Forest sawing is a cycle of actions using a variety of technologies aimed at obtaining lumber from round timber suitable for further use in industry. The duration and labor intensity of the process depend on the chosen method of processing round timber, as well as the time of year.

Tools and equipment

Trunks and large branches are used for production. All material is divided into groups according to thickness and presence of bark. Often, timber processing enterprises have workshops near the harvesting site, in which machines for the initial processing of wood are installed.

Manual debarking of wood

Wood that has not passed the debarking stage can be used for flooring or as ridge beam in the appropriate interior, or as a supporting device during construction.

Industrial debarking of forests

If another option for using the wood is planned, then sawing is carried out, resulting in the following segments:

- unedged and semi-edged (rough material from which the bases of the floor, walls or ceiling are mounted);

- edged (intended for finishing flooring).

The cutting can be carried out by a mobile organization that has all the necessary tool.

Wood cutting map

Rational use of the material is ensured by compliance with the cutting map. This allows you to reduce costs due to waste, the percentage of which the card can significantly reduce. The tools and types of forest processing equipment used depend on the volume, desired quality and size of the finished lumber.

The most commonly used are a circular saw and various machines:

- circular due circular saw allows you to make precise cuts in various directions. Suitable for both professional and home use, copes well with above-average round timber diameters;

- chainsaw;

- machines for clean bark removal;

- sawing on a band sawmill makes it possible to process dense logs; it is considered the most popular, since the yield gives quality material and a small amount of waste;

- disk machine: production of double-edged timber and unedged boards;

- a frame sawmill does not require a foundation, the technology using it allows you to install the equipment in close proximity to the felling site;

- the fine gauge is processed by universal machines, the output is high-quality building materials even from low-grade logs;

- sawing round timber at a large woodworking enterprise should be produced with the largest number lumber that differs from the rest in its special quality and precise dimensions. For this purpose, special lines are installed for sawing.

At the sawmill, timber and edged boards are obtained by cutting logs up to 7 m long and 15-80 cm in diameter along the longitudinal line. A circular saw has one or several disks, processes different diameters of wood according to their number.

If you need to process a small amount of wood at home, you can use a regular chainsaw.

Cutting wood

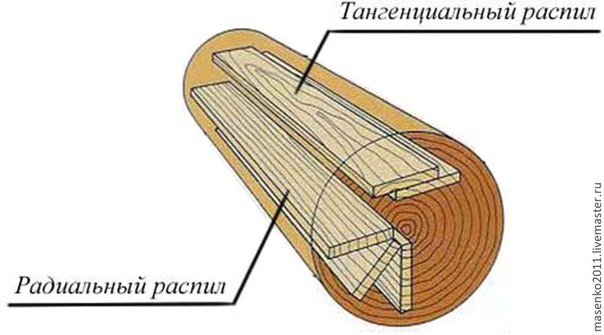

Before choosing a tool, you need to decide on the type of cut, focusing on the annual rings of the log. There are several types:

- radial (along the radius);

- tangential (the cut is parallel to one radius and touches the annual rings);

- the fibers are located parallel to the cutting being performed.

Among the cutting methods, the one that is most suitable for a particular case is selected:

- Waddle. Sawing wood in this way is done for deciduous trees with a small trunk thickness, it is considered the simplest processing. Output: unedged elements and slabs.

- If you have another forest processing machine, then it is possible to cut up to 65% of the material to produce edged boards of equal width. First, a double-edged beam and boards on the sides are cut out, and then a certain amount is obtained from the timber edged lumber.

- More specific methods are sector and segment sawing. The number of elements in the first method varies from 4 to 8, and depends on the thickness of the trunk. After dividing, elements are cut from each sector along a tangential or radial line. The second method begins with the timber coming out of the central part, and boards are cut from the side segments in a tangential direction.

- For individual cutting of wood, the circular method is suitable. It is based on turning the log along the longitudinal line by 90° after each sawn board. This allows you to monitor the quality of the wood and promptly remove affected areas of the trunk.

Manual work: using a chainsaw

For home cutting of several trunks, it is not advisable to purchase a tool whose cost is several times higher than the price of finished products. If you have the necessary skill, then it is more efficient and cheaper to do the whole necessary work a regular chainsaw, or chain equipment powered by electricity. Of course, such work requires much more physical effort and time, but the cost of the issue is significantly reduced.

Work for garden plot requires pruning fruit trees, and it also becomes possible to additionally produce material for outbuildings, without resorting to the services of specialists, so any prudent owner will prefer to buy a chainsaw. Most often, coniferous wood is harvested for the home, and this tool does an excellent job of cutting it. Thanks to straight trunks, it is easier to mark cutting lines, which increases the speed of work. Professionals, by the way, most often use a chainsaw, since it is more powerful than an electric one and can be used anywhere, regardless of whether there are power sources at the cutting or cutting site.

To use a chainsaw to cut logs, you will need a device such as a saw attachment, as well as cutting guides and base-trunk fasteners. The frame-shaped attachment is attached to the tool so that it remains possible to adjust the distance between the chain and the frame itself. This is done to make it possible to produce finished lumber of different thicknesses. For the role of a guide, you can take either a profile of the required length, or an even wooden plank with sufficient rigidity. A special chain is selected for the tool, designed to cut the trunk lengthwise. Its difference from the others lies in the teeth sharpened at a certain angle.

Before you start work, you need to not only prepare all the necessary tools. Regardless of whether a woodworking machine is intended for processing a trunk or hand tool, the first thing you need to do is familiarize yourself with the cutting map. This is done in order to minimize the percentage of waste and increase the yield of useful products.

The first thing you need to worry about when longitudinal cut– uniform density of finished boards. To do this, a competent sawyer guides the tool with east side logs to the west, or in the opposite direction. This is explained by the higher density of round timber in its northern part than in the southern part.

Next, use a chainsaw to remove the slab from both sides so as to obtain a double-edged beam. It, in turn, is sawed in accordance with the cutting pattern chosen at the beginning of the work. The solution is an unedged board. If there is a certain percentage of defects in the trunk, then a circular cut is possible with the trunk turning at a right angle or 180°.

Quantity of finished material, cutting price

Exit useful material from conifers and hardwood differs in percentage. For lumber obtained from coniferous trees, the following indicators are characteristic:

- provided that the operation is carried out by a professional and a circular sawmill is used, the percentage of finished wood will be the highest (80-85%);

- the edged material produced by the machines averages 55-70%;

- When used with a chainsaw, an unedged board leaves up to 30% waste.

The figures are given without taking into account the finished culled timber, the amount of which can reach 30%. However, such material is used for products that allow certain defects.

Deciduous round timber produces 60% of the finished product unedged timber and about 40% trimmed. This is explained by the initial curvature of the round timber. It is possible to increase the amount of products obtained: this will require forest processing machines of various types. A certain kind of device can increase the amount of lumber by 10-20%. For one cube of lumber you will need about 10 cubes of deciduous round timber. The cost of installing additional equipment will be recouped by the cost of the finished timber. Special lines provide greater volume, but their use is only advisable over a large area. The average price of sawing wood at a regular sawmill will be approximately 150-180 rubles per cubic meter of boards.

Sawing map

The sawing map is a calculation of the optimal amount of finished lumber from one log. You can calculate it yourself for each specific log diameter, or you can use computer program, which greatly facilitates the calculation, and the price of which is quite affordable.

Or the source could be a regular sawmill reference book. The result is a table that is used as a basis. The sawmill attachment should always be oriented to its data in order to obtain more lumber of any type of wood.

Lumber is obtained by cutting logs (blanks). In essence it is lumber products certain sizes with two plane-parallel sides (faces). Sawing can be either radial or tangential.

In Fig. 1 presented different kinds lumber - from plate to edged boards.

Figure 1. Types of lumber: a - plate; b - two-roll beam; c - not edged board; g- quarter; d - four-edged beam with wane; e - semi-edged board with wane; g - clean-edged timber; h - croaker; and - edged board; k - planed tongue and groove boards; 1- face; 2 - edge; 3 - rib; 4 - end; 5 - wane

The following elements are distinguished in lumber: layers, edges, ribs, ends. Face - the longitudinal wide side of lumber, as well as any side of square lumber. The best face of lumber has the least amount of defects, best quality processing. The face of lumber facing the core is called the inner face, and the face facing the sapwood is called the outer face. Edge - the longitudinal narrow side of lumber. Edge - the line of intersection of two adjacent sides of lumber. End - the end transverse side of the lumber. Wane is not a mandatory element of lumber; it is, so to speak, an element of defective edged boards due to poor condition source material(logs or blanks).

Lumber is produced according to GOST 8486-86E:

1) made of wood coniferous species- pine, spruce, larch, cedar and fir;

2) from deciduous wood - beech, birch, alder, linden, aspen and poplar.

The following are used: boards with a thickness of 100 mm or less with a width to thickness ratio of 2 or less; beams with a thickness of more than 100 mm (four-edged and double-edged).

Length of lumber: softwood no more than 6.5 m, hardwood no more than 5 m. For special structures, lumber up to 9 m long, made to special order, can be used. The thickness and width of lumber are determined by the assortment (Tables 1, 2, 3).

Table 1. Standard output of edged lumber per 1 m 3 logs

|

Type of wood |

Log diameter, mm |

Output from 1 m 3 |

|||

|

Lumber, m 5 |

Wood waste, m 3 |

Sawdust, m 3 |

|||

|

Conifers |

|||||

|

Hardwood (including birch) |

|||||

Note:

1) When the roundwood grade increases to 1, the lumber yield standard increases by 3%.

2) When the grade of roundwood is reduced to grade 3, the lumber yield standard is reduced by 2%, to grade 4 - by 7%.

3) With a mixed supply of large and medium logs, the lumber yield standard is taken as the arithmetic mean between medium and large logs.

Table 2. Thickness and width of softwood lumber in mm

|

Name |

|||

|

Least |

Greatest |

||

Table 3. Thickness and width of hardwood lumber in mm

|

Name |

|||

|

Least |

Greatest |

||

The ends of lumber and rough blanks must be sawn at right angles to the longitudinal axis. Wane beams (with a partial absence of a cut in the edge) with a cross-section of 120 x 120 mm or more must have a cut width at the thin end of at least one third of the side of the beam.

The highest permissible moisture content of lumber for load-bearing structures- 25%, for glued structures - 15%.

The use of lumber from hardwood is allowed for parts of rafters, internal stairs, internal linings walls and partitions, ceiling trim, soffits, gables, interior architectural details, millwork and finished floors.

The use of birch, linden and poplar wood for rafters is not allowed; linden, alder, aspen and poplar for treads wooden stairs; linden and poplar for clean floors.

Dependence of volumetric output of trimming

lumber from the method of sawing logs

Ulasovets V.G. (USFTU. Yekaterinburg, Russian Federation)

The influence of the ways of log-sawing the volume outcome of edged boards was examined in this paper.

In sawmilling practice, the main method is to saw logs parallel to their longitudinal axis. The use of band saws and circular saws makes it possible to saw logs parallel to the generatrix, i.e. on the run. With the same location relative to the top end of the log, unedged boards of the same thickness, cut in different ways, will have different shape and volume. At the same time, the yield of edged rectangular lumber from them will also be different.

If the unedged board under study and the rectangular edged board obtained from it have the same thickness and length, then the volumes can be compared by the ratio of their widths

where is the volumetric yield of edged boards from unedged ones, %;

b o- width of the edged rectangular board;

b n.o.- average width of the original unedged boards.

We study the dependence of changes in the volumetric yield of edged lumber from unedged timber on the methods of sawing logs parallel to the longitudinal axis and parallel to the generatrix.

IN general view width of edged rectangular board b o for both cutting methods are calculated using the formula

![]() ,

(2)

,

(2)

Where r - radius of the log at the top;

e vn.v.- the distance from the center of the top end of the log to the inner surface of the board under study;

N= (A + u a)/2r- the thickness of the sawn board with an allowance for shrinkage in fractions of the top diameter of the log.

The average width of the original unedged board when sawing parallel to the longitudinal axis of the log (first method) is calculated using the following formulas:

Where TO– log run-off coefficient.

Let us draw some conclusions about the volumetric yield of edged lumber from unedged timber obtained in the first sawing method:

At constant e vn.v./r with an increase in the thickness of the unedged board, the width of the edged board decreases and the volume of the slats increases, so the volumetric yield of edged lumber decreases. For example, when e vn.v/r= 0.45 and log run-off coefficient TO=1.15 with a change in board thickness from 0.05 d up to 0.2 d the volumetric yield of the studied boards cut from logs with a truncated paraboloid trunk shape will decrease from 87.5 to 61.3%, and the corresponding volumetric yield of edged boards with a log trunk shape of a truncated cone will decrease from 87.8 to 61.5%;

With increase e vn.v /r the run-off coefficient of unedged boards increases and the volume of slats during trimming increases, so the volumetric output of edged lumber decreases. For example, when sawing a log with a run-out coefficient TO= 1.3 for boards thickness 0.15 d when changing value e vn.v /r=0.05to e vn.v /r=0.45 run-off coefficients of unedged boards vary accordingly from K d. 1 = 1.304 to K d. 1 =1.397, while the volumetric output (truncated paraboloid) will decrease from 82.0 to 66.6%, and the volumetric output (truncated cone) will decrease from 82.7 to 67.4%;

With an increase in the run-off coefficient of the original log, the run-off coefficient of the unedged board increases, and the volumetric yield of edged lumber decreases. For example, when cutting unedged boards with a thickness of 0.25 d at e vn.v/r=0.25 with an increase in the coefficients of logs running away from TO=1.05to TO=1.45 runoff coefficients of the corresponding unedged boards vary from K d.1 =1.058to K d.1 =1.511, and the volumetric yield of edged lumber (truncated paraboloid) decreases from 73.8 to 58.0%; volumetric yield (truncated cone) decreases from 73.9 to 59.1%;

As the diameter of the log at the top increases, the ratio of the thickness of the board to it decreases and the relative volume of the slats decreases, so the yield of edged lumber increases. For example, when cutting boards 32 mm thick with e vn.v/r= 0.3 from logs with run-off coefficient TO= 1.35 when the log diameters change from 20 to 50 cm, the ratio of the board thickness to the log diameter changes from 0.16 to 0.064, and the studied volumetric yield of edged lumber increases accordingly from 71.6 to 79.9%; the volumetric yield of edged lumber increases from 72.6 to 80.9%.

The average width of an unedged board when sawing parallel to the generatrix of a log (second method) is calculated using the following formulas:

For logs with a trunk shape in the form of a truncated paraboloid

For logs with a truncated cone shape

Let us draw some conclusions about the volumetric yield of edged lumber from unedged timber obtained in the second sawing method:

At a constant distance from the center of the apical end of the log to the inner face of the sawn board, with an increase in the thickness of the unedged board, the width of the edged and unedged boards decreases, the volume of the slats increases, and the volumetric yield of edged lumber decreases. For example, when e vn.v/r=0.45 and log run-off coefficient TO=1.15 with a change in board thickness from 0.05 d up to 0.2 d the volumetric yield of edged boards (the shape of the log trunk is a truncated paraboloid) will decrease from 91.8 to 66.3%, and (the shape of the log trunk is a truncated cone) will decrease from 91.9 to 66.4%;

With increase e vn.v/r the runoff coefficient of the unedged board decreases, its width and volume, as well as the width and volume of the edged board, decrease, and the volumetric yield of edged lumber decreases. For example, when sawing a log with a runoff coefficient TO= 1.3 for boards 0.15 thick d when changing value e vn.v /r= 0.05to e vn.v /r= 0.45 runoff coefficients of unedged boards vary from K d. 2 = 1.238to K d.2 =1.18, and the volumetric yield of edged lumber (truncated paraboloid) will decrease from 85.0 to 75.5%, the volumetric yield of edged lumber (truncated cone) will decrease from 85.5 to 75.9%;

With an increase in the run-off coefficient of the original log, the run-off coefficient of the unedged board increases, and the volumetric yield of edged lumber decreases. For example, when sawing unedged boards with a thickness of 0.25 d at e vn.v /r=0.25 with an increase in the coefficients of logs running away from TO=1.05to TO= 1.45 runoff coefficients of the corresponding unedged boards vary from K d. 2 =1.036 up to K d. 2 = 1.286, and the volumetric yield of edged lumber produced from them decreases from 75.12 to 66.3%, respectively, the volumetric yield of lumber decreases from 75.13 to 67.0%;

With an increase in the diameter of the log, the ratio of the thickness of the board to the diameter of the log at the top decreases and the relative volume of the slats decreases, so the yield of edged lumber increases. For example, when cutting boards 32mm thick at e vn.v/r =0.3 from logs with run-off coefficient TO= 1.35 when the log diameters change from 20 to 50 cm, the volumetric yield of edged lumber increases from 78.8 to 85.9%, respectively, the volumetric yield increases from 79.4 to 86.6%.

Note that, just as when sawing a log parallel to the longitudinal axis, in the second sawing method the volumetric output of edged lumber from unedged timber obtained by cutting logs with a truncated cone shape of a trunk is slightly higher than when cutting logs with a trunk shape - a truncated paraboloid . This can be explained by the slightly larger volume of the rung zone of unedged boards cut from logs with a truncated paraboloid shape of the trunk, which turns into slats during the production of edged lumber.

It should be noted that in the second method, when sawing logs with a high runoff coefficient into boards with a thickness of no more than 0.1 d,with increase e vn.v/r There is an increase in the volumetric yield of edged lumber from unedged timber. For example, in the case of sawing a log having the shape of a trunk in the form of a truncated paraboloid, with a runoff coefficient TO= 1.5 per board thickness 0.05 d at values e vn.v=0, e vn.v/r= 0,1,e vn.v/r=0,2, e vn.v /r=0.3, the volumetric yield of edged lumber from unedged timber will correspondingly take values of 80.72, 81.52, 82.11, 82.48%, reaching a maximum at e vn.v/r = 0.38…0.387, respectively - 82.59%.

For logs with a trunk shape in the form of a truncated cone for the above conditions, the volumetric yield of edged lumber from unedged timber will correspondingly take values of 81.99, 82.73, 83.27, 83.58%, reaching a maximum at e vn.v/r= 0.36…0.37, respectively -83.64%.

The relative difference in the volumetric yield of edged lumber from the corresponding unedged timber obtained in both cutting methods is calculated by the formula

. (8)

. (8)

Where V o . 2 - volume of edged board in the second method of sawing logs;

V o . 1 - volume of edged board in the first method of sawing logs.

When sawing logs using the compared methods, the relative difference in the volumetric yield of edged lumber from unedged lumber can be significant. For example, when sawing a log with a runoff coefficient TO= 1.25 for boards 0.1 thick d when the distance from the center of the top end of the log to the inner surface of the board changes e vn.v/r= 0...0.6, the relative difference in the volumetric yield of edged lumber from unedged timber changes: for logs with a truncated paraboloid trunk shape - from 1.7 to 15.9%; for logs with a truncated cone shape – from 1.6 to 15.1%.

The conducted studies indicate that it is economically profitable for enterprises producing long edged lumber, blanks and parts to cut logs parallel to the generatrix.

TIMBER YIELD BASED ON FIR ROUND TIMBER VOLUME TABLES

Koptev Artem Sergeevich 1, Weiss Andrey Andreevich 2

1 Federal State Budgetary Educational Institution of Higher Education "Siberian State Technological University", Bachelor in Forestry

2 Federal State Budgetary Educational Institution of Higher Education "Siberian State Technological University", Doctor of Agricultural Sciences, Associate Professor of the Department of Forest Taxation, Forest Management and Geodesy

annotation

As a result of the studies, it was found that standard values in most cases, log volumes are underestimated by thickness level in comparison with the truncated cone formula (-33.2-+6.4%). In the thicker part of the logs, this difference stabilizes and is about 10%. At the same time, in relation to the formula for the median section, the tabulated values of fir logs in most cases overestimate the actual volume of round timber. In value terms, for 100 logs the difference can be (36 cm step) up to 60,000 rubles.

OUT OF LUMBER BASED ON THE TABLES OF VOLUMES OF ROUNDWOOD FIR

Koptev Artem Sergeevich 1, Weis Andrey Andreevich 2

1 Siberian state technological university, bachelor in "Forestry business"

2 Siberian state technological university, doctor of agricultural sciences, assistant professor of forest inventory, forest management and geodesy

Abstract

The studies found that the standard values in most cases underestimate volume timber according to diameter compared with frustum formula (-33.2- + 6.4%). As part of thick logs, this difference has stabilized at around 10%. At the same formula applied to the midsection tabulated values fir logs in most cases overestimate the real volume of roundwood. In terms of value for the timber 100 may be a difference (see step 36) to 60,000 rubles.

Back in the second half of the twentieth century, in forest taxation it was considered advisable to determine volumes for practical purposes using special tables. Of all the tables compiled, the most widely used in our country are the tables of A.A. Kründer, common for all species, without taking into account the location of the harvested assortments on the trunks. These tables were later recalculated by G.M. Tursky into the metric system, supplemented by N.P. Anuchin and approved as GOST 2708-44.

Other tables were also used in practice before. For example, Provatorov’s table, which was compiled without any basic taxation material, purely mathematically calculated the volumes of logs, assuming one constant run for logs of all species and categories.

Klimashevsky’s tables, as well as Provatorov’s tables, were characterized by the fact that the volumes of logs were calculated purely mathematically, assuming their division into five classes, respectively, with a run of 1/8, 1/4, 3/8, 1/3 and 5/ 8 tops by a fathom.

The tables of Tour, Arnold, Toursky, Rudzsky were characterized by the compilation of the volume of logs based on numerous observations of the run-off and volume of logs of different species, and the possibility of giving one general table for logs of all classes and species was recognized.

However, these tables had certain disadvantages. For example, the tables of Tour, Arnold, Toursky, Rudzki were not adapted to the normal taxation of logs individually and acceptable determined the volume only when taxing a larger number of logs together, when one should expect a smoothing of the extremes in the average result.

Also, the tables did not provide that the accuracy of estimating logs is influenced by the degree of granularity of thickness steps for log diameters and the total length of logs. When taking a very large step for log diameters of 4 cm, tables for single logs or for a small number of them should give large errors due to the rounding of diameters.

In modern forestry practice, the relationship between the characteristics of the entire forest stand and the parameters of individual trees in this tree stand is known. For example, according to research, the density of the grown tree stand affects the quality of the timber. To improve the quality of timber, a greater density of the tree stand is needed in the early phase of rotation to reduce the growth of branches in the lower part of the trunk, their accelerated death and self-cleaning of the trunks. In the late phase of cutting rotation, a relatively sparse tree stand is desirable to clear branches and accelerate the overgrowth of nodes. As is known, the greater the density, the smaller the runoff and vice versa, the lower the density, the greater the runoff, which in turn, as is already clear from the presented material, greatly influences the accuracy of determining the volume of assortments.

It is also necessary to take into account the influence of felling on the characteristics of the renewed subsequent forest stand. It is known that thinning contributed to a significant increase in trunk diameter at breast level, height growth, crown-to-trunk size ratio, crown width, but led to a decrease in trunk height to diameter at breast height. The trunk run-off also increased significantly, and therefore the determination of the wood supply turned out to be overestimated by 2-15%, especially for trees in thinned stands.

International trade in timber products is developing very dynamically. According to FAO, global roundwood exports for last decade in quantitative terms increased by 8 million m 3. This was facilitated by the constant growth of global consumption of lumber in various sectors of the economy and the increasing importance of wood as a natural, environmentally friendly universal material. International trade in unprocessed wood today is developing in the context of growing volumes of its consumption. The leading exporters of roundwood in the world are Russia, New Zealand, and the USA, and the main importers of unprocessed wood are China, Austria, and Germany. The main factor in volume growth international trade Currently, there is an increase in wood consumption in the world, and in the next few years this trend in the world market will continue.

Experimental studies. The research was carried out in the Biryusinsky district forestry of the educational and experimental forestry enterprise of Siberian State Technical University. Measurements of Siberian fir round timber were taken at the lower warehouse. Subsequently, the volumes of round timber were determined in various ways. The yield of cubic meters of lumber from a log was determined using Table 1 below.

Table 1 - Determination of lumber yield

|

Type of wood |

Log diameter, cm |

Output 1m 3 |

|||

|

lumber, m 3 |

wood waste, m 3 |

sawdust, m 3 |

|||

|

Conifers |

|||||

|

Hardwood (including birch) |

|||||

Note: When the roundwood grade increases to 1, the lumber yield standard increases by 3%. When the grade of roundwood is reduced to grade 3, the lumber yield standard is reduced by 2%, to grade 4 – by 7%. With a mixed supply of large and medium logs, the lumber yield standard is taken as the arithmetic mean between medium and large logs.

As can be seen from the table, approximately 50% of the volume of the entire log is lumber. It is worth noting that coniferous trees have a higher lumber yield than deciduous trees.

Below is a table showing how many cubic meters of lumber, wood waste and sawdust come out when using the calculation results using the truncated cone formula and tabular data (Table 2), as well as using the median section formula (Table 3). The volumes were found for one log and for one hundred logs. The difference between the two lumber yields is also shown as a percentage. The yield of lumber obtained by calculation using the truncated cone formula for the first table and the median section formula for the second is taken as 100%.

Additionally, the cost of lumber obtained from 100 logs was calculated, the volume of which was determined from tabular data and the truncated cone formula (Table 3), as well as from tabular data and the formula for the median section (Table 4). In addition, the difference between the costs of lumber has been established.

Conclusions. A comparative analysis showed that standard values in most cases underestimate the volume of logs by thickness level in comparison with the truncated cone formula (-33.2-+6.4%). In the thicker part of the logs, this difference stabilizes and is about 10%. At the same time, in relation to the formula for the median section, the tabulated values of fir logs in most cases overestimate the actual volume of round timber. In value terms, for 100 logs the difference can be (36 cm step) up to 60,000 rubles.

Thus, the use of the truncated cone formula makes it possible to significantly reduce the error in determining the volume of fir logs in relation to the local East Sayan mountain taiga region.

Table 2 - Lumber output

|

Volume, m3 1) GOST 2708 2) truncated cone |

Lumber output, m3 |

Wood waste output, m3 |

Sawdust yield, m3 |

Difference, % |

|||||

|

100 logs |

100 logs |

100 logs |

|||||||

Continuation of Table 2

|

Timber group by thickness, cm |

Volume, m3 2) truncated cone |

Lumber output, m3 |

Wood waste output, m3 |

Sawdust yield, m3 |

Difference, % |

||||

|

100 logs |

100 logs |

100 logs |

|||||||

Table 3 - Lumber output

|

Timber group by thickness |

Volume, m3 2) average section |

Lumber output, m3 |

Wood waste output, m3 |

Sawdust yield, m3 |

Difference, % |

||||

|

100 logs |

100 logs |

100 logs |

|||||||

Table 4 - Cost of lumber

|

Lumber output per 100 logs |

Deviations, rub |

||||

|

Group of timber by thickness |

Truncated cone formula |

||||

Bibliography

- “European Agreement concerning the International Carriage of Dangerous Goods by Road” (ADR/ADR) (Concluded in Geneva on September 30, 1957).

- Orlov M.M. Taxation of various assortments of industrial wood // Forest taxation. 1932. Chapter 14. With. 74-75.

- Sawn timber properties of Scots pine affected by initial stand density, Thinning and pruning: A simulation based approach: Dokl. / IkonenVeli-Pekka, Kellomoki Seppo, Peltola Heli // Silva fenn. 2009. 43. No. 3. p. 411-431.

- Long-term effects of precommercial thinning on the stem dimensions, form and branch characteristics of red spruce and balsam fir crop trees in Maine, USA: Report_ / Weiskittel Aaron R., Kenefic Laura S,. Seymour Robert S., Phillips Leah M. // Silva fenn. 2009. 43. No. 3. p. 397-409.

- Varivodina I.N. , Kuznetsova E.V. , Perelygina O.G. Features of determining the volume of round timber in Russia and abroad // EUROPEAN STUDENT SCIENTIFIC JOURNAL. 2014. No. 1.

When sawing wood, it is important to immediately calculate what the consumption will be, as this will affect the cost of lumber. The yield of finished products may vary. It all depends on the quality of the wood used and whether measures are taken to optimize cutting. There are special measures to increase work efficiency, make the output better, and the quality of sawing higher. Before sawing, you need to pre-calculate everything. This is not as difficult as it might seem, but the consumption of round timber will be optimal and profitable to obtain an excellent result.

How to increase cutting efficiency

In order for the yield of lumber to be significant, it is necessary to use special measures to increase the efficiency of the process:

- The calculation should be carried out only when using special programs; manually it will have low results, and the percentage of defects will be high.

- The round timber must first be sorted so that processing is carried out correctly.

- For cutting you need to use equipment High Quality. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will be low.

- It is best to cut wide lumber first; narrow lumber takes longer to process.

- It is not recommended to take long logs.

- Before work, you should set up the equipment.

The yield of finished lumber may vary. It must be remembered that at the first stage boards are obtained, then they are sorted. As a result, the percentage decreases even more; for example, for deciduous trees it can be only 10-20%.

How to optimize cutting

To increase the yield of lumber, the cutting process must be optimized. This applies primarily to those workpieces that have significant curvature. To cut a crooked round timber, you need to perform a number of steps:

- First, only suitable wood is selected for work. If the remaining logs have rot, sprouts, or cracks at the ends, then it is necessary to trim off some areas.

- If a rotten core is discovered during work, you can carefully remove it, and then saw the remaining part. This will allow you to avoid large losses and obtain boards with a length of 1 m or more with the required quality.

- It is recommended to use logs with a larger diameter so that the yield percentage is higher. The coefficient can be 1.48-2.1, but it all depends on the diameter, quality of the round timber, sorting, and equipment. For frame shops this coefficient will be 1.48-1.6, and for lines with milling equipment– 1.6 for large forest. With a round log diameter of 12 cm or more, the coefficient can exceed 2.1.

Volume of waste after sawing

To finished board came out with a high percentage, it is necessary to prepare everything correctly, the work must be carried out only in accordance with the technology. Roundwood of coniferous and deciduous species produces different yields. In the latter case, the volume is smaller, even if special additional equipment is used. Needles are considered more convenient for sawing, since their trunk is straight and the log has a larger diameter. Coniferous forest is not so susceptible to rotting, so there is less waste. For hardwood, 2 cutting technologies are usually used:

- using a band sawmill on Z75, Z63;

- into collapse, when a half-beam is cut out in the core of the material and passed through a multi-saw machine.

The volume of a band sawmill is 40-50%. When using technology for collapse, the yield is different, it can be increased up to 70%, but the costs of such work are higher. If you cut round timber, the length of which is 3 m, you can see that the percentage of scrap is quite large, and the remaining material requires processing. This applies to the bulk with boards 22x105(110, 115)x3000 mm. There are many options for such a marriage. For example, it could be a wormhole, which is no longer suitable for most jobs.

After sorting, the volume of hardwood material, which belongs to grade 0-2, will be only 20-30% of the amount obtained after sawing. This means that of the total mass of harvested round timber, the yield of normal boards will be only 10-20%. The remaining materials are mainly used for firewood. For coniferous round timber, the yield will be different, but attention must be paid to what average values of the resulting volume are observed.

Lumber output

In order for the yield of lumber to be optimal, numerous conditions must be taken into account. To calculate correctly, you can consider the example of round timber yield. The data was obtained from the real experience of specialists and from the performance of sawmills. This makes it possible to compare percentages and calculate optimal average numbers.

For conifers, the following solution is possible:

- For unedged boards and other unedged materials during sawing, the yield will be 70%. This is the amount of material obtained during processing, the amount of waste will be equal to 30%.

- For edged material, when using sawmills of 63, 65, 75, there will be a lower yield of lumber, only around 45%. U band sawmills yield is usually up to 55-60% finished material. If you use means to increase efficiency, you can reach 70%, although this requires great experience work.

- WITH disk sawmill you can get lumber in quantities of 70-75%, although using methods to increase efficiency it may well be 80-75%. But work experience is required.

According to GOST 8486-86, for grade 0-3, the yield percentage, not taking into account sorting, is approximately 70%.

Another 30% can be left for rejecting the finished material. The rejected material is not thrown away; it is used for the manufacture of other types of lumber, which allow for the presence of certain defects.

For deciduous roundwood, a different yield percentage is observed:

- For unedged material – 60%.

- For edged wood - up to 35-40%, since the curvature of the original deciduous wood is usually large.

The output can be increased; additional equipment is used for this. This can be a special multi-sawing machine, an edge trimming machine, or a slab machine. In this case, the yield of lumber will increase by about 20%. The given percentage is given based on data on obtaining boards of grade 0-4. When sorting grades 0-1, the percentage of lumber obtained is 10%. To get a cube of finished edged hardwood material, you need to cut 10 cubes of the original round wood.

The yield of lumber from roundwood may vary. It all depends on the original type of wood used by the sawmill. Special measures to increase efficiency allow you to get a larger percentage than is possible, but for this you must have some experience.