The laser level is designed to determine the horizontal and vertical lines and planes during construction building structures and finishing. Using this device, the geometry of the element can be observed with great accuracy. This is important for the strength and durability of the object being built. But it is not always possible to purchase an industrial device. However skilled craftsman able to create a laser level with his own hands. Let's look at how to do this, and whether it is possible to repair a broken level at home.

What is a laser level

The body of this instrument contains LEDs, which are sources of laser radiation. Using a bright luminous line, you can mark any object in both the horizontal and vertical planes. Moreover, one person can easily cope with this work.

There are three types of lasers:

- prismatic;

- rotary;

- point.

Prism devices create a linear beam projection. When the luminous line collides with an obstacle, the device records the data and displays the required markings. Such levels are equipped with an auto-leveling system necessary to compensate for errors of up to 6°. The laser beam projection angle does not exceed 120°.

A prism laser level has a short beam range - on average from 10 to 50 m.

The prism laser level allows you to obtain horizontal and vertical planes intersecting at right angles

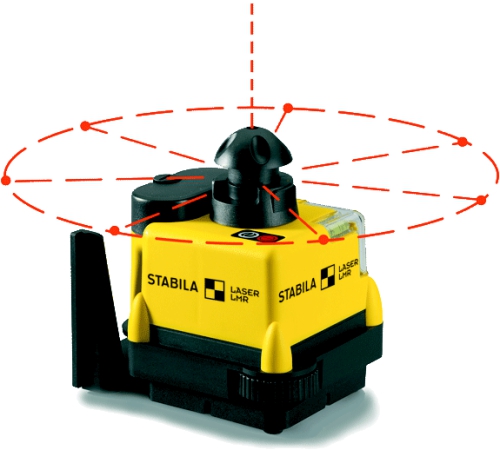

Rotary devices are classified as professional instruments. They are equipped with point laser devices, but not fixed ones, but rotating with an adjustable frequency. Designed for marking very large areas, for example, on a construction site. The rotary level can project a plane 360°.

Rotary levels have a longer laser beam range - from 200 to 500 m.

By installing a rotary level in the middle of the room, you can mark all the necessary points along the entire perimeter

The point level is the simplest: the laser device is clearly fixed, and behind it there is only a focusing lens. It directs the light flux to one point. Set up the device manually. Such levels are equipped with one or more lasers. In the latter case, they are directed in different directions, which makes it possible to transfer markings from several planes - walls, floor and ceiling large area. The laser beam projection angle does not exceed 160°.

The operating range of the point level is from 15 to 50 m, depending on the model.

Compact and universal point laser level is designed for any leveling work at short distances

What is the device for?

Purpose laser devices varied. They are necessary when the following types works:

- layout of the territory and installation of equipment with horizontal and vertical position control;

- marking and determining direction;

- surface leveling of floors, walls and ceilings;

- arrangement concrete screed and assembly of floors with adjustable level;

- construction of communication highways;

- installation of bulkheads and hanging accessories;

- installation of staircases.

In the latter case, the device’s ability to mark is used inclined planes. For example, it is necessary to install railings on a flight of stairs. By fixing a level with a laser on it, it is easier to install the railing parallel to the flight.

You can understand how to use a level using the example of common construction and repair work.

Leveling floor, wall and ceiling surfaces

When conducting similar works additional control marks will be needed. Then the laser beam is directed along the plane. The laser is adjusted according to the marks to more accurately determine the evenness of the surfaces.

When using a laser level and obtaining the same data, the floor turns out to be absolutely flat

Laying ceramic tiles

For such work, it is better to take a device with the function of cross-projection of rays horizontally and vertically. Thanks to them, even a novice master will be able to lay tiles flawlessly.

The intersection of the level lines is placed at the center of the proposed tile joints

Wallpapering

The gluing process itself is quite easy, but using a level makes the work even easier. Focusing on the laser beam projected onto the wall, it is much more convenient to align the wallpaper.

Horizontal projection will facilitate the correct gluing of fillets and borders

Assembly of cabinet furniture

Even if there are straight walls in the house, which is a rather rare occurrence, the interior can be ruined by crookedly hung cabinets, shelves and other hanging accessories. And with the help of a laser that creates a circular level line, you will immediately see how to install hanging furniture without distortions.

The horizontal beam of a laser level will help when installing curtain rods

Redevelopment

The plane builder allows you to simplify this process. To determine the exact placement of plasterboard walls and partition elements, you will need to install the laser so that its projection on the floor, walls and ceiling is a mark for the intended partition.

When installing a metal frame under plasterboard wall The laser level is placed on the floor, the beam is directed upward so that it marks the profile installation line

A simple device can be used outdoors only in cloudy weather or at dusk.

If a lot is expected external works(digging trenches, laying communication lines, laying foundations), it is better to get a professional plane builder with a beam visible in sunlight.

How to make it yourself

The idea of a DIY laser level is quite simple - the pointer is mounted on a movable platform. The use of such a mechanism allows marking by rotating it at the same level by 360°.

Required tools and materials

In addition to the laser pointer, you will need the following materials:

- glue;

- metal files;

- jigsaw;

- a piece of corrugated plastic (for example, a bicycle headlight).

Step by step guide

You can make a laser level with your own hands from a pointer in just an hour:

- Let's improve the pointer. We saw off its tip, leaving the threaded part.

Laser pointer emits a dot

- From a piece of plastic we cut a circle with a diameter like the tip of a laser pointer.

If you pass the beam of a pointer through corrugated plastic, you get a line

- Glue a plastic circle onto the tip of the pointer.

The place where the parts are glued can be additionally coated cold welding and sharpen

The imperfection of this version of the level is its one-sided mobility - only horizontally.

The laser level must be fixed perpendicular to the plane

If you need to mark not only horizontally, but also vertically, you can try to mount a more advanced device:

- IN wooden post a hole is drilled so that a long groove is obtained (or a ready-made plastic tube is taken). A pin, bolt or self-tapping screw is inserted and fixed into the hole in the center. The hardware is placed with the head down and secured with adhesive.

- A wide articulated fork is installed on the pin. To prevent it from loosening and twisting, a rubber gasket is installed between it and the rack. A base made of plastic or wood is placed in the fork. A screw fastener passes through it, securing the workpiece on both sides of the fork.

- The building level and an improved pointer are fixed on the base.

This type of assembly allows the device to change the location of the laser in the vertical direction. If you are smart and choose a suitable fork, you can actually assemble a device with a vertical rotation of 270°.

It must be taken into account that the larger the fork size, the wider the workpiece will be required to create a stable position.

This device is collapsible. To ensure stability of the base, you will need to find a fork with a hinged part of the required cross-section.

If a suitable plug is not available, you can make it yourself from a durable metal-plastic ring of the required cross-section.

You will need to drill three holes: two on the sides, opposite each other, and the third exactly in the center between the two future “teeth” of the fork. Then the ring is cut to form a semicircle with three holes.

A homemade laser can be modified: screw an ordinary nut or “wing” onto the mounting screw, which allows you to quickly loosen and fix the base, as well as change the direction of the laser up or down.

Video: DIY laser level

Setup and calibration

After assembly homemade device You need to configure the laser level yourself. It is necessary to check it - calibrate it for measurement accuracy. To perform the test, you will need an additional bubble level. Calibration is carried out as follows:

- The device is placed in the center of the room and marks are made on opposite walls at the point of intersection of the planes.

- The level is moved to one of the walls at a distance of approximately half a meter, another mark is made above or below the first one.

- The device turns to the opposite wall, a mark is placed.

- The distance between the marks on both walls is measured and the error is calculated.

For example, the difference between the marks on the first wall is 4 mm, and on the second - 3 mm. The resulting error is 1 mm. If it is larger, then the device requires adjustment.

The measuring device, assembled independently, can be placed on a tripod or adjustable pedestal, which will give the product convenience and functionality

To perform vertical calibration, mark two points in the vertical plane and check the marks against the bubble level.

If no deviations are noticed, then the plane builder is ready for use. If there is a discrepancy in the readings, a homemade laser device adjust by changing the location of the platform or articulated fork.

How to repair

If the laser mechanism fails, it may display the wrong level or not work at all.

Homemade device requires repair:

- in case of diode failures;

- when buttons and switches stick or fail;

- when the emitter malfunctions, when the laser does not glow or the beam is very dim.

Most often, repair of laser levels is required after the device has been dropped. In this case, the settings are lost, which leads to the device producing incorrect indicators.

If repairs are required homemade laser, you need to disassemble the device and reassemble it. If the problem is in the pointer, it is easier to replace it with a new one.

In order to avoid repairing a homemade laser level, it is important to be careful when working with it, especially outdoors.

To build level planes on large-scale construction sites, industrial levels with a large operating range have been created. For minor repairs, you can make a laser level yourself.

It is impossible to imagine carrying out any construction and repair work without using a level. Good level- a guarantee of the quality of work performed. It is thanks to the construction level, of course, combined with the conscientiousness of the builders themselves, that we get perfectly rectangular corners in the rooms, smooth walls, smooth horizontal floors, correctly installed door and window openings. It is impossible to imagine repairs, even basic cosmetic ones, without using a level. The level is used when gluing wallpaper, while laying tiles. However, it is not at all necessary to buy it. The building level is easy to make with your own hands.

Types of building levels

A building level is a device by which the vertical and horizontal position of planes is determined. It is thanks to the use of the level Construction Materials, used in finishing and repairs, are installed as accurately, evenly and correctly as possible.

Modern industry offers users building levels for every taste. Various lengths, from different materials. When selecting a device for a particular type of work, it is necessary to pay attention to Special attention on the ease of use and, of course, accuracy.

The following main types of building levels are distinguished:

- Water level.

- Bubble level.

- Laser level.

- Pipe level.

- Magnetic level.

Let's consider each of the listed types of levels, their disadvantages and advantages in more detail.

Water level

The water level allows you to determine whether the surface deviates from a horizontal position. It consists of two flasks connected to each other by a tube. The length of the tube ranges from 5 to 25 m. A scale is applied to the flasks. The weight of the water level depends on the model and ranges from 300 to 1100 g.

Main advantages of a water level:

- Lightweight and convenient to use.

- Long hose length.

- Low cost.

During the operation of the water level, a number of problems arise:

- When filling the tube with water, do not allow air bubbles to get into it. Air in the tube will cause significant measurement errors.

- Do not use the device near heat sources. Place the measuring device at least 1.5 m from heating devices.

- The device is designed to work exclusively with horizontal surfaces.

- Using a long hose small room not very convenient.

Bubble level

One of the most popular types of building levels is the bubble level. It consists of a solid body with one or more ampoules built into it. Maximum amount ampoules - 3.. They are filled with liquid, usually alcohol. Liquid in mandatory contains an air bubble.

The purpose of the device, equipped with one ampoule, is to work with horizontal surfaces.

But with the help of a device equipped with two ampoules, it becomes possible to work with vertical surfaces.

Thanks to the third ampoule, it became possible to display rotary levels.

Most often, bubble levels are made rectangular shape. The range of sizes is very large. The length of the device ranges from 0.2 to 2.5 m. There are models reaching 4 m in length.

The materials for the production of the housing of these measuring instruments are aluminum, wood, impact-resistant polystyrene and many others. The main filler for ampoules is alcohol.

Among the main advantages of the bubble level I would like to highlight:

- High accuracy.

- Ease of use.

- Acceptable price.

- Huge variety of models.

The price range for such measuring instruments is very wide. The cost of the device depends on its size, manufacturer and many other factors. It is not advisable to purchase the cheapest devices. They are neither accurate nor durable. Even if you plan to use the level very irregularly, a professional construction device will become best choice. It is made from more durable material, withstands impacts better and has the highest accuracy.

When purchasing a bubble level, pay attention to the following points:

- The flasks must stand very firmly. Wobbling is unacceptable. You should not choose a model with fastening the flasks with screws. Opportunity self-adjustment brings only unnecessary worries and problems to the consumer. The adjustment goes wrong almost immediately. You have to configure it again. The best option- tightly mounted flasks.

- The divisions on the flask should be clear, the bubble should be clearly visible. The smaller the gap between adjacent divisions, the more convenient it is to work with the device.

- It has long been noted that the heavier the bubble level, the more accurate it is. When choosing a tool, pay attention to models whose body is made of aluminum.

- The most popular among consumers are models made in the shape of the letter “X” and equipped with rubber handles. Their ease of use has been repeatedly noted.

Magnetic building level

One type of bubble level is a magnetic building level. Its main difference is the presence of special magnetic fastenings. Thanks to them, the level can be easily attached to metal surfaces. It doesn't fall or slide.

Pipe building levels

Another type of bubble level is the pipe level. Distinctive feature pipe construction levels - small sizes and weight. As a rule, they are made in the form of a rectangle. A less common option is folding pipe levels. The main area of use is working with profiles and pipes.

For the purpose of reliable attachment to the pipe, a similar type measuring instrument equipped with additional accessories:

- Magnets.

- Perforated tape.

- With a cord.

Laser level

A laser level is a small device that can be attached to any surface. Among the most popular types of fastening I would like to highlight:

- Magnets.

- Tripod.

- Fastening with straps.

There are laser levels used for the purpose of constructing a direction and constructing a plane. The level designed to build a direction simply picks off points. But the device for constructing a plane is equipped with an optical system that turns the beam into a plane.

There are several types of laser levels:

- Rotary. This device rotates around an axis. This creates a line. It features a very durable body, good protection from external influences. Perfectly suitable for many repair work, for example, for installing suspended ceilings.

- Positional. Two radiation sources allow the formation of visible planes. The main application is finishing work.

- Self-leveling. The laser level is equipped with an internal pendulum that emits five beams and a cross-shaped sight.

Main advantages of a laser level:

- High range. Some models operate at a distance of 100 m.

- Highest precision.

- A number of models are equipped with cross lines.

The main disadvantage of laser levels is that they are very high price. The price of the most ordinary and very unpretentious laser level is the same as the cost of a professional bubble device.

How to make a water level with your own hands

Most simple variety level - water level. And it’s very easy to do it yourself:

- Take two 20 ml syringes without needles and a thin hose of arbitrary length. An ordinary dropper is perfect as a hose.

- Remove the plunger from one syringe and connect it to one end of the hose.

- Prepare liquid to fill the level. Use ordinary liquid as liquid. tap water, slightly tinted with tea leaves.

- Using a second syringe, fill the system with liquid. Not only the hose must be completely filled, but also the first syringe.

- Remove the plunger from the second syringe, having previously connected it to the hose. The water level is ready. This is a liquid-filled design of two syringes connected to each other by a hose.

The device operates on the principle of connecting vessels. To mark a horizontal surface you must:

- Measure and mark the desired height on one of the walls.

- Apply one of the syringes to the mark so that the water level coincides with the mark. Secure the syringe to the wall with tape. When working together, there is no need to attach the syringe; a partner will hold it.

- Apply the second syringe to the walls and note the water level. All received marks will correspond to the same level above the sea surface. When they are connected, you will get an ideal horizontal surface.

When storing a homemade water level, the syringes are closed with pistons.

The main advantages of using a homemade water level are:

- Low cost of the device.

- Ease of manufacture.

- Ease of operation of the device.

How to make a laser level with your own hands

The purpose of using a laser level is to mark a plane, both vertical and horizontal. They are indispensable in the process of pouring the floor, during installation interior partitions, laying tiles, gluing wallpaper and many other works. Even for evenly arranging furniture, a laser level will come in handy.

There are two ways to make a laser level with your own hands.

First manufacturing method:

- Take laser pointer. Seal the hole in the nozzle with a piece of cardboard. It is better to take a nozzle without a pattern. Punch a small hole in the middle of the nozzle. Attach the attachment to the laser pointer. Turn on the pointer and point at a vertical surface. If a small bright dot appears on the surface, everything is done correctly.

- Take wooden block. Its length is about 130 cm. Using an ax, trim one end. The result is a stake pointed on one side.

- Take flat piece plywood or boards. The shape of the piece is square. Side size 10 cm. Attach to the flat end of the peg.

- Use a screw or nail to attach the strip to the center of the plywood. The length of the bar should match the length of the bubble level. The bar should be able to rotate in a circle.

- Attach a bubble level to the bar.

- Place a piece of thick rubber on the level. Attach the laser pointer to the rubber using a clamp.

- The device is ready.

The method of using such a laser level is as follows:

- Place a stake on the site. Level it using a bubble level. When installed correctly, the level bubble is in the center and does not move when the bar rotates.

- Turn on the laser pointer. Mark where the beam is reflected on the wall.

- Rotate the bar and mark other points where the beam hits the walls. All received marks lie on the same horizontal surface.

Let's look at how to make a level using the second method:

- Take a small container and fill it to the brim with water. This can be a basin, a bucket or a regular pan.

- Attach a laser pointer to a piece of foam. Use a nozzle without a pattern, in the form of a dot. Try to keep the pointer lying flat on the foam. You can attach it using an elastic band or a clamp.

- Place a container of water at the height required for marking.

- Dip the foam into the water.

- Turn on the laser pointer.

- Rotating the foam around its axis, mark the points of intersection of the laser beam with the surfaces. The resulting marks are on the same horizontal surface.

Of course, the homemade levels considered are far from ideal. However, they are quite functional.

How to make basic instruments for determining horizontal and vertical

- The most basic device for checking verticality is a plumb line. It is widely used during renovation, for example, in the process of wallpapering: Take a small, heavy object. A fishing weight is perfect. In a pinch, even scissors will do.

- Tie a thick thread or fishing line about 2 m long to the weight. The length of the thread depends on the height of the room.

- Place the end of the string against the top of the wall, releasing the weight. The load must not touch the floor.

- Use a pencil or marker to make marks on the wall along taut thread. As a result of connecting the marks, a perfectly vertical line is obtained.

Checking the horizontal surface is also very easy:

- Take the most ordinary wooden isosceles triangle.

- Drill a small hole in the top opposite the base.

- Attach a thread or fishing line with a weight to the hole. A lead fishing weight is ideal as a weight.

- Mark the middle of the base of the triangle with a line.

- Place the base of the triangle on the surface to be tested so that the load falls freely down. The coincidence of the thread with the line on the base means that the surface is horizontal.

Electronic laser level is one of the most necessary tools, which are needed both by builders and people of other professions. While using this level, you can project the intersecting points and see if you get a right angle. Buying such a device in a store can reach up to 100-200 dollars, and if you spend a little time and effort, creating a homemade laser level will cost pennies.

The cost of a laser level is quite high, and if you plan to use it only a few times, then such a purchase will be inappropriate. Therefore, you can do it yourself.

This tool will come in handy when construction work :

- During installation of the floor and wall tiles different sizes;

- When pouring the floor with concrete or other material that requires uniform distribution;

- When pasting wallpaper, both on the walls and on the ceiling;

- During installation suspended ceilings and windows.

Making a construction laser level with your own hands is not difficult. A

In terms of its qualities, it is not inferior to the purchased one; you only need to prepare some materials.

Namely:

- Cheap laser pointer, sold in any children's stores;

- A small piece of porous rubber, preferably thick enough;

- Regular bubble level of small size;

- A sanded block of wood the size of a matchbox;

- A small, flat stick that serves as a support;

- A bar corresponding to the length of the level;

- A small piece of plywood sheet measuring 10 by 10;

- A clamp corresponding to the diameter of the pointer - it is necessary to secure it;

- The required number of screws.

After preparing all the materials, you can start working.

Homemade laser level: instructions for creating

Following the advice of experts, you can make a homemade laser pointer-level in a short period of time.

5 important points in preparation:

- When starting work, you must first remove the area of the pointer where the insert with the pattern is missing, this hole is sealed with cardboard, where a small hole is made, then the cap is carefully installed in its place.

- These procedures are necessary to achieve a clearer point while pointing.

- An ordinary stick needs to be sharpened at the end to make a stake, it will serve as a leg for the level, and on top flat base plywood is fixed. This must be done accurately enough so that the angle corresponds to 90°.

- On top, on the surface of the board, a strip is attached, having the same length as the bubble level. It must be installed using a screw so that it can be rotated in different directions.

- The final step is to attach the laser pointer to the bubble level, using a clamp and porous rubber; if there is a need for a cut, then make a recess.

Having done everything necessary instructions, we need to get to work.

Instructions: how to make a tripod for a laser level with your own hands

You can make a homemade tripod pointer different ways: with magnetic mount, where there is also a ruler; using a cross tripod; using straps for fastening. The most commonly used mount is the use of a tripod from an old camera, onto which a rotating mechanism from an old player is attached. Top installed old disk, onto which laser pointers are attached crosswise.

This method is perfect if you need to accurately install a painting or hang cabinets correctly.

If you need to quickly make the necessary marks while working, but don’t have a laser pointer at hand, there is step by step guide, to create a disposable level yourself, without using a tripod.

To make a similar pointer, which is designed in the most in a simple way, and has a self-leveling element, it is necessary:

- Prepare a small bowl or bucket of water;

- Take a piece of polystyrene foam in the shape of a rectangle and secure the laser pointer with an elastic band;

- The container with water is set to a certain desired height, foam with a pointer is lowered into it, then it must be turned on.

After a few minutes, the water will calm down and by moving the foam you can get ready-made dots.

DIY laser level: proper use

It’s not enough to make a laser level at home, you also need to know how to use it. You need to fix the stick with the sharp end down on the desired surface, then using a bubble level, level the angle of the bar to achieve the most accurate horizontal position. You need to turn on the laser pointer and carefully point it at the desired surface.

After the pointer appears, you need to make a small mark, then move the pointer a little to the side to accurately check whether the level mark has gone astray.

After there are two points, you need to carry out horizontal line, connecting them together. If the result is a perfectly straight line, the level is working and installed correctly. The dots indicate whether the stand and stand are installed perfectly. While working with similar device, it is better to have safety glasses that relieve eye strain. Adjustment will be even faster if you use a plumb bob to help with the work. A homemade laser level has a bit of a primitive design, but the ability to save a decent amount of money mitigates this problem.

Experts highlight a number of advantages that a home level has:

- The beam length is sufficiently long, allowing it to be used in almost all work related to repair and construction;

- A small level of error, which is an insignificant drawback;

- High speed of marking and convenience, which a regular bubble level does not have;

- But builders highlight the main and most significant feature - the ability to project rays in a horizontal plane.

The homemade device can also be used in further work, it will serve faithfully during the construction of a fence, if necessary, to mark the boundaries on a personal plot, during the cladding of any building. Professional workers will need purchased levels, they come in these types. Bubble - it is a plastic or wooden case with three flasks inside. Each of them is filled with alcohol and has a bubble, it should be located in the middle, indicating the exact location.

Water - they are a hose of small diameter and up to 25 meters long, with two flasks, all elements are connected to each other. Each flask has a printed scale; such a device has both advantages, in the form of low cost, and disadvantages - you need to be careful when pouring liquid, and it only works on horizontal surfaces. Magnetic - their advantage is ease of fastening - it is quickly and firmly installed on any metal surface and gives accurate readings. Tubular - it is made in the form of a rectangle and is equipped with a magnet and a cord. Laser - it is characterized by high accuracy and range, but has one significant drawback - high cost.

How to make a laser level with your own hands (video)

Each of us decides which level to use. We described all types of devices and revealed the principle of manufacturing the simplest device. The choice is yours.

For people of different construction professions, the accuracy of lines and angles is of particular importance in the work process. After all, clarity and accuracy are an indicator of quality and professionalism. Helps achieve high accuracy special tools, however, even a homemade laser level allows you to get excellent result with less effort.

For specialists in the field of construction and installation, a factory-made laser level is a professional necessity. Such a tool is not cheap. For those who need it occasionally, an amount of 100-200 dollars may seem high.

It is in such cases the best solution there will be a homemade laser level. You can assemble it with your own hands from scrap materials with minimal financial investment. Thanks to this, you will receive excellent construction and installation equipment that performs its function no worse than its industrial counterparts.

It is in such cases the best solution there will be a homemade laser level. You can assemble it with your own hands from scrap materials with minimal financial investment. Thanks to this, you will receive excellent construction and installation equipment that performs its function no worse than its industrial counterparts.

Laser levels may vary in appearance. But in all cases it is small standalone device, emitting a laser beam and powered by batteries or accumulator. Depending on the type and function, the beam shape may vary. By installing such a level on the selected surface, a light projection is obtained on the walls, ceiling and floor, which allows you to apply the most accurate markings or record unevenness and inaccuracies in the parts of the room being processed.

There are three options for laser levels:

Any of them performs its function perfectly in a given area. But a do-it-yourself device is not much different from those made in production.

Besides, Laser levels may also differ in mounting device:

This is the most popular types systems that allow you to install the device. Although there are lesser known ones, they are not so popular.

The rays are also emitted differently. Some create only a direction, while others allow you to project a plane. Each option has its own purpose and scope.

DIY methods

There are several ways to make a device yourself. To do this, you will have to purchase some materials, but most of them can be found in almost any home.

From a laser pointer

The simplest and least expensive option can be made from a regular laser pointer. To do this you will need to buy the pointer itself. In addition to this, you will need:

- a block of wood 50 cm long and with a side size of 25 mm;

- construction cord or its analogues;

- stick to support the finished level;

- drill.

Holes are drilled in the beam at both ends. One of them is intended for attaching the emitter, and the second is for a cord or rope. The pointer is securely attached to one end, and the cord is threaded through the other end so that it can fit freely in the hole.

Holes are drilled in the beam at both ends. One of them is intended for attaching the emitter, and the second is for a cord or rope. The pointer is securely attached to one end, and the cord is threaded through the other end so that it can fit freely in the hole.

You can use absolutely any stick for support. Even a shovel stuck in the ground will do. The main thing is to be able to freely hang the resulting structure. The support must be securely fixed, and only this will allow you to obtain the most accurate markings.

This level allows you to mark the necessary surfaces wherever needed, and also use it as a homemade level. When using it, it is preferable to reduce the illumination, which will give clearer marks.

Install assembled structure better within the center of the room. And you can control the accuracy using a stick, on which a mark will be applied when the first point is fixed.

Styrofoam and container with water

This DIY level method is even simpler. All you need to make it is:

- laser pointer;

- a piece of foam;

- plasticine, electrical tape, adhesive tape;

- a small container of water, for example an old saucepan.

It is necessary to attach the laser pointer to the foam as evenly as possible. Fill the prepared container with water to the very top. Carefully place the foam with the emitter on the surface of the water. Now all that remains is to position the resulting system at the required height.

It is necessary to attach the laser pointer to the foam as evenly as possible. Fill the prepared container with water to the very top. Carefully place the foam with the emitter on the surface of the water. Now all that remains is to position the resulting system at the required height.

When making the next mark, the foam is turned to the next marked location. When all the points are ready, it is enough to connect them together with a construction tape.

This type of device, although not ideal, allows you to get fairly accurate results.

Emitter in the form of a cross

A more complex, but very accurate laser level is convenient to use in any situation, especially for installing hanging furniture. Although it can only be called complex in relation to others, it is easy to assemble. For this option you will need:

The use of a tripod is due to the fact that it allows you to place the pointer as level as possible relative to the horizon, move installed structure horizontally by required height, rotate the emitters without changing the set parameters.

First, you need to firmly fix the drive from the player to the tripod. Glue the CDs together and install them in the drive. Attach laser pointers to them in the shape of a cross. And the device is completely ready for use.

The advantage of this model is that it can be rotated in any direction, as well as raised and lowered without loss of accuracy. This allows you to hit the level without constant readjustment.

Having made a simple laser level with your own hands, you can try to create more complex models that are as close as possible to factory analogues. Very accurate data is provided by a level using a pendulum system. In this case, most of the work will be done by the pendulum itself, while the radiating system will not take much force.

In this case, a pointer will not be needed. Instead, a laser module is used with prisms already installed in it, allowing the projection of horizontal and vertical lines.

In this case, a pointer will not be needed. Instead, a laser module is used with prisms already installed in it, allowing the projection of horizontal and vertical lines.

The module itself runs on three to four AA batteries. This is the optimal number of batteries: two are discharged too quickly, and a larger number makes the system too heavy. You will need a compartment for them; you can take it from an old toy.

The module, batteries and other parts involved in the process must be assembled into one unit. When this part is ready, it needs to be installed on a pendulum prepared in advance. And after that you can think about the body of the structure.

A piece of plastic is perfect for it. plumbing pipe, in which holes for the beams are pre-cut. A switch is also installed here. This completes the level assembly.

But it still has to be calibrated. For these purposes, you can use a water level, which is used to make two marks on the wall at a distance of five to six meters. If the beam coincides with the marks, then no additional adjustment will be needed. Otherwise, you will have to adjust the pendulum.

Advantages and disadvantages

Homemade tools always have a number of advantages, among which price can be called fundamental. After all, a thing made with your own hands will always be cheaper in cost. And this is exactly what many craftsmen pay attention to. In addition, such a device is always adjusted to the needs of the owner.

Among the main advantages of laser levels can be distinguished:

- low cost;

- long beam length;

- low error rates;

- speed when using;

- quick and easy creation with a minimum of materials.

Such devices can mark not only a room, but also personal plots, facades and other areas.

There are very few disadvantages:

- inconvenience of using some designs;

- You still need to purchase something for manufacturing, for example, a laser pointer.

As you can see, there are not so many disadvantages. Therefore, there is no need to run to the store to buy a device when you can create it yourself in a matter of minutes.

A DIY laser level made from scrap materials will help you save a decent amount of money and will be a good alternative to a professional one. construction equipment. During repair and construction work, it often becomes necessary to mark at the same level, but at a large distance. The bubble level is too inconvenient for this type of marking, so you need to get a tool for creating marks at a distance. A construction laser level is perfect for such work. But such a tool is incredibly expensive, so the only option for most may be to create such a tool yourself.

Laser level - indispensable tool during repair and construction, which you can make yourself.

Differences between a homemade model

A homemade laser level can be used for mirror and symmetrical markings over long distances during construction or repair. Certainly, homemade version has a short range of action: approximately 10-12 meters. But this is quite enough to complete most of the necessary notes.

Professional devices are capable of creating marks, calculating angles and much more. But the big disadvantage of such devices is their price.

Some of the electronic models start at two hundred dollars, which is not that cheap. But in most cases, many of the offered capabilities of professional equipment will not be needed, so you can get by with homemade design. Homemade level will cost tens of times less, and you will need available materials to assemble it.

Tripod or adjustable support option

You can place your DIY laser level on a tripod or adjustable stand. It will be quite a convenient and functional design. Tools you will need:

- drill;

- set of wrenches;

- hammer;

- needle.

The materials we use are:

- wooden block;

- laser pointer;

- bubble level;

- electrical tape;

- plastic clamps;

- scotch;

- nails, screws, self-tapping screws or screws;

- plastic and wooden planes of the same size (planks, tiles).

The design idea is quite simple - the laser pointer is placed on a movable element. Using such a device, you can make markings 360 degrees around an axis at the same level. We will need a children's or more powerful laser pointer, depending on the budget. It's from this small element work begins.

How to make such a device is described below:

- Let's start with modifying the pointer. The glass or plastic lens must be removed from the attachment. Instead, you can place a small piece of cardboard inside or cover the hole with electrical tape on the outside.

- Next, using a needle, you need to make a hole exactly in the center where the beam will pass. The small hole made by the needle will reduce scattering and increase the accuracy of the instrument.

- The next element is the platform. To make a movable plane, you can connect a plastic plate and a wooden plank same sizes self-tapping screw. This part will allow our device to rotate around its axis.

- We place a bubble level on the platform, and on it a rubber shock absorber (a piece of rubber of a suitable size).

- We install a laser pointer on the rubber and secure it with tape, clamps or other possible means.

The homemade design is ready. But it must be tested before work.

For calibration, you can select two points, mark them using the resulting laser level and connect them with thread or fishing line. Check the slope with a level. If there are no mistakes, then the equipment is suitable for creating marks.

More mobile option

The disadvantage of the first type of structure is its limited mobility - only horizontal rotation. If there is a need to make marks not only horizontally, but also vertically, you can try to build next type designs:

- You will need a plastic or wooden base.

- A small pin, bolt or screw is secured to the base. The last elements are placed with the cap down.

- A wide articulated fork clings to the resulting mount.

- The articulated fork will house a plastic or wooden narrow piece on which the laser pointer will be attached.

- A hole is drilled in the workpiece with a diameter equal to the screw, which will pass through it approximately equal to the diameter of the fork ears.

- A pointer is attached to the workpiece, and if there is space left, a bubble level is used.

Thanks to this type of design, you can change vertical angle provisions. Depending on ingenuity and the fork found, almost a full 270 degree vertical rotation can be achieved. Using a nut with lugs, you can quickly unscrew the fixation screw and change its position. It is worth considering that the larger the fork, the wider the base will be needed to ensure a stable position.

The design can also be improved:

- IN wooden blank You can make a groove in which to conveniently and securely attach the pointer.

- In the adjusting screw, you can use either a regular nut or an element with ears, but the second is much more convenient.

- The design with a pin without thread will be collapsible. To make it stable, you will have to select the appropriate diameter of the connecting element of the hinge fork. In the case of threads, you can also use homemade forks.

- If you don’t have a fork, its semblance can be made from a metal-plastic ring of sufficient strength, you just have to choose correct diameter. You will need to make three holes: two on the sides, opposite each other, and the third at an equal distance from the two future “ears”. Next you need to cut the ring opposite the last hole. You will get a semicircular blank with a hole at the bottom and ears for the bolt on the sides.

- To prevent the homemade fork from loosening and twisting too much when turning, you can place a rubber gasket under it.

Conclusion on the topic

If it is not possible to purchase expensive Building tools, you can try to make their home analogue.

Using available materials, you can get a cheap, functional model that is perfect for creating markup. This tool can be used for mirror marking of rooms during renovation or planning suburban area. Just take into account the small radius of the laser. Although the tool does not look impressive, it is great for marking points.