At home, you want to relax in a comfortable environment, feeling coziness around you. A mandatory attribute for its creation is upholstered furniture. The sofas and armchairs presented in stores are not always satisfactory in design or quality, not to mention the current prices. Alternatively, you can make a chair with your own hands, which is guaranteed to meet all individual preferences. Sizes, upholstery tone and level of softness - everything can be chosen to your liking, resulting in a designer piece of furniture.

Before starting work on assembling a chair at home, you need to decide on the basic parameters of the future product. You should start with the appearance. In accordance with the style of the room where the upholstered furniture will be installed, a suitable model is selected.

It is advisable to explore the range finished products in exhibition halls or look at photos in catalogs. In the first case, you can clearly see and touch the planned model, but the search will take some time. In the second case, the time spent will be minimal, but the final appearance may differ significantly from the desired one.

Having studied the range of chairs and decided on the model, you can begin preparatory work. First, you should measure the place where you plan to put the furniture and calculate the dimensions. To avoid mistakes in fitting parts and not to forget anything, competent drawings and diagrams are drawn up.

The generally accepted ergonomic seat height is approximately 45 cm, its width and depth vary from 40 to 45 cm. The height of the backrest from the floor should be about 1 meter. For comfortable sitting, a slope of 3 cm is made from the edge to the back.

To make a drawing of a chair on a sheet of graph paper or checkered paper, first draw a complete finished model, after which the following are displayed separately:

- back;

- side detail;

- seat;

- armrests.

When schematic modeling, it is necessary to take into account the thickness of the material from which the chair will be made. Synthetic and natural fabrics have different parameters, which can affect the final collection of parts. After completing the drawing, it is advisable to draw part templates on cardboard and cut them out. This will allow you to try on sizes in life size and project the necessary elements on the material.

Before purchasing, a full calculation of the quantity of required materials must be carried out. This is done in order to avoid going to the store again and purchasing unnecessary parts.

For components, you can go to the construction market or a specialized store. You can also order materials for delivery, but in this case it will not be possible to visually evaluate their appearance and quality.

Materials and tools

The frame is an important part for any furniture. To make a chair correctly, you should decide on the material in advance. Most often used:

- tree;

- Chipboard, laminated chipboard;

- plywood;

- metal.

Wooden frames are the most environmentally friendly and do not cause allergies. A chair made from boards will last a long time if the wood good quality and chosen correctly. You should not take lumber with bark, cracks, or unclear geometry - all this will lead to cracking and deformation of the finished product.

A homemade chair with a frame made of chipboard is durable if the material is of sufficient density, thickness, dry and does not crumble. Unlike wood synthetic material You cannot paint or give the surface the desired texture and tone.

Plywood is also used to make the frame of a home chair. Due to the unattractive texture of the material, it is closed soft upholstery. With proper fastening, plywood thickness 15 mm and above, the part can be used for a long time.

On the market building materials laminated plywood appeared, which has an attractive appearance. It can be used for open parts of the chair without losing the visual effect.

A do-it-yourself chair frame made of metal will be the most durable, but its weight will significantly exceed other options. The disadvantage is that it can be done only with specialized welding tools. You can fasten the metal parts with nuts and bolts, but over time such a frame will begin to loosen and rattle.

Regardless of what material the frame for the chair will be made from with your own hands, this part is the main one and must be assembled with high quality and durability.

Solid wood

Thick furniture fabric is prepared for upholstery. The most common options:

- chenille;

- tapestry;

- jacquard;

- velours;

- flock;

- synthetic or genuine leather.

The choice of material is made taking into account future operating conditions. So, if you have pets or children who, due to their age, can damage or stain the fabric, it is better to give preference to easy-to-care, wear-resistant materials. Parts must be cut out with seam allowances, so material should be purchased with a small margin.

Soft elements are filled with furniture foam rubber with a density of 30 and higher. You can make upholstery from scrap materials, for example, use old blankets or pillows instead of foam rubber.

To make a chair with your own hands you will need:

- screwdriver or welding machine;

- a jigsaw with the necessary attachments or a grinder saw;

- furniture stapler;

- sewing machine;

- scissors;

- chalk or a piece of dry soap;

- Sander;

- hardware for fastening parts.

All tools, as well as components, must be prepared before the installation process begins, so as not to waste time searching for the necessary elements.

Tools

Manufacturing stages based on the model

The process of making a chair with your own hands directly depends on the chosen model. Homemade products may not even be inferior in terms of comfort and appearance factory analogues.

Traditional

Traditional chair is great design solution to create a comfortable environment in the home. Unlike sofas, armchairs take up much less space, and making them with your own hands from wood, chipboard or metal is faster and easier.

After preparing the tools, a location for assembly is selected. It is advisable that no one moves the laid out materials. It is important to provide side effects from the manufacturing process and their consequences for others. When cutting wood with a jigsaw, sawdust should not get on furniture and interior items, and when using inverter welding requirements must be adhered to fire safety. When all preparations are completed, you can begin installation.

Stages of work:

- using cardboard templates, transfer the layout of the parts onto the frame materials;

- use a jigsaw or grinder to cut elements along the lines of the drawing;

- if necessary, process open parts made of beams with a grinding machine;

- screwdriver or using welding machine fasten the frame parts;

- draw the upholstery pattern on the furniture fabric, cut it with 1 cm seam allowances, sew the parts;

- cut and cut furniture foam rubber, fill the upholstery;

- the armrests are wrapped in foam rubber and secured with a special stapler. Decorative wooden armrests, if necessary, are secured on top with a screwdriver and self-tapping screws.

If a wooden chair will be placed in a room with high humidity, after assembling the frame, it should be treated with bioprotective agents.

After completing the installation work, you can decorate the chair to your liking. Furniture fabric is used to cover small buttons, which are sewn onto the product in a checkerboard pattern. By applying paints different colors and sanding wooden elements decorated in an antique style with your own hands.

Folding

A folding chair is a great way to organize a place to relax. Such a piece of furniture made for use on garden plots, indispensable in summer period. Garden chair made with your own hands will do its job functional purpose fully and will not be inferior to factory analogues. The possibilities of using a folding piece of furniture allow it to be used in the most unexpected situations: overnight guests, moving, relaxing on the veranda. Wooden chair manufactured in the most different styles. Having chosen a design and completed a drawing, you can begin assembly work:

- cut the prepared materials with a jigsaw or grinder to the required sizes;

- treat the surface with a grinding machine to make it smooth, otherwise sharp traumatic particles may separate;

- treat with bioprotective agents and dry well;

- paint all the parts in the desired color;

- assemble the chair frame using a screwdriver, self-tapping screws and the necessary fasteners.

Wooden chairs can be decorated to suit almost any style. Varnishes, paints and patinated enamels are used for processing.

The finished chair should definitely be checked for strength. At correct execution all points folding chair made of timber will last a long time.

From pallets

Construction pallets are assembled from flat boards that have dried and will no longer change their geometry. However, their use as a material for self-made chairs are widespread. Pallets make original loft-style models that are almost no different from design options. Manufacturing includes several stages:

- After selecting the model and carrying out the preparation using grinder the boards are sanded. Without this process, the wood may delaminate.

- Using a jigsaw or grinder, the pallets are cut in half, the edges are sanded and painted over.

- From the elements you need to assemble a frame chair from boards the desired shape, then secure the elements with self-tapping screws and a screwdriver.

This DIY garden chair looks no worse than store-bought counterparts. For comfortable use of pallet seats, it is necessary to sew cushions on them. The fabric is selected based on the operating conditions of the furniture. As a filler you can use foam rubber, holofiber, synthetic padding polystyrene, polystyrene foam balls.

The vast majority of soft chairs can be divided into frame and frameless. Children's chairs stand apart, the production of which has a number of technological differences. The question arises: is it necessary to pay a lot of money for a finished product if you can make something similar with your own hands?

We will tell you about the process of making upholstered chairs, provide drawings, photographs and videos that will allow you to successfully complete the task. You will also find a list necessary materials and tools.

- 1 What will you need?

- 2 How to do easy chair with your own hands?

- 2.1 Traditional soft product

- 2.2 Beanbag

- 2.3 Child seat

- 3 Drawings and useful video

What will you need?

First of all, you need to decide on the upholstery material. There are significant differences in both the cost of upholstery and its physical properties Oh. Let's look at the most popular options:

- Velours. Velvety and fleecy fabric. Externally it resembles faux fur.

- Chenille. Natural material, “diluted” with synthetic fibers. Thanks to this, the surface does not roll off and is practical and durable.

- Flock. The fabric vaguely resembles velor, but experts recommend using flock to make child seats. The fabric is easy to clean and wash, has water-repellent and wear-resistant qualities, and does not fade.

- Jacquard. The fabric is easy to clean and highly durable, but the structure includes synthetic fibers. Therefore, loose loops can lead to tightness.

- Faux suede. The material is fleecy and durable, does not fade and can “breathe”. Ease of care is an added bonus.

- Faux leather. The material is characterized by high wear resistance. In this case, the leather is distinguished by the presence of embossing.

- Tapestry. This is a natural and very expensive fabric, which can be distinguished by its visible weaving. Multi-colored threads, woven into the overall structure, form beautiful patterns.

At the heart of the most primitive frame structures there is a plywood template. Therefore, you will need sheets of birch plywood, screws, nails and a standard set of tools:

- protractor;

- steel ruler;

- compass;

- bench and hand vices;

- scriber;

- files;

- hand scissors;

- hammer;

- hacksaw;

- adjustable wrenches;

- soldering iron;

- pliers;

- table anvil;

- hand drill;

- chisel;

- sharpener;

- punch;

- center punch

If you make a bean bag chair, your toolkit will be significantly reduced. In addition, there are simplified technologies developed by folk craftsmen that allow you to assemble an upholstered chair quickly and with a minimum set of equipment.

DIY photo of soft chairs

On wheels

Folding

With knitted element

With low seat

How to make an upholstered chair with your own hands?

Any work cannot be started without a clear action plan. Decide on the design of the future piece of furniture. It is more difficult to create a frame chair, but it looks more respectable.

If you decide to sew a bean bag chair, get ready to master the patterns. Your actions will lie not so much in the field of furniture production, but in the field of sewing art. In any case, you will need an approximate budget and an idea of the consumption of materials. For example, a bean bag chair costs 1200-1300 rubles. This includes fabric for the outer (about 300-500) and inner (200-300) covers. Also, 500 rubles are allocated for the purchase of filler.

Perhaps you already have an old “grandfather’s” easy chair that has lost its presentation? Then you can retighten and repair it with your own hands, as shown in the following video:

Traditional soft product

An ordinary chair requires a thorough approach and extensive preparatory stage. Let's look at the list of materials and tools required to make a plywood chair with upholstery:

- 20mm plywood;

- electric drill;

- emery cloth;

- screws;

- jigsaw;

- metal rims;

- thin nails;

- foam;

- wood glue;

- artificial leather;

- stain;

- black glossy paint;

- pencil;

- masking tape;

- roulette.

Let's get started:

Modern easy chair with your own hands

Bag chair

The simplest version of the bag is the so-called pear chair. You cannot do without the following materials:

- calico or satin (about three meters);

- a piece of fabric for the outer cover (about 3.5 meters);

- meter-long zipper;

- filler;

- fabric for appliqué;

- scissors, pins and thread with needles.

Manufacturing:

Pay attention to the strength of the seams of the inner cover - they should not come apart under the influence of the weight of a sitting person.

We will discuss further how to make a children's soft chair with your own hands.

DIY bean bag chair

Baby chair

Making a frameless soft chair for a baby is as simple as making a regular bean bag chair. The difference lies solely in the dimensions and colors of this piece of furniture. Bright, cheerful colors that do not irritate the eyes and set the mood for positivity are welcome.

- You can make a soft frame chair for a child with your own hands in the shape of a semicircular “sandwich” from wooden blocks and chipboard. The front wall of this design is made of plywood, the back wall is made of hardboard. Inner space glue along the bend of the back is filled with glued pieces of cardboard.

- After waiting for the wall to dry, smooth out the unevenness construction knife. A layer of foam rubber is carefully glued on top, on which the upholstery will subsequently lie. As upholstery fabric You can use eco-leather or flock - these options will allow your design to survive the unequal struggle with felt-tip pens and paints.

- Now about the dimensions. A standard adult chair has a meter height (some models reach 120 centimeters) with a bottom diameter of 30 centimeters and a top diameter of 15 centimeters. The height of the child seat should not exceed 60 centimeters (diameters will be 25 and 11 cm, respectively). Take this nuance into account at the pattern design stage.

DIY frameless children's chair

Drawings and useful video

In this section we have selected photographs of the most successful homemade chairs, which we could find on the RuNet. It is impossible to imagine the process of independent furniture production without drawings, so we post detailed diagrams and patterns for bean bags.

Drawings of chairs for making them yourself

Oblique

Retro style

Folding

With soft pillow

You will also enjoy a master class on creating an upholstered chair with your own hands. Watch the video, repeat the steps of the wizard and adhere to the described technological standards.

So, with the help of the presented video, you will learn how to make a bean bag chair with your own hands, which has gained immense popularity in our country:

By the way, if you have Euro pallets, you can make a chair with your own hands from such material, and then just throw a comfortable soft pillow on the seat. Don't believe me? Watch the following video:

Many people think that furniture manufacturing- this is magic, the secret of which a mere mortal is not able to comprehend. Believe me, with a minimum set of tools, desire, attentiveness and perseverance, you can easily cope with the task. We have presented everything you need - drawings, photographs and videos, so go ahead and amaze your loved ones with your art!

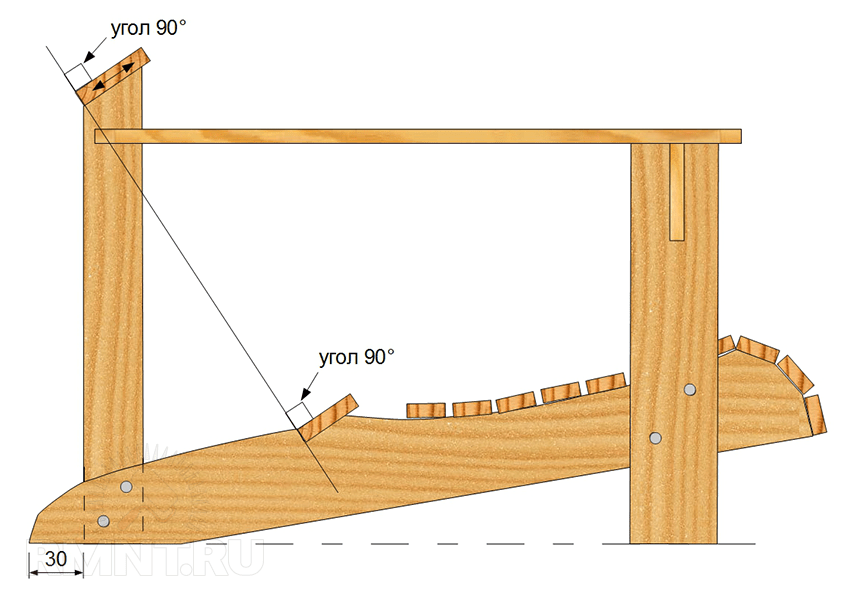

In the considered option for making an Adirondack chair with your own hands, the design features are preserved, but there are no difficult carpentry joints. It will not be difficult to repeat the project by making wooden parts according to our drawings and assembling the product using screws.

The work uses planed 20 mm pine boards, galvanized screws 4.5x40 mm, bolts 10x60 mm with a square headrest and nuts with washers. A jigsaw and a grinder will speed up the process, and manual frezer will allow you to carefully round the edges, but all workpieces can be cut with a regular hacksaw, and the burrs can be removed manually with sandpaper.

Adirondack chair structure: 1 - backrest bar; 2 - screws; 3 — upper cross member; 4 - posterior leg; 5 — side support (spar); 6 - bolts; 7 — armrest; 8 — front leg; 9 — seat bar; 10 — armrest support

Adirondack chair structure: 1 - backrest bar; 2 - screws; 3 — upper cross member; 4 - posterior leg; 5 — side support (spar); 6 - bolts; 7 — armrest; 8 — front leg; 9 — seat bar; 10 — armrest support

Manufacturing of parts

The most complex elements of the chair are the two side supports of the seat. Make a full-size template on paper for the spars.

Side support drawing

Side support drawing

Draw bottom side parts, lift the first perpendicular segment from the left and two more at the corresponding angles to point A. Mark point C and draw a cutout for the transverse tie as shown in the diagram.

Mark an angle of 75° with vertex C, extend its lower side with a line. Draw an arc with a radius of 116 mm, measure the angle at point D and connect them with a segment.

Draw a curve between points A and B using a square grid or an improvised pattern as in the photo.

Place the cut template on the board, avoiding large knots and leaving small ones away from the edges of the workpieces. Trace the contours and file the parts using a saw on straight sections, and cut out the curly contours with a jigsaw. Guide the tool blade in the direction of the grain so that the wood is less likely to chip.

Transfer the drawings of the remaining elements of the chair onto the boards, also using a template, or draw directly on the blanks and mark the next identical part according to the first one cut out.

Drawings of parts: 1 - upper backrest guide; 2 — lower cross member of the backrest; 3 — armrest (2 pcs.); 4 — armrest stop (2 pcs.)

Drawings of parts: 1 - upper backrest guide; 2 — lower cross member of the backrest; 3 — armrest (2 pcs.); 4 — armrest stop (2 pcs.)

The shape of the curves of the armrests is not structurally important; you can draw them by hand or using a pattern. Mark the second part in a mirror image so that the chips when sawing are at the bottom of the workpiece.

Parts drawing: 1 — backrest strip (7 pcs.); 2 — seat bar (8 pcs.); 3 — front leg (2 pcs.) 4 — rear leg (2 pcs.)

Parts drawing: 1 — backrest strip (7 pcs.); 2 — seat bar (8 pcs.); 3 — front leg (2 pcs.) 4 — rear leg (2 pcs.)

Sand the ends, joining similar pieces together if possible. Route the edges of the top surfaces of the armrests and backrest slats, or simply soften the sharp edges with a sander.

Assembling the chair

Wooden furniture always begins to rot from the joints, the internal surfaces of which cannot be processed on a finished chair. Therefore, cover the parts with 2-3 layers of antiseptic before assembly.

Most of the components of the chair are connected with screws; the guide holes for them are drilled with a combined countersink, selected according to the thickness of the screws. When they want to hide the caps, they are deepened and covered with glue plugs.

Place a scrap board on the table and place the left side support and front leg on top. Align the workpieces according to the drawing, mark the drilling points.

Chair side assembly diagram

Chair side assembly diagram

Make holes for the bolts and fasten the parts. Install the rear leg, placing it perpendicular to the bevel of the support. Assemble the right side of the frame in the same way. Connect the sides of the chair with the lower backrest crossbar and the first seat rail.

Install supports on the front legs, securing them with clamps for convenience. Screw the armrests with screws.

Secure the top backrest rail, aligning it with the bottom crossbar. Right now it is possible to correct possible millimeter-by-millimeter marking inaccuracies and uneven cuts.

Small errors can be eliminated by shifting the upper cross member and trimming the angle under it. In extreme cases, you will have to unscrew the bottom crossbar and adjust the cutout.

Mark the center lines on the cross boards and on the center backrest strip. Holding the latter at the top with your hand or grabbing it with a clamp, drill a pilot hole and tighten the bottom screw. Check the vertical position and secure the top of the rail.

Screw all the strips one by one at even intervals. Take a piece of string and tie one end to a pencil and the other to a nail secured at the junction of the seat and backrest. Draw a radius of curvature, cut the strips according to the markings and sand the edges.

Having adjusted the width of the last seat rail, put it in place. Inspect assembled chair and sand down markings, chips and other defects. Carefully sand the top surfaces of the backrest and seat parts.

Coat the wood with oil if you want to preserve its natural shade. Use synthetic resin glaze to create an opaque colored surface.

In modern furniture stores you can find any piece of furniture to suit every taste and style. Occasionally financial situation or too high requirements do not allow you to find a suitable chair in terms of style and comfort.

That is why now you can find instructions on how to make a chair with your own hands step by step.

What kind of chairs can you make with your own hands?

You can find a lot of instructions on the Internet on how to make a chair, which is why anyone can do it, especially if you know how to use a standard set of tools.

First you need to buy everything you need, the missing tools and materials, and then start creating sketches and drawings of the future piece of furniture.

The peculiarity of a DIY chair is that it makes no difference which sketch you use. There are certain step-by-step instructions, the points of which everyone adheres to.

Before starting work, you should familiarize yourself with the possible seating options and choose the one that interests you. However, I note that some types are very difficult to make without special equipment, and for some you need great experience. We also recommend that you watch a master class on how to make a chair with your own hands.

Types of chairs

If you have a question about which chair to make with your own hands, then here is a list of all possible options that you can make yourself:

Usually a chair

An ordinary chair, it is also called soft. It consists of three main things: frame, upholstery, and filling. Suitable for installation in the home.

Folding chair

It has a frame that can be folded or unfolded. This option simply cannot be replaced when relaxing outdoors, at sea, or even at home if, for example, you always have a lot of guests and there aren’t enough chairs for everyone.

Kentucky

Chair for the garden or cottage. Looks great in the garden or country house, easy to make.

Ladle

Armchair sports type, on which several belts can be installed, thereby effectively securing the person sitting in place.

Photon

A transformable chair that is both a chair and a mattress. Moreover, this “transformation” is very easy to implement.

Sliding chair

Perfect for small rooms, due to the fact that they simultaneously serve as both a bed and a chair.

Chair on small wheels

It is convenient to ride around the entire apartment or house. Will help elderly and sick people with housework.

However, it is worth remembering that wheels under the weight of the human body can leave scratches on the floor, especially if you have varnished parquet at home.

High back chair

Perfect for people who sit for a long time, for example, at the computer, no matter on personal initiative or for work.

Thanks to the fact that you can fully lean on it, you can sit in it for much longer. It is also very comfortable. By the way, there are soft and hard options.

Rocking chair

Surely, you associate the mention of this piece of furniture with an elderly person. However, this type chairs help many people, for example, with sleep disorders or mothers of babies.

The latter not only rock the baby to sleep, but also relax themselves. For example, after a sleepless night, this great option, you will definitely be sure that you will not accidentally drop your child due to fatigue.

Non-folding chair

Very convenient to use, helps to fully relax and unwind after a hard day working day. Now their choice is huge, so you can not only make it yourself, but also look for the right option in the shop.

Previously, non-folding chairs with so-called ears were very popular, on which it was convenient to lean and they also served as a kind of fence.

Bag chair

Probably the most comfortable armchair from the entire list. It does not have a frame, but inside there is a soft filler that can completely replicate the contours of the human body.

Due to this feature, it is truly the most comfortable and you can relax and unwind in it. Not only is there a huge amount of design for these chairs, but you won’t spend a lot of money and effort to make it.

By the way, if you don’t understand a certain type, then look at the photo of the chair with your own hands of this type. This way you will not only understand what kind of chair we are talking about, but you can also stumble upon step-by-step instructions for the piece of furniture you like.

So today you found out best ideas DIY armchairs, namely their types, which you can make yourself at home. I hope you have no questions left on the topic and have chosen the appropriate type of chair.

Photos of armchairs with your own hands

Not only craftsmen know how to make an exclusive product from scrap materials comfortable furniture. The advantage of such an activity is obvious - it is the opportunity to translate into reality the most daring ideas for diversifying the living space. An additional bonus One can note the low cost of making home soft chairs with your own hands. Following the advice of designers, you can make a soft chair for a pleasant time in own home. At home, you can exactly repeat all the stages of factory production of this modern and convenient attribute for decorating a children's or living room. On the Internet you can find both the simplest and most complex schemes.

The first step in making homemade upholstered furniture serves as the choice of fabric for external design soft parts of the structure. Each master selects upholstery depending on the physical properties and price aspects and features that different drawings have. Let's look at the most common fabrics for decorating chairs in our time:

- velor – velvety to the touch, gives the furniture a certain charm;

Velor upholstery

- flog is a distant analogue of velor, easy to clean, so designers use it to decorate children's upholstered furniture;

Upholstered flog

- chenille is a fabric based on a combination of natural and synthetic fibers, has particular wear resistance (a well-thought-out structure prevents the formation of pellets);

Chinille in upholstery

- jacquard - the upholstery is considered durable, but over time the loops turn into puffs;

- natural tapestry is the most expensive and beautiful view upholstery fabrics;

Upholstered jacquard

- artificial suede is a universal option for chairs in a sunny room, resistant to UV rays and easy to clean;

Faux suede upholstery

- leatherette – durable material, allowing you to play with decorative embossing.

Leatherette upholstery

Material, fittings, tools for frame attributes

Creation frame chair starting from scratch presents some difficulties. But the finished product will have a more respectable appearance. You can verify this by looking at the photo. finished products home craftsmen. You can also use an old Soviet “grandmother’s” chair for the base.

For the manufacture of simple frame Under the soft chair you need to choose durable sheets of 20 mm plywood for cutting out parts yourself. Also useful standard kit repair tools with an electric drill, jigsaw, steel ruler, emery cloth, metal rims, masking tape, pencil, tape measure, thin nails, self-tapping screws, wood glue, stain, glossy paint. For upholstery you need: artificial leather or fabric, foam rubber (filler).

Step-by-step creation of upholstered furniture with a wooden base

- If you don't know how to make a drawing for the base, then look ready-made options schemes on the network. As a rule, they are transferred to a cardboard template with a pencil. Only after this they begin to perform the operations of the described algorithm. This will help you save on excess material, or vice versa – avoid purchasing missing parts.

- Using a cardboard template, future constituent elements are cut out from plywood sheets:

- banana-shaped sidewalls;

- cross bars.

It is important to determine the required angles of inclination, bending and dimensions of the future frame. A photo of the finished chair, created according to your design, will help with this.

- The next stage is surface treatment of wooden parts by stripping and grinding. The ends are worked with special care to improve the quality of the work done. These parts are first impregnated with heated drying oil and only then bends are formed with a hammer, if they are provided for in the sketch. Each component element is cut out with an electric jigsaw.

- The sidewalls are painted or treated with varnish-stain. The ends of the side parts are reinforced with metal rims.

- The further course of action is related to the covering of the frame. Using an electric drill, make the required holes. The rims are fixed with screws.

- First, the back part of the back is covered with artificial leather or fabric, then the remaining fragments of the structure, incl. and seats.

- The upholstery material is secured with wallpaper nails, which are characterized by large heads. In the back of the frame chair, the upholstery is fixed along the edge, along the transverse parts, to better cover the slats.

Pattern round chair

Wooden frame We cover the frame with fiberboard cardboard

Experienced furniture makers recommend additionally treating the fastening points with wood glue. This move is needed to increase the durability of the furniture you create yourself.

Secrets of reliable upholstery: how to sew

The process of stretching the upholstery of soft chairs has its own nuances:

- Foam rubber is cut to the size of the seat (average thickness - 5 cm). The part is glued to the surface of the plywood sheet.

- Horizontal and vertical fabric straps are secured to the back with a construction stapler. Similar belts are added to the armrests and sides from the inside along the shape.

- A piece is cut from a piece of foam rubber 0.1 cm thick, which will be larger in size than the area of the seat (the difference is 4-5 cm). Take a piece of synthetic padding fabric of a similar size with an elongated front part and fasten it with your own hands.

- After the manipulations have been completed, the upholstery is covered furniture fabric. Using a stapler, the textiles are secured to all corners of the cover and the synthetic foam layer to the frame of the chair seat.

- The sides and armrests are also covered with padding polyester, secured with aerosol glue over the entire surface. Only after this the parts are sheathed with fabric, securing the flap along the staples.

We cover the chair with foam rubber. Additionally we put padding polyester