Ennobling local area, many owners often wonder what to cover the paths, front and back yard, recreation area... Paving slabs are great for these purposes. The functional covering in landscaping has no equal. The price of the material is far from fabulous, and the installation paving slabs DIY is quite easy to do. So, the design of paths and areas on the site will not cost too much, and at the same time it will be a worthy frame for the garden and decoration of the local area.

Variety of colors, shapes and textures

This allows you to create a harmonious ensemble, combining all the elements of the site into a complete picture, and embody any design and architectural plans.

Thanks to their aesthetic appeal and excellent performance characteristics, paving slabs are indispensable in landscape design

Environmental friendliness and comfort

Paving slabs do not emit harmful volatile substances when heated and do not soften under the scorching rays of the sun. Sand-filled between tile joints allow excess moisture to seep out after rain, preventing the formation of puddles.

The tiled path does not disturb the natural need of plants on the site for water and gas exchange

Easy to maintain and durable

Paving slabs – perfect coverage in frosty winter conditions, it has high strength and low abrasion.

With high-quality installation, tiles can last more than 15 years

Both the technology for laying paving slabs and their subsequent care are quite simple. If the coating is damaged, it is always possible to restore the area by selecting and replacing just a few tiles.

In order for the paved paths and areas on the site to become not only an original addition to the landscape design, but also to serve well for many years, when carrying out work it is important to take into account a number of basic points on how to properly lay paving slabs. For example, depending on the location and purpose of the coating, paving slabs can be laid either on mortar or on sand or crushed stone.

To arrange garden paths and recreation areas, it is enough to use a sand and crushed stone “cushion”

Tile laying work step by step

At the stage of preparation for laying paving slabs, it is extremely important to correctly select from a wide range of products the products and necessary tools that will be easy and convenient to work with. When choosing tiles, you need to focus not only on taste preferences, but also take into account the performance characteristics of the material. So, when equipping a recreation area or a covered carport, you should ask the manufacturer whether the tiles are capable of supporting heavy structures or are designed only for human weight.

Attention is paid to the surface roughness, the shape of the product: are there any adjustments, will it need to be trimmed?

To carry out the work you will need the following tools:

- Master OK;

- wooden or rubber mallet;

- manual tamper;

- metal or wooden pegs;

- cord-order;

- building level;

- I-beam or pipe of any diameter;

- watering can or watering hose with sprayer;

- rake and broom;

- M500 cement and sand.

To determine the number of tiles and raw materials for the base, it is necessary to think through the layout of the site, taking into account the location and size of its paths and platforms.

One of the basic rules for laying paving slabs is the need to arrange paths with a slight slope of 5 mm per meter so that water can freely flow from them into wells or onto lawns.

Arrangement of the base

The success of the entire construction directly depends on the reliability of the base surface. When arranging the base, stakes with notches are hammered along the edges of the location of the future path at a height of 5-7 cm, at the level of which the cord is pulled. A layer of turf, stones and debris are removed from the construction site.

In order to lay any paving slabs with your own hands, you must first carefully prepare the base

To level the surface of the outlined area, in elevated places the excess layer of soil is removed, and in depressions, holes and basins, on the contrary, it is added. The base, leveled with a rake, is carefully compacted. When working with soft soil, it is advisable to moisten the leveled soil surface with water before compacting. Careful compaction of the base will prevent uneven settlement of the sidewalk.

The depth of the base is calculated with a margin of a couple of centimeters, taking into account the fact that shrinkage always occurs during compaction. On average, it takes from 20 to 30 cm to lay a layer of sand and the tile itself.

After excavation front side the tiles should reach the desired level

The entire surface of the future path is given a transverse, longitudinal or longitudinal-transverse slope. At this stage of arrangement of platforms and paths, work on laying communications is also carried out. Laying geotextiles before filling with sand will prevent the growth of weeds between the tiles.

Creating a “pillow” from sand or crushed stone

Sand can be laid on the prepared base layer of soil, which will not only increase the stability of the sidewalk, but will also act as drainage system. The poured sand must be leveled with a rake and watered until puddles form on its surface. Already after 3-4 hours with sunny weather The “pillow” can be given a smooth, even shape using a profile, which can also be an ordinary pipe or beam.

To level the surface of the sand layer, you can use inch PVC pipes

The pipes are placed like rails at a distance of 2-3 meters from each other. The gaps between them are filled with sand to the same height, ensuring a flat surface throughout the entire area.

To give greater strength to the coating, paving slabs can also be laid either on a crushed stone base or on a mortar. To do this, you need to prepare a dry sand-cement mixture in a 3:1 ratio. The mixture is laid out in an even layer on the base, and the screed is performed using a channel. When working with “difficult” soils, it is advisable to use a combined installation consisting of a layer of cement-sand mixture and concrete.

Installation of paving stones

Before laying the paving stones, it is necessary to pull the cord along the chamfer. It is better to start laying paving slabs with your own hands from the curb. The first row is laid out strictly along the cord. The tiles are laid in the direction away from you.

The “bricks” must be placed in such a way that they fit tightly together

This will avoid increasing the width of the seams. Using crosses will make it possible to set equal intervals of 1-2 mm between the tiles. If the tiles lie unevenly, you can use a trowel to remove or add a layer of sand under it and then compact it again.

It is necessary to level paving slabs using a building level and a mallet. Upon completion of the tile laying work, the seams are covered with a layer of cement-sand mixture and watered with water.

To give the path a more neat and attractive appearance, the seams between the tiles can be “rubbed” with quartz sand

If the tiles do not fit well with other buildings or elements of landscape design, you can trim its edges using a grinder.

Upon completion of work, debris and remaining sand are swept away from the finished path. Installing the border with M100 liquid mortar will prevent loosening of the tiles and “creeping” of the path.

Video master classes with installation examples

In the future, it is enough just to renew the sand washed out by water in the seams of the paving stones. A path decorated with paving slabs will be an excellent decoration of the site.

My name is Rostislav, I am 37 years old, and I am a builder with twelve years of experience. I started at a construction site as a helper, like many others. He worked according to the rule: “bring it, serve it, hold it and don’t interfere.” But time has passed - I have grown over the years and professionally, acquired a personal instrument and started working on my own.

My first rule when carrying out any project is to carefully prepare the material and tools to achieve a good final result.

We will talk about the technology of laying paving slabs.

Paving slabs have confidently occupied their niche in the decoration of personal plots, gradually displacing their direct competitors - asphalting and concreting.

And the most important advantage is the natural drainage of precipitation into the ground, without its retention on the surface.

Before you get started, read this article to the end, because at the end there will be calculations from which we will need to begin preparing for implementation.

So, materials and tools:

Materials

1. Paving slabs.

2. Curbs: road, sidewalk.

4. Cement grade 400.

6. Crushed stone, fractions 5x20mm.

7. Screenings, medium-grained

8. Geotextiles

Tools

1.Hydraulic level.

2. Pegs (wooden or reinforcement).

4.Roulette.

5. Angle grinder (grinder)

6.Manual tamping or tamping machine.

7. Concrete mixer.

9. Shovel.

10. Rubber hammer, weight 400 grams.

11. Guide pipes 20 – 30mm in diameter.

12.Rule or flat strip 50x50mm

So, when starting work on a site, you first need to carefully calculate the square footage of the area where the work will be carried out. This can be done using a calculator, which

Selection of paving slabs and curbs for the path

It should be taken into account that when ordering or purchasing paving slabs, you need to purchase material that is 5-7% larger than the calculated area, because during laying and transportation, very often chips may appear on the tiles. You also need to take into account the undercuts, and if after installation you have 10-15 pieces left, they may be useful to you in case of repairs or in other unforeseen situations. We will also calculate the footage of curbs and gutters.

I would like to focus on why “Old Town” paving slabs. This tile has a number of advantages.

Firstly: the tile size is four-component, that is, the set consists of four different sizes.

Using this, we can calculate the width and length of the area being developed as approximately as possible, avoiding cutting the tiles as much as possible.

Secondly: tiles have different color scheme. This allows us to take a more expansive approach to the issue of the design project of the territory being developed.

Thirdly: depending on the purpose, this tile has different thickness in the range of 40, 60, 80mm. For example, in areas of the developed territory that are intended only for pedestrians, it is recommended to use tiles with a thickness of 40mm. Where short-term vehicle traffic is expected, 60mm. And where the constant load from vehicles and other factors is projected - 80mm.

The tiles are also divided into types according to the manufacturing method: cast, vibro-cast, and vibro-pressed.

Cast- These are tiles prepared by pouring liquid concrete mortar into molds. Without affecting the workpieces by a mechanical process, the tiles are brought to readiness by solidifying the solution in molds at favorable conditions. It is characterized by a low price, but low performance properties - it is afraid of constant exposure to serious weather and mechanical factors.

Vibrocast – involves the same preparation process as cast, but with the use of an electric vibrating table, with the help of which a more compacted texture and composition of the component materials used in the preparation of tiles are achieved during production. At the same time, the amount of water in the prepared mixture for making tiles is much less than that of cast tiles. This affects the operating time during the operational period.

Vibration pressed. Unlike the technologies of cast and vibro-cast tile production, during vibro-compression concrete is compacted not only by vibration, but also by compression. Installations for the production of vibropressed tiles provide vertical pressure on the form with concrete (compression, pressing) and at the same time subject the form to vibration. Due to this, the density of the finished tile is higher than the density of cast or vibrocast tiles. The difference from vibrocast tiles is the amount of water. For vibrocompression, “dry” mixtures with a minimum amount of water are used. The mobility of such concrete is low, so vibration without additional pressing will not force the mixture to completely fill the mold. The minimum amount of water in the mixture for vibropressed tiles increases its strength, abrasion resistance and reduces the ability to absorb water (frost resistance). Strength, abrasion and water resistance are increased by additives and additives.

Curbs also differ in type:

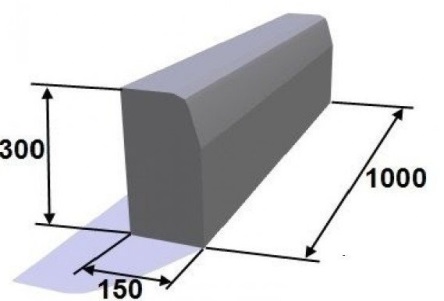

- Road curb. The most popular is a 1 m long road curb. The height and width vary depending on the location of application. To separate roads from sidewalks and lawns, a curb 30 cm wide and 15 cm high is used. At public transport stops, a curb also 30 cm wide and 18 cm high is used.

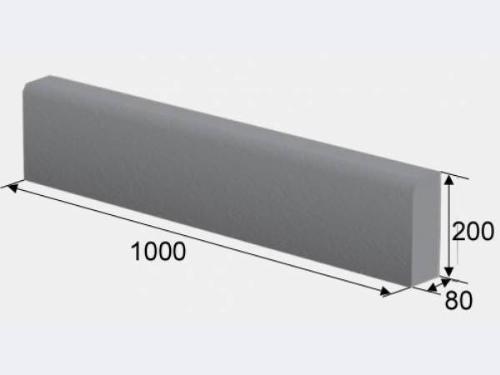

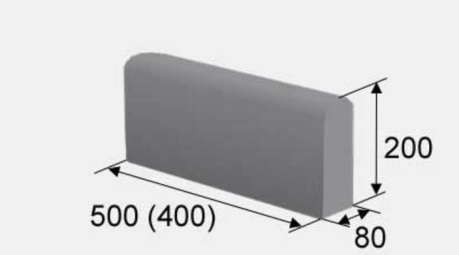

- Sidewalk curb. It has dimensions of 1000x200x80mm, and also 500x200x80mm. It is used for landscaping sidewalks, paths, blind areas, lawns, and various sites; it can serve as an element of landscape design, enclose structures and give them a finished look. The most important thing is that the curb is a stop for the road or tiled surface, and it is with its installation that the preparation of the base begins.

Today, the color range of borders is very diverse. In principle, color and even size can be discussed with the manufacturer or supplier when purchasing equipment for the construction site.

Gutter. The main purpose of the gutter is to drain rain or melt water to drainage well or storm water inlet, and in a simplified version - to the place of discharge. Concrete gutters consist of separate ready-made gutters, and they differ in shape:

- for small ones - open semicircular gutters, have dimensions of 250x160x40mm, 500x200x65mm, and also 340x155x60mm.

- to in-depth – having in cross section rectangular shape and closed at the top with a lattice. They have dimensions: length -1000mm, width -165mm, and height can be 80,100,165,190 and 215mm.

Open gutters are quite safe and easy to maintain, but in the event of heavy rainfall they cannot cope with the flow of water. Recessed concrete gutters are covered with metal protective grilles to prevent injury and to allow unimpeded passage of vehicles.

The grates protect the gutters from large debris getting inside, but the gutters need to be cleaned periodically.

Concrete gutter can perform additional function– decorative. Often used when laying sidewalks different types, shapes and colors of tiles. In this case, the drain can become a kind of separator.

Gutters, like curbs, can be matched to the color of the tiles, or vice versa, to highlight certain sectors in the area being developed.

When calculating gutters and curbs, you also need to take into account a 5 percent margin for trimming areas and installation complexity.

We begin installation work before installation

When approaching a project and having completed all the calculation work, we first carry out a breakdown of the territory. We determine according to project plan or a plan agreed with the customer, into which sectors the territory will be divided, which areas need to be highlighted in the high-rise plan - that is: areas for gazebos, barbecues, ramps or parapets, slopes, places where gutters pass and water discharge points. From my own experience, I will say that if the work is carried out on the territory of a private residential sector, then all slopes are arranged at the maximum distance from the buildings, that is, after the work has been done, it should visually appear that the buildings are located above the sidewalk or roadway of the site. This is done in order to remove moisture from buildings as much as possible.

Preparing the foundation

All work begins with preparing the foundation. In the area where the work will be carried out, the top layer of soil is removed in order to remove as much as possible root system plants (no more than 40cm) and go deeper to the depth we need to fill the base under the tiles. You must understand that all slopes on the site must be started when leveling the roadbed. Then the added layers will lie in an even layer, creating and correcting the slope we need. If you are paving the area small area and you have enough strength to remove the required thickness of the layer of soil, you can do this with a pick and shovel. After removing the soil, clean the bottom of the trough to remove tubercles and hummocks. After this, you need to thoroughly compact the subgrade using a tamper or vibrating plate. Without these tools, it is impossible to properly compact the surface of the earthen trough. Laying underlying layers and tiles on uncompacted soil will lead to subsidence of individual sections of the coating.

To find out at what depth we need to remove the soil, we need to drive stakes around the perimeter of the site. If the area is large or has hidden areas, then you need to split one large plot into several small ones - visible. On these stakes, using a hydraulic level, we beat off the “horizon” (I wrote how to do this correctly in the article “Installing an armored belt for an attic roof”). When we have horizontal marks, we determine the slopes of the areas. The slope is necessary so that precipitation does not accumulate in one place, but is diverted away from buildings and pedestrian areas. The most optimal slope is “Road slope”.

Road slope is the slope that is used in the construction of the roadway and is equal to 1 meter = 1 centimeter. That is, the deviation from the horizon at one meter is one centimeter.

Example: if the length of the area is 10 meters, then at the beginning and at the end of the area we hammer in a peg. Using a hydraulic level, we mark horizontal marks, and where we need (at the beginning or end) to lower the area, on this peg we mark down 10 cm from the horizontal mark.

When the slopes and grading are finished, you can begin installing curbs. To do this, in the places where the curbs will be installed, we hammer in guide stakes and set an altitude mark on them, tighten the fishing line or string. This will be the High Altitude Lighthouse.

It should be noted that if the tile area is laid with a slope, then the curbs should be installed with the same degree of slope.

From the elevation mark down, we mark the height of our border, plus 10 cm for the bedding and concrete on which the border will be installed and, if necessary, remove excess soil. Next, we prepare the base, tamp the bottom, sprinkle it with crushed stone in a 5cm layer, and tamp again. Preparing concrete. The concrete should be thick, prepared in a ratio of 1/3. One portion of cement and three portions of sand and crushed stone. Evenly, with a shovel, on top of the compacted crushed stone, apply concrete along the entire length of the curb, in an approximate layer of 6-7 cm, and install the curb so that the top of the curb is along the line, touching.

So, when all the curbs are installed and the concrete has begun to set, we begin installing the gutters. In principle, the technology for installing gutters is almost the same as installing curbs. We agree on the place where the water will drain, take it as the most low point and using pegs and a hydraulic level we make markings for the installation of gutters. It should be remembered that the top of our gutter is already the top of the future tile. The gutters must be placed very carefully under the fishing line, since the slightest failure at the junction of the elements will lead to inhibition of water drainage and subsequently to freezing of ice and destruction of the concrete elements of our site. Sidewalk gutters must be connected to the pipes of the drainage system of buildings on the site, since during rain or other precipitation the roofs of buildings have a large area for water intake, and when water flows from the roof, it will first wash out the tile seams, and in the autumn - spring period freezing stage - freezing will destroy concrete elements. For safety reasons, meter-long gutters should be covered with a special grill, which is included when purchasing gutters.

Rolling out geotextiles for paving slabs

The next stage of our work is rolling out geotextiles. Geotextiles are roll material. As a material, it has recently appeared on the market, but has very useful functions. With the help of geotextiles, we prevent the appearance of weeds, which with their roots destroy the structure of the base under the tiles, prevent sand from being washed out, and protect from ant holes and other beetles and insects. Geotextile is also a drainage material in our design.

It rolls out very simply, directly onto the ground surface - where the tiles will be laid, with an overlap of 15 cm over the previous section, and with small vertical flaps. As a rule, 10 - 15cm. Immediately sprinkle with a small layer of sand.

Installation of sand and crushed stone base for paving slabs

Using a wheelbarrow and a shovel, scatter sand over the rolled out geotextile. Layer thickness 4-6cm. We compact it using a hand tamper or vibrating plate. It is better, of course, to compact large areas using a vibrating plate, since it not only compacts, but also levels the surface of the area. You need to tamp so that there are 5 blows or passes of the vibrating plate in one place.

When the sand is leveled and compacted, we lay a layer of crushed stone with a fraction of 5 – 20mm. The thickness of the crushed stone layer should be 15cm. This is quite enough for sidewalks and pedestrian areas with average traffic. Crushed stone also needs to be compacted, and as practice shows, manual compaction is ineffective here; a vibrating plate is better. When compacting crushed stone, it is recommended to do the so-called “unclinging”. Decluttering is a mixture of dry sand with screenings in equal parts. That is, we take sand and screenings in equal proportions and use a concrete mixer to mix until homogeneous, and when the vibrating plate has filled one pass over the entire area, we take a shovel, scoop up the mixture and spread the mixture over the area with a fan. Thus, sand and screenings clog all the cracks that form on the surface of the crushed stone base. After declinging, we go through it again with a vibrating plate. Vibration and pressure will help the decluttering mixture sink to the bottom of the crushed stone cushion. We repeat these operations until the lining mixture lies in a thin layer on the surface of the crushed stone base. The final stage of preparing the base is watering it with water from a hose. You need to pour thoroughly and using the “falling water” method, lifting the tip of the hose up. After watering, tamp again. If the preparation is done correctly, the base becomes level and dense.

If there is asphalt concrete on the site where we are going to lay the tiles and it is not of poor quality and visually there are no dips or bumps, and we are satisfied with the hydraulic level height, then we can assume that our preparations are ready, the tiles can be laid using only a leveling screening layer of cement.

And yet, sand and crushed stone base is used only on sidewalks and pedestrian areas. In places where there is traffic and constant heavy load, paving slabs are laid on a prepared concrete base.

Getting ready to prance

Gartsovka is a dry mixture of screenings and cement in a ratio of 1:3. One part cement and three parts screenings, without adding water.

On the compacted surface we make markings for the top of the tile. To do this, we hammer in pegs, in pairs, at the beginning and end of our site and stretch the fishing lines along the visual top of the tile. When this operation is done, lower the fishing line down to the thickness of the tile, minus one centimeter. For example: if our tile is 6cm thick, then we lower the fishing line 5cm from the level of the top of the tile. Do not forget also about the longitudinal and transverse slope. We check all slopes with a building level, touching the line or with a hydraulic level. We set up our lighthouse pipes along these lines. It is advisable to choose a round pipe - this makes it easier to position. The pipes are placed at a distance from each other so that our rule applies to the pipes with a margin of length. For example: if our rule is 2 meters long, then the pipes are placed at a distance of no more than 1.7 meters from each other. We backfill the pipes where the pipes will lie, lay the pipes so that the top of the pipe touches the fishing line. Then, using a wheelbarrow or shovel, we fill the space between the pipes with a prance and usually pull it towards ourselves, so that the prance stretches out in an even layer over the entire grip.

If we are making paths that are no more than 1.5 meters wide, we can use a wide but even board, having previously cut grooves in it for the border to the thickness of the tiles being laid. In this situation, the use of pipes is not necessary.

After aligning the trample with our grip, it is necessary to compact it using a manual tamper in one pass, without removing the pipes. The garter will immediately thicken and show the gaps where you need to add more. Using a shovel, we make a bedding and pull it together again

rule. And we ram it. We repeat this operation two to three times until a perfectly flat, compacted area is formed on our grip. Only after this do we take out the lighthouse pipes and fill the grooves after the pipes. Compact with a rubber hammer and level with a trowel.

Important point: When preparing the leveling layer of the tile, you need to use the entire prepared mixture, that is, lay, tamp and lay the tiles. Since the prancing consists of cement and screenings, and the screenings have a certain degree of moisture, the cement reacts with this moisture and a ready-made prancing left, say, for tomorrow will no longer perform its functions.

Laying paving slabs with your own hands

Paving slabs "Old Town" have an advantage when laying in that it has different design. That is, there are a lot of design and styling options. But the process itself has some rules. Firstly: the evenness of the seams. Every three to four rows, check the direction of the seam with a stretched fishing line; if necessary, straighten it with blows of a rubber hammer. Secondly: flatness on the plane. Also, every three to four rows, take a level or rule and apply it on top of the laid tile and look at the bottom gap. It should hit the minimum, if this is not the case, then we will also trim it with hammer blows, only from above. And thirdly: when laying tiles, each one should be tapped a little with a hammer. This provides additional compaction of the underlying layer of the garnet.

At the beginning of the article I gave information that the calculations will be at the end. So, when we start working on paving slabs, we ask ourselves the question: to what depth should we remove the soil and prepare the base? So, now we can calculate it. To do this, we need to know the “anchor points”, the thickness of the tiles, the features of the territory (where there will be garden paths, platforms, and most importantly - the races).

Anchor point – These are places on the territory where the top of the paving slabs must coincide with the elements of the building on the territory. For example: the threshold of a house, the bottom of a step, the bottom of a dedicated area, etc.

When we have all this data, we summarize the construct: the thickness of the sand cushion, plus the thickness of the crushed stone base, plus the thickness of the bedding, plus the thickness of the tiles. The thickness of the tile can be taken minus one centimeter. This centimeter is compensated when compacting the laid tiles with a vibrating plate. It must be taken into account that the thickness of the tiles may vary throughout the area, depending on the technological purpose.

So, when we have the tiles laid, if there is trimming , (trimming is places where a whole tile does not fit) then we perform the trimming using a grinder with a diamond-coated disc, not forgetting about personal safety equipment (glasses, gloves), spill ready plots sand. The sand must be dry, finely calibrated and clean. Using a broom or garden brush, distribute the sand along the seams so that it fills the seams as much as possible; we do not sweep away the remaining sand, but leave it in an approximately even layer on the tiles.

Tamping tiles

AND final stage- This is the compaction of finished areas using a vibrating plate. The vibrating plate must have a rubber sole, which comes complete with the vibrating plate, otherwise the metal sole can simply destroy the elements of our work. If the preparatory base for the tiles is well compacted, one pass of the vibrating plate over the area will be sufficient. At the same time, the sand that we swept into the seams will sag a little and become compacted. Here the sand that we left on the square will help us, especially since it is well high. After compaction with a vibrating plate, the tiles are leveled over the area, sag slightly, and compacted into a single monolithic platform. After this, we sweep the sand over the area again, but now we sweep away the remaining sand so that the pattern on the area gains brightness.

How to lay paving slabs? This question has a modern sound, since arranging paths with its help is gaining impressive popularity. It is posted not only because it is fashionable. This is facilitated by its beautiful appearance, practicality, and ease of installation. The modern construction industry makes it possible to choose materials from a wide range of products that differ in shape, color, and size. However, it should be taken into account that the tiles also differ in quality, and therefore you should not use the services of dubious sellers - such a product will not last long.

Essence of the material

At its core, paving slabs are a high-strength tile block designed for street laying when forming sidewalks, paths, and platforms. It is not for nothing that they are also called paving stones, since their appearance resembles a stone covering. Laying outdoor tiles allows you to get rid of procedures such as asphalting or concreting.

The main advantages of such a coating are ease of installation and operation, the possibility of repair, high strength and wear resistance, resistance to sun rays, heating, precipitation, temperature changes and frost resistance. Particularly noteworthy is its decorative effect, since the variety of shapes and colors make it possible to create various ornaments and even designs on the ground.

Paving slabs can be made from various materials. The most widespread are concrete products formed using a special technology with the addition of pigments. Less commonly (taking into account the increased cost) tiles made of natural stone, baked clay to create an original texture, and also rubber-based are used.

You can make concrete tiles yourself. For this, as in the factory version, one of 2 methods is used: vibration casting and vibration pressing. In the first case, the form is filled out concrete mortar with compaction, after which it is subjected to vibration for a specified time, and then dried under natural conditions. The second method is more complex, as it involves combining vibration with compression of the workpiece using a press, that is, vibration is produced under pressure, which ensures a more monolithic structure of the product.

In general, the choice of paving slabs is carried out according to the following parameters: size, thickness, shape, color, surface topography. Smooth tiles are not placed on the sidewalk to prevent feet from slipping. A certain relief is created on its surface, which can also play a decorative role. The relief pattern is considered important parameter selection of products. It may be slightly noticeable, that is, in this case the tile simply has a rough surface. When forming specific design sometimes preference is given to a pronounced relief in the form of an ornament or design.

The shape of paving slabs, even factory-made, can be very different: square, rectangle, polygon, round, etc. The most popular forms are: paving stone (rectangle), honeycomb (hexagon), wave, gzhelka, flower, scale, clover, fleece.

Required Tools

When laying paving slabs with your own hands, you will need the following tool:

- grinder or angle grinder;

- tamping;

- Master OK;

- putty knife;

- shovel;

- scoop;

- mallet;

- hammer;

- hacksaw;

- hacksaw for metal;

- jigsaw;

- construction level;

- metal ruler;

- square;

- protractor;

- roulette;

- spray nozzle for hose.

Laying rules

Paths and areas on the site will delight the eye for a long time if the issue of how to properly lay paving slabs has been resolved. The event itself, although it requires a lot of time, is carried out quite simply, and therefore everything can be done independently. Will help with this certain rules laying paving slabs.

In general, the entire installation process can be divided into several important stages:

- development of laying scheme;

- preparatory work;

- directly laying tiles;

- filling tile joints;

- installation of curbs.

It should be noted that planning an event is very important. At this stage, a laying scheme is developed, namely, the shape of the track, the pattern on the surface, color scheme. Already at this stage it is important to accurately calculate the need for specific elements. It should be taken into account that if there is a shortage of tiles, problems with size variation in different batches of goods and with color shade will certainly arise. Everything must be purchased in one go.

When designing tile masonry it is necessary to take into account that such an element of arrangement catches the eye, so it must be harmoniously combined with the style of the entire landscape design. The choice of element sizes should also take into account the load on the laid out surface, in particular, the possibility of being run over by vehicles or rolling heavy carts.

The question of how to lay paving slabs is related to the dimensions of the site, its location on the site, and the purpose of the coating. Paving slabs can be laid in several ways, which provide different visual perceptions. Most often, traditional laying patterns are used: brick (row), column, herringbone, checkerboard. This masonry forms the correct geometric figures and can be carried out in a horizontal, vertical or diagonal direction, as well as in a combined way. At the same time, you can satisfy your imagination and provide styling using unconventional methods: in a circle, in a wave and other fancy options.

In order to lay paving slabs with your own hands, you should remember that it is impossible to lay out the surface using only solid elements. You will definitely have to cut the bricks, and to do this, without the skill, you may have to ruin more than one tile. In this case, the amount of required cutting increases when choosing diagonal system laying, especially with an unconventional scheme. Cutting the tiles is done with a special knife or grinder with a disc for cutting concrete.

Proper coating formation implies satisfaction following conditions:

- the elements are placed in recesses, and the protrusion above the ground surface should not exceed 3.5-4.5 cm;

- the tiles are laid only on carefully compacted dense soil;

- the surface must be flat;

- Good drainage (gutter) must be ensured to prevent the appearance of puddles on the laid paving stones.

Preparatory stage

The solution to the question of how to properly lay paving slabs is largely determined by careful preparation of the area where the process will be carried out. At the preparatory stage, the following main work is carried out:

- Digging a hole. The work begins with removing the top layer of soil, which helps solve two problems at once: leveling the work site and creating the necessary recesses for laying tiles. As a rule, soil is removed to a depth of about 19-22 cm for pedestrian paths and 28-32 cm for possible collisions with vehicles.

- Soil compaction. It is necessary to thoroughly compact the soil over the entire area of the dug hole. This condition is especially important when solving the problem of how to lay paving slabs on sand. In this case, it is recommended to wet the bottom of the recess well with a hose terminated with a sprayer.

In preparation working area the need to provide drainage should be taken into account. Most often, it is ensured by forming a general slope of the entire site (approximately 3-4 º per meter).

Zone Restriction

Required element sidewalk or paving area is a side limiter in the form of a curb. In its absence, the outer tiles will move over time under load and moisture. It is best to use a ready-made concrete curb for this purpose. You can do it yourself by pouring concrete into formwork or using bricks, which are then plastered.

Installation of curb slabs is carried out in this order. A trench is dug along the entire perimeter, which is 5-10 cm larger than the width of the curb. A sand cushion 6-8 cm thick is poured into the bottom of the trench and thoroughly compacted. Plates are installed on top of the pillow, which are aligned with each other and in a vertical position. To prevent their displacement during work, fixation is ensured using pegs. To secure the limiter, the prepared trench is filled with concrete mortar.

Preparing the base

Laying paving slabs is done on a prepared base - a cushion. Its main tasks are to level the surface and prevent subsidence of individual elements. It is made of sand and crushed stone in several layers.

The first layer is sand 5-8 cm thick. The next layer is provided with crushed stone, and it is designed to redistribute loads over the entire area. Its thickness is 14-18 cm. Additional filling of crushed stone with sand allows you to get rid of voids. If in the first layer of the cushion there are no special requirements for the quality of sand, then the outer layer is formed from fine sand. After this, the entire surface is moistened and thoroughly compacted to create a level area with the required slope. Finally, it is recommended to fix the pillow when falling asleep. thin layer from a mixture of sand and dry cement.

Laying paving slabs is done without haste and in the “away” direction, which is important to avoid disturbing the even surface of the cushion. The elements fall into in a certain order, corresponding to the selected scheme (picture). A gap of 1.5-2.5 mm is left between them, and wedges made of wood or plastic are used to form the same width throughout the entire area.

The tile is deepened into the sand layer by approximately half its thickness. Leveling on a plane is carried out using a mallet and wooden block. As the installation proceeds, the evenness is checked with a level. First, all solid elements are placed on the pillow. The final stage involves cutting the tiles. To do this, it is applied to the installation site, where the cutting line is carefully marked. All elements are cut after the fact.

The laying of paving slabs is completed by sealing the seams. Their shift at this stage is prevented by filling the gaps with a dry mixture of sand and cement powder. After filling, water is sprayed over the entire surface of the sidewalk, as a result of which the cement holds together individual elements between themselves. Before the solution dries completely, the fixing wedges are removed. The procedure is carried out several times (3-4 times) - for better filling of the seams. Excess mass is removed without waiting for complete hardening. At decorative design Pigment can be added to this mixture the desired shade.

The durability of paths or paving slabs depends on the correct preparation of the work area and the installation of elements. Such work can be done with your own hands, but taking into account the recommendations of specialists. High-quality styling tiles will provide practicality and a beautiful appearance that will delight the owner of the site for a long time.

Laying is an opportunity to create not only durable and high-quality, but aesthetic and beautiful coating garden paths, pedestrian areas, entrances and other areas in the personal territory. Manufacturers offer big choice modern material that meets the most high requirements in quality and makes it possible to realize any design idea.

Laying paving slabs with your own hands is not as difficult a task as it might seem at first glance. However, it requires knowledge of paving technology, necessary tools and materials, and preparation. There are a huge number of options for laying tiles, and before starting work you need to decide on the scheme and study all the stages of paving.

The main advantages of using paving slabs

Before laying tiles in a country house or around a private house, you need to select a material. Paving slabs are made in two ways - vibration casting and vibration pressing. Vibro-cast paving stones are made from plastic solutions, poured into special vibroforms. The tile turns out beautiful and can imitate different materials, suitable for arranging garden plots of cottages, country houses, laying paths and paths.

Vibration-pressed tiles are made by pouring a solution into a mold and applying pressure to the material using a vibropress. The paving stones are rough, with a strict geometric shape, more durable and reliable. Often in Moscow you can see pedestrian areas, pavements, squares and even roads made of such tiles.

The advantages and disadvantages of paving slabs largely depend on the production method and materials. Laying usually involves choosing a relatively inexpensive material made of clay and concrete, the strength of which is sufficient to create a high-quality and durable coating. On suburban areas Clay tiles, which are similar to roofing tiles, are often installed.

If you add to the tile granite chips, then it acquires maximum strength and resistance to various negative factors, serving up to 25 years. Granite does not need to be protected with anything, but it is quite expensive.

- Resistance to sudden temperature changes, severe frost and heat, which makes operation possible in any conditions.

- Environmental friendliness and safety – natural material does not harm the health and life of people, does not emit toxins.

- Resistance to ultraviolet radiation.

- High level of strength.

- Simplicity and ease of installation - the technology for laying paving slabs in the courtyard of a private house is clear and assumes the ability to complete all stages independently.

- No puddles on the surface due to water seeping through the tiles into the ground.

- A large selection of shapes, configurations, shades, materials - installation options can be both simple and complex, realizing an exclusive design idea.

Among the disadvantages of the material, it is worth mentioning such as the risk of covering with ice in cold weather and increasing the danger of the coating, the possibility of subsidence of the layer if the rules for laying paving slabs were not followed.

Choosing tiles is a very important issue. It all depends on technical requirements to the material, financial capabilities, personal preferences.

What types of paving slabs are there (based on raw materials):- Natural – made of hard/soft stone

- Made from artificial stone

- From ceramics and various firing materials

- From monochrome or - the most popular option for installation where there are no very high loads

- From polymer mixtures

In individual construction, paving slabs are most often made from concrete mixtures(colored or plain). The material has excellent technical characteristics and an affordable cost. High quality concrete tiles They are made by vibration casting or vibration pressing; stamped tiles are also available for sale.

- Thickness – for pedestrian paths in private households, a thickness of 4 centimeters is sufficient, for car parking – 6 centimeters. For the sidewalk on the street along the site, it is better to choose 6 centimeters, and for the road common use– at least 8 centimeters.

- Color and shade - it all depends on the elements of the architectural ensemble and personal preferences.

- Vibration casting or vibrocompression– the second option allows you to get more durable tiles, but when laying them at the dacha with your own hands, the vibro-cast method is also quite suitable.

- Material quality– checked upon purchase: the tiles must be perfect geometric shape, without chips or deformations, evenly painted, making a ringing sound.

- Shape – here it is also worth focusing on preferences and installation features: for multi-colored ornaments you will need a laying pattern, there may be a lot of waste. Simple two/three color patterns will take less time to work on.

Materials required for installation

When paving slabs are chosen to design paths and areas on the territory, installation is relatively simple, but requires some preparation.

What materials are needed:- or plastic, concrete

- Cement grade M400-M500

- River or washed sand

- Crushed stone fraction maximum 4 centimeters

- Geotextiles

The volumes of materials are determined in accordance with the volume of work performed and the area of tiles to be laid. Before laying the coating, you need to take care of the tools.

Basic set of styling tools:- Shovel

- Trowel

- Rubber mallet

- Rule

- Roulette

- Garden wheelbarrow

- Guides

- Grinder and its cutting discs for concrete 225 millimeters

- Zakolnik

- Small sledgehammer

Before laying paving slabs with your own hands, you need to acquire all of the above tools. The quality and strength of paving directly depend on their quality. It is especially important to choose a good mallet, small sledgehammer and trowel. When laying paving slabs with your own hands, step-by-step instructions necessarily include the choice of tools.

The mallet should weigh up to 700 grams, with a soft rubber coating to accurately hammer the tiles and not leave chips. It is advisable to take a trowel that is hard and pointed; it is needed for leveling and prying up the tiles. The sledgehammer should weigh 350-500 grams and be comfortable in the hand.

Additional tools: a template for marking chip lines, a template for marking corners, a straightening crowbar for leveling the laying line, an extractor for extracting elements.

A crowbar will be needed when making a curved line and late detection of a defect. The extractor helps remove compacted tiles if necessary.

Preparing for installation at home

Having learned how to properly lay paving slabs yourself, you can get to work. You cannot ignore all stages of installation - everything is done consistently and according to the rules.

Marking future paths

Before you begin installing paving slabs on the ground, you need to make markings. It is advisable to take a copy of the site plan with buildings, flower beds, trees and other elements marked on it. A diagram is drawn on it, clearly marking the placement locations. When drawing up the diagram, take into account the direction of the slopes for water drainage from the coating.

The minimum width of the paths should be sufficient for two people to pass through - at least 100-120 centimeters. For the passage of a car, the zone is made larger, taking into account the width of the car and the space for passage.

The marking is carried out according to plan using a tape measure and a cord: it is pulled between pegs driven in along the contours of the coating. By pulling the cord, 10 centimeters are added to the total width of the path on both sides (allowance for installing curbs).

Excavation and protective layer

The work of laying tiles begins with the ground. Volume earthworks depends on the level of density of its top layer: dense clay and similar soils require the delivery of bulk soil (so the surface is simply leveled), in other cases up to 35 centimeters of the layer is removed from the surface around the perimeter.

The bottom of the trench is covered with a thin layer of sand for leveling and compacted with soil. Next, the layer is covered with geotextile (it will help prevent the germination of weeds, will remove water from the drainage, and will not allow it to rise groundwater) with an overlap of 20 centimeters in the canvases; a fold of at least 20 centimeters is made along the edges.

Drainage device

The bottom of the trench, compacted and covered with geotextile, is filled with crushed stone in a layer of 15-18 centimeters, which will become drainage for draining surface and melt water, will eliminate the risk of moisture accumulation and swelling of the tiles. The crushed stone is carefully compacted, sprinkled with sand, and geotextiles are laid on top again.

Placement of boundary borders

When considering how to lay paving slabs in your dacha, you should not forget about curbs. Borders can be anything - stone, concrete, plastic, slate, brick or wood.

Most often chosen concrete products, plastic, which is inexpensive, durable, and easy to install, can also be a good option. The curb is installed before laying the paving slabs.

Types of bases for paving stones and tiles

The base for the tile covering can be different - sand, cement-sand and concrete. A concrete base is the most expensive and allows paving slabs to withstand considerable loads. Sand is used for light loads and the complete absence of heaving soils and movements. The most common choice is pouring concrete or using a cement-sand mixture.

Pouring the concrete base

Such preparation for installation will be expensive. Work begins with reinforcement - usually take ordinary steel mesh 10x10 centimeters. Pieces will also work metal pipes, different types of wire, rods with a diameter greater than 5 millimeters and other metal elements.

The metal is laid out on special clamps or pieces of brick (the height should be 3-5 centimeters from the surface) in a lattice format in the place of pouring, and knitted with wire. Concrete is poured in a layer up to 12 centimeters thick, but the finished surface should be below the level by an amount equal to the thickness of the tile minus 3 centimeters.

Before laying paving slabs with your own hands and pouring concrete, evaluate the depth of the trench. If it is larger, the excess must be covered with carefully compacted sand. Concrete is prepared from M400 cement in the following proportions: 1 part cement, 3 parts sand, 5 parts crushed stone. They pour everything at once, if necessary, ordering a large volume of concrete at the factory. 3-5 days after setting, you can lay the tiles.

Sand and cement base

When thinking about what to lay areas and paths made of paving slabs on, they often choose a cement-sand mixture. The mixture is prepared from 1 part cement and 5 parts sand, poured onto compacted sand in a layer of 15 centimeters, always equal to the level.

Tiles on a dry mixture must be laid only in dry weather. The poured mixture is carefully compacted and leveled. It is best to choose quarry or river washed sand, which should not contain clay or lime.

Treating tiles before laying

Before laying paving slabs at the dacha or around the house, they must be properly processed. To do this, hydrophobic compounds are used that protect the material from moisture and frost, extend its service life, eliminate fungus and mold, and eliminate the possibility of efflorescence.

How the processing occurs: the tile is dipped into a hydrophobic solution, dried, then both procedures are repeated. During the process, the products are inspected for defects, chips and cracks. Rejected tiles are set aside - they can be used in inconspicuous areas, and pieces may also be needed in the process of laying out patterns.

Step-by-step instructions for laying outdoor tiles of any complexity on your own

Knowing the features of the coating laying technology, it will not be difficult to do everything quickly and correctly. The main thing is not to skimp on the quality of materials and to have all the necessary tools at hand.

Laying technique on sand and crushed stone

There are different types of laying paving slabs, the main two are making a base of sand and crushed stone or concrete. The first option is cheaper, the second creates more durable coating. But both are appropriate for creating coverage on private property.

How to lay tiles on crushed stone and sand:- Removing the fertile layer of soil with plants and debris, tamping with water. The recess should be 15-30 centimeters deep.

- Backfilling of crushed stone with a layer up to 10 centimeters thick, compaction with a vibrating plate.

- Laying geotextiles on crushed stone.

- Filling with a layer of clean sand 40 centimeters thick, pouring with water until puddles appear, thoroughly compacting. If a cement-sand mixture is used, a layer of 20-30 centimeters will be sufficient.

- Next, we lay paving slabs using one of the methods - diagonal, traditional, combined.

- Preparation of cement-sand mixture in proportions 1:6.

- Wetting and strengthening of the layer poured as a base.

- Laying pipes parallel to the cord markings.

- Leveling the mixture using the rule, carefully pressing against the pipes. Adding the mixture where there is little and removing where there is a lot.

- Checking the tiles for chips and deformations.

- Lay the tiles away from you tightly onto the mixture, tapping with a mallet to best connection. To obtain pieces, the tiles are sawed with an angle grinder or grinder.

- After the entire coating has been laid, a cement-sand mixture is poured on top and water is poured in.

- Installing a curb (if it was not installed at the preparation stage) in a pre-prepared hole so that it holds the tiles on the ground and aligns the edge of the covering. The border should be level with the tiles or slightly higher. How to lay: filling with sand in a layer of 5 centimeters, pouring with water, compacting, pouring concrete to the bottom of the ditch, quickly installing a curb on the concrete, filling the cracks with mortar.

Scheme of laying on a concrete base

When considering methods for laying paving slabs, do not forget about the concrete base. This is a more durable layer, thanks to which the coating can withstand even heavy equipment without cracking or sagging. Using this method, a solid, immovable base is created, without the need to compact the tiles after installation.

The only disadvantage of concrete is its inability to pass water - sand and crushed stone allow it to seep down and go into the ground; in the case of a concrete base, water can accumulate in the seams and freeze in winter.

To avoid problems when choosing concrete base They do drainage - point moisture inlets, storm drains, slope, etc. On old concrete Usually tiles are not laid, as this is dangerous due to rapid destruction.

- Marking the area for pouring, installing pegs, pulling the string at an angle of 5 degrees.

- Removing the top layer of soil 25 centimeters thick, clearing leaves, plants and debris.

- Backfilling of crushed stone with a layer of 10-15 centimeters with a slope (what kind of crushed stone is needed for laying was indicated above), tamping.

- Making drainage holes 15-20 centimeters high in meter increments. After the concrete has hardened, the holes can be filled with crushed stone.

- Installation of formwork from boards 4 centimeters thick, secured with pegs.

- Preparation of the solution: part cement, 3 parts sand and 1 part crushed stone are mixed and poured into a layer 3-5 centimeters thick.

- Installation of the reinforcement cage, re-pouring of concrete with a layer of 5-10 centimeters.

- Laying paving stones can be done in 2-3 days.

- Creating a groove for the curb with the desired slope.

- Mixing a mixture of cement and sand in a ratio of 1:3, backfilling with a layer of up to 5 centimeters, installing a curb by driving it into the solution with a mallet. After the mixture dries, all cracks should be filled with sand and spilled with water.

- Filling the concrete base with a cement-sand mixture (1:6), leveling, compacting and laying with a vibrating plate, filling 10 centimeters of the mixture, installing beacons, leveling. Next, the tiles are laid with a gap of about 5 centimeters for expansion, the cracks are filled with sand and gravel, and water is poured.

Some rules for beautiful tile laying

When thinking about how to properly lay tiles on any base, you need to take into account not only the requirements for strength and reliability, but also aesthetics.

How to lay tiles beautifully:- Make sure it's level - use a level from the very first row and check everything carefully.

- Decide in advance on the installation option and pattern, carefully follow the pattern.

- To cut the tiles, use a powerful grinder or angle grinder and properly process the cut area so that the laid pieces look beautiful.

- Correct all errors immediately - do not wait for it to sit down on its own or in general series the tiles will be noticeably slightly crooked or unevenly laid.

- Use several harmoniously combined colors in installation - this will make the tiles look expensive and stylish.

- Do not skimp on material - choose only truly high-quality material that meets the requirements paving stones. Then the installation will be simpler and smoother.

Sealing seams and cracks

For flooring high-quality coating It’s not enough to know how to lay paving slabs. It is also necessary to properly seal the seams and cracks. First, a thin layer of dry, sifted and clean sand is poured onto the laid layer. Use a brush or broom to sweep the material between the tiles. Then sand or a mixture of sand and cement in equal proportions is poured onto the path. Again, use a broom to fill the seams. You can use a ready-made dry mixture - Quick-mix PFN or M150, for example.

Tile laying options

Types of tile laying allow you to realize almost any design idea. Tile paving options different forms, colors and sizes are presented in a huge variety. The most complex species paving – “paving stones”, “brick”, “rhombus”. The most popular patterns are “chess”, “parquet”, circle, diamond, classic masonry or offset.

The paths can be smooth or curved, which look much more beautiful and original, but are more difficult to execute. Classic style the paths are paved according to the “herringbone” pattern (when the tiles are laid at an angle of 45/90 degrees), “braid” (alternating transverse/longitudinal products), “chess” (two colors are laid out in the appropriate order).

For paths with curves, choose a “brick bond”, which allows you to create curves and smooth corners.

The easiest tiles to design are square or rectangular. The more colors used, the more difficult it becomes. Also original patterns and drawings will require a lot of time and effort to complete the task.

To visually “shorten” the track, the tiles are laid perpendicular to the direction of movement, but if the direction of the rows of laying and the axis of the track coincide, the object is stretched. “Herringbone” compresses space. Below are several tile laying schemes.

Use and care

After the tiles have been laid, it is important to ensure that they proper care. The most simple rules– regular sweeping with a broom and washing with water. In winter, you need to remove snow without using shovels or metal, crowbars or ice axes. It is better to sprinkle the coating in advance special compounds preventing ice from forming.

Concrete absorbs moisture, from which it must be protected: coated with special water repellents at least once a year. They saturate the surface of the tile and do not allow water to accumulate, freeze, and then cause the spread of cracks and deformations. Impregnation can be carried out with the following compositions: Penetron, Neogard, Neomid H2O Stop, Tiprom M, GKZh-11.

How to apply impregnation: dilute with water according to the instructions, pour into a sprayer, spray on the surface of the tile, spraying until the material is completely saturated and drops appear. The tile will look as if it is wet, but will not absorb any rainwater, nor melting.

Properly selected and laid paving slabs are the key to the beauty and aesthetics of the coating, as well as for long years services. Having prepared all the materials and tools, you can do the work yourself.

The main condition for success is your desire. Laying paving slabs is not difficult construction work. Although, undoubtedly, it will not be easy for a person inexperienced in such matters. But the moral effect of the work performed will overcome all difficulties. Now you will learn how to lay paving slabs yourself.

Choosing paving slabs

The time of ceramic tiles has already passed. Nowadays, polymer tiles are widely used, which are made from polymer materials with high quality characteristics. First of all, such tiles have strength and elasticity, they are resistant to negative environmental factors. In addition, it has a wide variety of both color and texture. As they say, choose what you want. And most importantly, don’t worry about how to lay polymer paving slabs. Because, if desired, any intelligent person will be able to cope with this matter. You just need to approach the matter responsibly.

Planning work

Any important work requires a preparatory stage. Therefore, when deciding how to lay paving slabs, you first need to plan the entire scope of work.

First of all, you need to decide on the site, its size, configuration, as well as the choice of tiles and other materials. When the final choice in favor of one or another type of paving slab has already been made, then a plan drawing is drawn up, on which detailed dimensions area planned for laying tiles. With its help, you can easily calculate how much material is needed for the job.

By the way, the width and length of the area should be correlated with the size of the paving slabs that will be used to pave, for example, a path, so as not to cut the tiles. After all, this also comes with certain difficulties.

Preparing tools and materials

Before you seriously think about how to beautifully lay paving slabs, you need to stock up on tools and materials. So that nothing distracts you from doing your work later.

First of all, you will need a trowel, a building level, wooden or metal pegs, a long strong thread or twine, a rubber hammer, as well as a wooden hammer, a hand rammer, a channel or a long pipe, a shovel, a rake, a hose with a diffuser for watering, buckets and a broom .

The required materials are crushed stone or gravel, sand, dry plaster mixture or cement, curb stone and finally paving slabs. The latter comes in various thicknesses. If the tiles will be used for paths, their thickness can be no more than 30-40 mm. For vehicle parking, paving slabs with a thickness of 50-60 mm are used.

Contour marking

In order to feel satisfied after the work has been completed, you need to learn how to properly lay paving slabs and strictly follow the sequence of operations.

The first stage consists of breaking out the contour, that is, marking the path or site. But first you need to decide on the slope. It is necessary so that water after rain does not stagnate and ultimately destroy the path. The slope can be directed from the house to the street. In this case, the street can be taken as the zero mark.

Then two pegs are driven in at the corners of the site along zero level, and a strong thick thread or twine is pulled between them. Levelness should be checked using a level. A new piece of twine is tied to one of the pegs, it is pulled parallel to the first and attached to the third peg, which is installed slightly above the zero level.

The next two sides of the rectangle are also limited by twine. It is important not to forget to check the horizontal level with a level.

Laying the foundation

Preparing the base for tiles is an important condition for the durability of the completed coating, since laying paving slabs on unprepared soil means significantly reducing its service life.

Initially, you should carefully cut the turf on the marked area, to a depth of no less than 20-25 cm, so that no roots remain. Then the soil is leveled, if necessary, mounds are cut off or earth is poured into depressions or holes. The entire site is raked and compacted well.

We must not forget to maintain a slope for water drainage. If you lay geotextiles on the bottom of the site, this will prevent grass from growing between the tiles.

Is crushed stone necessary?

There are two ways to prepare the base. How to lay paving slabs will depend on the purpose of the area to be covered. If you are going to build a pedestrian path, you should take into account that the load on it will be light. This means that only sand can be used for the base. If this is a parking area for vehicles, then a crushed stone base is required.

In the first case, sand is poured into the prepared trench to a height of 10-15 cm, then it is leveled with a rake, well watered with water from a hose or watering can and compacted tightly with a hand tamper.

In the second case, crushed stone or gravel is poured onto the bottom of the site. It is leveled over the entire surface in a layer of about 15 cm and compacted. After installing the curbs, a layer of dry cement-sand mixture is still poured.

Installation of curbs

Small grooves are dug on the sides of the trench, their bottom is compacted and filled with 5 centimeters of sand. Then curbs are installed there on the liquid solution. The joints between them should be poured with mortar and sprinkled with sand.

The procedure for installing curbs is the same for both sand and crushed stone bases. Only then you must remember to pour a layer of sand-cement mixture onto the crushed stone in a layer of 5-10 cm.

By the way, a smooth and even surface should be given to the base using a profile or an ordinary pipe.

How to lay paving slabs?

When the preparation of the base has been carried out in good faith, laying the tiles will not be difficult. Laying methods can be different, for example, you can lay them diagonally, or you can lay them one row at a time from the curb. However, you must comply general rule- lay the tiles away from you so as not to spoil the prepared base.

To ensure that there are equal gaps between the tiles, it is best to use special crosses. When all the tiles have been laid, they must be compacted wooden hammer. If the tiles adhere unevenly to the base, you should add a sand-cement mixture under it with a trowel and level it, then compact the tiles well with a hammer again.

Sprinkle all the seams between the tiles with a dry sand-cement mixture, sweep away the excess with a broom, and water the entire tile with a hose so that the mixture in the gaps is well saturated. If necessary, you can add a little more mixture into the gaps and moisten it with water again.

Caring for paving slabs

Now we know how to lay paving slabs. The photo will help you see this with your own eyes. It remains to be said that tiles require some maintenance, just like any other coating. Here are some of the most basic principles for caring for tiles.

- Firstly, you can walk on freshly laid tiles no sooner than after 2-3 days.

- Secondly, the tiles need to be cleaned, and if they are colored tiles and not gray, then they should be washed from time to time.

- Thirdly, in winter you cannot use it to clean tiles. metal objects(shovels, crowbars, picks), otherwise it can be damaged. Just as you should not sprinkle it with salt-containing abrasive mixtures. It is better to use river sand.

How to lay rubber paving slabs?

Probably not even everyone knows that such tiles exist. It turns out that it is made from old tires, or rather from the material that is obtained after recycling these tires. Its main advantage is that it is absolutely non-slippery, and, of course, it does not break. Abroad it is often used for sports grounds. However, it is also suitable for garden paths near country houses.

Such tiles are laid both on the ground and on a solid base. For summer cottages, the first method is preferable.

So, first the top layer of soil with turf is removed. After compacting the soil, a layer of crushed stone is poured onto it, which is evenly leveled (80-100 mm thick) over the entire surface of the area intended for laying tiles. Then follows a layer of cement-sand mixture, on which the rubber tiles are laid.

By the way, when laying it there is no need to provide for a slope, because such tiles absorb and evaporate moisture well.

The nuances of laying some types of paving slabs

- How to lay large paving slabs. Size practically does not matter here; the installation technology is the same. Another thing is that when laying large tiles, you may need a “grinder” to cut the tiles into pieces, especially if you have a design in mind. You also need to keep in mind that large tiles should not be placed in places where cars will drive. In this case, it will not last long. It is very suitable for pedestrian paths.

- How to lay plastic paving slabs. Pure plastic tiles have low frost resistance; they quickly begin to break, crumble, and soon fade. It is used as a temporary covering, for example, near the threshold, so as not to carry dirt into the house, or near outbuildings, where appearance is not so important. Plastic tiles most often have a perforated surface through which dust and moisture freely escape. Such tiles are very easily connected to each other using special locks that are located along the edges of the ribs. The only condition is that they must be laid on a very flat surface so that the height differences do not exceed half a centimeter.

- How to lay polymer sand paving slabs. Such tiles consist of plastic, sand, pigment dyes and other composite elements. It is highly durable, lightweight, waterproof and anti-slip. However, due to its comparable ease, it is better to lay such tiles on mortar. After preparing the base, which consists of sand and gravel, it is necessary to make a screed from a regular mortar (cement and sand) approximately 3 cm thick. After a few days, when the screed “sets” well, you can begin laying the tiles themselves. If the screed turns out to be smooth, then the layer of mortar that is applied to the tile may be minimal. After all the elements have been laid out, the borders are installed, and then the seams between the tiles are filled with mortar. It is made from cement, sand and moisture-resistant compounds, such as liquid glass. The seams must be sanded in several layers. You can use the plastic tile path after two days.

Design for laying paving slabs

Paving slabs can become a decoration for any garden plot. You just need to approach her choice responsibly and with imagination. A rich range of colors and different configurations of commercially available tiles, and most importantly the flight of your thoughts, will help give your site uniqueness and comfort.

If you need to diversify a large area with tiles, then perhaps you should use the services of a professional designer. If your garden plot small, it can be easily handled on our own. To do this, you need to arm yourself with paper, a pencil, and a ruler to sketch out the pattern you have in mind. In addition, there are many already tried options for laying tiles.

Diagonal herringbone patterns are popular, as are laying squares with a transverse direction in a checkerboard pattern. A method that imitates brickwork is in demand. All in your hands.