space between the logs. It’s good if TV can find polystyrene foam in one piece of a suitable size. But you can also use several smaller pieces if you can arrange them neatly and tightly.

- Place five across the logs to hold the foam in place. Nail the boards.

- Turn the raft over and launch it into the water. It should be able to support one average-sized adult on board.

Attention!

If you take your raft onto the lake, don't forget to wear a life jacket. Don't take the raft to the river. It is not stable enough and can be dangerous in moving water. Only an inflatable raft is suitable for the river. An inflatable raft is used in a sport such as rafting on stormy mountain rivers. It is safer, but costs a lot of money. But our hands are not for boredom, and we will build the raft ourselves. If the raft is on the lake, then get off it, or sunbathe...

A raft is a fairly simple means of transportation on water, which is often used by fishermen or tourists on hikes. Such devices are made from different materials. The most popular and effective is a raft made of logs. Its design is completely accessible, so make wooden device for swimming you can do it yourself.

The wooden raft has a simple structure. Its main components are:

- Pontoons. With the help of such a part, the watercraft floats on the surface of the water. Floating pontoons are made from lightweight material, the density of which is much less than the density of the liquid.

- Frame. The base of the raft consists of strong elements installed transversely or lengthwise that help connect all parts of the floating structure. When constructing a frame, its weight and rigidity should be taken into account. Too heavy base parts make the raft inconvenient for launching. The rigidity of the device is necessary to maintain the shape of the frame, on which the integrity of the entire swimming device depends.

- Control mechanism. To direct the raft in the desired direction, adjustment elements such as oars are installed big size– row, keel or six. The type of control mechanism is selected depending on the depth at which the raft will be used and the current in the reservoir.

- Safety elements. When the raft is moving quickly or when it hits a hard surface, safety devices are required to ensure the safety of passengers. These could be parts of the control mechanism that you can hold on to with your hands or special supports that prevent people from falling into the water.

- Covering the boat. Flooring is not always installed on a raft. This design element is used for external design devices for swimming and for the purpose of creating comfort. The material used to cover the raft must be strong enough.

- Device for things. Some watercraft are equipped with a special cover in the form of a tent. This device allows you to store things in rainy weather. To prevent luggage from falling into the water, it is tied with ropes.

All valuable items are transported in bright, waterproof bags so that they can be easily found even in the river.

Selection and preparation of material

Logs are the most common material for building a raft. The tree has excellent floating characteristics. In addition, the material is quite affordable.

The wood for the raft must be:

- dry;

- flat;

- without knots;

- easy.

Wood with a high moisture content does not float well in water. To check the quality of the logs, you should hit them with an ax - sufficiently dry wood makes a ringing sound.

The most lightweight material considered balsa wood. It's completely easy to handle. But this breed grows in the tropics. Therefore, dry pine or spruce is most often used. Logs are selected with a diameter of no less than ten and no more than thirty centimeters.

To prepare a tree for a raft, cut off all branches with an ax and inspect for splits and knots. If necessary, the wood surface is leveled.

Determination of the raft's carrying capacity

In order for the raft to stay securely on the water with passengers, the characteristics of the future watercraft should be checked before construction. Such calculations allow you to find out the amount of wood material required for construction.

The main purpose of the calculation is to determine the carrying capacity of the raft. To calculate you need:

- Establish the total weight of all passengers and equipment. Multiply the resulting value by the buoyancy reserve coefficient. This indicator is important in calculations. With its sufficient value, the raft does not bend while group members move along it, and also passes through rough sections of the river and whirlpools without problems. The optimal buoyancy reserve coefficient is considered to be 1.5. For bodies of water with strong currents and the presence of large stones that create obstacles, the indicator increases to 2.5.

- Find out the diameter. For five people, it is enough to select logs with a diameter of thirty centimeters. When carrying more passengers, a larger tree with a diameter of forty centimeters is required.

The carrying capacity of a raft can be determined using the following equation:

In this formula, D is the length of the logs, N is their number and A is the load capacity linear meter logs The last value is taken from special established tables.

Calculate the volume of logs according to the formula Q = G/ (1 – U). In this case, Q is the volume of wood in cubic meters, G is the required load capacity and U is specific gravity wooden material. The last indicator for pine is 0.19-0.35, and for spruce – 0.3-0.44.

Construction technology

Building a raft from logs is quite easy. Almost anyone with some carpentry skills can make a watercraft with their own hands.

Required tools and materials

In the process of building a boat from logs, you cannot do without the following woodworking tools:

- axe;

- hammer;

- saw;

- sharp knife.

You also need to purchase fastening elements:

- vines;

- nails;

- ropes.

The materials used are:

- dry logs;

- wooden beams.

For flooring, you can take plywood, boards or bark.

Installation of logs

The construction of a raft is best done near a reservoir, since the design, especially for large quantity the person can be very heavy.

To make a simple raft yourself you need:

- Place the selected logs near the water so that thin material was in the middle, and thicker at the edges. This placement will increase the strength of the entire structure.

- Install wooden beams across the top. You can secure them with nails, vines, or tie them with ropes pre-soaked in water. The beams are fixed both above and below the logs laid in a row. In this case, you should carefully ensure that there are no cracks or gaps in the structure. Cross beams should be slightly longer than the logs.

After this, the steering mechanism is attached and, if necessary, small fences are installed along the edges of the craft.

You can also secure the logs with special steel staples. In this case, the construction of a frame base is not required.

Fastening the deck

The flooring is mounted on already fixed logs. Sheets of selected material are attached so as to create a flat, smooth surface.

Launching the raft

When building a raft near a body of water, it is quite easy to release its water. It is recommended to start laying out logs at the same level as the shore. This will allow you to easily move the craft to the river.

The easiest way to launch a raft is built on supports located parallel to the bed of the reservoir. Such a structure should simply be rolled into the river.

Small raft for three

You can make a small raft from logs with a diameter of up to thirty centimeters. Its construction consists of the following stages:

- Select even logs about three and a half meters long. All tree trunks cleared of branches and trimmed must be exactly the same size so that when they are laid in a row, a flat surface is obtained.

- Lay two separate logs parallel to the river mouth as guides. Such supports should be fairly even and equal in volume.

- Cut grooves on both ends and sides of the logs. For each log they should be at the same distance from the edge so that when the structure is laid out, one continuous line is formed. The location of the upper grooves should be close to the edge, and the lower ones should be slightly directed towards the middle of the log.

- Wooden lintels are prepared thirty centimeters longer than the width of the laid logs.

- The jumpers are inserted through the grooves first in the lower part of the structure, and then installed on top of the raft.

- The blowing edges of the jumpers are tied with vines or ropes. This fixation is not necessary, since when launched into the water, the wood swells and is firmly fixed in the cut grooves.

Flooring is laid on top. If desired, supports are made from slats to cover the hut.

Storage and care of a wooden raft

In order for a craft made from logs to be launched more than once, you should follow the rules for storing and caring for it:

- Don't leave the raft long time in water. After using the flotation device, you should immediately pull it ashore. For this purpose, guide logs are used. They facilitate the movement of the structure on land and prevent dirt from sticking to the lower part of the craft.

- Dry after each swim. To prevent the wood from deteriorating, you should allow the raft to dry completely before storing it. To prevent wood from rotting, it is recommended to treat it with special water-repellent impregnations.

- The raft should be stored in a dry, well-ventilated area. A barn is well suited for these purposes. If this is not possible, then the watercraft is placed on the street, while completely covering it with a tarpaulin. Boards or logs are placed at the bottom of the raft to create ventilation.

At correct operation the swimming device will last long years without changing its original characteristics.

A raft made of logs is a convenient watercraft that allows you to move reliably across various bodies of water. You can make it yourself, adhering to precise construction technology. If you equip the upper part as a shelter from the rain, install a control mechanism and take care of the safety elements, then you can safely go on a short trip with friends along the river.

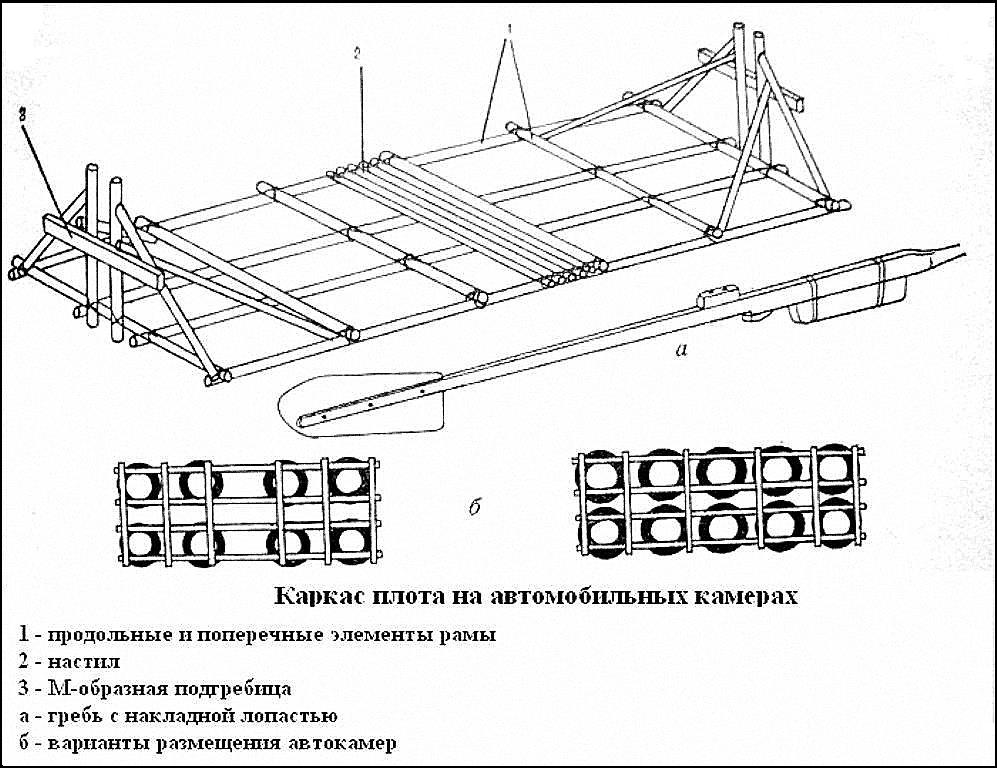

If you, a small but friendly company, are planning a long rafting trip along the middle Siberian river and cannot find the necessary watercraft for this, try to consider the option of building a raft from car inner tubes.

The best option, of course, would be to deliver you and the cargo directly to the river, but a raft from inner tubes can be carried to the place by correctly distributing the weight among travelers and taking minimum required for construction. And this:

1. ZIL, GAZ, MAZ, Kamaz cameras - 6 or 8 pieces, depending on their availability, the number of rafters and the weight of the luggage.

2. Pump for chambers.

3. Nails from 100 to 200 mm.

4. Axe.

5. Hacksaw.

6. A roll of keeper tape.

7. Two blades for rowing, 200-250 mm wide, 500-600 mm long (best made of thick plywood, but can be made from wide inch boards).

I remember in 1991, Serb and I and six schoolchildren carried materials for the construction of an 8-chamber raft ten kilometers away. At the same time, Seryoga and I, as the eldest, in addition to our things, carried two ZIL cameras, the rest was distributed among the boys And nothing, we went in quietly, because, as the old proverb says, “the eyes are afraid, but the hands are active.”

By the way, we simply begged for cameras at the plant, went to the right people- KAMAZ drivers, mechanics and supervisors. They glued the ones with holes themselves, fortunately little pressure was needed. Then we pumped it up and checked it, in general, over the winter we collected materials for the raft without any problems or material costs.

The most pleasant thing about rafting, of course, is a canopy to protect people and things from the rain, which will also serve as a drying rack. Some of the most simple materials for canopy - toast polyethylene film or tarpaulin. But keep in mind that you will have to pay for the acquired comfort with a small minus - the windage of the vessel. On reaches in the rain and headwind, you will not raft, but stand still or climb up the river, so get ready to row against the wind. But the canopy-sail also has positive aspects - a fair wind and the ability to control the drift alone.

The next nice addition to the raft could be a deck made of boards or plywood. In the minimum case, we would use poles and spruce branches for flooring. But, whatever one may say, there will be in the raft large gaps, where during the rafting many small, but necessary little things(from lighters, spoons and knives to caught fish). But with tightly packed flooring this will not happen.

One day, we were driving onto a river in a passing military UAZ. The driver, a major, asked us about all the plans for building a raft and rafting, and told us one military secret. If, he says, you swim to the first reach and go a hundred meters into the forest, you will find there a toilet made of boards. And it was done by prisoners. Of course, we didn’t believe the major and even quietly giggled at his words, but we didn’t finish building the raft. We inflated the cameras, made a frame and swam to the reach. All the way we neighed like horses at the driver’s joke. When we actually came across a toilet in the taiga, some of us were dumbfounded, and the rest were taken aback. There’s not a soul around, no buildings, and there’s a toilet on top of you! Without thinking twice, we dismantled it and put together a luxurious deck for ourselves, without a single crack:

In general, on a raft for a comfortable rafting you can make many useful things, for example, a metal or stone hearth for a fire, a bench or lighting... Let's leave room for your designer fantasy and finally, let's start building the raft.

skeleton

Choose free place for construction on the river bank with adjacent young forest for harvesting poles. Then it is necessary to correctly distribute responsibilities between the builders. The main thing at the beginning is to pump up the inner tubes and cut down the poles - the skeleton of our ship. Pumping so many chambers with a hand or foot pump is a very monotonous and time-consuming task. It's good if there is a compressor nearby. If not, then the pumpers and preparers need to be changed periodically.

Finished car cameras are laid out according to the following scheme:

Fig.1

Please note that when pumping, the diameter of the chamber increases by about one and a half times. And one moment. It is often impossible to assemble car cameras same size, in this case, the large ones are placed closer to the middle of the raft and if they do not fit in size, then when pumped they are compressed into an oval, for which they are tied with a keeper tape of the required length.

For the frame, longitudinal and transverse poles are cut so that their size protrudes slightly beyond the dimensions. In the future, it will be convenient to grab them to moor the raft to the shore, refloat it or tow it.

Fig.2

The transverse poles are laid down, the longitudinal ones are placed on top, and the upper transverse ones are placed in front and behind the longitudinal ones for subsequent fastening of the ridge.

We carefully fasten the frame with nails and keeper tape, then tie it to the cameras in the most critical places.

The base of our raft is ready. In principle, we can already cut down the poles and hit the road, but we will continue the construction.

Podgrebica

The rower serves to transmit rowing force to the raft. Accordingly, the main requirement for it is strength. Also important is the energy intensity of the stroke, which is achieved optimal location and row the stroke of the handle.

The following diagrams show options for making a ridge from planed bars

Fig.3

And from the poles.

Fig.4

Racks (1) are nailed to the upper and lower outer transverse poles with the distance between them required for rowing (8-10 cm). In this case, the ridge (5) should pass freely, but without gaps, between the posts (see Fig. 4).

Then the racks are strengthened first with longitudinal jibs (3), and then with transverse ones (4). The jibs are attached with nails to the posts and frame of the raft.

For rowing (5), take a pair of strong, even poles from 3.5 m to 4.5 m long with a top diameter of at least 50 mm. Next, a cushion (2) under the ridge is nailed horizontally to the posts and longitudinal jibs. The height to which the cushion is nailed is best determined by installing the row between the posts so that the rower can comfortably hold it at waist or chest level.

Row pads must be made at the bow and stern of the raft. In some construction options, the bow ridge is not on the edge, but a little deeper, at the level of the second cross member. This is done for more serious rafting along rapids and the edge of the raft acts as a bumper. But at the same time we have a serious reduction in the size of the canopy.

Fig.5

The blade (8), lower (7) and upper (6) supports are attached to the ridge (5) with nails in one plane. The lower support is designed to prevent the rowing from slipping into the water, and the upper one so that the blade is in a vertical position. For more comfortable grip with your hands, you can make a handle by cutting off the thick end of the row with an ax.

Deck

We make the deck from materials prepared for this purpose. In the case of using poles, spruce branches are collected in parallel with the preparation of poles, which are then evenly laid out on top of the flooring.

Canopy

Building a canopy will not take much time and effort. First, a frame is made from thin poles, then the top is tied with keeper tape and the entire structure is covered with material.

It is advisable to provide the ability to quickly assemble (roll up) and install the awning.

So, our raft is ready. All that remains is to name the ship, launch it and celebrate the completion of such a big undertaking. Believe me, rafting on a raft made by yourself will give you a lot of pleasure.

P.S. For those who did not fall asleep while reading, here are some surviving photos from our rafting trips.

1989 or 1990. At the mouth of the Dry Pit.

Serb, me and Vovochka on an 8-chamber raft (3 variants of chamber arrangement). They even lowered the gangplank to the shore for the sake of order.

The seven of us rafted on this raft for about 200 km.

6-chamber raft. The four of us rafted very comfortably. In the photo, Arishonok and I are eating blueberries.

Me, Serb and Andryukha are swimming, diving and swimming around the raft. It's very interesting to play catch and hide and seek. You dive under the camera - and you're in the house.

I'm at the helm of a 6-chamber raft.

The most responsible rowers Serb and Gray are rowing in a dangerous area.

Serb and I are supervising the construction of a raft of poles.

For some reason we nicknamed the towed boat “consumer” in childhood.

Launching an 8-chamber raft (2 chamber arrangement options)

It’s not for nothing that this part was called a pillow.

Why should we build a raft...

Ending station. The raft is being dismantled.

Happy sailing and fair wind!

Probably every person made in USSR had a childhood dream of making a raft and sailing to distant places. Dreams Come True! We tried it and it worked!

There were many projects on exactly how to build a raft, what size it was and what it was made of. After much discussion, it was decided that the base of the raft would be car cameras large radius, their number depended on size.

In fact, it turned out that buying inexpensive cameras is not an easy task, the most profitable and quick option there were much smaller cameras than expected R16. The cameras turned out to be Chinese and the seller honestly warned us that they would not stick properly. But we decided to take a risk.

Considering that 8 people were going to sail on the raft (in fact it turned out to be 6) + things + food + the weight of the wooden flooring, the carrying capacity of the cylinders should have been at least 800 kg, but we took it with a reserve - 43 cameras, which corresponded to a carrying capacity of 1200 kg.

The cameras were supposed to be covered wooden shield, assembled from boards, size 4x6 meters. But here, too, circumstances intervened: at the sawmill, we managed to buy boards only 4 meters long. So it was decided to make the raft square 4x4 meters.

This is how the design turned out.

Let's look at the main points in more detail.

The raft was assembled directly on the river bank.

First we use car compressor 43 cameras started downloading.

The compressor did not like this task and refused to work halfway. We had to urgently resuscitate him because... pump frog, which was supposed to swim with us, until the desired state I couldn’t pump up the cameras, which affected the size. If in case of repair this would be acceptable, then I didn’t want to start the journey with under-inflated inner tubes.

In the end, we won the compressor and, applying wet rags to it to cool it, we pumped up all the chambers.

They brought the purchased boards and beams, the length, as I already said, is 4 meters.

Let's try out how it will be.

The assembled raft frame with the first layer of chambers. For the frame, timber 100x50 and 200x50 was used.

40 cameras were used, 3 were taken as spare parts.

We stuffed 25 mm boards on top. I would like the gaps between the boards to be much smaller, but we didn’t calculate the number of boards when purchasing, so we decided not to bother with the purchase again. They lowered the raft into the water.

Beginning of construction of supports for the awning.

50x50 mm timber was used for supports. The height of the side supports is 2 meters, the central one is 2.5 meters (in the photo they are just making it). Initially, the awning was intended to be used only as a roof, but in the end it was also used as a sail, I will talk about this below.

All wooden structures fastened together with screw nails.

The raft was named “Gena” - as they say in the well-known cartoon about Cheburashka: “Because it is green and flat.” The construction took 1 day (we started early in the morning and hit the road in the evening).

In this photo, it is ready to sail; all that remains is to firmly secure the rubber boat with ropes along one of its sides.

Why the boat was needed is an interesting question, the correct answer would be: it was safer for us. In fact, it turned out to be very useful: they dumped all the shmurdyak into it, which was only needed for spending the night, clothes and tents, in the evening we fished from it, when we needed to be in the village, but it was not possible to properly land on the raft on the shore, messengers were sent by boat .

All things, sleeping bags, first aid kit and other things that were wet were packed in specially sewn hermetic bags. Cereals, salt, sugar, etc. poured into plastic bottles. Documents, phones, cameras and other equipment were stored in a separate hermetic bag, which “if anything” was supposed to be dropped first.

In the center of the raft there were piles of essentials and some food in a large bag. It didn’t look aesthetically pleasing at all, but overall it turned out to be comfortable.

Foam was spread on the boards i.e. At night we slept on them in tents, during the day they moved to the raft.

Spare tubes turned out to be successful seats, although one of them was soon used for its intended purpose - it went under the corner of the raft, on which both (2 layers) of the tubes burst.

At night we landed on the shore and set up camp there, but in the morning you won’t have enough tea for the whole day and you won’t be able to go to the toilet.

Everything was simple with the kitchen: a barbecue was rigidly fixed on two elongated boards above the water. Firewood was collected on the shore, sawed and chopped while moving. For ignition, so as not to fool around, we used dry fuel tablets.

The toilet is more difficult: under the oar you can see two shortened boards - this is the coveted point.

There are beams on both sides that you can hold on to. An opaque reinforced film was thrown over the rope, behind which the man did his business. Initially, the idea was to make something like a permanent screen out of film, but it did not always create the necessary windage, then they wanted to attach it to the rope with clothespins, but in the end they simply held it with their hands.

During the voyage, many things had their regular places. So the ax was drowned on the very first evening, and the new one they got was tied and left to live near the firewood. A pot with bowls and spoons was hung on a nail near the barbecue, and dishwashing liquid along with a sponge was inserted into a tape pocket near the food.

Regular place for fishing rods.

Solar battery. It was supposed to be used to charge phones and camera batteries, but in reality there was no connection, we only took a few pictures, and it wasn’t really needed.

Cooling of liquids.

On the central support on a nail hung all sorts of necessities that I didn’t want to get wet and drown, but they were needed during the sailing process. The main thing is Garmin, which runs on batteries; we used it to find out where we were, how fast we were moving and what to expect ahead.

All that remains to be said is about handling.

In general, everything affects the raft: wind, current, how many people are crowded on one side, which side the raft is turned, etc. and so on.

At first there were 2 controls: an oar and a cue.

The oars were boat oars and there were only 2 of them; if they knew that they would be the most effective during maneuvers, they would have taken 4. The rowing process is not the easiest task.

A cue is a long pole (we had about 2 meters) with which you can push off from the bottom in shallow water. At first we had 4 of them, then one was sunk, another was used for a sail. Unfortunately, not a single photo of the cue was preserved - everyone was busy at those moments.

On the third day of the journey, a fair wind blew and another way to control the raft was revealed to us - a sail.

The length of the awning was enough not only to serve as a roof, but also to cover one of the sides. By long games A movement strategy was developed using ropes, sticks and an awning. The sail was turned with its feet, pulled up with ropes, and when unnecessary, it was rolled up and tied to the supports. If the wind was headwind, it was necessary to fold not only the sail, but also the “roof”.

Thanks to the sail, the raft acquired an additional letter in the name “Gena-M” (which means Gena - modified) and developed a speed of just over 6 km/h with a river flow speed of 2.3 km/h, although this happened infrequently. Mostly we moved at a speed of 3-4 km/hour.

The Mezen River along which we sailed is replete with sandbanks. At first, we thought that we would constantly fly into them and pull off the raft, tearing the cameras. As a result, we ran aground literally a couple of times.

When the bottom was very close, they jumped off the raft and pushed or pulled it down to the depth on a rope.

Gena-M served us faithfully for 6 days and 130 kilometers; during this period, the edges of 2 boards broke off, the structure of the tent-sail became a little loose, and for various reasons about 10 inner tubes ran out (more precisely, they didn’t count). All this had no effect on buoyancy.

How the design could be improved:

- The possibility of launching reinforced film under the cylinders to protect the cylinders from snags and abrasion from the shallows, in fact this turned out to be not necessary, but to put the same film between wooden flooring and some cylinders wouldn't hurt. This would protect the cylinders from friction against the boards, save a number of small objects from drowning, and protect the cylinders from sharp objects and sparks from the barbecue.

- Our assumption that in the middle of a wide river there would be no mosquitoes, horse flies and midges turned out to be incorrect. As soon as we approached the shore, the insects happily attacked us, and then we floated on the raft together. This problem could be partially solved by placing a large mosquito tent in the center of the raft. How much windage such a tent would create is an open question.