The wood-burning sauna stove attracts attention with its compact, aesthetic appearance and inexpensive price.

Heating speed With positive side characterizes the technological component of the design, and ease of maintenance allows you to keep the heating device in good condition.

Which one to choose? Requirements for wood-burning sauna stoves

The construction of wood-burning bath products includes:

- installation of furnace and screens, made of metal;

- presence around the structure chimney, insulated from heat;

- arrangement in the next room fireboxes consuming oxygen;

- air access and circulation;

- air circulation at facing the casing with brick;

- firebox firewood mainly hardwood ;

- timely removal of combustion products;

- regular chimney cleaning from soot.

Important! Fire safety during the construction and operation of sauna stoves requires strict implementation established rules.

Criteria for choosing the most suitable stove for a bath

Taking into account the features of the installed structure will depend efficiency and quality of heating premises. Wood-burning sauna structures are mainly built made of brick, they rarely require cladding and have good balanced thermal output.

Metal Wood products can be purchased at specialized retail outlets. Industrial enterprises have mastered the production of these products and offer consumers different models indicating technical characteristics.

When purchasing a stove you must be guided by certain criteria, among which:

- power ratio designs to volume bath room ( per 1 cu. m - 1 kW power);

- thermal output steel or cast iron structure (air temperature at the bottom of the steam room should be 40-50 degrees);

- duration of combustion of one bookmark firewood (determined by the consumer individually);

- Availability combustion tunnel ensuring unhindered air flow;

- presence in the combustion door heat resistant glass, through which the flame of fire is visible.

Reference. The choice of heating design is significantly influenced by square steam room, as well as properties and characteristics of the material, from which the stove is made.

Room area

The power of the heating structure must correspond to the area and volume of the steam room. During construction ovens taken into account:

- type, power and volume future heating device;

- location;

- volume designs together with facing;

- ceiling height indoors.

Important! Often, consumers mistakenly believe that the power of the structure should be greater than necessary. Exceeding power indicators leads to temperature imbalance and reducing the resulting effect from staying in the steam room.

High-quality and uniform heating is achieved only when it is found correct ratio power to the steam room area.

Furnace size

The power of any heating device directly depends on firebox dimensions. At independent construction For a wood-burning stove, all the necessary parameters must be correctly calculated that will correspond to the size of the room.

Based on the total volume of the steam room, the power is calculated according to the following scheme: 1 cu. m = 1 kW power. If power divide by a factor of 0.5, we'll find out firebox volume in liters, A extracting from the received volume cube root — linear quantities wood firebox.

Based on the established dimensions, the parameters of the structure constructed from brick will be determined. Standard size of one brick(long 250 , width 120 and height 65 mm) will allow you to calculate the dimensions of the heating installation. Wherein 5 mm is added for each seam.

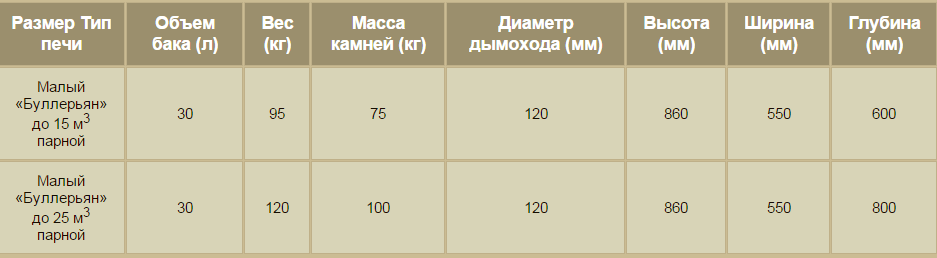

Produced metal structures have established dimensions And specifications. Thus, the device is selected taking into account the volume of the steam room.

You might also be interested in:

Materials

The manufacture of sauna stoves involves the construction of a structure from the appropriate grades fireproof heat-resistant bricks or its production made of metal.

Brick construction is characterized by a long warm-up period, but retains heat for a long time and distributes heat evenly. The brick sauna stove is safe by accidental touch.

Metal structures heat up quickly and cool down just as quickly. High if handled carelessly the likelihood of getting burned.

To solve the problem of heat loss and safety, the owners of most bathhouses are trying impose metal constructions natural stones, artificial stone or brick.

Efficiency from facing with these materials significantly increases, the design begins to conserve thermal energy and use it rationally.

Descriptions of the best stoves: how to make a personal rating

The choice of design largely depends from goals, purpose and characteristic features premises. Bathhouse and sauna are completely different directions with opposite temperature conditions, dry or humid air, as well as the absence or presence of steam.

Interior decoration The design of such premises is different and requires a special approach to the selection of heating devices.

For a wooden bath

Wooden baths are different increased fire hazard. The walls, ceiling - almost all elements of the steam room are made of wood. Furnaces are built in wooden rooms mostly made of brick. Purchased from a retail chain, metal structures are faced with natural stones, brick or artificial stone.

When choosing a heating device, the main attention is paid to designs with remote firebox, which for safety reasons is taken to a room adjacent to the steam room.

Photo 1. Brick stove for a wooden bath with an external firebox; firewood can be placed from the dressing room.

The choice of oven depends on technology for its production and is characterized by a volumetric firebox, as well as the presence of space for placing a certain number of stones above the heating structure.

Special attention when purchasing a design please pay attention on the chimney, which is made of metal and for safety reasons must be insulated from the ceiling with non-combustible materials.

Reference. The choice of furnace largely depends on criteria that take into account features and characteristics of the structure, as well as the existing decoration of the steam room.

For a traditional Russian bath

The Russian bathhouse features a heavy stove high power , which retains heat for a long time and gives wet steam. The requirements for choosing a design for a Russian bath are much higher, and choosing a heating device to constantly maintain high air humidity can be difficult.

To reach in the steam room 100% humidity air and temperatures 50-70 degrees, the oven should be checked for compliance with the instructions.

Photo 2. A brick stove with a closed heater and a boiler for heating water is perfect for a Russian bath.

The design for the Russian bath is made in such a way that stones are located behind a constantly closed door inside the heating device. Access to the stones is opened only when there is a need to add water. This feature allows you to increase the heating of the stones several times more than when they are placed on the surface.

The selection of a stove for a Russian bath is also carried out according to a criterion that provides for the possibility heat water in a boiler.

Important! Unlike a sauna, a person staying in the steam room of a Russian bath is constantly on the move, throwing water on the stones. Rest comes after leaving the steam room. This fact also influences the choice of a suitable heating device.

For sauna

Saunas are characterized by dry hot air, temperature which reaches 120 degrees, A humidity does not exceed 25%.

In saunas, as in wooden baths Periodic overturning of water onto the stones is also provided. But the process of generating steam in a sauna is not the main one and the steam effect quickly disappears due to good ventilation of the room.

Photo 3. A compact metal stove with an open heater will provide the sauna with heat and dry steam.

The choice of heating devices for a sauna is based on designs that, according to the features and characteristics of the room, can provide dry hot air.

Important! When choosing a sauna stove, pay attention to low human activity relaxing in the steam room. Thanks to dry steam, sweating is achieved naturally, after which the person calmly leaves the steam room.

The choice can fall on any wood-burning stove with an open arrangement of stones. The power of the structure is selected according to the size of the room.

Useful video

A video that talks about some of the intricacies of choosing a stove for a bath: when to start planning the installation, what to heat with and what heating modes are used.

Safety precautions: the wood-burning stove must be heated correctly!

Any oven where fuel is used to heat the room, considered a fire hazard. Basic Rules safe use of wood-burning sauna stoves:

- forbidden leave burning stove unattended; Odnoklassniki

The conditions of the steam room differ sharply from the microclimate of other rooms. It is difficult to say which stoves are best for a bath; the choice depends on the design of the building and the preferences of the owner. Air humidity in steam rooms various types varies from 0 to 100%, temperature - from 30 to 150 °C.

- Ensuring a sufficient level of heating of the stones (200-700 ° C). The water that gets on them should turn into light steam.

- Creating an optimal temperature regime. It is better to stick to 40-45 °C near the floor and 90-100 °C near the ceiling.

- Safe removal of carbon monoxide and other combustion products is required.

- Uniform combustion of fuel in the stove and heat distribution in the bathhouse.

- Safety for the body, protection against fire. It is better to avoid excessive infrared radiation.

- Contact of the housing surface with flammable substances, materials, etc. is prohibited.

When choosing heating equipment, you should take into account some parameters of the sauna and bathhouse stove design:

The answer to the question of which stove to put in the bathhouse is obvious - a heater is best. The heat accumulator is dense rounded cobblestones of different sizes. The stones heat up to high temperatures, after which they give off heat for a long time. An open backfill is characterized by moist steam and rapid heating and cooling of air. Closed heaters are more powerful, heat cobblestones better, and you can’t get burned on them. But they take longer to heat up and cool down; they can only be used to create dry sauna conditions.

Main types of sauna stoves

1. Metal heaters.

Made from steel, cast iron or combinations thereof. Cast iron structures durable and reliable, quickly reaching significant temperatures. The walls of steel units are thinner and less heat-resistant; they can deform from excessive thermal loads. Reputable manufacturers make heaters from stainless steel containing 13% chromium. It is better to choose a metal sauna stove based on the size of the room; it is not suitable for spacious public steam rooms. Compared to brick stoves, metal stoves are cheaper, mobile, heat-resistant, compact, and multifunctional. Their installation is less labor-intensive and complicated.

Made from steel, cast iron or combinations thereof. Cast iron structures durable and reliable, quickly reaching significant temperatures. The walls of steel units are thinner and less heat-resistant; they can deform from excessive thermal loads. Reputable manufacturers make heaters from stainless steel containing 13% chromium. It is better to choose a metal sauna stove based on the size of the room; it is not suitable for spacious public steam rooms. Compared to brick stoves, metal stoves are cheaper, mobile, heat-resistant, compact, and multifunctional. Their installation is less labor-intensive and complicated.

The efficiency of such stoves is higher, the air warms up better and faster, for this reason the room has low humidity and high temperature. Metal is stronger than brick and can withstand heavy loads. There are a number of disadvantages: rapid cooling, low fire safety, risk of heat stroke.

2. Wood-burning.

Hard wood and sawdust briquettes are suitable for kindling. Professionals agree that wood stoves- best for use in the bath. Their advantages include: independence from electricity, economical fuel, long-term maintenance of optimal temperature, crackling and live fire create a special atmosphere. Disadvantages of wood-burning heaters: fire hazard, the need for regular cleaning and installation of the chimney, lack of autonomy.

3. Electric sauna stoves.

The least troublesome to operate and maintain, but the most expensive. The heating part is a ceramic or metal heating element; all elements are subject to electrical safety requirements. Double casing reduces the risk of burns. If we compare wood-burning and electric sauna stoves, the latter are as compact as possible, better automated, without a chimney, while the stones heat up to the same high temperatures, and in less time. Difficulties arise when there are power outages and lack of good ventilation.

4. Gas oven.

It is turned off when people enter the steam room. The equipment runs on natural or bottled gas. The design includes a chimney. A gas heater, like an electric one, is compact, environmentally friendly, easy to use and maintain. But when using it, the air in the bath takes a long time to heat up. Gas will cost more than firewood and less than electricity.

The question often arises which stove is better for a bath: with an external firebox or an internal one. It is advisable to store firewood from the dressing room in a small steam room if you want to keep this room clean. The disadvantage of the scheme is the expensive construction of the tunnel, lack of control from the inside.

Avid bathhouse attendants, in a debate about which sauna stove is better: brick or iron, always defend the first option. This choice is due to tradition, environmental friendliness, ability to retain heat, durability and uniform heating. Metal bath units are better in terms of heating speed, level of control, automation capabilities and ease of installation.

Review of models from popular manufacturers

1. Ermak. Wood-burning options 12, 16, 20, 24, 30, 50 with a pre-furnace tunnel are popular. Demand is due to variable functionality. The design can be supplemented with one or more options: a heat exchanger, a heater grid or a hanging tank. The numbers tell you how to choose a stove for a bath. For example, Ermak-12 is suitable for a steam room of 12 m3, its cost: 8,500 - 13,000 rubles.

1. Ermak. Wood-burning options 12, 16, 20, 24, 30, 50 with a pre-furnace tunnel are popular. Demand is due to variable functionality. The design can be supplemented with one or more options: a heat exchanger, a heater grid or a hanging tank. The numbers tell you how to choose a stove for a bath. For example, Ermak-12 is suitable for a steam room of 12 m3, its cost: 8,500 - 13,000 rubles.

2. Termofor. The Tunguska stove for baths, produced in two sizes (16 m3 and 24 m3), with different configurations and appearance, has become widespread. Stainless steel better in terms of weight and heat transfer efficiency. The cast iron grate can withstand intense heat well. It is possible to connect a heat exchanger. In specialized stores it sells for 12,000 - 23,000 rubles.

3. Teplodar. Reliable representatives of the Rus line for baths give control over the balance of temperature and air humidity. The design is attractive due to its lack of corners. All models are equipped with a large-capacity convection-ventilated stove and a self-cooling door. The load of stones on the chimney collector is reduced. The water heating tank can be moved outside the steam room. The cost varies from 7,000 – 30,000 rubles.

4. Breneran produces the best-rated ovens for dry air baths (Breneran-Premium AOT-12 and others). The products are famous for their reasonable price, ease of maintenance and high quality. The grates are made of cast iron, so they do not burn; options with a closed and open heater have been developed. The cost ranges from 10,000 to 52,000 rubles.

4. Breneran produces the best-rated ovens for dry air baths (Breneran-Premium AOT-12 and others). The products are famous for their reasonable price, ease of maintenance and high quality. The grates are made of cast iron, so they do not burn; options with a closed and open heater have been developed. The cost ranges from 10,000 to 52,000 rubles.

Feringer. It has been proven that the Mini Lamel in stone copes better than other models with creating the conditions of a Russian bath or sauna. Several types available facing material. The furnace blowing system allows you to quickly dry and warm up the steam room. The package includes: a door with heat-resistant glass, a steam gun, and a phytocontainer. You can purchase the device for 54,000 rubles.

The stove is the heart of any sauna, so the choice of equipment for heating a steam room must be approached with maximum responsibility and knowledge of the matter. The available range of offers is impressive: you can install either a home-made stove or a factory-made unit, give preference to a brick or metal structure, equip the steam room with a traditional device that burns fuel, or buy a modern electric model, etc.

In Soviet and even more ancient times, lovers of steam baths did not have to be particularly picky when choosing a stove: it was almost impossible to find a ready-made design for sale, and even if it was possible, the cost of the unit was simply unaffordable for most citizens.

The only option for solving this problem was self-production stoves or entrusting this activity to a business neighbor - it took an experienced welder a maximum of 2-3 days to assemble the structure. Homemade stoves, made of durable Soviet metal, served well for decades, conscientiously coping with all the tasks assigned to them. Modern designs, assembled with your own hands, last noticeably less. And with the purchase of a ready-made unit, everything is much simpler nowadays - if only there was money.

So what to choose: a homemade stove or a ready-made model?

Table. Comparative characteristics of homemade and ready-made sauna stoves

| Criteria for evaluation |

|

|

|---|---|---|

| Cost and functionality | Making your own sauna stove will require more modest financial investments compared to purchasing the simplest factory-made heating unit. However, the functionality of a “makeshift” stove will be limited: it can only heat the steam room and prepare hot water. | Buying a ready-made factory sauna stove will cost more than assembling such a unit on our own. However, the functionality of the factory models is at the same level. For example, a stove can heat not only the steam room itself, but also the rooms adjacent to it, perform the functions of a mini-fireplace, provide more efficient and voluminous preparation of hot water, etc. |

| Security and Performance | In terms of performance, homemade stoves are inferior to the vast majority of high-quality factory-made analogues. Of course, with a competent and qualified approach to the design and manufacture of a homemade stove, it will be able to demonstrate quite good efficiency, however, any errors in the design process can lead to fatal consequences, including fire, complete destruction of the bathhouse. It is for this reason that the assembly of a homemade stove should be carried out exclusively a competent specialist with relevant knowledge and experience. | There are no complaints about the safety of high-quality and certified factory sauna stoves - as a rule, similar designs assembled from heat-resistant steel, capable of withstanding temperatures up to +750 degrees or more. Efficiency varies depending on the model - information on this matter is provided by default in the device passport. |

| Cost-effective and easy to use | Homemade sauna stoves are made of thicker metal compared to their factory-made counterparts. The result is longer warm-up times and increased operating costs. Along with this, if you have the proper knowledge, you can assemble a very economical long-burning sauna stove on your own. | Factory ovens heat up in less time and generally use fuel more economically. |

| Other options | The appearance of a homemade stove, its dimensions, performance, service life and other similar indicators directly depend on the skill of the manufacturer, as well as the operating conditions of the unit. | Most finished stoves have compact dimensions, weigh a little, look beautiful and last quite a long time when compared with “handicraft” heaters. |

As practice shows, if you have sufficient financial resources, it is better not to “play the lottery” and buy a modern, functional, productive, safe and durable factory-made sauna stove. You can use a homemade analogue only if the owner is confident in the skill, qualifications and responsibility of the manufacturer.

Prices for sauna stove

sauna stove

“In black” and “in white”: what is the difference between such stoves?

Since ancient times, they knew how to heat the traditional Russian bathhouse “black” and “white”. Not only the characteristics of the bath procedures differed, but also the characteristics of the stoves used.

Table. Features of the “black” and “white” baths

| Type of bath | Description |

|---|---|

| A classic stove for a black sauna works like this: A fireplace covered with a metal grill is built directly in the steam room; Several rows of stones are laid on top of the lattice; During the combustion of wood in the hearth, the stones on the grate become heated and give off heat to the space around. There is no chimney provided. The resulting smoke escapes through window and door openings, providing additional uniform heating of surrounding surfaces. In the process of firing the stove, a large amount of soot is formed, which settles on the walls - it looks far from in the best possible way, but provides effective antiseptic protection of wood. The furnace lasts on average up to 2-3 hours. Finally, the coals and ash are removed from the room. Nowadays, almost no one does black baths, primarily because of the soot. At the same time, it is the settling soot that contributes to a significant increase in the hygiene and environmental friendliness of the steam room, which in many ways exceeds the similar characteristics for a traditional “white” bathhouse. |

| When it comes to talking about a bathhouse, the vast majority of people imagine a bathhouse “the white way” - this option has long become classic and taken for granted. Modern “white baths” have undergone a number of changes compared to their ancient Russian predecessors. Firstly, the steam room and wash room today, as a rule, are arranged in the form of separate rooms. Secondly, the part of the stove with the firebox is now often installed in the dressing room/rest room, and the side with the stones is located directly in the steam room. White stoves are equipped with a chimney and other additional elements, the presence of which ensures the most comfortable and safe operation baths |

Brick or metal: which stove material is better?

Metal and brick are traditional materials for making sauna stoves.

Brick stoves for baths

Traditionally in Rus', bathhouses were equipped with stationary brick kilns. This design has a number of advantages, among which the most important for the user are:

- uniform heating of the serviced room;

- light steam in a bath of any volume (provided proper arrangement ovens).

The construction of a full-fledged brick sauna stove is associated with a number of difficulties and important features.

Important! Brick stoves can only be equipped with a flow-through heater, which is why the ability to “add steam” appears only after the fuel has completely burned. At the same time, it takes at least 3-4 hours to heat the steam room.

An additional drawback in terms of ease of use of a brick sauna stove is the fact that even after 3-5 days of “downtime” the structure will require drying and heating. Otherwise, microcracks may appear, which, as they expand, will become a source of waste.

Otherwise, brick sauna stoves have solid advantages: they are solid, reliable, efficient and durable buildings that require only a competent approach to their arrangement and strict adherence to the rules for further operation.

Brick prices

Table. Types of brick sauna stoves

| Type of design | Description |

|---|---|

| Advantages of a closed heater: - very fast warming up; - creation of the most useful dry steam. The key drawback is the inability to supply water to the heater - if you do this, the stove will have to be heated again. Operating a closed heater is an extremely responsible undertaking: the slightest errors in the combustion mode, choice of fuel or stones can provoke the deposition of unburnt organic products inside the heater. As a result, users will not enjoy dry steam, but will be poisoned by carcinogenic and toxic substances. |

| It is characterized by higher safety indicators compared to the option discussed above, but it heats up noticeably slower. If you are planning bath procedures with “superheating”, the stove with an open heater will need to be constantly heated. Consequently, a creation of such a design should be taken out into the dressing room. If the visitor carelessly adds too much water, the heater will simply get cold and the bathing day will end. |

| A more advanced, safe and efficient unit compared to the previously discussed options. The section with stones is evenly heated by hot gases from each direction, with the exception of the front side. The features of this design make it possible to ensure rapid heating of the heater and the possibility of even more intense “boosting”. |

| The most perfect option. The heater is designed on the so-called vault. cap The highest temperature is observed in the space below it - the main source of heat. At the same time, there is nowhere for the heat to escape except into the laid stones. As a result, heating the stones takes just a few minutes, and you can press as much as you like. The stove does not require heating - the design independently selects the optimal mode, focusing on heat consumption. The main thing is that the firebox is not empty. Disadvantages of a stove with a bell-type heater: Complexity and high cost of arrangement; Additional costs for constructing a cap made of heat-resistant steel - a product made of ordinary steel will burn out very quickly; You can only add pressure using the built-in shower, i.e. water. For example, adding kvass, as many bathhouse attendants like, will not work here. |

Metal stoves for baths

Homemade structures are usually welded and made of steel. Factory models are mostly cast, cast iron.

Metal structures can boast of more rapid heating - just 1-2 hours after kindling, the steam room will be ready to receive visitors, but such stoves also cool down extremely quickly, which requires additional heating (recharging fuel) during the bathing procedures.

Activities for the design and assembly of a metal stove for a bath must be carried out in strict accordance with technology and safety provisions: mistakes made will, at a minimum, lead to an increase in fuel consumption and the inability to obtain light steam, and at a maximum, to fires with all the ensuing consequences.

The costs of installing a metal sauna stove are more modest compared to erecting a brick structure. Firstly, metal stoves do not need a solid foundation - usually they either make a light, non-buried support, or simply install the stove on a pre-laid dense sheet of material that does not support combustion.

Secondly, the cost of the metal used to make a sauna stove will by default be much more modest than the cost of laying a brick unit. Along with this, a metal stove without lining can effectively heat a room with a volume of no more than 20-25 m3. To increase the productivity of the furnace, it is lined with bricks.

Table. Popular designs of metal stoves

| Design | Description |

|---|---|

| The traditional potbelly stove is known to almost every owner of a country house, garage or some kind of utility room or storage room. The sauna option has 2 key differences from the traditional one: The design is complemented by a tray for placing stones; Under the stove firebox is paved with fireclay refractory bricks. In this case, masonry mortar is not used. A potbelly stove in a sauna requires a screen: the presence of a tray with stones prevents hot gases from circulating in the firebox, while the stones take away a significant portion of the heat. A compact potbelly stove of the specified dimensions will be able to serve a steam room with a volume of up to 20 m3. The stove does not require an individual foundation. The sauna potbelly stove is equipped with a chimney 400-500 cm high. The damper is not included in the design. To regulate the draft in the furnace there is a damper made of galvanized steel. You can apply no more than 250 ml of liquid to the stones in 20-30 minutes. Otherwise, the heater will get cold, and further stay in the sauna will be possible only if you are able to tolerate heavy steam. |

| All-welded stove made of steel with a thickness of about 4-6 mm. The capabilities of the unit are sufficient to warm up a small bathhouse with a volume of up to 25 m3. The main advantages of this solution are the simplicity of its design and high heating speed. The key disadvantage is the inability to attach a tank for preparing warm water. The stove does not need shielding - the stones already absorb the bulk of the heat, so the screen simply will not have anything to reflect. A blower must be made - without it, the efficiency of the furnace will drop significantly. |

| Brick structure in a case made of 3-4 mm steel. It can be installed in a bathhouse with a volume of up to 30-40 m3 - it will take about 2 hours to warm up such a room with this stove. It is possible to place a U-shaped hot water register in the smoke circulation - during the specified heating time it can supply about 50 liters of water heated to +40 degrees into the storage tank, which is enough for 2-4 people. Fireclay bricks are used for masonry. No foundation or screen needed. |

| In terms of its properties, this unit is in many ways similar to the all-welded design discussed earlier - it is almost impossible to install a water heater, but it is very easy to assemble the stove. The maximum room volume that such a stove can effectively heat is no more than 15 m3. Pressing is prohibited: the heater, in order to simplify the design, is not equipped with a cleaning/loading hatch. The key disadvantage of the stove is its short service life if used frequently. |

| The body is made from a barrel, the grille is made from reinforcement bars. As in the previous case, the internal lining is performed with fireclay bricks. On large premises This type of stove is definitely not designed for this. Its objective limit is a steam room with a volume of up to 10-12 m3 per visitor. The oven can heat such a space in 20 minutes. It cools down just as quickly. There is a small water tank (20 liters) covering the chimney pipe. |

Important! It is strongly recommended to cover any metal stove with a protective fence made of bricks or take other suitable safety measures - during operation of the unit, its metal body will heat up to fairly high values, and you are unlikely to be pleased with burns resulting from one careless movement.

Thus, metal wins if the budget for arranging a steam room is limited, or if the owner does not want to spend a lot of time on this event and the steam room, at the same time, has small area. Brick kilns are preferred when they want to get an efficient, reliable, most convenient and functional capital building that can fully serve for more than a dozen years.

Classic and modern, or heaters and electric stoves

Any combustion furnace solid fuel(in the bathhouse, following safety precautions, only firewood can be used for heating) are heaters. The principle of their operation is as follows: when burned, the fuel heats the stones, which, in turn, give off heat to the surrounding air.

A modern alternative to classic sauna stoves is a functional and safe electric heater. Purchasing one frees the owner from the need to prepare firewood and install a chimney - the stove runs on electricity and does not produce smoke. The design includes special heating elements, on top of which stones are laid. Next, you are invited to familiarize yourself with the comparative characteristics of the mentioned units and study the features of each of them.

Prices for electric heaters

electric heaters

Comparison of wood-burning and electric heaters

First, you are invited to familiarize yourself with the comparative assessment of wood-burning and electric stoves in accordance with key operational and technical parameters on a 5-point scale. Following the table will be more detailed information about the benefits of both options.

Table. Comparative assessment wood and electric heaters

| Evaluation criterion, out of 5 possible | ||

|---|---|---|

| Safety | 3 | 5 |

| Inertia | 2 | 4 |

| Ease of maintenance | 2 | 4 |

| Mode accuracy | 2 | 5 |

| Warm-up speed | 2 | 5 |

| Fuel storage | 2 | 5 |

Thus, the electric stove is superior to its wood-burning predecessor in all the given parameters - modern units easy to install, convenient to use and low maintenance. The only indicator by which a solid fuel stove can outperform a unit with heating elements is the amount of operating costs - the cost of firewood in practice turns out to be more modest than the cost of paying electricity bills.

So why do people still prefer traditional heaters, whether made of brick or metal? The whole point, by and large, is the ability to observe a “live fire”, the presence of which for many users makes visiting a bathhouse a more comfortable experience.

Electric ovens are chosen by supporters modern solutions and effective technologies. Among the main advantages of an electric heater over a solid fuel unit, it should be noted that there is no need to prepare fuel reserves, and there is no need to be distracted by reloading firewood during bathing procedures - the stove is simply plugged into the network and works as long as the owner needs, without distracting him from rest.

An additional advantage, especially for owners of modest-sized steam rooms, is the ability to install an electric stove on the wall, and not just on the floor, as is the case with a traditional heater.

Electric sauna stoves provide more opportunities for setting the required temperature with an accuracy of up to one degree. The possibility of generating steam is not excluded - water still flows onto heated stones, you just need to avoid getting the electric heating elements wet.

Electric sauna stoves (assortment in one of the stores)

Thus, if the presence of a “live fire” is fundamental for you, and you simply cannot imagine visiting a bathhouse without it, build a traditional brick oven or equip the steam room with a metal unit that runs on wood. If you want the installation and subsequent operation of the stove to require minimal effort and generally be as comfortable as possible, buy an electric stove.

Features of the heater stove

Wood-burning stoves, as noted, can be made of brick or metal. You have already become familiar with the features of each option. It's time to consider information about the nuances of the design, configuration and operation of heaters. You can do this in the following table.

Table. Important information about heater stoves

| Criterion under consideration | Description |

|---|---|

| A heater is one of the main elements of any sauna stove. Functionally, it is a container in which stones are placed. The latter, in turn, work on the principle of heat accumulators: absorbing the heat released during the combustion of wood, they subsequently radiate it into the surrounding space. The stone mass has low permeability, which is why the level of convection is not too high. As a result, about 70% of the heating time of the sauna stove heats the space around it due to infrared rays. The heater can have a flow-through or solid design. A solid partition is installed between the solid-type heaters and the firebox. The heater itself, at the same time, is open at the top, which allows you to add water to produce steam without any unnecessary difficulties. The disadvantage of a blind type heater is its lower heating rate compared to its flow-through counterpart. In practice, it has been established that it is advisable to equip such a heater exclusively with metal sauna stoves, the power of which does not exceed 25 kW. It is generally impractical to make a blind heater in brick sauna stoves - the stones simply will not be able to warm up enough. Important note! The ceiling height in a steam room equipped with a stove with a solid heater can be a maximum of 220 cm. Otherwise, there is a high probability of heavy steam. In flow-through heaters, stones are laid on top of a grate mounted above the stove firebox. In this case, the flue gases, unlike the previous design option, have the ability to pass through the laid stones before being discharged from the room through the chimney. The casing of such a heater must be equipped with a tightly closing hatch for cleaning. It is recommended to use only firewood, the combustion of which is not accompanied by the formation of soot. For example, aspen wood or pressed pellets are suitable. Stones, unlike the previous case, must be periodically removed from the heater and cleaned. But the backfill warms up more quickly and evenly. There are no restrictions on the dimensions and power ratings of the furnace unit. |

| One thing is presented to the stones important requirement: the ratio of their heat capacity to thermal conductivity should exceed the same indicator for brick and metal. This requirement is met by: soapstone (one of the most popular options), diabase, basalt, etc. It is impossible to equip the heater with metamorphic rocks such as marble, dolomite, as well as limestone and slates - these materials, firstly, do not meet the above-mentioned requirement, -secondly, during the heating process they release substances harmful to human health. The stones should be round in shape and more or less smooth surface. The most preferable option is stones shaped like a ball - if they are used, the heat accumulation/heat transfer parameters will be as efficient as possible. It is important to understand the nuances of laying stones. If the firebox is flow-through, the largest stones (the size of 1-2 man’s fists) are placed underneath. With each subsequent row, the size of the stones decreases proportionally, so that the topmost layer is made of pebbles with dimensions not exceeding the phalanx of the thumb. If the heater is solid, the stones are laid in the reverse order: the smallest ones on the bottom, the largest ones on top. |

| It is recommended to heat a traditional stove-stove exclusively with wood - the use of such fuel allows you to achieve the necessary heating, during which the heat spreads from the walls of the steam room to the center. You should not use coal - it gives off the first heat quite quickly and smolderes for a long time. In the case of home heating, this is good, but in a steam room, such a combustion mode will not lead to anything other than heavy steam. A good alternative to conventional firewood are pellets made by pressing from straw, sawdust and other similar waste. In theory, gas would be suitable for heating a bath if the stove was equipped with professional automation that controls the burning intensity in accordance with the readings of temperature sensors. However, it is not possible to assemble such a stove on your own, and factory models are unreasonably expensive, and they are not 100% safe. |

Electric heater - heating element and stones

Electric heater - heating element and stones

Table. Choosing an electric stove for a bath

| Parameter | Description |

|---|---|

| The main characteristic of any heating unit. For electrical devices, the requirements regarding this point differ from those that apply to traditional solid fuel heaters. Both very low-power stoves for the most compact steam rooms, as well as very powerful units capable of uninterruptedly serving large public saunas, are available for sale. Standard calculation of the required power of an electric heater is carried out according to the rule according to which 1 kW of power is required to heat 1 m2 of steam room. Additionally, the thermal insulation and internal conditions of the steam room should be taken into account. In general, all these nuances are covered in detail in the instructions for the furnaces, as well as information regarding what area a particular unit can serve - please check separately. |

| Stainless steel is the strongest, most durable and most expensive option. Zinc-aluminum alloys and sheet steel are a little more modest. The shape and design of stoves can also vary: from standard designs with right angles to original design solutions. |

| Electric sauna stoves are equipped with control panels. Some models are stationary, i.e. equipped on the body, some - external, some - both. What to choose is up to the owner to decide. If preference is given to a model with a remote control, it is best to buy a control device whose design will allow it to be placed both directly in the steam room and outside it. |

| Units operating on 220 V or 380 V are available for sale. As a rule, high-power models require connection to 380 V. For the rest, be guided by the features of the electrical network of your bathhouse. Under any circumstances, it is recommended to equip the system with a voltage stabilizer. The presence of this element will eliminate the likelihood of the furnace failing in the event of a sudden |

| An evaluation criterion that requires no less careful study than power. The furnaces are equipped with tubular heating elements and tape heating elements. Heating elements are very effective - they heat up to +800 degrees, which is more than enough for even the most notorious amateurs to take bath procedures. The disadvantages of tubular heaters are fragility and, as a result, fragility. This is especially true for budget models. Expensive heating elements made of stainless steel last much longer. Advantages of tape heaters: - fast heating; - efficiency; - environmental friendliness; - safety. Also available for sale are combined models of electric heaters, equipped with tubular and strip heating elements. They combine the advantages of both solutions, but are obscenely expensive. |

Furnace calculation in accordance with standardized requirements

One of the key stages in choosing the design of a sauna stove is its preliminary calculation, the results of which can be used to judge how large, massive and productive the stove needs to be installed in a particular sauna.

With metal structures, everything is simple - the power and area/volume of space that a particular stove can serve is indicated by the manufacturer. If we are talking about a self-assembled metal unit, the required values are selected individually. You can take the previously cited drawings and the accompanying description or recommendations from the following table as a basis.

With brick kilns everything is much more complicated. Now you are invited to familiarize yourself with the procedure for calculating a brick stove, taking into account the current standardized provisions, and then in accordance with the requirements for sauna stoves.

Basic information

The basis for the calculation, as a rule, is the heat transfer rate of the furnace (measured in kcal/hour) or its power (dimensional unit - kW/hour). After combustion, as the furnace unit cools, its heat transfer rate decreases. At the same time, the air temperature in the room cools down. Therefore, the calculation, among other things, must be carried out so that the room maintains desired temperature until the next fire.

To calculate a stove being built in a bathhouse with high-quality insulation, you can use the TMEP method developed by I.V. Kuznetsov. According to it, to heat 1 m2 of area, 0.5 kW of stove power is required in normal heating mode and up to 0.76 kW per square meter in heating mode (the first option is relevant for a residential building, the second is often used for a bathhouse. Along with With this in mind, to effectively heat a bathhouse, many experts advise designing a stove unit with a design power of 1 kW/m2).

For example, a stove has dimensions of 1x1 m and a height of 2 m. The total area of the walls of this structure will be 1x2x4 = 12 m2. Additionally, 1 m2 will be added here - the roof area. Total – 13 m2. In accordance with the previously given coefficients, such a furnace will be able to produce 6.5-9.88 kW of heat. Based on the calculation results, it will be possible to select the optimal furnace power for a steam room with specific overall dimensions. You can use the following table as an example. The optimal mass of stones is also indicated here.

Firebox calculation

To calculate the firebox of a sauna stove, you must first set the maximum volume of loaded fuel. To determine it, the required thermal power is used. Also, the following indicators are taken into account:

- expected efficiency of the unit;

- calorific value of the fuel used;

- specific gravity of fuel.

The volume of the firebox should be 2-3 times the maximum loading volume. In general, it is recommended to load the firebox no more than 65-70% of its total volume.

Study independent calculation fireboxes are an objectively thankless task. Minimal mistakes will lead to a number of troubles. Take, for example, such an “insignificant” structural element as the grate. If too much air passes through it, this will lead to accelerated combustion of the fuel. As a result, the stove will not be able to absorb the resulting heat, and most of it will simply evaporate through the chimney. If there is not enough air, the fuel will not be able to burn efficiently enough.

And there are a great many similar nuances. That is why the more preferable option is to purchase a firebox designed for the appropriate thermal power and fuel. To purchase finished product you will spend much less money than ordering a professional calculation and production of this structural element.

When choosing a firebox, pay attention to the following important parameters:

- The dimensions of the product and fastening elements (mustaches, pins, etc.) must correspond to the dimensions of the brick used. There are several sizes of bricks available for sale that are suitable for laying a stove. In accordance with this point, modifications of fireboxes also differ;

- manufacturing material. If the sauna stove is designed for occasional use, buy a welded firebox made of sheet steel. If you are installing a long-term sauna stove, it is more advisable to buy a cast iron structure;

- ash pit depth. Sauna stoves, as noted, are heated primarily with wood. In the case of this type of fuel, the ash pan should have a depth not exceeding 20% of the height of the combustion chamber being equipped. Otherwise, the fuel mass will quickly become clogged with the resulting ash, as a result of which the air intensity will decrease and the fuel will not have the opportunity to burn out completely.

Chimney calculation

- the chimney has a rectangular cross-section;

- the chimney has no kinks and is vertical;

- the mouth of the pipe rises 400-1200 cm above the equipped grate.

In such situations, the cross-section is selected in accordance with the power of the furnace:

- for stoves whose power does not exceed 3.5 kW, the optimal chimney cross-section is 14x14 cm;

- for stoves with a power of 3.5-5.2 kW, it is recommended to build a chimney measuring 14x20 cm;

- in combination with stoves with a power of 5.2-7.2 kW, smoke exhaust structures with a cross-section of 14x27 cm work effectively;

- if the stove has a power in the range of 7.2-10.5 kW, a chimney measuring 20x20 cm is built;

- sauna stoves with a power of 10.5-14 kW are equipped with chimneys measuring 20x27 cm.

The given values are the minimum permissible - with the mentioned sections no “whistle” will form. “Whistling” is understood as a phenomenon in which a counterflow of cold air descends through the chimney into the “body” of the stove. Because of this, heat is lost and many other problems arise.

Helpful advice! If the stove smokes even occasionally, the chimney must be increased by 25-50 cm. The “old-fashioned” method: put an unnecessary bucket on the chimney. A modern option: install the required section of asbestos cement pipe, the cross-section of which should not be smaller than the size of the chimney. The most effective method: add several (usually 2-4) rows of bricks.

As a rule, the need to expand the chimney arises if the aerodynamic features of the area change. For example, if a high-rise building is built next to the bathhouse or a forest grows, the chimney will have to be expanded. Surely you have at least once seen chimneys with two “otters”. Their presence in such quantities indicates that the owner was forced to increase the height of the structure.

Additional nuances

The required furnace power is traditionally selected in accordance with the volume of the room served, to calculate which the values of length, width and height are simply multiplied. However, this is not enough. To ensure that the calculation is performed correctly and the furnace operates as efficiently as possible, be sure to take into account the following nuances during the design process:

- if the surfaces of the room have uninsulated areas ( window glazing, brickwork, tiled cladding, etc.), you need to calculate the area of each such area, then multiply the total value by 1.2 and add the result to the volume of the steam room;

- if a glass door is installed in the steam room, the calculated volume of the room must be increased by 1 m3;

- if the partitions are built from logs and do not have any additional interior finishing (traditionally this is thermal insulation and lining), the volume of the room must be multiplied by 1.5.

Calculation of the furnace in accordance with the requirements for it

There are a number of requirements for a sauna stove, the most significant of which are listed below:

- ensuring optimal temperature and humidity conditions in the premises;

- sufficient heat storage capacity of the heater to ensure comfortable steaming for the planned number of visitors (for example, 12-15 people, can be reduced to suit your needs);

- sufficient power to quickly switch the sauna to ventilation mode after steaming;

- sufficient heat capacity to ensure prompt (within 1-2 days) drying of the premises after visiting the bathhouse.

Let us consider the listed requirements and accompanying calculations in more detail.

Requirements for temperature and humidity conditions

Back in the 70s of the last century, it was found that the range of +40-65 degrees in the steam room is the most comfortable for the average person. Recommended humidity is not lower than 60-40%. At his own discretion, the bathhouse visitor can increase the air humidity by applying water to the stones. It is strongly not recommended to increase the temperature.

Methodological provisions covering the design of baths, as well as bath and health complexes, insist that after the completion of the heating of the sauna stove, the air temperature in the steam room corresponds to +40 degrees. During the heating process, this figure increases to +60-65.

Temperatures exceeding 100 degrees (and some bath attendants somehow manage to endure such fantastic conditions) pose a danger to human life, contributing to the development of cancer of the skin and respiratory system.

In accordance with current guidelines, to service 1 m3 of steam room volume you need about 30-35 kg of stones. As an example, we will consider a heater weighing about 300-350 kg (you will see the calculation procedure below). It will take about 3 hours to heat the appropriate number of stones red-hot (which corresponds to a temperature of about 600 degrees), during which time the steam room should not be hotter than 30-40 degrees.

In order for heating of such a number of stones to be carried out without simultaneous heating of the steam room space, the oven must, firstly, have thick walls, and secondly, be characterized by low thermal conductivity. For example, an unbricked metal stove with that many stones would heat the steam room to more than 130 degrees within three hours.

In accordance with the previously mentioned methodological requirements, the recommended temperature conditions in other rooms of the bath are as follows:

- washing room – +30-32°C (in showers – at +25-27°C);

- relaxation room – about +22-25°C, higher at the discretion of the owner;

- dressing room/section – +24-27°C.

Calculation of the storage capacity of a stove heater

The value of the storage capacity of the stove determines whether a particular stove can provide effective heating of a steam room for a planned number of people to visit it. This example considers calculations for 12-15 people. After familiarizing yourself with the formulas and accompanying explanations, you can proportionally reduce the found indicators for your conditions.

Let's find the required mass of stacked stones. In our situation, a heater is designed in which the heat and smoke generated pass through the laid stones, which makes it possible to heat them red hot for about 3 hours.

During one visit to the steam room, 4 people can enter. It will take about 4 hours for 12-15 visitors to take a steam bath. The bathhouse is ventilated 5 times within one hour. Taking this indicator into account, the consumption of 70-degree water, which will be supplied to the furnace to generate steam, will be about 10 liters per hour.

We determine how much heat is needed to distill 40 liters of water, heated to 70 degrees, to form steam at a temperature of 110 degrees. The source data is presented in the image below.

In accordance with the above values, water at a temperature of 70 degrees in an amount of 40 liters will heat up to 100 degrees, spending the following amount of heat.

This is exactly how much heat in total needs to be spent on steam generation.

Next, we need to calculate how many stones can produce a certain amount of heat during cooling from 550 degrees to 200 degrees. The calculated heat capacity of the stones corresponds to 0.84 kJ/kg °C. We find how much heat will be released during cooling by 1 kg of stacked stones with the declared heat capacity.

To determine the total mass of stones we do the following.

Thus, in order for 12-15 people to steam comfortably in the bathhouse, it is necessary to equip a heater weighing 326 kg. Considering that the volume of the steam room is about 10-12 m3, the calculation results confirm the relevance of the statement, according to which heating 1 m3 of the steam room requires the use of 30-35 kg of stones.

Obviously, 12-15 people never go to a simple home bathhouse. By following the above calculations, you can determine the required storage capacity of the heater and its weight.

Requirements for furnace power to quickly switch the bathhouse to ventilation mode

According to the rules, the steam room must be ventilated after each use.

If the sauna is equipped with a stove in which the stones are heated directly, i.e. heat and smoke during the heating process pass through the laid stones; if the calculated requirements for the weight of the sauna stove heater and its heating temperature (given in the previous paragraph) are met, such a stove will be the most powerful.

If the stones are heated indirectly (through the sheet metal material, on top of which stones are laid), with the parameters from the previous paragraph, the power of such a furnace will be approximately 2 times lower than that mentioned above, because It is unlikely that it will be possible to heat stones through metal to a temperature of more than 400 degrees. That is why such stoves have to be heated continuously during steaming and the point in using them is exclusively in the case of arranging a public bathhouse.

Metal stoves are not considered at all in this section - it will not be possible to place more than 100 kg of stones on such a heater, because... the walls of the structure will simply bend immediately or after some time. And in general, the power of a metal sauna stove for heating and drying a free-standing sauna during cold periods of the year is unlikely to be enough, which imposes significant restrictions on the available time for visiting the steam room.

This issue must be approached with maximum responsibility. The lack of regular drying of the bath will lead to the fact that after an average of 9-12 months the room will be inhabited by fungi and mold, as a result of which the wood will begin to actively rot. In another year, being in a bathhouse will not only be uncomfortable, but simply dangerous. The situation is aggravated by the fact that it is almost impossible to defeat pests once they occur.

Various companies actively advertise chemicals, promising 100% protection against fungi and mold. But the use of antiseptics in the bathhouse is a rather controversial issue. At high temperatures, such substances can emit vapors that are harmful to human health.

To protect both the bathhouse and your own body, initially approach drying issues wisely. A wood moisture level of up to 19-20% is considered safe - in this case there is no risk of contamination of the material.

For example, let’s calculate how much a stove should weigh in order to dry a bathhouse with an area of about 20-25 m2 in a day during the cold season. Using the above calculation as an example, you can determine optimal weight stoves for saunas of any size.

During the first day outer side the oven cools down from an average of 90 degrees to 40 degrees. The temperature of the internal surface, at the same time, decreases from 450 degrees to 150 degrees. Having calculated the arithmetic mean, we find the average value of the cooling temperature. In this case it will be 105 degrees. The brick has a heat capacity of 0.92 kJ/kg °C.

In the above example, about 40 liters of water are consumed during bath procedures. The wood of the walls and ceiling absorbs about 40% of the generated steam. Some more of it goes through the ventilation. If the bathhouse you are installing has a shower, during washing, some of the water used will splash and enter inside wooden structures. The average value is 5 l. In total, during the day in the example under consideration, about 20 liters of water will have to be dried. At a temperature of +30 degrees, the specific heat of evaporation of water is 2428 kJ/kg.

During the calculation process it is necessary to take into account heat losses, which increase significantly in cold weather. The bulk of the heat escapes through the floor and walls of the bathhouse, as well as through the ceiling. Formula for calculation total heat loss looks like that.

Let's study each component of the formula separately. Let's calculate how much heat escapes through the walls of the bathhouse.

Let's perform a similar calculation for the ceiling.

In reality, heat losses will be more modest, because To simplify the calculations, the parameters of the ceiling boards and floor of the under-roof room are not included here.

About 220 watts of heat will escape through the windows and doors of our bathhouse. As a result, we determine the total heat loss.

As a result. To compensate for heat loss and dry bath rooms, you need to spend this amount of heat per day.

And finally, we determine the required amount of bricks.

Thus, in order to dry a bathhouse with an area of 20-25 m2 in 1 day in winter, we will need a stove made of 3013 kg of brick. In terms of units, the required number of bricks will be 860 pieces. Quite a massive oven.

Important! Some owners, wanting to save time, effort and money on the construction of a furnace, still give preference to metal structures, covering them with bricks in order to increase operational efficiency. In practice, such a brick casing rarely consists of more than 200 bricks. Based on the calculation data, a metal stove with a brick casing will not be able to ensure quick drying of the bathhouse in the cold season.

Baths are built mainly from wooden beams or logs. Even if stone materials are used for construction, interior decoration is still predominantly done using wood. In view of this, close attention should be paid to compliance with fire safety rules when choosing a stove and its subsequent installation.

The key provisions are as follows:

- Direct contacts of wooden surfaces with the heating elements of the stove are excluded. Failure to comply with this requirement will result in the building material catching fire. For safety reasons, a distance of 40-50 cm is maintained between the stove and surrounding flammable surfaces;

- presence of cracks in brickwork is considered unacceptable;

- a minimum distance of 15-20 centimeters must be maintained between the floor surface and the stove ash pit, and 22-28 centimeters between the floor surface and the bottom of the smoke ducts;

- a metal sheet with a thickness of at least 10 mm is laid on the floor in front of the oven door;

- the distance between the ceiling and the upper part of the sauna stove, depending on the dimensions, weight and power of the latter, should be at least 35-50 cm. If the stove is not heat-intensive, the specified distance should be 70-100 cm, depending on the degree of protection of the ceiling in steam room

The above provisions are fundamental and... In addition, various minor related rules and nuances must be observed to ensure that the operation of the stove is as safe as possible.

So, for example, in a steam room equipped with a metal stove, you can easily get a second-degree burn or even more serious damage. For safety reasons and to further increase efficiency, previously metal stoves lined with bricks. Today, a simpler solution is available - basalt cardboard. This material conducts heat poorly and, at the same time, is durable and durable. With basalt cardboard you can cover the screen of a homemade stove like a potbelly stove, make a fire protection area, or even fix it on pre-installed racks, building a protective fence.

The Harvia HGL6 fence in the sauna, bathhouse ensures a safe distance between the hot heater and people in the sauna, bathhouse

In conditions high humidity the risk of carbon monoxide increases. In view of this, it is possible to “add” only after the firebox is completed and the ash has been removed.

To summarize, we can say comparison table modern electric stoves, brick and metal heaters. For convenience, ratings are given on a 3-point scale.

Table. Comparative evaluation of furnaces

| Evaluation criterion | Brick oven | Metal oven | |

|---|---|---|---|

| Power and performance | 2 | 3 | 1 |

| Ease of installation and operation (3 – easiest and most convenient) | 3 | 1 | 2 |

| Reliability and safety | 3 | 3 | 2 |

| Life time | 2 | 3 | 1 |

| Economical (3 – most economical) | 2 | 3 | 1 |

| Price | 2 | 3 | 1 |

Good luck with your choice!

Video - Which stove to install in the bathhouse

What does it mean, a stove for a bath? In fact, this is the heart of the steam room, on which it depends whether it will be comfortable in the bathhouse or not, whether the room will be hot or not, whether it will be an economical consumption of firewood or not. Therefore, it is worth understanding all the popular models that have only positive reviews from both specialists and ordinary consumers, and decide which model is better. That is, let’s make a small rating of wood-burning stoves for Russian baths.

Brands and models of stoves for Russian baths

Let's start with the fact that in the modern wood stove market there is a huge variety of equipment offered. Which ones exactly? The best representatives are here European manufacturers, and brands from neighboring factories, as well as domestic samples. In order not to disturb priorities, we will start the rating with domestic stoves.

Termofor

Their main representative is the Termofor company from Novosibirsk. This is a huge number of offers of different models of wood-burning stoves for Russian baths. Founded in 2003, the company quickly conquered the domestic market. And there was something to conquer, because these are the best examples.

Here are just a few models that are very popular today.

Teplodar

Another company from Novosibirsk, which is represented on the market with twenty models of stoves for Russian baths. Of these, five models are very popular. By the way, their popularity is not only in the domestic market, but also in the market of neighboring countries.

Let us add that the model line of stoves for Russian baths from the Teplodar company has two more popular brands. These are "Cascade" and "Siberian Cliff". The first of the two models is used today for both Russian baths and saunas.

Volcano

The Vulcan brand is represented by Kamenka LLC, which has been present on the Russian market since 1998. What is under the Vulcan brand today? These are five models:

- Prometheus.

- Etna.

- Elbrus.

- TAAL.

- Mont Blanc.

"Vulcan" differs from its competitors in many ways, which is why the reviews are positive. There is also a powerful cast iron grate, made according to a special design. It ensures combustion even of raw fuel. This is a turbo firebox made of alloy steel, which protects the walls from changing shape and size. This is a chimney pipe 10 mm thick. These are dividers installed inside the firebox; they increase the efficiency of the unit, and accordingly, firewood is saved.

The furnace body is equipped with stiffening ribs, which increases its service life. Let's also add a fairly impressive volume of the heater, which provides steam for the steam room of the bathhouse. Let us add that Vulcan stoves are equipped with four types of doors. These are classic, antique cast iron, and panoramic. Let us add that the Vulcan stoves are a wonderful design of the unit, as well as its accessories. The Elbrus model is shown in the photo below. Please note that "Elbrus" ("Vulcan") are several modifications that contain a water tank and a heat exchanger for it. In addition, "Elbrus" is equipped with both steel firebox doors and panoramic glass doors, which allows you to see the burning of wood, as in a fireplace. By the way, the largest model, “Elbrus” (“Vulcan”), has a huge heater that can hold 75 kg of stones.

Of all the Vulcan models offered, Elbrus is the best. In any case, reviews about it from both consumers and specialists are only positive. Anyone who has built a large bathhouse on his country property, when choosing a stove, always pays attention to the Elbrus model of the Vulcan brand.

Hephaestus

The Belarusian manufacturer of sauna stoves, the Hephaestus company, stands for old traditions and excellent quality. This is one of the manufacturers that produces cast iron sauna stoves. It is clear that due to the complex production of cast iron elements, as well as the large weight of the units, cast iron sauna stoves are rarely made today, and not by all companies. Hephaestus is an exception to this list.

Hephaestus sauna stoves are powerful units that can be used to heat all rooms of a sauna at once. The advantages include:

- Energy efficiency is high;

- Retains heat for a long time;

- Such furnaces operate for a very long time;

- Some models allow the use of combined fuel;

- Efficiency at its best high level.

There are also disadvantages:

- Heavy construction;

- High price.

Foreign analogues

Europe is represented on the Russian market by two brands: Harvia and Narvi. Both companies are Finnish. As for the first, first of all it is a prominent representative of the production of sauna stoves. But its model line also includes sauna stoves for Russian baths. It is surprising that the company is a small production facility that employs no more than 300 people. At the same time, the scale of turnover is enormous.

As for the second company, this is a production that grew out of a small workshop that began producing wood-burning stoves in 1937. After its merger with another company Aito-Lämpö, turnover and assortment grew quickly, where a place was found for sauna stoves.

The stove is the heart of any sauna. Wood-burning, electric or gas, home-made or factory-made, budget or expensive - a person who decides to get his own bathhouse is faced with an almost limitless range of stoves. We decided to make the choice easier and systematized the main requirements for such installations, trying to take into account all the significant points.

The stove can be maintained within any dimensional limits, operate on different fuels and have a wide variety of designs, but first of all, it is subject to 2 key requirements:

- optimal power for a particular steam room;

- installation in compliance with approved rules and regulations.

Power is the first thing you need to pay attention to when choosing a stove. It is pointless to cite any specific universal figures - it is basically impossible. The main thing is that this indicator is optimal for a particular case.

Already at this stage, many developers make a big mistake by purchasing a stove unit with a large power reserve, hoping that this will reduce the time spent on warming up the steam room. Yes, the room will heat up faster, but then the oven will switch to the minimum operating mode. The result is the same - the air will be hot, the stones will be cold. There is no point in pouring water on stones that are not warmed up enough - steam in such conditions will either not form at all, or will come out in clouds, like from a kettle. And in a bathhouse, as you know, the steam should be transparent and light, otherwise being in the steam room will become extremely unpleasant or simply impossible.

Heater in the bathhouse – photo

The other extreme is also a mistake - installing a low-power unit for the purpose of simply reducing the total costs of arranging a steam room. Even if a stove with low power warms up the room to the required level, it will have to work as hard as possible to do this. What do you think happens to a system that constantly wears out? That's right, it breaks down very quickly.

Important note! You can ignore such an indicator as the power of the heat source only in the case of building a hammam (), in which there is no stove in its classical sense. But we are talking specifically about a bathhouse, so we are considering units designed for operation in its conditions.

- power, usually measured in kW;

- the volume of the steam room that can efficiently serve the stove of the declared power.

To save ourselves from complex, lengthy calculations, let’s take the simplest route: determine the volume of the steam room and, based on it, set the required power.

First step. We calculate the volume of the steam room. To do this, we need to measure its length, width, and height. Then we multiply the resulting numbers, thus finding the volume indicator. If preserved project documentation, we turn to it and save ourselves from this stage of calculation. Let's say the length of our steam room is 2 m, the width is 1.5 m, and the height is 2.2 m. The volume of this room will be 6.6 m3.

Second step. We carefully examine the walls and ceiling. Here we need to determine whether there are uninsulated areas on them, for example, masonry, tiled cladding, double-glazed windows, etc. We calculate the area of each such section (multiply the length and width). Let's sum up the obtained values. For example, we have a window measuring 60x60 cm and tiled cladding 100x100 cm. The calculation is as follows:

(0.6x0.6)+(1x1)=1.36 m2.

We multiply the resulting number by a factor of 1.2 - this gives us a new value equal to 1.632. Add to the volume of the steam room and get 8.232.

Third step. If the door to the steam room is made of glass, increase the final number from the previous step by 1.5. The result is 9.732.

In the presence of glass door increase the calculated coefficient

Thus, the stove must be designed to heat 9.732 m3. There is a very important note here: the accompanying instructions for the furnaces indicate working volumes in intervals, for example, 4-9 m3. In our example, it is reasonable to purchase a stove with some reserve, for example, a unit for 7-12 m3 will work well, while the resource of a stove for 5-10 m3 will not be enough.

When determining the required optimal power in kW, it is customary to adhere to the pattern according to which 1 kW of power is consumed per 1 m3 of space.

Important! In order for the heater to successfully cope with servicing the volume stated by the manufacturer, load it with exactly the same number of stones as recommended in the accompanying instructions.

Additional selection criteria

Having determined the required power and displacement indicators, we can let ourselves “go wild” in relation to the accompanying selection criteria.

Material of manufacture

Most often, stoves are made from the following materials: cast iron, steel, brick. The service life of the structure directly depends on their quality.

Modern stoves made of chrome steel are currently considered the most durable. Such installations produce " fresh air", which eliminates the risk of burning out oxygen in the room. The best steel stoves are produced by Finnish companies Helo and Harvia.

It is a rarity to find a sauna stove with a cast iron firebox today, although this material is, in principle, very good. Among the factory stoves with a cast iron firebox, the only one that deserves attention is the “Sudarushka M” model produced by the domestic company Inzhkomcenter.

Brick stoves are a tribute to history and respect for ancestors. If you find a good stove maker, you will be satisfied for many decades to come. But such units also have their disadvantages:

- comparative complexity of kindling with many nuances;

- relatively long warm-up;

- the need to construct an individual powerful foundation, which leads to a significant increase in total costs.

Features of the firebox location

Stoves with two types of fireboxes are available for sale:

- extended for wall mounting;

- ordinary.

The first allow you to organize the furnace of the stove from the room adjacent to the steam room, which increases fire safety indicators and the overall microclimate, but such models are more expensive.

Steam source

In a traditional Russian bath, the steam should be dry and light. However, not every modern furnace is capable of producing just such steam. For maximum comfort, it is wise to buy a separate electric steam generator - this way you can solve all the problems associated with this point.

Steam generator for a bath - installation diagram

Video - Steam generators for baths and saunas

Design requirements

A good stove should be able to:

- warm the air to 40-50 degrees at the bottom of the room with a gradual increase to 80 degrees under the ceiling;

- heat the stones relatively quickly and maintain their temperature at the required level;

- eliminate the possibility of smoke and carbon monoxide entering the steam room.

Additional requirements are at the discretion of the owner. For example, it may be important for someone that the stove can not only heat the room, but also prepare hot water.

Video - Hot water in the bathhouse, water heater + piping

Heater type

Most private stoves are equipped with open or closed heaters.

Duration of operation on one fill of fuel

Ideally, the stove will provide heat for as long as possible without the need to add new fuel. This criterion is determined by the user individually.

Firebox of a sauna stove – photo

There is little choice here.

The oven can be:

- hot. Heat is released through the outer walls of the furnace, heating up to 100 degrees or more. A very good option for a private steam room. But there are also disadvantages: it is difficult to regulate the heating temperature and you can get burned. To avoid unpleasant consequences, the heating parts of the stove must be carefully insulated, for example, using a brick screen;

- cold. The walls of such a unit will not heat up above 40-45 degrees. Direct heating is carried out through circulation channels. Such ovens are safer and easier to use.

Type of fuel used

| Type of fuel used | Description |

|---|---|

| The most traditional and popular option. Guarantees uniform and rapid heating of the room, creating the most favorable microclimate. Wood-burning stoves can be heated “black” or “white”. In the first case, a chimney is usually not made - the fumes are removed through an vent in the wall or ceiling, or simply through open door. The “black” firebox is almost never seen today - it is not aesthetically pleasing and difficult. Stove "on white" - traditional version modern wood stove. Must be equipped with a chimney. The only disadvantages include the need to monitor the combustion process and periodically add fuel. | |