In this article, there is a model of a car refrigerator, which was made by the author of the channel, Alex Shev, with his own hands, despite the sophisticated nature of the resulting product, in just three days. The device operates on Peltier elements. Below, at the end of the publication, is another model that works on the same basis.

A number of materials and parts were used.

Work on the product

We cut the foam using a 1 kilowatt spiral and a 5 volt power source. The spiral was secured between the legs of the table. I glued the foam together with polyurethane foam. We cut grooves in the lid so that it does not fidget.

It was supposed to cover the tray with polystyrene foam, but it was easier to make a box out of it and use the tray to strengthen the strength of the car refrigerator. The dimensions turned out to be 38 X 30 centimeters, depth 28. Capacity: 3 bottles of 1.5 liters in a row. You can have two such rows, or 2 by 2 liters side by side.

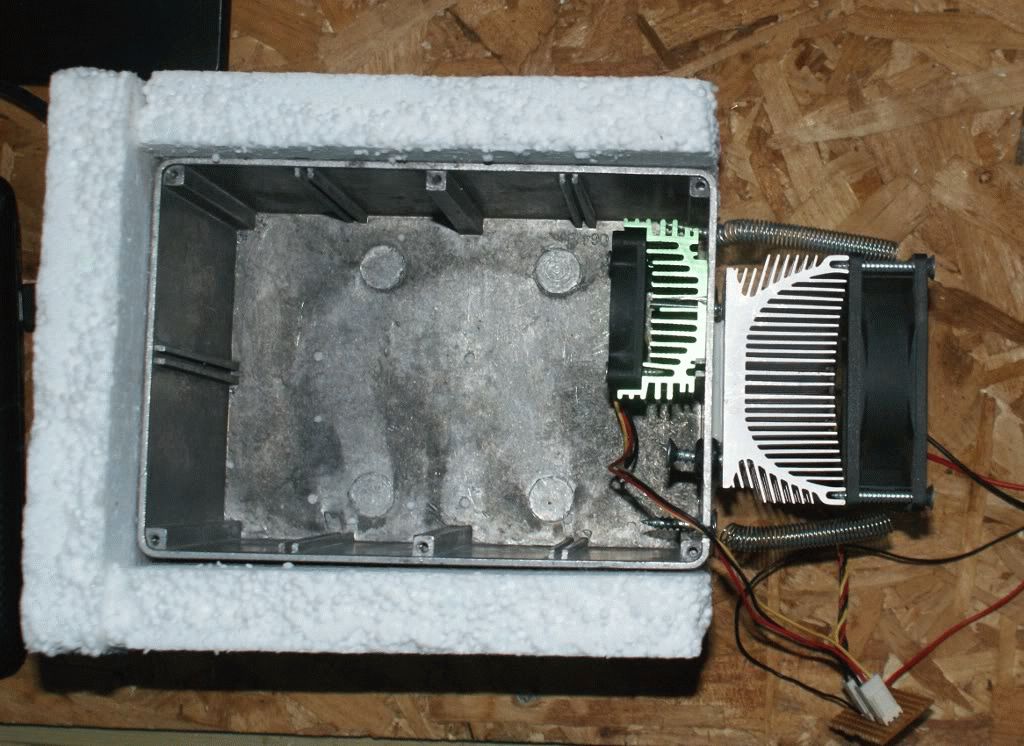

We drill holes in two radiators for thermistors to control the temperature. In cold weather also for fastening. We cut a hole in the lid of the car refrigerator and heat the heat exchanger inward by 1 -1.5 centimeters. Next, using thermal conductive glue, we fasten the two Peltier elements to the radiators. One just fits two Peltier elements. The gap between the foam and the radiator is also insulated. In the example shown, bestizol was used.

We put it together, screw the fans onto the heat exchanger, install the microcontroller, LSD monitor, and relay. So far only using the hanging method.

Also check out the cool designs with free shipping in this Chinese store. There you will also find Peltier elements.

We are writing a program for a microcontroller. The author of this video tutorial used an insert to turn off Peltier elements when the temperature of a hot radiator is more than 55 degrees. And also when the temperature in the refrigerator itself is less than 5 degrees. Only the elements themselves are disabled. The fan and microcontroller continue to work.

The temperature is measured by an ADC converter: on a hot radiator, on a cold one, in the refrigerator itself. Shown on the display.

Power is supplied to the elements through an additional relay only when the ignition is on (engine is running), so as not to drain the battery.

When checking at home, the temperature in the car refrigerator dropped to 12 degrees in 1 hour and stayed there. The temperature of the hot radiator stopped at 49 degrees. In the car, when cooling 4 bottles of Mojito and using Peltier cold accumulators, the Peltier turned off in the first hour at 55 degrees of the hot heat exchanger. And subsequently they turned off when the temperature inside was less than 5 degrees. Operation interval: 4 minutes on, 1.5 minutes off.

Conclusions:

Do-it-yourself car refrigerator-thermobox

Greetings, dear readers! Since my family and I travel a lot in the summer and regularly go out for barbecues, the issue of food storage came to the fore. How in long trips, and for one day.  It became clear that we couldn’t do without a refrigerator or a thermal bag. Familiarization with the market has begun. The simplest thing is thermal bags. We will not consider thermal packages. They are soft, take up little space, light, and the cheapest. The downside for me is that there is fabric and seams inside, which is inconvenient to wash. Average price 500-1000 rub. Thermal containers. Hard plastic body, easy to clean. Cons: They take up space regardless of whether there is food inside or not. Average price from 2500 rub.

It became clear that we couldn’t do without a refrigerator or a thermal bag. Familiarization with the market has begun. The simplest thing is thermal bags. We will not consider thermal packages. They are soft, take up little space, light, and the cheapest. The downside for me is that there is fabric and seams inside, which is inconvenient to wash. Average price 500-1000 rub. Thermal containers. Hard plastic body, easy to clean. Cons: They take up space regardless of whether there is food inside or not. Average price from 2500 rub.  Both bags and containers require cold storage batteries. Refrigerators with Peltier elements are the same thermal containers, but with a cooling system built into the lid. Depending on the power of the elements, it can cool up to 20°C from the outside temperature. Nutrition from electrical network car. Minus - if it is not equipped with a shutdown system, it can drain the car’s battery. Average price from 3500 rub. Compressor car refrigerators. The most serious of all. Designed for long trips. They can operate on both electricity and gas. They cope with their responsibilities perfectly. The downside is that they cost the same as two regular home refrigerators. *** I looked at all this and decided, in order to understand what I needed, to make a refrigerator with my own hands.

Both bags and containers require cold storage batteries. Refrigerators with Peltier elements are the same thermal containers, but with a cooling system built into the lid. Depending on the power of the elements, it can cool up to 20°C from the outside temperature. Nutrition from electrical network car. Minus - if it is not equipped with a shutdown system, it can drain the car’s battery. Average price from 3500 rub. Compressor car refrigerators. The most serious of all. Designed for long trips. They can operate on both electricity and gas. They cope with their responsibilities perfectly. The downside is that they cost the same as two regular home refrigerators. *** I looked at all this and decided, in order to understand what I needed, to make a refrigerator with my own hands.

Well, to be more precise, a thermal box. For me, the main thing is that condensation does not drip anywhere and the food does not get choked on the road. I took a sheet of penoplex (the insulation is orange). Cut it out. Assembled using self-tapping screws and sealant. There are no corners, no insulation on top, no upholstery or painting. Everything is “as is”. Why complicate things?

Photo by the channel author. Cutouts were made at the joints of the walls and on the roof to reduce heat loss. Conducted sea trials under load. Considering that the lid is solid, that is, every time you open it, it gets into the container. warm air, boxing performed well. The cold lasts for at least a day and a half (on one stack of cold accumulators), with regular openings. Watermelons, water, chilled foods, meat - everything feels great. In general, I left everything as it is for now; it suits my purposes perfectly. And it’s not a pity, if anything. Nothing is as permanent as something temporary. And you choose what suits you best.

Photo by the channel author. Cutouts were made at the joints of the walls and on the roof to reduce heat loss. Conducted sea trials under load. Considering that the lid is solid, that is, every time you open it, it gets into the container. warm air, boxing performed well. The cold lasts for at least a day and a half (on one stack of cold accumulators), with regular openings. Watermelons, water, chilled foods, meat - everything feels great. In general, I left everything as it is for now; it suits my purposes perfectly. And it’s not a pity, if anything. Nothing is as permanent as something temporary. And you choose what suits you best.

Refrigerator made of foam plastic and Peltier modules

Today’s article is not about turning packaging foam into glue by dissolving it in acetone. Today we’ll talk about a homemade product that’s a little more complex, but very useful in the household, garage or home. Since our school days, we have known about the Peltier element, which, when some voltage is applied to it, emits heat on one side and cold on the other.  The same element, 75 Watt. So, we will make a mini refrigerator, you can call it a tabletop one. And, to begin with, let's take thin packaging foam and use double-sided tape to assemble a box with a door from it. We take the size of the box approximately as a 5 liter water bottle.

The same element, 75 Watt. So, we will make a mini refrigerator, you can call it a tabletop one. And, to begin with, let's take thin packaging foam and use double-sided tape to assemble a box with a door from it. We take the size of the box approximately as a 5 liter water bottle.  A box made of polystyrene foam. Next, we assemble the main part. We glue a small aluminum radiator from electronics to the cold side of the element using thermal paste. On the hot side we glue a processor radiator with a fan onto the same compound.

A box made of polystyrene foam. Next, we assemble the main part. We glue a small aluminum radiator from electronics to the cold side of the element using thermal paste. On the hot side we glue a processor radiator with a fan onto the same compound.  The main unit of the device. Having cut a hole in the back wall of the box, insert a cold radiator inside and glue the entire unit to the back wall.

The main unit of the device. Having cut a hole in the back wall of the box, insert a cold radiator inside and glue the entire unit to the back wall.  Rear wall of the refrigerator. Connect the ends of the element and the fan in parallel, supply 12 Volts. We put a couple of cans of foam in our refrigerator. After an hour, drink the drink at a temperature of 15 degrees.

Rear wall of the refrigerator. Connect the ends of the element and the fan in parallel, supply 12 Volts. We put a couple of cans of foam in our refrigerator. After an hour, drink the drink at a temperature of 15 degrees.

Everything you need to know about auto-refrigerators for Fishermen and Autotourists

It is best to make a car refrigerator with your own hands using Peltier elements. The design of such a refrigerator is much simpler than the usual unit with a compressor and freon as a refrigerant. Despite the fact that a compressor refrigerator has a higher efficiency than one operating based on the Peltier effect, the latter is preferable for use in cars. Since it has other important advantages: smaller dimensions and silent operation.

Compressor room air conditioning equipment still used in cars, for example air conditioning. This is explained by the fact that the air conditioner cools a large volume and cannot be made based on the Peltier effect. In addition, the air conditioner must remove heat from the car interior further than the design of the Peltier element allows. If you received an old home air conditioner, do not rush to rejoice, since it is unlikely that you will be able to turn it into a car refrigerator.

Cooling without compressor

The Peltier effect is that when electric current through contact of two semiconductors with various types conductivity ( p-n junction) depending on the direction of the current, either cooling or heating occurs. This is explained by the interaction of electrons with thermal vibrations of the atoms of the crystal lattice. And when current passes through series-connected junctions, the thermal energy absorbed by one p-n junction is released on the other.

If you arrange the Peltier element so that one p-n junction is inside a container with good thermal insulation, and the other outside, you will get a small refrigerator that is sufficiently powered by car cigarette lighter. Another refrigerator that operates without a compressor is absorption. You can make a refrigerator for your car from such an old unit. But in this case, the design will depend on what you got, so you will definitely need to change the heaters and thermostats to 12 volt ones.

Making the body

To make the case you will need materials:

One Peltier element will not be able to significantly cool a large volume, so for one thermoelectric element do not make the housing larger than 40x40x30 cm.

To cut hardboard, use electric jigsaw or circular saw, if they are not in your arsenal, an ordinary hacksaw with a fine tooth will do. From MDF sheets, using corners and blind rivets, assemble a box that will be the body of your mini-fridge. Place the corners from the inside so that the rivets are held more securely. Fill all cavities in the joints between structural parts with sealant. After the sealant has dried, cover the inside surface of the resulting box with insulation. Use “liquid nails” for this.

Apply foam rubber seal to the upper ends of the walls. MDF is very hygroscopic, so it must be primed before gluing the body. Instead of a primer, dilute a little PVA with water (add 2 parts liquid to 1 part glue). Prime the body, let it dry and cover it with oilcloth. Do not tape the door, as it is a radiator, and tape will worsen its heat transfer.

Cooler installation

For this you will need:

First you need to make two radiators from aluminum, mount a cooling element between them and separate them from each other with a sheet of thermal insulation. This design will double as the refrigerator door. With the outer dimensions of the case being 40x40x30 cm, the top radiator should be 40x40 cm, since it will cover the box, and the bottom one should be 38x38 cm, because it should go inside. Cut a 38x38 cm square from a sheet of insulation, cut a hole in its center the size of the cooling element and glue it to the smaller radiator using “liquid nails”. Solder the power wires to the terminals of the element (the red terminal should be “+”, and the black terminal should be “ground”).

Place the large radiator down, and the small one on top of it, with the insulation facing up, so that their centers coincide. A centimeter from each corner of the cutout in the thermal insulation, drill a Ø 3 mm hole simultaneously in two radiators. Lubricate the cooling element on both sides with heat-conducting paste and place it on an area of the smaller radiator free of insulation with the cooling side facing the metal. Cover it with a large radiator so that the previously made holes coincide, and tighten the resulting sandwich with screws and nuts until the thermal insulation is compressed and the radiators touch the cooler. Monitor compression using a caliper by measuring the distance between the radiators. The thickness of the element is 3.8 mm. After reducing the gap to this value, tightening the radiator plates should be stopped.

Attach the resulting door to the hinges, and them to the body so that when it closes, the smaller radiator fits inside the body. To remove the wires from the housing, place a piece of rubber tube of suitable diameter on them.  In the top plate, next to the cooler power connection contacts, drill a hole slightly smaller than the outer diameter of the tube. Route the wires through it, leaving the tube in the hole so that the wire does not rub against its edges. Attach the fan to the door so that it points towards it and connect it to the same pair of wires. All that remains is to attach a latch and some kind of handle for carrying the device and the cold generator is ready.

In the top plate, next to the cooler power connection contacts, drill a hole slightly smaller than the outer diameter of the tube. Route the wires through it, leaving the tube in the hole so that the wire does not rub against its edges. Attach the fan to the door so that it points towards it and connect it to the same pair of wires. All that remains is to attach a latch and some kind of handle for carrying the device and the cold generator is ready.

Selecting wire cross-section

To find out the current consumed by the built air conditioner, add the rated current of the fan with the same parameter of the cooling element. After this, all that remains is to select from the directory the wire cross-section corresponding to this current. We provide below a fragment of the reference book sufficient to make a decision in this case. For connection lengths up to 2 m:

- current up to 1.5 A, wire cross-section - 0.3 mm 2;

- current - 2.5 A, cross-section - 0.5 mm 2;

- current – 3.5 A, wire – 0.7 squares;

- current - 7.5 A, wire 1.5 square;

- current – 10 A, wire – 2 mm 2.

With a connection length of 3 m:

- I nom up to 1.5 A, wire – 0.4 mm 2;

- I nom – 2.5 A, wire – 0.8 mm 2;

- I nom – 3.5 A, wire – 1.1 square;

- I nom - 7.5 A, cross-section - 2.3 mm 2;

- I nom – 10 A, cross-section – 3.2 square.

If your air conditioner draws more current than the cigarette lighter fuse is designed for, you will have to connect it to the battery terminals through its own fuse link. But you will save on the connector for connecting to the cigarette lighter socket.

The cross-section of a single-core wire S after measuring its diameter d can be calculated using the formula - S=π * (d/2) 2. To determine the cross-section of a stranded wire, you need to count the number of strands under the insulation, calculate the cross-section of one and multiply by their number.

If you don't have a caliper, you can determine the diameter of a single-core wire using a regular ruler. To do this, wind 10 turns of wire around a screwdriver, turn to turn, and measure the length of the resulting winding with a ruler. Divide the result by 10 to get the wire diameter.

Power Requirements

The device must be powered by a direct current voltage of no more than 15 V. Small ripples do not interfere with operation. So, in special conditions homemade air conditioner does not need it and can simply be connected to the on-board network of a car with 12 volt electrical equipment. For owners of cars with a 24 V on-board voltage, it is recommended to connect two cooling elements in series.

Advantages and disadvantages of thermoelectric cooling devices

Thermoelectric cooling air conditioner based on the Peltier effect has the following advantages:

- High specific cooling power. With dimensions 40×40×3.8 mm, one element can drain thermal energy power up to 57 W.

- Quiet operation.

- Low cost. One element costs no more than $3.

- High reliability. The time of continuous operation before failure reaches 200 thousand hours.

Disadvantages of Peltier coolers:

- Low efficiency. Therefore, with a large cooled volume, it is difficult to achieve a significant temperature difference between opposite surfaces.

- The air conditioner consumes relatively more power. The current consumed by one element reaches 6 A.

- Part of the power consumption is spent on heating the radiator, which releases heat to the atmosphere.

A self-made refrigerator, of course, will not notice air conditioning or climate control, but in any case it will make traveling in hot weather easier.

While I was doing construction country house I couldn’t help but want to figure out how else I could use extruded polystyrene foam. Today this is one of the most effective insulation materials with a huge number of advantages and very affordable price. The first thing I realized was that for grocery shopping trips to the hypermarket it is very useful to have a thermos container in which you can safely transport frozen food. To make such a box it took 160 rubles and half an hour of free time. But I decided to go further and modify the design in order to use it as a stand-alone refrigerator.

Let's start making!

2. So, let's start with a thermos container. We will need one sheet of expanded polystyrene with dimensions 1200x600 mm, thickness 50 mm, stationery knife and roulette. The cost of such a sheet in any hardware store is 160 rubles. We cut the sheet according to the template, take the polyurethane foam and glue together such a container.

3. Here is a diagram for cutting the sheet. The sheet has sides 20 mm thick; they need to be cut off on all sides except the bottom. The sheets are glued together with polyurethane foam. The technology is simple. Apply a little foam to the gluing area, wait 1 minute, press the sheets tightly against each other and then manually control for 5 minutes so that they do not move due to the expansion of the foam. The main thing is not to leave it unattended. Only a small piece of polystyrene foam, marked gray on the diagram.

4. Pay attention to the design of the cover, one of large sheets from the diagram above, I cut it into 3 parts in place when gluing it to ensure a tight fit. After this, the outside of the box can be painted. The paint slightly corrodes the polystyrene foam, so it is better to paint in two stages. The resulting container weighs 820 grams and has incredible heat loss performance. You can put several kilograms of frozen food in such a box and transport it for several hours without any problems. The main thing is not to mix frozen and chilled foods. You can supplement the design with a cold accumulator.

5. Or you can modify the design to get a full-fledged refrigerator. For these purposes, we will use a Peltier element - a thermoelectric converter, the operating principle of which is based on the occurrence of a temperature difference when an electric current flows. These are the elements that are used in serial car refrigerators, as well as car seats with ventilation.

Cost of one Pelte element maximum power 60 W on aliexpress - 130-150 rubles. Model TEC1-12706. During operation, one side of the element heats up, the other cools. To prevent the element from burning, it is necessary to intensively remove heat from the hot side. To do this, we need a processor cooler with a radiator from a computer store, costing 250 rubles. To improve air circulation inside refrigeration chamber To avoid freezing of the radiator, I decided to install fans on both sides. We will also need a thermostat with an external temperature sensor and a relay, costing 170 rubles, which will allow us to control the set temperature inside the container. Well, an extension cable with a connector for a car cigarette lighter for 100 rubles.

So, let's start assembling.

6. Install the Peltier element using thermal paste (included with the cooler) between the two aluminum radiators. It is worth noting here that the temperature gradient of the installation can be increased by assembling 2 or 3 Peltier elements installed in series. Thus, so that one Peltier element cools the other. In this version, it is possible to get in the container negative temperature up to -18 degrees Celsius. We lay a piece of foam thermal insulation along the perimeter between the element.

7. We connect the radiators to each other with standard mounting plates to the motherboard, connecting them using plastic clamps. This also allows the cold and hot sides to be thermally isolated from each other. Trial run installations. The more intensely we cool the hot side, the lower the temperature on the cold side will be. Here the fans are aimed at supplying air to the radiators; this is less efficient than if they are turned over to blow them out. In the improvised box we managed to achieve a temperature of -3 degrees, at a temperature environment+26. The photo clearly shows the cooler model, their advantage is large area support platform radiators. And as a thermal insulation pad, I used a piece of thermal insulation for round pipes.

8. Now let's integrate the thermoelectric converter into the new container lid. For the convenience of placing the entire structure, we will increase the thickness of the cover to 100 mm (2 sheets of polystyrene foam). This photo clearly shows the perimeter gasket between the two radiators.

9. Artistic cutting for polystyrene foam and processing sandpaper. Let's paint again. After painting outer shell expanded polystyrene becomes stronger.

10. Coat the seams with sealant, turn both fans over to blow out. Among the potential improvements, it might be worth reducing the fan speed on the cold side (currently both fans operate at maximum speed).

11. We install the thermostat board next to the case and fix the power wire in this simple way. First we press the plate using self-tapping screws, then fix it with sealant.

12. Container assembled. The weight of the container without a lid is 800 grams; the lid with the assembled thermoelectric converter weighs the same. Total expenses - 1000 rubles and a couple of hours of time. Tests with cooled products in the trunk of a car showed the system’s ability to maintain the temperature at the bottom (!) of the container within +5 degrees Celsius, at an ambient temperature of +29 degrees (yes, it is much warmer in the trunk, even with the air conditioner running) and current consumption - 3 Ampere. I think this is excellent result.

I plan to make the next container from 3 in series installed elements Peltier to get a full-fledged freezer.

During the struggle for environmental friendliness and a decent existence, attention is paid to the smallest details. Are you tired of the constant noise of the cooler in the processor - remember, the device requires cooling, otherwise the BIOS will simply turn off the system unit along with operating system. And in the heat you want peace and quiet. The solution has been found. Previously they said that refrigerators do not rely exclusively on compressors; alternative models have been created. Let's think, perhaps we will be able to assemble the refrigerator with our own hands.

The history of refrigerators, or a manual for the inventor

We mentioned in reviews about adsorption refrigerators running on blue fuel. The gas, when burned, causes the refrigerant to circulate and cool the compartments. The undoubted advantage of the design is noiselessness. You can hear a slight hiss from the combustion of fuel and the flow of liquid through the tubes. But the solution is far from the only one. They wrote that expensive car refrigerators work on a different principle - on Peltier elements.

In 1834 it was established that when passing direct current Heat is released or absorbed through conductors and semiconductors. The effect was not attributed to the Joule-Lenz law: in the latter case, heat was released, but cooling remained unattainable. No one gave a scientific explanation, but it became known that when current is passed in one direction, heat is absorbed and released in the other!

There is a known case when a student reported to the teacher on the subject digital technologies, computers have not yet achieved the power they have today. Pentium II processors have just appeared on the Russian market, although fourth ones have, of course, already been seen in the USA. It came down to powering the computer's brain, to the desire to constantly reduce the voltage.

We noticed that the processor consumes 75 W. At the same time, the supply voltage remained around 3 V. It turns out that the small crystal consumed current... 25 A. Any battery when charging is not capable of this. The teacher spoke out, but turned out to be not entirely right.

At this low voltage, the processor actually consumes a huge current, part of the power is spent on useful needs, and heat is inevitably released into the environment. And tangible! Without a cooler, the processor can reach the boiling point; it would heat up further, but the protection systems will turn off the power earlier. It turns out that the processor consumes significant power. Recently, Peltier elements have appeared on the market, designed to cool the raging brain. A certain user noticed that the processor cooled down... to minus 10 degrees Celsius. Impressive?

Peltier elements cannot be called cheap. How to build a homemade refrigerator based on them: place them parallel inside a thermally insulated container, where the temperature will begin to gradually drop. But the freezing power of refrigerators is not measured in watts, it is calculated by the number (in kilograms) of products whose temperature can be reduced to a given temperature. We don’t know what is meant by the statement that the power of the Peltier element is 77 W. At a price of 300 rubles per piece, it’s worth trying to calculate the cost homemade refrigerator, correlating the specified parameters. We offer a different way.

Remember, in the reviews they presented a method for determining the required heating power of a room, and now we use it in the reverse order. Experiment steps:

- You will need an ordinary thermometer. Better than a simple street one. We will place the thermometer in our homemade refrigerator.

- We make the body. Real refrigerators use polyurethane foam for thermal insulation. Buy a can at the store building materials. Foam plastic will also work; we recommend using reflective insulation of the Penofol type or similar. For example, take a box, tightly trim it on both sides with the mentioned material, in fact, a good homemade refrigerator is already ready. For information, the material was taken from the space industry, where it was used to create spacesuits. Sun rays are deadly outside the atmosphere, and the cosmic cold will make Sauron himself shudder, but all of the above did not harm the astronaut special harm under a layer of Penofol. Of course, gold and silver were used in the spacesuits, and not aluminum; perhaps they did not use polyethylene. Fact - the characteristics of the material are amazing.

- The cooler will initially be a single Peltier element. We mount it with adhesive sealant. Then we will show a technique that allows you to find the number of modules needed for a homemade refrigerator to start freezing.

Calculation method for a homemade refrigerator using Peltier elements

We proceed from the fact that heat loss depends linearly on the temperature difference inside and outside a homemade refrigerator. Let's go from simple to complex:

- Let’s say the temperature in the room is 20 ºС and remains unchanged throughout the experiment. Let's start the research. Obviously, in the absence of Peltier elements, the temperature inside the refrigerator will be 20 ºС. This is the first point on the straight line (losses increase linearly from the temperature difference between the outside and inside of a homemade refrigerator). We will install a Peltier element with radiators on both sides, and the outer one will be blown by a cooler to enhance the effect.

- After a while, the temperature in the 30-liter compartment was 14 ºС. We claim that by adding two more Peltier elements with radiators and coolers, anyone will receive 2 degrees of heat inside a homemade refrigerator if the room is 20 ºC warm. Scheme:

Conclusions on the design of a homemade refrigerator

Readers will draw the rest of their conclusions on their own: a homemade refrigerator will give 2 degrees of heat on the Celsius scale if you equip the device with three Peltier elements with coolers. It is permissible to generalize experience, select optimal insulation, and vary conditions. For example, remove coolers so as not to make noise and waste energy. This will simplify the design. But we want to cool the ardor of the inventors: in real, not homemade refrigerators, two fans are used, for the cold and hot circuits. Experiment.

The refrigerator device will withstand the computer power supply. Remember how much the processor consumes! The Peltier element is far from the most important thing inside. The voltage has already been adjusted in advance, so you don’t have to look for rare parts. You buy three Peltier elements to make your own refrigerator, take a power supply from an old PC, build a box with two coolers, and get the finished product. Moreover, it can operate from a car battery.

The principle of operation of the refrigerator is so obvious that children can understand it. When the direction of the current changes, the Peltier elements work to heat. It's good to have warm food nearby when there is no heating device around. In the latter case, the law works in reverse side. Three Peltier elements inside a homemade refrigerator will provide a temperature 18 ºС above the environment. If the car has 25, the box will show 43. Enough to have a snack and not complain. It turns out that there are two devices in one person.

We would like to thank the author of the YouTube video for the great idea on how to make a refrigerator yourself. Let the idea not be very successful, but only because the volume is large. Peltier processor elements are not so powerful that they can single-handedly overcome a large volume that is not fully formed.

We offer an article on how to make a refrigerator with your own hands, having understood the principle of its operation.

The method of generating cold directly depends on the dimensions of the future device. For large sizes, choose a circuit with freon, for small ones - electrical elements Peltier.

Important! At self-production Pay attention to the second option, implemented at home.

Next, we’ll look at how to make a refrigerator for your garden and car yourself, powered by 12 volt USB. What can you take from your computer or water cooler? How to assemble a body from sheet material? How are ammonia and trailer refrigerators made?

Operating principle and advantages of the Peltier cooling element

During operation of the Peltier converter, its two parts have different temperatures. When electric current passes through the cooler, heat is generated in the upper half, and a cold flow is generated in the lower half.

Attention! You can purchase a cooling device in a store that sells computer components or radio parts.

The advantages of such a refrigerator include the absence of:

- moving elements;

- transported media;

- noise.

Instructions for assembling a thermoelectric refrigerator with your own hands

To make a refrigerator using Peltier elements with your own hands, check out step by step instructions. It describes the steps in detail and provides useful recommendations.

Materials and tools

To work you will need:

- expanded polystyrene. Suitable sheets with a thickness of 50 mm;

- Peltier element;

- radiators with coolers. Can be removed from old computer equipment;

- thermal paste;

- regulator with temperature sensor;

- polyurethane foam;

- wires;

- plugs for connecting to a USB car and/or socket;

- stationery knife;

- measuring tool and pencil;

- soldering iron

Housing assembly

To ensure the geometric accuracy of the refrigerator body, a template is made. Its dimensions must correspond to the required volume of the future device. The wine rack should be high enough to accommodate the bottles.

Attention! As a template, use a drawing of a box or box of a suitable size.

Drawn elements:

- cut to size using a utility knife;

- are connected to each other using polyurethane foam. To do this, elements with foam applied to their surface are connected and left in a stationary state until the composition dries completely. To enhance thermal insulation characteristics The walls are made double.

The assembled box is painted in the selected color in several layers.

Insulation with aluminum foil is glued to the inner surface of the refrigeration unit using liquid nails.

In the absence of sheets of extruded polystyrene foam, you can use:

- laminate. Special grooves facilitate the assembly of the structure. The material has sufficient strength;

- Styrofoam. Well processed cutting tool. Moisture resistant. A refrigerator made of polystyrene foam will cost less than its counterpart made of polystyrene foam;

- MDF or fiberboard. Required additional processing due to low resistance to moisture;

- plastic. Ready-made boxes with lids are preferred. A tool box or water cooler will do.

Installation of the cooling unit

To ensure the efficient flow of physical processes inside a portable mini-refrigerator, installation is performed in the following sequence:

- An aluminum profile is mounted perpendicular to the side wall of the box from the inside. It will be used to transfer cold to the interior space;

- to the fixed aluminum profile a radiator is attached from the inside, with the help of which the redistribution of cold air throughout the internal volume will be ensured;

- a Peltier element is mounted on the outside of the profile. It is better to avoid using adhesive sealants due to their low efficiency. Screws are preferred.

In order for the car refrigerator to provide the necessary temperature regime, three elements are used to cool the container. A computer block is used as a power source. If the refrigerator will be connected to a car battery, you will need an extension cord with a cigarette lighter connector. To regulate the temperature, a thermostat is connected to the refrigerator.

The installation of the Peltier element must be carried out in compliance with a number of rules. Necessary:

- Observe the polarity of the wires. An incorrect connection will cause the inside to heat up and the outside to cool;

- remove heat from the top in a timely manner by installing a cooler. Without it, the element overheats. The intensity of air flow exhaust determines the power of the system;

- securely secure the insulating gasket. Its characteristics determine the efficiency of the cooler;

- during installation, thermal paste should be applied between the parts of the element and the insulating plate;

- To distribute the cold evenly and quickly cool inside the container, another cooler is attached to the inner surface. It will also prevent condensation from occurring.

Other types of refrigerators

If you need a freezer, you should try to assemble a compressor unit. It is characterized by fast and reliable freezing. It is difficult to make such a device yourself. You must have certain knowledge and have a compressor, evaporator and condenser available. Such a unit can be installed in a car trailer when going outdoors.

There are devices absorption type. They include:

- a generator into which a mixture saturated with ammonia is supplied. After connecting to the power supply system, it boils;

- a condenser that removes heat outside the refrigerator;

- an absorber in which, due to the pressure difference, the ammonia-water solution absorbs ammonia vapor. The process is accompanied by the release of heat. To prevent overheating, it is cooled with water;

- an evaporator in which refrigerant vapor is released;

Thus, the simplest version of a refrigerator for a car is a device based on Peltier elements. This optimal solution in a situation where a travel thermos bag does not suit you. Camping, 12 volts, will be suitable option for a summer residence, if you provide a special adapter for 220 V.

Video: DIY refrigerator bag