Sun loungers are attractive because they are light in weight and can be used for relaxing anywhere - on the veranda, in the garden, when going out of town, and so on. Based on this, the appropriate design is selected - monolithic, sliding, portable (a very convenient option for transportation) and a number of others.

The cost of the simplest models of sun loungers available for sale starts from 3,080 rubles. On the one hand, it’s attractive. But main drawback finished products is that many of them are simply not suitable for the buyer - one in size, another in design, and another in frame material. The conclusion suggests itself - make a chaise longue with your own hands, just “for yourself”.

Tree

This is a general concept. An important question is which breed to focus on. Before you look at the drawings of a chaise longue and the progress of work on its manufacture, it is worth clarifying which wood is best suited.

Firstly, mostly those who make things with their own hands (if we are not talking about a professional working on orders) are those who want to save money wisely. Consequently, it is unlikely that anyone will use expensive wood (for example, beech or oak).

Secondly, all breeds are different various properties and characteristics, including the density of the structure (and this means the weight and ease of moving the sun lounger). Consequently, when choosing a tree, you need to take into account the specifics of its operation, depending on which the corresponding drawing is developed.

Thirdly, such sunbeds for a home (apartment) are not purchased or assembled with your own hands. The main place for installing a sun lounger is outside the building (near the pool, in a summer cottage, etc.). Consequently, the tree will be exposed not only to dampness, but also to sun rays. And here there is some contradiction. Coniferous trees less susceptible to rotting, but when heated they “resin”. Even if the lounger is made and (painted), this is not a way out.

Therefore, for example, cheap It is not advisable to use spruce to make a sun lounger. In addition, not everyone can easily tolerate the tart smell of resin. There are numerous tips on the Internet for assembling a sun lounger with your own hands from this very tree. The author has already outlined his arguments against. Well, it’s up to you, the reader, to decide whether to take them into account or not.

- Larch. Strength and durability will be ensured.

- Ash. Good texture and ease of processing are advantages. Disadvantages - it will cost a little more, and it is not very suitable for a portable chaise lounge model due to the density (and therefore weight) of the wood. Although for a stationary lounger it is one of the best options.

Plywood

There are quite a lot of different schemes and drawings of sun loungers. In some cases, when making such a lounge chair with your own hands, for individual structural elements, not solid wood is used, but materials based on it. Mainly multilayer plywood. This partially reduces the overall weight of the product. The range of such products is quite large, but this does not mean that you can take any type of it. From budget options In the private sector, two types of plywood are popular -.

The sizes of their sheets and basic characteristics are almost identical. The fundamental difference is in the adhesive composition that holds the veneer layers together. The FSF used in the manufacture is somewhat toxic. That is why this type plywood is recommended only for external works (continuous lathing under soft roof, facade cladding and so on). Therefore, it is definitely not suitable for a sun lounger - only FC. In terms of “environmental friendliness” there are no complaints about it.

Textile

It is also used in some models of sun loungers. There are few criteria here - strength, minimal stretchability and susceptibility to fading. Therefore, you should focus primarily on material that is fairly dense and monochromatic. The fact is that coloring substances (pigments) fade with different intensities, and “bald spots” may gradually appear on a canvas with bright designs.

Fastening elements

Briefly on this point - with protective coating or from stainless metals (alloys). Since sun loungers are often made for installation outdoors, corrosion of the “iron” cannot be avoided. “Rust” will quickly appear even through the paint, and in terms of maintainability (with the replacement of individual parts) difficulties will arise.

Examples of drawings of sun loungers

It is not difficult for an owner who is used to doing everything with his own hands to develop his own model. Moreover, if you accurately imagine what the result should be. Examples may suggest some ideas, features engineering solutions– and nothing more.

- A chaise longue is almost always made for one user. Consequently, its optimal length (in the unfolded position) is 200±10, width – 65±5 (cm).

- The optimal parameters of lumber are (in mm): sheets (slabs) with a thickness of 10 to 15, bars - from 3 x 4 to 5 x 5, boards - 15. This is quite enough to ensure the reliability of the sun lounger in combination with a low weight. The use of larger samples (similar models are found, judging by the drawings) is impractical. Children will not jump on such pieces of furniture, unlike armchairs, beds, and sofas. A wooden blanks the indicated dimensions will fully support the weight of one person, especially in “static” conditions.

Do-it-yourself chaise longue - progress of work

Tree marking

During production simple models sun loungers, this is easy to do if you have finished drawing, and, accordingly, the sizes of all components. The only thing that needs to be taken into account is the rational use of lumber. In other words, make markings in such a way as to minimize the amount of waste.

It’s more difficult if the chaise longue has some kind of curly structural elements- handles, supports, etc. In this case, you will have to make patterns. First, a given part is drawn on a sheet of graph paper, then its dimensions are projected onto thick cardboard. A blank is cut out of it, placed on lumber, on which its outline is outlined. Next is a selection of wood. If we are talking about plywood, then the easiest way is to make the cutouts yourself using.

Parts processing

- This applies to both grinding surfaces and rounding all edges. No matter what tool you use to cut the wood, its microscopic fractions along the cut line will certainly remain. And these are potential thorns.

- Wood, regardless of the variety, is affected by mold and mildew. It's all a matter of time, and this largely depends on the breed and operating conditions. But in any case it is necessary.

Drying lumber

IN in this case This means additional exposure before assembling the sun lounger, after impregnation. Even if the tree was initially selected dry, there is a high probability that during storage it was partially saturated with moisture. Therefore, drying after processing will not hurt. At the same time, you can make sure that the geometry of the parts is not broken. If any distortions appear, it is better to level them out immediately than to later disassemble the finished chaise longue and eliminate the shortcomings (or completely replace the part).

Assembly of the structure

There is a drawing that shows, in addition to the dimensions, the joints of the parts, so the algorithm of actions is chosen independently. Some features worth noting:

The specifics of fastening structural elements raise many questions. What to use?

Firstly, only self-tapping screws, and for wood, are used as fasteners. Nails are not suitable for these purposes because they easily split dry material. And it’s not always possible to hammer them strictly vertically. Taking into account the small thickness of the wood blanks, it is not a fact that the tips of the fasteners will not come out. In terms of maintainability, self-tapping screws also benefit - disassembling/replacing parts/assembling a chaise longue is not difficult.

Secondly, you shouldn’t limit yourself to just one fastener. You definitely need to think about strengthening the structure. How to do this depends on the skills of the master and the specific scheme. Tenon-groove joints (with adhesive fit), corners, strips, earrings – there are plenty of options.

Installation of fasteners also has its own peculiarity. To prevent cracks from appearing in the wood and to ensure that the self-tapping screw goes without distortions, a channel is first drilled. The cross-section is slightly smaller than that of the hardware leg. Next is a chamfer (according to the diameter of its head), with the expectation that it will “sink” by about 0.5 - 1 mm. Disguising fasteners in wood is easy. There are not only sealants and mastics on sale, but also mini plastic plugs designed specifically for hiding connecting elements in furniture. And any color, so you can match it general design sun lounger.

If it turns out to be quite massive, you should think about installing roller bearings in the lower parts of the legs. IN furniture showrooms can be found suitable option. This chaise longue will be easy to move alone.

These are the main recommendations, since assembling it yourself is a creative process. Having a ready-made drawing of a sun lounger and minimal skills in working with the simplest household tool, it is not difficult to manufacture individual structural elements and assemble them. The main thing is to think everything through carefully, and success is guaranteed.

A chaise longue in a garden plot is an important furniture attribute, which is suitable for a useful and comfortable pastime, and also adds a special originality to the design. local area. Made from natural materials the product can be placed either on sunny area, and in the shade, but in any case it will harmoniously fit into the home interior.

Do-it-yourself wooden sun loungers for a summer residence are nearby distinctive characteristics and the advantages thanks to which this piece of furniture has gained popularity. Among the main advantages of its use are the following:

- the design features of the chaise lounge, the structure of its back, armrests and seat allow a person to comfortably be in a semi-lying or semi-sitting state, which contributes to greater relaxation;

- possibility of use for sunbathing;

- due to the lightness of the material and simplicity of design, the chaise longue is quite portable and can be moved from place to place;

- a folding chaise longue with your own hands can be used as a bench for relaxation;

- has small dimensions when folded, which facilitates its storage;

- wooden sun loungers are famous for their durability and endurance in use;

- has high aesthetic appeal.

Types of country lounge chairs

Depending on the design features, the chaise lounge chair is conventionally divided into several types:

- Monolithic products– these are chairs in which all components are interconnected during manufacturing and cannot be disassembled. These sun loungers have good performance strength, endurance and can withstand heavy loads. However, when using such a piece of furniture, certain inconveniences may arise. For example, in such a product it is impossible to change the angle of the backrest, it cannot be folded, due to which moving from place to place will be problematic.

- Monolithic chair with inserts. This type of DIY chaise lounge made of wood has a decorative appeal. The presence of additional fragments made of various materials, will reduce strength and reliability, but this will make the chair more aesthetically pleasing and neat.

- Portable sun lounger. The design of such a product provides for a mechanism through which you can quickly and easily change the position and overall configuration of the chair. You can change the angle of the footrest, headrest or backrest. In addition, a folding lounge chair can be transformed into a compact cargo and taken with you when traveling out of town.

- Armchair on a metal base. It is somewhat more difficult to make such a chaise lounge with your own hands from a photo, and you often buy a ready-made product. It is distinguished by the presence of an aluminum or steel frame on which it is mounted fabric cloth. The advantage of the chair is its light weight, compactness, resistance to dirt and mobility.

Standard chaise longue: manufacturing guide

Install a multifunctional and decorative furniture simple enough. To make a chaise lounge with your own hands, you will need drawings. It takes a little effort and physical labor, and as a result get reliable design for leisure activities.

Crafting tools

- saw;

- self-tapping screws;

- wood putty;

- roulette;

- sandpaper;

- marker;

- paint of the desired color;

- drill;

- square

Materials for product processing

- wooden boards 400x2.5x8 cm – 4 pcs.;

- wooden blocks 400x5x10 cm – 3 pcs.;

- pins for fixation – 2 pcs.

Instructions for making a sun lounger

1. The primary task is to build a reliable frame. To do this you will need to make 4 parts from wooden beam: 2 longitudinal 215 cm and 2 transverse 50 cm long.

2. Let's start making the seat. To do this, you need to take a board and cut it into uniform bars 60 cm long. The design will require 13 such fragments.

3. Using self-tapping screws, we fix these sections to the chaise lounge frame so that there is a distance of 1 cm between them.

4. Making legs for future design. To give greater stability, in the seating area you need to make double supports 35 cm long. We make them from a block. To the side of the headboard, it is enough to attach single legs with a similar length.

5. We construct the back of the product. To make the frame, we prepare 2 parts 88 cm long, 3 parts 39 cm long. These dimensions must be observed so that the frame can fit into the main structure. In this case, small gaps should remain on all sides.

6. In the direction of the length of the product, you need to fix the boards on the back frame. To make the appearance more aesthetic, the top edge of the boards should be rounded.

7. We attach the backrest to the base of the chaise lounge so that it can easily change the raised and lowered position. To do this, you need to make holes at a distance of 9 cm from the edge of the seat. The grooves must be through and pass freely through both structures.

8. We fix the structure on both sides of the product with pins.

9. We make two grooves in the base of the sun lounger, where the support bars will be placed. This will allow you to hold the back of the product in different positions. One notch 5x10 cm should be made at a distance of 9 cm from the stud. The second groove is made 20 cm from the first, but with a slot size of 5x5 cm.

10. A support beam 60 cm long should be placed horizontally in the first groove. This will allow the backrest to rest on it and maintain a semi-sitting position.

11. To change the angle of inclination and make a reclining position, you need to remove the first beam and put a board in the second groove, only vertically.

12. Making your own sun lounger is almost complete. All that remains is to complete the final finishing of the structure by sanding and painting.

A guide to making a garden sun lounger with your own hands can be seen in the video here:

The original country chaise lounge: a step-by-step guide

An extraordinary chaise lounge for garden plot- not only a beautiful piece of furniture, but also suitable way wood recycling. Its advantage is that it is environmentally friendly, harmonizes with the countryside exterior and does not require additional decorative processing. And for a comfortable position of the body, you can cover it with a warm blanket or pillows.

Tools and materials for processing

- Round logs with a diameter of 75-120 mm.

- 18 V chainsaw.

- Cordless drill.

- Impact wrench 18 V.

- Screws.

- Deck screws and brackets.

- Drill.

Important! These sizes of logs are considered optimal, since they are easy to drill and the chaise longue will be light in weight.

Manufacturing instructions

- Initially, you need to prepare fragments from the log, each 45 cm long.

- Then you should create a layout for the future chaise lounge. To do this, use electrical tape that can be used to mark an outline on the floor.

3. Use a drill to make holes in the cut logs. These grooves will allow you to use shorter screws in the future.

4. Fasten all the pieces of wood together one by one. To do this, you can use a socket wrench and a cordless drill. You need to screw 4 screws into each log.

5. Turn the structure over and do the first test: sit, lie on it to see where it swings. In these places you can add another fragment for stability.

6. At the back of the lounge chair, fix the deck screws and steel brackets to make the structure more rigid and durable.

Ready! Construction works completed. Despite some difficulties and troubles of the process, as a result you get an original chaise lounge, which will become a useful and beautiful attribute of your summer cottage.

Examples of extraordinary ideas for making a sun lounger can be seen in the video:

How nice after hard times working day retire to the garden or sit on the lawn by the pond to relax, unwind and enjoy the sounds of nature. And what subject garden furniture most people associate with comfortable stay? Yes, a lawn chair! A comfortable portable extended chair, in addition to its direct functional value, will act as effective element exterior, emphasizing the style of the summer cottage. There is nothing difficult about making a garden sun lounger with your own hands. We have selected for you several options for easy-to-make sun loungers. It won’t be difficult to choose among them suitable model, which anyone can build.

This chaise lounge can be safely used instead of a bed: a flat surface, an adjustable backrest. What else do you need for an afternoon relaxation?! The only drawback of this design is that it is very problematic to move it around the site yourself.

Sun loungers of this design are very popular both among vacationers on the sea coast and among owners of suburban areas

But there is a way out! We suggest considering the option of a chaise lounge equipped with rollers. To make a sun lounger you need to prepare:

- 18 mm thick slabs of laminated spruce wood;

- Wooden beams 45x45 mm (for the frame);

- Boards 25 mm thick for cladding the sides;

- Jigsaw and screwdriver;

- Drills with a diameter of 40 mm for wood work;

- 4 mounting brackets for beds;

- Countersunk head screws;

- 4 rollers 100 mm high;

- Sanding sheet, grit 120-240;

- Varnish or paint for woodwork.

Plates of the required size can be purchased at a carpentry workshop or at the construction market. When choosing slabs, it is better to give preference to products made from coniferous species, since they are more resistant to precipitation.

The size of the sun lounger depends on the wishes of its owner. In most cases, the design is made with dimensions of 60x190 cm. Having decided on the dimensions of the sun lounger, we make two long and two short sides from wooden blocks. We assemble the structure frame from them, securing them together using fastening angles. We cover the outer side of the frame with boards.

On long slats at a distance of 5-8 cm from the corner, we attach the legs of the chaise lounge, the material for the manufacture of which was bars 5-10 cm long

We fix the legs to the boards using screws 60 mm long.

We mount the wheels: we install rollers in the center of the short legs of the chaise longue, fixing them with screws 30 mm long, equipped with a semicircular head with a diameter of 4 mm

For the manufacture of wooden lattice using a jigsaw, cut boards measuring 60x8 cm from the slabs.

We attach the slats to the bed using self-tapping screws, leaving a gap of 1-2 cm. To maintain the gap, it is most convenient to use special spacers

When planning to make a chaise lounge with an adjustable backrest, the lattice should be divided into two parts: the lounger and the headboard. We place both parts on connecting boards and fasten them together using a door hinge.

To arrange the fastening strip between the long beams of the chaise lounge frame, we fix the transverse rail. We fix the support stand on the mounting strip, fixing it on both sides with screws

The finished chaise lounge can only be processed by walking grinder, and open with varnish or paint.

We invite you to watch a video that shows how this chaise lounge model is assembled:

Option #2 – fabric chaise lounge on a frame

Another equally popular chaise lounge model that can be folded into an almost flat shape.

It is convenient to move a light chair around the site, choosing open sunny meadows for relaxation, or, on the contrary, shaded and hidden ones. prying eyes corners in the garden

To do folding chaise lounge you need to prepare:

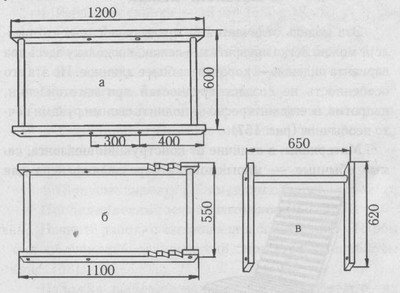

- Reiki rectangular section 25x60 mm thick (2 parts 120 cm long, two 110 cm long and two 62 cm long);

- Reiki round section 2 cm in diameter (one piece is 65 cm long, two are 60 cm long, two are 50 cm long);

- Cut durable fabric size 200x50 cm;

- Nuts and furniture bolts D8 mm;

- Fine-grained sandpaper and round needle file;

- PVA glue.

It is better to make slats from hardwood species, which include birch, beech or oak. To make a sun lounger, it is better to use fabrics that are highly durable and resistant to abrasion. For example: canvas, tarpaulin, denim, mattress teak, camouflage.

Cut the slats to the required length. By using sandpaper carefully sand the surface.

According to the diagram, where A and B indicate the main frames, B represents the stop-regulator, we assemble the main structural elements

In the long slats of the main frames, at a distance of 40 and 70 cm from the corners of the structure, we drill holes with a diameter of 8 mm, and then grind them using a round needle file.

So that you can change the position of the backrest in the chaise lounge, we make 3-4 cutouts in frame B at a distance of 7-10 cm. To arrange the seat, we drill holes with a diameter of 2 cm, stepping back from the two ends of the slats. We install crossbars into the holes - round slats, the ends of which are pre-lubricated with PVA glue.

Let's start assembling the sun lounger: we connect parts A and B using screws inserted through the upper holes. Using the same principle, we connect parts A and B, only through the lower holes

The frame is assembled. All that remains is to cut out and sew the seat. The length of the cut is determined by the possibility of folding. A cut that is too short will not allow the chaise longue to fold, and a cut that is too long will sag when folded down. To determine optimal length, you need to fold the chaise longue and measure the fabric: it should be slightly stretched, but without force.

We nail a piece of fabric with processed edges to the round slats located on parts A and B. To do this, we wrap the edge of the cut around the crossbars, and then fix them with small nails with thick heads. An option is possible in which “loops” are made at the edges of the cut and put on the crossbars.

Option #3 – Kentucky folding chair

The original chair is assembled entirely from blocks. If necessary, the chair can always be folded and stored.

The advantage of this garden chair the fact that when disassembled it does not take up much space, while the design is designed in such a way that it allows you to completely relax your muscles

To make a chair we will need:

- Wooden blocks measuring 45x30 mm;

- Galvanized wire D 4 mm;

- 16 pieces of galvanized staples for fixing the wire;

- Fine-grained sandpaper;

- Hammer and wire cutters.

For making a chair, bars measuring 50x33 mm are also quite suitable, which can be obtained by sawing a 50x100 mm board into three equal parts. The total length of the bars should be 13 meters.

Instead of galvanized wire and staples, you can use galvanized studs, the edges of which are secured with eight nuts and washers.

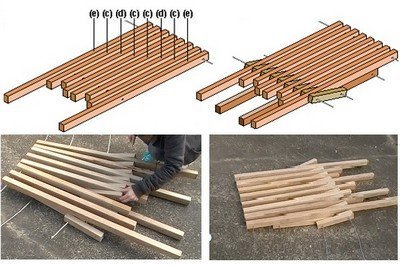

To determine the required number and length of wooden blocks it is convenient to use pivot table. We carry out according to the drawing through holes

The diameter of the holes should be 1.5-2 mm greater than the thickness of the wire used. Having prepared required amount bars, you should carefully process all the edges, sanding the surface with fine-grained sandpaper.

Let's start assembling the structure.

For clarity, we use the assembly diagram of the seat with dividers, as well as the back of the chair. The dotted lines indicate the locations of through holes with wire threaded through them.

On a flat surface, according to the diagram, we lay out the bars for arranging the seat. Pass wire through through holes

Using the same principle, we assemble seats with dividers, connecting wooden blocks with pieces of galvanized wire

The main structural elements have been assembled. We take the ends of the wire, holding the sides of the structure, and carefully lift the chair.

All that remains is to cut off the excess wire with wire cutters, and then bend and secure the ends with galvanized staples

Chaise lounge for the garden: 8 DIY models

The garden chair is ready. If desired, it can be coated with a semi-matte woodworking varnish. This will significantly extend the service life of such a popular element of garden furniture.

Chaise lounge - comfortable and lightweight design armchairs, which are used in recreation areas: on the beaches, by the pools, an integral part of the decoration of the dacha. It can be used to relax after a hard day at work, caress yourself in the sun's rays or take a nap under the shade of the local trees, away from the prying eyes of ordinary people.

In this article we will talk to you about how you can make a regular wooden chaise lounge, we give examples of photographs, videos and instructions.

How to make a sun lounger with your own hands?

First we select suitable look and modification of the chaise lounge. The main material can be plastic, wood, synthetic fabric and aluminum. We have chosen the most affordable option wooden sun lounger.

Type of wood for a sun lounger

The choice of tree is based on the following principles:

- material capabilities;

- future owner's preferences:

- garden style;

- available materials.

When choosing future wood for your sun lounger, you pay attention to mechanical properties one type of wood or another. For example, the most durable wood species are considered to be: ash, oak, larch and beech. With them the design will delight you long years. Wood is distinguished not only by its durability, but also by its aesthetic component.

In its turn, finished goods made from noble wood is not the cheapest pleasure for the buyer. Such a thing is not always available to the average consumer who is trying to save every extra penny, because money is never too much. Before assembling the sun lounger with my own hands, look at the drawings of the sun lounger.

Type of wooden chaise lounge

A hand-made chaise lounge will not only be an example of prudent spending of the family budget, but will also add a special touch. appearance To your fabulous country garden.

Countless drawings, projects and ready-made solutions wooden sun loungers. The dimensions of homemade sun loungers are identical to industrial models.

A folding chaise lounge is much more comfortable than a regular one. It is easy to move around the area, and in winter it can be folded and put away, even cloudy weather will not create any interference.

Preparing and making a sun lounger

Pre-purchased parts for the structures of the future sun lounger must be treated, we impregnate the wood with an antiseptic and an anti-corrosion compound. We grind the surface to a perfectly smooth state. We put the resulting details aside and begin to study the drawing.

If you turn to the latter, you will notice that crossbars are attached to the lower part of the legs. They allow you to fix the backrest in the desired position. When installing only one plank, it is first necessary to make cuts in the places where the planks are installed in increments of 5 cm, starting from 20 centimeters.

The back frame must have places for attaching bolts, we retreat from the edge on each side by 41 centimeters, and on the very base of the seat - 43 centimeters from the top.

First you need to assemble the frame for the back. The main load will be transferred to the 20 x 60 x 610 mm bar, so pay attention Special attention its consolidation. It should be recorded as efficiently as possible. It is customary to leave a distance of 1 centimeter between the slats. It will be needed to secure the fabric in the future.

Using the instructions described above, we assemble the main frame. Then, we connect 2 frames together - the back and the seat. Pay attention to the back frame, you need to drill a hole on it on both sides, the distance is 41 centimeters for the back and 43 centimeters for the seat. Screw the two parts together using nuts and bolts.

Attention! During regular use of the chair, the nuts may gradually loosen and unscrew. To avoid this problem completely, tighten the locknuts. For better fixation of the nuts, “Moment” or regular paint can be used.

To determine the degree of free play, first tighten the nut tightly and then gradually loosen it. Let the paint and glue completely set.

On next stage you need to install backrest support. The planks are secured with bolts and washers. Choose only thick fabric for seats, optimal choice there will be tarpaulin, canvas and denim.

The fabric blank is folded in half and stitched with an indentation of 1.5 centimeters. After this, it must be turned out. We bend a piece of fabric on one side so that the rod can be inserted and stitch it. We do the same on the other side.

We push each end of the folded fabric between the slats and insert a rod into it. We will get a tightly fixed seat, and dismantling it for washing at the same time will not cause any problems.

DIY photo of sun loungers

Camping is a great way to relax. Some go to the village, others go to the dacha, where they are expected comfortable sun loungers allowing you to forget about environment and take a little nap. Such attributes relieve tension from the spine and almost all muscles; you just have to choose the most comfortable option for yourself: a rocking chair, a regular folding chair or a lounger.

The easiest way is to buy a ready-made chaise longue, choosing it to match the interior of the dacha or to suit your individual needs. But not everyone has the financial means to do this. A handmade model is more valuable and fully suits the taste of its owner.

Kinds

Create homemade sun loungers is not difficult. Before starting work, you need to choose the type of furniture you want to bring to life. There are several of them:

- Armchair. As a base, you can take elements from a crib or cot. Armrests are made upon request.

- Sun lounger. The creation process takes about four hours. The product can be made of plastic or wood, which is ideally sanded and varnished.

- Rocking chair. Its back is at an angle, so it is possible to lie down, relax, and take a nap. At the same time, it is important to make the bottom of the attribute strong so that it does not become loose when swinging.

In addition to the distribution of products across appearance, there are variations in the types of structures:

- Monolithic. When it is created, all elements are fastened together, so disassembly is impossible. This chaise lounge is strong and durable, but the backrest is not adjustable and the product as a whole does not fold. As a result, problems may arise with its transportation.

- Portable. The reliable and compact folding attribute has special mechanism, which allows you to easily adjust its position.

- Soldered with inserts. This practical product will decorate any interior thanks to its attractive appearance. But inserts made from other materials do not guarantee durability.

If the chaise lounge is made from durable materials, it can be supplemented with a blanket, pillows and other items for a comfortable rest.

Possible materials

When choosing the material for making a sun lounger, you need to take into account its location. It could be country cottage area, beach, special place by the pool or even at home. The following options exist:

- Wooden. This design is durable, comfortable, environmentally friendly, and differs in shape and appearance. The only drawback is the heavy weight. To make it easier to carry the chaise lounge, wheels are attached to the legs.

- Plastic. The products are lightweight, inexpensive, and easy to care for. One of the negative aspects is its fragility.

- Fabric. The attributes are convenient and compact. The frame can be made of boards, metal, profile pipe.

- Made from rattan. Against the backdrop of nature, such sun loungers look incomparable. They are environmentally friendly, but expensive. If you have the skills to weave, it’s easy to make such an attribute for relaxation.

- Made from PVC. The same lounger with a fabric base, but the frame is based on PVC pipes.

Making a sun lounger yourself is not difficult; you need to correctly determine the dimensions of all the elements and spend several hours assembling them.

Manufacturing diagram of various options

Before you start making a recreational attribute, you need to draw its diagram. She plays important role, because it determines the dimensions of the elements for the product, their shape, quantity and other details. You can make such a scheme yourself, but not everyone can do it. Therefore, we will give an example of such a scheme. A high-quality chaise lounge (fabric) will be obtained according to this drawing with dimensions.

All that remains is to find the materials to create a lounger. There are also other drawing options different types sun loungers.

From a wooden lattice

This chaise lounge is quite durable, reliable, and its backrest is adjustable. For such a model you should take wood slabs from coniferous trees, as they are resistant to climate change. Here is a diagram with the indicated dimensions:

All work is carried out in stages:

- A frame is created from bars, it is fastened with metal corners.

- TO outside boards are attached, and legs are attached to them.

- The slab is sawed using a jigsaw and a wooden lattice is made.

- The adjustable backrest is separated from the main part of the attribute and secured to it with a door hinge.

- A fastening strip is attached to the headboard area, and a stand is attached to it with screws.

- The finished product is sanded and varnished.

If the lounger will often move from one place to another in the future, it is better to attach wheels to its legs, because the weight of the attribute itself will be considerable.

Fabric on frame

Work on the frame occurs in the following order:

- A ready-made base is taken from a cot or crib. If this is not available, slats of the required length are taken or cut and sanded.

- Holes are drilled in the main frame, the other is equipped with cutouts (4 pieces) to adjust the backrest tilt.

- Holes are made at both ends of the slats to install the seat.

- Circular cross members lubricated with glue and installed in the holes.

Now you should prepare the seat itself. To do this, you need to fold the base of the product and measure out a piece of fabric. It should sag to accommodate the owner comfortably. On sewing machine All edges are processed. Then the cloth is wrapped around the transverse round crossbar and nailed on both sides with small nails. The attribute is ready and you can enjoy your vacation.

From pallets

This is the most easy option creating a sun lounger. This product is light in weight (easy to move to different places) and practical (you can put a mattress on it for more comfort). The work occurs in the following order:

- Pallets are dismantled, all the nails are pulled out.

- A frame is made from two even boards. They are laid edgewise and parallel to each other, and the rest are sawn in half and attached to the base. The result is a seat with two support legs behind.

- To create the front legs, a board from a pallet is sawn into two equal parts. Next, using bolts, they are screwed to the base of the seat and tightened with nuts and washers. A cross bar is necessary to strengthen the legs.

- The back is created from two boards, which are connected to the seat frame using bolts, nuts, and washers. This should be done under equal angle. After that on support boards The boards for the back are attached with screws. Behind it, a block is attached to the rear legs - this is necessary for the strength of the structure.

The final step is to sand the attribute with an emery sheet.

To prevent the boards from rotting, the product is varnished.

Made from polypropylene pipes

The design of such a chaise lounge is identical to the fabric one, only wooden frame here replaced by polypropylene pipes. To create the product, you need 2-inch pipes, fittings in the form of the letters “g” and “t”, 8 and 6 pieces, respectively. The assembly process has several stages:

- First, a vertical bar is made. Take a T-shaped connector and use it to fasten 30 and 45 cm pipes. L-shaped fittings are put on the ends. The lower vertical is also fastened and the two sides are connected.

- Important point: the horizontal crossbar must be solid and have a length of 66 cm. It is mounted closer to the connection with the letter “T”, which must be directed towards the inside of the structure. The other side is two 30 cm pipes, fastened with a T-fitting. This tee must be rotated 45 degrees from the oblong side. The final result is a rectangle.

- For a rotating seat, a 5-centimeter pipe is inserted into the triple connecting element, which is secured with the same part. This will be the basis of the horizontal frame.

- The long sides of the horizontal frame are made in the same way as the vertical ones. For the crossbars, take a tube 30 cm long and another, consisting of 2 x 20 cm with a tee fitting. The result is a rectangular figure within the same figure.

- The seat will be between a short section horizontal section and oblong vertical. After adjusting the tilt level, a support is inserted at the back.

The frame is ready, which means it is now necessary fabric base. To do this, take a thick canvas and attach it to the base.

"Kentucky"

This leisure attribute has a number of advantages: compact, convenient, easy to fold, light weight, durable and reliable, and takes up little space when folded. In appearance it resembles a chair with a high back. Unusual way the assembly looks original. To do this, you will need bars, galvanized wire (diameter 4 mm) and the same brackets for fixing the wire (16 pieces), wire cutters, and a hammer. The process goes like this:

- A protective coating is applied to the bars. But the parts must already be ready for assembly.

- Holes are made. However, they should be a couple of millimeters larger than the wire.

- The bars are assembled in an interesting way, which makes the whole design look creative. Here is the diagram:

At the end of the entire process, the chair carefully rises and unfolds. This folding product looks stylish and modern.

Original ideas

People with creative thinking do not always want to see simple sun loungers on their territory, so there are several original ideas creating models for recreation.

From birch logs

This design has unusual look, so you have to work hard. For such a lounger you need birch logs with a diameter of 75-120 mm. But you need to take into account that the larger the diameter of the chocks, the more the finished product will weigh. Before you start, you should stock up on the following tools:

- electric saw;

- drill;

- set of drills;

- self-tapping screws;

- staples.