Roof insulation has been of concern to people since time immemorial. Even in the most primitive buildings, various tricks were used to prevent heat from the fire from leaking out. With the development of construction, technologies changed. Not so long ago upper areas buildings were insulated with clay concrete or furnace slag, including ordinary shavings and cement. Today, such materials are gradually becoming a thing of the past. They replaced modern products and methods of isolation.

What do you need to know about materials?

It is necessary to insulate the roof in any case, the heat loss is too great. Click on photo to enlarge.

Insulation materials are made from different raw materials. The choice of products often depends on the type of thermal insulation itself. For example, they periodically use glass wool. Although this material is well known to many, it is not without a number of disadvantages. One of them is low environmental cleanliness. Of course, it cannot be said that it does not meet the given standards, but without following a number of rules, cotton wool from waste from the glass industry can cause a lot of trouble.

In addition, the technology of insulating a glass wool roof is not very reliable. Especially when arranging pitched roof structures. The fact is that such wool quite often slides off surfaces with a horizontal slope.

Despite the disadvantages, glass wool continues to be used. Why? First of all, most home owners are satisfied with the price of insulation. For those who like to save money, this is often considered decisive factor. If you choose glass wool, you should definitely consider the issue of protecting the material from moisture.

The situation is completely different with mineral wool or polystyrene foam. They are completely free of the disadvantages of the material described above. Plus they have a number of other advantages. Foam plastic, for example, has good strength; mineral wool perfectly insulates rooms. True, this has almost no effect on the order of work. You will still have to do waterproofing. As well as many other events.

Is it necessary to insulate the roof?

Mandatory, except for rare exceptions. But first, let's look at the issue related to temperature fluctuations. The latter have a very noticeable effect on any type of roof. If we take the lower section of the attic, which, in fact, is located under roofing structure, the temperature there is approximately the same as in the room itself.

From the outside, everything is completely different. Here the temperature varies depending on weather conditions. Insulation just solves the problem of temperature differences. What does this mean? Warm air masses do not seep out; external ones, on the contrary, do not get inside.

Temperature and many other features should be taken into account when choosing materials. Such nuances include the moisture resistance of the structure, capillary or diffusion type humidification, and loads exerted on the surface. Not to mention resistance to fungal growths and environmental friendliness.

The question of whether it is necessary to insulate the roof, as such, should not arise. Do you want to use the attic space and live in comfortable home, insulation must be done in mandatory. Moreover, take into account both the climatic conditions of the region and the characteristics of insulation materials.

Insulation technology – which one to choose?

Today, three approaches are used for roof thermal insulation. The first is to lay insulation between rafter structures. The second is based on installing insulators directly on the rafters. Finally, the third involves laying the same foam or mineral wool under the load-bearing elements of the roof. In practice, the first method is most often used.

We will not describe in detail each of the given methods on the basis of which roof insulation is carried out. Read about this in detail in other articles published on the site. However, a couple important recommendations we'll give it. Let's hope they will help you quickly cope with certain thermal insulation tasks.

- Any heat-protective layer must be continuous in the following areas - adjacent to window blocks, wall structures, pipes, etc.

- The size of the air layer must be calculated based on the minimum value of 20 cm. The layer includes both waterproofing and direct thermal insulation.

- Using insulation from mineral fiber, we must remember that after installation its dimensions increase by about 20%;

- When the depth of the rafters is less than the specified one, it needs to be increased using blocks or planks. Instead, a special overlay is sometimes used. Another way out of the situation is to divide the heat-protective layer into two parts. One is laid between the rafter structures, the second is mounted on areas causing problems.

- It is better to buy ready-made insulation systems, since the creators have already thought through many important points, from auxiliary materials before waterproofing.

- Questions like how much does it cost to insulate a roof or how to do it correctly insulation work, it is advisable to decide at the stage of building a house. We understand that this is not always possible. But if you are thinking about thermal protection now, while the building is just being erected or designed, be sure to protect the roof from the cold.

- When using a thermal insulator made from cellulose, you do not need to use a vapor barrier.

- Compliance with the established technology guarantees the absence of deformation of the rafters and finishing layer. The rule is simple, but it’s worth mentioning once again. There is no need to rush anywhere or, even worse, do work just to get away. You'll end up paying more more money when the system becomes unusable.

- Insulation materials must fill the entire space allocated for their installation. Areas through which air leaks are not permitted.

When is it really possible to do without thermal insulation?

If you live in a house with only one floor, you probably don't need attic insulation. If the structure is built according to all the rules, and there are no attic spaces in it, the roof, in theory, should already be normally insulated. The way out of the situation is often to insulate the ceiling. Air from the premises does not have the opportunity to leak upward, as a result of which heat is retained.

How much does it cost to insulate a roof?

The price of the work depends mainly on the cost of the materials used and the type of roof.

It is impossible to take and answer such a seemingly simple question right away. Why do we consider it simple? Market thermal insulation works has long been formed. Many companies have been offering the corresponding services for many years and provide professional insulation according to all modern standards. Knowing all the nuances of upcoming events, calculating the cost is not difficult.

Another thing is that it is impossible to indicate what the cost of roof insulation will be in a given situation without seeing the object. Even if you show the masters a photograph, it will give almost nothing. From the outside everything seems to be good, but inside the rafter system almost needs to be rebuilt. Sometimes this happens too. If you still want to know at least the approximate cost, here are a couple of tips.

Look online to see what they sell for. high-quality insulation materials. Knowing the cost, it is easy to calculate the amount for purchasing materials based on total area. Also, no one is stopping you from sitting down and making a detailed list of upcoming work in order to determine the approximate final option. Ask on specialized forums how much it will cost. Finally, simply call craftsmen from several companies at once. Few people can do a better job of calculating prices than a specialist.

Roof insulation plays a huge role in completion construction work. Having built a house or cottage, you have to think about how to make the building as comfortable, warm and cozy as possible. Regardless of whether there will be living space in the attic or not, the roof must be insulated in any case. This will reduce heat loss and contribute to energy saving.

Do-it-yourself roof insulation

Roof insulation work does not have to be done with the help of a specialist; everything can be done with your own hands. The whole process should start with the selection necessary materials and creating a work plan and scheme. Any roof consists of an outer (roof) and an inner (ceiling and rafter frame) parts.

All insulation work carried out only after checking these components and, if necessary, repairing them. Then excess moisture is removed and dampness and mold are removed.

To prevent bacterial damage to wooden structures, the inner surface of the roof is treated with an antiseptic, and to protect metal structures from rust, such surfaces are treated with anti-corrosion compounds.

Insulation materials

Modern manufacturers offer a wide range of materials for roof insulation. The most popular are:

- Mineral wool (fiberglass, stone slabs);

- Extruded polystyrene foam;

- Polyurethane foam.

The material you choose is determined by the features of the roof. For example, it is preferable to insulate pitched roofs with fiberglass.

Fiberglass

This material has excellent heat-insulating and sound-proofing properties. Fiberglass is also durable, its service life reaches fifty years, it is fire-resistant and vapor-permeable. And, of course, the price; purchasing such material is a very inexpensive pleasure.

The most popular materials in use are mineral wool and polystyrene foam. This popularity is due to the ease of manipulation with them.

Mineral wool

Depending on the original type of material (stone or glass), mineral wool is divided into two types:

— the fibrous structure of the material, formed by melting small particles of rock, as well as various slags and mixtures obtained in industrial metallurgy, makes the product truly unique.

The material is not afraid of high temperatures and is also quite resistant to aggressive chemicals.

Glass wool- a heat-insulating material containing air fibers that are particularly durable. The product is obtained by melting ordinary glass. Like stone wool, the insulation is highly resistant to chemical products and does not burn.

The thermal conductivity of glass wool is 0.05 W/m°C at 25°C. During operation, glass wool practically does not shrink, and its fibrous structure, even after a long period of time, remains the same elastic and elastic.

Mineral wool has excellent characteristics in the following indicators:

- Low thermal conductivity;

- Excellent sound insulation;

- Fire resistance, which is very important for roof material;

- Highly environmentally friendly and durable.

Foam plastic and penoplex

Both insulation materials have a fairly small specific gravity, so their use does not weigh down the roof, and also does not require additional use a material that insulates from steam, since neither polystyrene nor foam absorb moisture.

Polyurethane foam

One of the modern materials is.

It does not need to be glued or nailed to the surface, but is applied by spraying onto it. This material has excellent adhesion to surfaces and as a result a durable, seamless structure is formed that does not allow cold or moisture to pass through.

Insulating the ceiling in a house with a cold roof

Once the materials have been selected, you can proceed directly to the process of laying the material. The specifics of this process depend on the roof design and the future use of the attic.

If the attic is not intended to be used as a living space, then the insulating material is placed on the attic floor between the joists, and not between the roof rafters. A membrane is laid on top to improve vapor permeability, then it can be covered with any floor covering.

To prevent the formation of “cold bridges,” the insulation should fit as tightly as possible to the joists. To do this, when cutting insulation, its size must be determined according to 1-2 cm. wider than the distance between the joists.

Insulating the attic from the inside

If you decide to equip the attic as a living space, you should insulate the roof with your own hands using a different technology:

- Initially, a waterproofing layer is laid to protect the insulating material from getting wet. To do this, a waterproofing membrane is laid on top of the sheathing and secured with counter-lattice bars;

- Then the insulation itself is laid between the rafters. To avoid the formation of gaps, during installation you should follow the same technology as when insulating the ceiling - the insulation should be wider by 1-2 cm.

- As a vapor-permeable layer, a vapor barrier film is attached on top of the insulation and overlapped at the joints;

- The film is secured on top with bars, which will serve as the basis for the finishing.

How and with what to insulate a flat roof

Insulation of a flat roof takes place according to a slightly different scheme. The beginning of work is the determination of the purpose of the room. The intended use of the attic as a gym or some other place for entertainment suggests that the roof must be really strong to withstand serious loads.

- To form a slight slope of the roof, a cement screed is made on the reinforced concrete slab;

- Then, as in the case of a pitched roof, a waterproofing layer is laid;

- Upon completion of these works, everything is covered on top with a layer of heat-insulating material (foam plastic, stone wool, extruded polystyrene foam, etc.), on top of which a layer of fiberglass or geotextile is laid.

- And the final stage is the filling of pebbles or a layer of gravel and the subsequent laying of floor or paving slabs.

If there is no living space under the roof, then the vapor barrier layer and insulation are laid in the attic, and the waterproofing layer is placed under the roofing material. And in case of complete non-use of the attic space of a flat roof, insulation is carried out either from the inside or from the outside.

By insulating your roof you will not only get additional square meters, but also reliable protection for the home from severe frosts in winter and sultry heat in summer.

Hmm, interesting, how did Carlson choose insulation for the roof? In cold Sweden, this clearly needed attention Special attention...Or did he only warm himself with buns and hot chocolate? Is this “insulation” suitable for you? If you need something more serious, read on.

On our website we have already devoted quite a few articles to the principles of choosing different warm insulating materials. In this material we will look in detail at which insulation to choose for the roof and we will look at the choice of insulation specifically in this section. Here are a few things to consider about your roof.

- Roof enclosing structures have increased thermal resistance requirements. For example, in 2010 in Finland, the coefficient of such resistance for walls was 5.88 m2*C/W, and for the roof it was 11.11! Almost double the difference.

- The material on the roof is more susceptible than others exposure to moisture. And, as you know, water is the enemy of thermal insulation.

- Roof insulation is installed, in fact, according to the principle of ventilated facades. This means that it is not protected from fire, for example, by concrete or plaster elements. In this regard, the insulation itself must have increased fire resistance.

- And it doesn’t matter whether we are talking about a flat or pitched roof, the insulation area is quite high, so the cost of the material should be reasonable and fit organically into the estimate for building or renovating a house.

These are the main ones General requirements to thermal insulation for the roof. However, you need to take into account the type of roof.

Types of roofing and insulation for them

When choosing a material for insulating the roof of a house, the difference between the three types of roofing structures is important:

- Pitched roof (cold attic);

- Mansard roof (floor).

Each of the three types of roofs requires its own approach in choosing insulating materials.

Attic

Attic  Flat

Flat

A flat roof is most often used, which means that the thermal insulation of the roof must be rigid. For these purposes, extruded polystyrene foam is most often used, for example, penoplex or rigid mineral wool insulation. Typically, each manufacturer has special solutions for this type of roofing. Slabs with cuts allow you to create the desired slope and special gutters for discharging water. It is enough to lay such a layer of insulation correctly and the roof can be considered insulated.

Insulate pitched roof with a cold attic, maybe by floor. However, in some cases, insulation is also inserted between the rafters. For these purposes, soft and elastic mineral wool slabs are most often used, which are inserted into the spacer. The attic floor is insulated with various materials, both sheet, bulk and sprayed.

Mansard roof- these are, in fact, the walls of the room, but they are made not of concrete or brick, but of rafters and, for example, tiles. This design is more expensive than a separate, ordinary floor. Roof insulation for mansard roof must be environmentally friendly, because, in essence, we are talking about insulating the room from the inside. There are also increased fire safety requirements. In a separate article, we discussed in detail the issue of using . Most often, such roofs are insulated with mineral wool.

Is the most popular one suitable? - Styrofoam

It is worth mentioning that by foam plastic we mean both ordinary, white polystyrene foam (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

It is worth mentioning that by foam plastic we mean both ordinary, white polystyrene foam (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

So, for flat roofs PSB-15 is not used. Although it is much cheaper, it can still be damaged when installing insulation by simply stepping on the sheet. In addition, the foam is made without a quarter. But, for example, penoplex has special grooves at the edges that are fastened together and create one indestructible layer of insulation on the plane.

Overlap cold roof often insulated with polystyrene foam into the frame when it is laid between the joists. For the same purposes, more moisture-resistant polystyrene foam is used, which, by the way, has much greater compressive strength.

The issue of using this material for a residential floor under the roof was discussed separately, and this is generally a whole topic.

Thermal insulation materials start with polystyrene foam. But, alas, the title - best insulation for the roof, it is not suitable. That's why they mentioned it at the very beginning. Further - more interesting.

Roofing classics - mineral wool

By mineral wool, people most often mean:

- Stone;

- Fiberglass;

- Shlakvatu.

For residential premises use stone wool. Although it contains resins such as formaldehyde, their percentage is still insignificant, and moreover, it has undergone a polymerization process. This means that the resin has settled and is now in a solid state with a closed molecular structure.

For flat roofs, as already mentioned at the beginning, rigid mineral wool slabs with a density of 140-160 kg/m³ are used.

To insulate a pitched roof, soft slabs are inserted between the rafters, trimming them. The same slabs are inserted between the joists and covered on top protective coating in case of overlap. Mineral wool is most often used for roof insulation. This is due to its “breathable” structure. The fact is that any wooden structure must be well ventilated. And if polymer insulation is adjacent to it, this procedure becomes much more complicated. That's why they use cotton wool. In addition, cotton wool is a non-flammable material. Being in its essence a semblance of volcanic lava, cotton wool does not burn, it only melts, and even then at a huge temperature - above 1500 degrees.

However, the insulator is not without its disadvantages. It is associated with poor resistance to moisture. For example, if a cotton slab has a thermal conductivity coefficient of 0.036 W/m3 K, then when wet, this indicator can actually change by 2 times! And, as you know, the roof is a place where leaks can happen. In practice, this means that you will have to replace a section of thermal insulation that has become wet.

Over time, the mineral wool also crumbles, forming dust that can enter the room. Someone doesn't like this material precisely for this feature.

Feature - “slabs in rolls”

Manufacturers are increasingly trying to simplify the installation of insulation. Nowadays, you can increasingly find a mineral wool form factor, which is called “slabs in a roll.” This material has sufficient density to fit well in the frame. In this case, it is enough to fix the roll in the upper part, between the rafters and roll it out at the bottom. For example, about Izover Profi, it is even stated that it does not need to be trimmed (it is clear that we are talking about a not very significant change in the width between the rafters), but simply tighten it and the cotton wool will accept the required form. It is more convenient to use such rolls than to insulate using slabs. Installing slabs takes longer.

When deciding how to insulate the roof of a house, most owners or developers choose mineral wool

Bulk insulation for roofing

This type of insulating materials for the roof of a house attracts many people for three reasons:

- Low price;

- Environmental safety;

- Lack of interest in rodents.

It is immediately worth noting that the roof can be insulated using bulk thermal insulation materials only on the floor. They are poured into the frame. Therefore, the material is suitable for covering an attic. Most often used:

- Sawdust;

- Expanded clay.

Sawdust

Sawdust itself is a fairly inexpensive material. Its advantage is its absolute naturalness. But there are two problems with using it:

- Rodents;

- Shrinkage.

Both solve in the same way. Adding lime to sawdust. Gypsum is also used to impart viscosity to the mass. It is added in an amount of no more than 5% by weight of sawdust. The resulting mass becomes viscous and is perfectly applied and keeps its shape.

Expanded clay

Expanded clay is small crushed pebbles of different fractions (sizes). It is filled between the joists. Expanded clay is not afraid of either steam or rodents. In a sense, it is an ideal insulating material for roofing.

In addition, it is not quite expensive. We will talk in more detail about the use of this type of thermal insulation for roofing in a separate article. Mention here was necessary to understand the overall picture possible options insulation.

Spraying and blowing

There are two main representatives in this family of roofing materials:

- Polyurethane foam;

- Ecowool.

PPU

Polyurethane foam is one of the most effective thermal insulation materials. It is sprayed or blown into foam white. To blow in polyurethane foam you need a special suit and a compressor. This material does not allow steam to pass through and you need to use a lathing to blow it in.

PPU is synthetic material, ecowool - environmentally friendly. Both of these materials are rodent resistant and require special equipment to blow them out. A specially trained technician can apply polyurethane foam correctly.

Ecowool

Ecowool has been used in Western countries for about 50 years. This roof insulation came to the territory of the CIS relatively recently. Ecowool represents cellulose fiber and is made from waste paper. There are special machines for crushing raw materials and “cooking” such cotton wool. Using special pneumatic transport, the cotton wool is delivered to the blowing point, where, for example, it is placed between the lags.

Another obvious advantage of ecowool for roof insulation is that it is easy to blow into narrow space between the rafters. Laying even rolls of mineral wool in this area is very problematic.

Comparison table of roof insulation materials

Having disassembled 6 popular types materials for insulation, it’s time to draw a conclusion: what is the best way to insulate the roof of a house? A comparison table of the characteristics of several materials will help you see everything clearly.

| Material | Density, kg/m3 | Thermal conductivity | |

| From | Before | ||

| Styrofoam | 15-25 | 0,032 | 0,038 |

| Extruded polystyrene foam | 25-45 | 0,032 | 0,04 |

| Mineral wool | 15-190 | 0,036 | 0,047 |

| Expanded clay | - | 0,16 | 0,20 |

| Sawdust | 230 | 0,07 | 0,093 |

| PPU | 27-35 | 0,03 | 0,035 |

| Ecowool | 30-70 | 0,038 | 0,045 |

Insulation thickness

We talked more about the thickness of thermal insulation about enclosing structures in a separate article. Here we can say that there are generally accepted norms that set the coefficients thermal resistance roofs in different regions.

In other words, how much should the roof be able to resist heat escaping from the house. It is necessary to divide the coefficient required to obtain it by the thermal conductivity of the roofing insulating materials. Thanks to this calculation, you can find out what thickness of insulation for the roof of the house should be on the roof. A little later we will add a calculator that will allow you to calculate this important indicator.

Manufacturers

Insulation materials can be found on the market domestic production, also insulation materials from the USA, Finland, Germany, France and other countries.

The following brands are available:

- TechnoNikol;

- Knauf;

- Isoroc;

- Isover;

- Paroc;

- Rockwool;

- Ruspanel;

- Soudal;

- Tytan;

- Ursa;

- Akterm;

- Penoplex;

- Penofol;

- Tepofol;

- Tilit;

- And others.

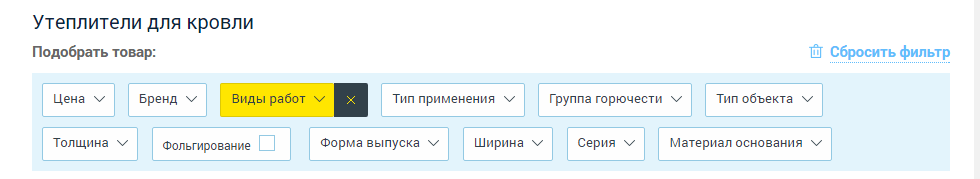

Go to any well-known online store and use filters to look at the characteristics of each individual product.

As you can see, there are very different ways insulation, but the important issue is always the price.

Choose by cost

The cost of insulation changes very quickly. Therefore, as an example, we present a small plate with the cost of some popular insulation materials.

Blowing polyurethane foam will cost 200-300 rubles per square meter (labor and material). Ecowool will cost 3000-4000 rubles per cubic meter. The cheapest insulation is probably sawdust, 300-500 rubles per cubic meter. Using the given figures you can calculate the approximate cost square meter isolation.

Life time

How long does an insulator installed on a roof last? All of our options have a service life of 50 years or more. (Except sawdust). However, in reality, most materials have to be changed within 10 years. After all, insulation is not the most weakness roofs. He suffers from its other elements. The rating of the most durable ones still starts with XPS. It can stand in the roof for 70 years.

conclusions

So, what is the best roof insulation? You can choose the option, like most, and use mineral wool. If we are talking about roof floor insulation, pay attention to ecowool. When calculated, its cost is not that high. But it's environmentally friendly pure material, which is not afraid of rodents. And this is a big plus. We have given enough general considerations to help you choose insulation. However, no matter how correctly the chosen material is selected, when laying the insulator it is important to adhere to the instructions that we described separately.

As we found out, roof insulation can be not only buns with hot chocolate, but also at least 6 other good materials. Choose and let your roof be as warm as Carlson’s.

It is necessary to insulate the roof of a house only when it is planned to make the attic spaces residential. If an attic is not provided, then it is not the roof that needs to be insulated, but the ceiling. The quality of roof insulation has almost no effect on the microclimate in the rooms; this is an unnecessary waste of time and large financial resources.

Currently, the construction industry has mastered the production large assortment products with excellent performance. Such a wide choice often puts inexperienced developers in a difficult position. They only read manufacturers' advertising brochures, and based on this information it is difficult to make a specific choice. All companies describe only positive sides their products and do not talk about negative ones. The article will give objective comparative characteristics various materials used for roof insulation. This information will allow you to make an informed decision in each specific case.

By what physical parameters are insulation materials classified?

| Insulation property | Short description |

|---|---|

| You should first pay attention to this indicator. Heat loss occurs in two ways: infrared rays and convection. How lower temperature body, the fewer rays it emits. Noticeable energy loss infrared radiation occur when high temperature heating solids. For a roof, such losses can be ignored due to the low temperature. But the thermal conductivity coefficient is crucial. The parameter is determined in W/m×K. The thermal conductivity values of different bodies differ by several orders of magnitude. For example, the thermal conductivity of wood is approximately 0.15 W/m×K, and that of foam plastic is 0.015 W/m×K. This means that it preserves ten times better thermal energy than a tree. |

| A very important indicator for all buildings, fire safety regulations have strict requirements for the safe operation of buildings. All materials are divided into several groups, from non-flammable (NG) to highly flammable (G4). The classification is carried out according to SNiP 21-01-97 standards and depends on several parameters: gas temperature, degree of damage along the length and weight and duration of spontaneous combustion. The non-flammable category includes mineral wool and expanded clay, and low-quality foam plastic belongs to the highly flammable category. The resistance class must be indicated on the packaging. It should be noted that the most modern polystyrene foam insulation, due to various additives, has a reduced flammability class (G2 and G3) and is allowed for limited use in residential construction. |

| A conventional value used to classify potentially hazardous materials. It is established on the basis of changes in the amount of harmful fumes, assigned taking into account the concentrations dangerous to the human body. The classification is made taking into account the provisions of GOST 12. 1. 007-76 and SanPiN 2. 1. 4. 1074-01. Construction materials are subject to strict regulatory control; substances of class III (moderately hazardous) and class IV (low-hazardous) are allowed for limited use. Mineral wool, expanded clay, and glass wool are completely safe. The fourth class includes only some types of foam and liquid insulation, they are recommended to be used with caution. |

| The thermal conductivity of water is much higher than that of insulating materials. Accordingly, the more water they can absorb, the lower the final heat saving indicators. Another disadvantage of high water absorption is wet materials in prolonged contact with wooden structures cause the appearance of rot and fungi. As a result, the wood loses its original properties, and the rafter system and cladding have to be repaired prematurely. The situation with the rafter system is especially unpleasant; its restoration not only requires a lot of time and money, but can also be done in warm and dry weather. And this greatly complicates repair work. Unfortunately, mineral wool has high water absorption; in order to prevent it from getting wet, it is necessary to carry out a complex of complex and expensive special construction measures. This is its significant drawback. Foam-based insulation materials absorb moisture the least. |

| The higher this indicator, the more heat is removed from the insulation, the lower the heat saving values. And in this indicator, mineral wool is significantly inferior to foam plastic; it is freely blown by the wind. Even pressed mineral wool has this drawback, although to a slightly lesser extent than rolled mineral wool. To reduce energy losses, mineral wool insulation must be protected from the wind, and the shelter must allow steam to pass through. If the steam cannot escape, condensation processes will begin and the cotton wool will get wet with all the negative consequences. For shelter, modern diffusion membranes, they are quite expensive. |

| The parameter characterizes the resistance of insulation to the effects of various active chemical compounds. There is always smog in city air, and it contains various chemical compounds. More stable than all mineral wool insulation materials, polystyrene foam at certain concentrations can react negatively to certain compounds. But this is only possible in cases of a critical increase in concentration; in practice, these situations happen very rarely. |

| The rafter system of a house constantly changes its linear dimensions. The reasons may be violations of construction technology and calculations, excessive snow and wind loads, changes relative humidity wooden elements. Insulation materials must constantly compensate for their dimensions without losing their strength. Mineral wool works best in such conditions. Foam materials can compensate for vibrations up to certain limits; if they are exceeded, the sheets are destroyed. |

| For roof insulation, this parameter does not have of great importance. But there is one caveat. Mineral wool ranks last among the insulation materials used in terms of strength. If the angle of inclination of the slopes is large, then over time it can shrink or sag under its own weight, cracks form, the effectiveness of thermal insulation decreases, and very unpleasant cold bridges appear. If the angle of inclination of the slopes exceeds 20°, then it is recommended to take measures to fix the mineral wool. |

As can be seen from the table, there is no ideal roof insulation for all cases; each has its own strengths and weak sides. They must be taken into account before making a final decision.

Performance characteristics of roof insulation

Let's consider the most used modern materials, talk about quite exotic ones at present loose insulation materials not worth it. Not only are they almost never used, but they are also much inferior modern technologies by all indicators. What is the most common way to insulate a roof today?

Prices for mineral wool

Mineral wool has now almost completely replaced glass wool.

What are its advantages over traditional insulation?

- Lower thermal conductivity values. Mineral wool has a thermal conductivity of 0.03-0.05 W/m×K, glass wool has a thermal conductivity of 0.41 W/m×K. The higher the density of mineral wool mats, the higher the thermal conductivity. In practice, the difference in thermal conductivity can be neglected; it is leveled out due to the gaps in the places adjacent to the rafter system.

- Elasticity and manufacturability. These indicators are interconnected, so it makes sense to consider them simultaneously. Glass wool manufacturing technology assumes that the diameter of the fibers will be approximately 15 microns, the diameter of mineral wool fibers is much smaller and does not exceed 2–8 microns. This explains the difference in terms of manufacturability and elasticity. It is difficult to work with glass wool; thick glass fibers damage and irritate the skin; you need to use gloves and a respirator. Mineral wool is much softer and does not have such disadvantages. In addition, it is more elastic; after removing static loads, it completely restores its original thickness. Glass wool cannot be completely restored; thick glass fibers break.

- Weight. It has a significant effect in the case of a large slope of the pitched roof. If big slope, then the material can deform under its own weight. According to this performance indicator, mineral wool is ahead of glass wool.

With regard to environmental friendliness, fire resistance, hygroscopicity and chemical resistance, the materials are almost no different from each other. But there is one note - the cost of mineral wool is much higher than glass wool.

The service life of mineral wool is practically unlimited, but provided that the material is not damaged by rodents.

Mineral wool can be rolled or pressed. How do their performance characteristics differ?

It has a thickness from 5 cm to 15 cm. The width of the sheets is standard 60 cm, the length may vary for each manufacturer. The advantages of such cotton wool are the speed of installation. The sheets are tightly inserted between the rafters and are kept from falling out by taut ropes; no additional fixation is required. Cotton wool can be easily cut with an ordinary mounting knife.

The material is tightly rolled into rolls, and after removing the packaging, the factory thickness is restored. Has two advantages: low price and the possibility of insulating rafter systems with complex geometries.

Prices for expanded polystyrene

Widely used modern insulation material. The density, depending on the specifics of the manufacturing technology, ranges from 16–30 kg/m3; the higher the density, the greater the load the insulation can withstand.

There are brands of polystyrene foam that do not support open combustion; they melt, and fire occurs after a strong increase in temperature. This type of polystyrene foam can be used for insulating flat roofs multi-storey buildings, there are no restrictions for personal homes. For example, paper ignites when heated to +2300°C, wood at +2600°C, and modified polystyrene foam spontaneously ignites at a temperature of +4900°C.

Expanded polystyrene is very afraid of hard ultraviolet radiation, but for roof insulation this does not matter, the material is located under the roofing. Service life is approximately thirty years. The slabs are easy to cut; all roof insulation work can be performed without special expensive tools and devices.

To reduce the number of cracks, they need to be foamed with construction foam.

Practical advice. Professional builders strongly recommend using high-quality imported foam; it has high elasticity. Domestic materials crack when compressed - the fixation strength of the plates decreases, and thermal conductivity increases.

Expanded polystyrene is almost non-hygroscopic; in two days of direct contact with water, it absorbs no more than 2% of the volume of moisture. Such low values have no visible effect negative consequences on performance characteristics.

Thermal conductivity depending on density 0.028–0.034 W/m×K.

Polyurethane foam

One of the least flammable plastic insulation materials, it can be used in liquid form. But such insulation of the roof of a private house has more disadvantages than advantages and professional builders Not recommended. Insulation is much more profitable to do ready-made slabs. Up to 99% of the pores are closed, which almost completely eliminates the absorption of moisture; thermal conductivity, depending on the type of polyurethane foam, is 0.019–0.028 W/m×K. Service life of at least 20 years if manufacturers' recommendations are followed, withstands frosts down to -160°C.

The material is technologically advanced, the release of harmful chemical compounds into the air does not exceed controlled limits state standards norms. Weight no more than 60 kg/m3, has excellent adhesion to all building materials, which simplifies the process finishing internal surfaces attic spaces. One of the important advantages is that it is little damaged by rodents. For example, slabs of foam plastic can be completely turned into dust by a mouse within one year.

Penoizol

It is characterized by very low weight (from 10 kg/m3), thermal conductivity in the range of 0.036–0.038 W/m×K. The difference between the material and other types of polymers is a large number of open pores, which increases vapor permeability to 0.21. Vapor permeability is a positive parameter for roof insulation - it can be removed without problems excess moisture, the risks of condensation formation are minimized. But there are also problems. Condensation not only increases thermal conductivity, but also destroys the insulation when it freezes.

On one's own open fire does not support, service life is at least 50 years, but subject to several conditions:

- penoizol must be reliably protected from UV rays;

- relative humidity should not exceed the current tolerance ranges.

Penoizol insulation with a thickness of only 5 cm provides the same thermal protection structures, like foam plastic 7.5 cm thick, mineral wool 12.5 cm thick or wood 34 cm thick.

The material is easily cut with an ordinary hacksaw, but in the process a lot of fine crumbs. It is necessary to take measures to prevent it from getting into all areas of the house.

Liquid insulation

Some polymer materials can be sprayed on the roof in liquid form. This method has no advantages, but only some disadvantages. Let's list just a few of them.

These are not all problems, you can add to them an increase in time and cost, a large influence of the human factor, etc.

Modern and fashionable insulation, manufactured from recycled materials. More than 80% of the composition is recycled cellulose, the rest is fillers and binders. To insulate the roof, it is recommended to use pressed ecowool; it is easier to work with, and its performance indicators are much superior to powder wool. Thermal conductivity is in the range of 0.032–0.040 W/m×K, density up to 75 kg/m3, vapor permeability 0.3 mg/m×h×Pa.

Relatively large weight can create difficulties when insulating the roof; additional loads must be taken into account at the design stage rafter system. To increase fire resistance, a fire retardant is added to the material; inhibition of the development of microorganisms is achieved by adding boric acid. As can be seen from the composition, there is no reason to call such a material absolutely environmentally friendly.

A wide selection of insulation materials by name, unfortunately, does not mean the same wide choice according to operational properties. Minor differences in thermal conductivity do not play a noticeable role. They are nullified during certain deviations from the recommended insulation technology, and such deviations will always exist.

Practical advice on choosing insulation for the roof of a private house

Prices for windproof membranes

Windproof membrane

There are a few practical advice, which will provide real help when planning work on insulating the roof of a private house.

Correctly calculate the estimated cost of work. The costs must include not only the price of the insulation, but also the cost of its delivery. If the work is carried out independently, then it can be ignored. But if construction companies are involved, the estimated cost of insulation increases significantly. Most of them simply price their services - they are equal to at least half the cost of all materials. But these are minimum values; there are companies whose cost of services exceeds the cost of purchasing insulation materials.

Wind protection for roofing

These are synthetic modern membranes with quite high cost. In addition to the membranes, it is necessary to make a counter-lattice for natural ventilation– add the price of lumber and hardware.

Compare specifications various insulation materials. At the same time, you should not pay much attention to thermal conductivity indicators; it differs only slightly. Important for long service life it has the weight and elasticity of the material. Information should be taken not only from manufacturers’ websites about the benefits; look for practical user reviews. Especially those who, for one reason or another, had to deal repair work roof after its insulation.

Soberly assess the complexity of the recommended technologies with your capabilities. The roof is not a building element with which you can experiment. Even seemingly insignificant violations of technology can cause very big problems for the building as a whole.

Before starting work, you need to prepare materials and tools in advance. Do not allow interruptions in insulation due to a shortage of insulation or other materials. After the resumption of work, some earlier work will have to be carried out installed structures dismantle, and this costs money.

Always try to buy insulation of the required thickness. If, taking into account the climatic zone of residence, the thickness of the insulation should be 15 cm, then it is much more profitable to buy sheets of the same thickness, rather than making three layers 5 cm thick. You can come across assurances that if three layers are laid with offset joints, cold bridges will be eliminated. This is not true, there are no cold bridges where there are completely no joints, that is, in the entire slab. In addition, one slab of polystyrene foam or mineral wool 15 cm thick costs less than three 5 cm each. And lastly. It is much faster to install one layer of insulation than three.

It is not recommended to begin insulation immediately after the construction of the roof is completed. We need to wait for the first rain and make sure there are no leaks. Noticing and eliminating problems that have arisen due to a violation of the roof’s tightness after insulation is much more difficult and will always cost several times more.

Video - Insulation for the roof of a private house